Multistage efficient soybean milk grinder

A refiner and high-efficiency technology, which is applied in the direction of grain processing, etc., can solve the problems of soybeans not being effectively ground, the grinding efficiency of the refiner is not high, and the grinding efficiency of soybean milk is reduced, so as to facilitate adjustment, change the gap, and improve practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

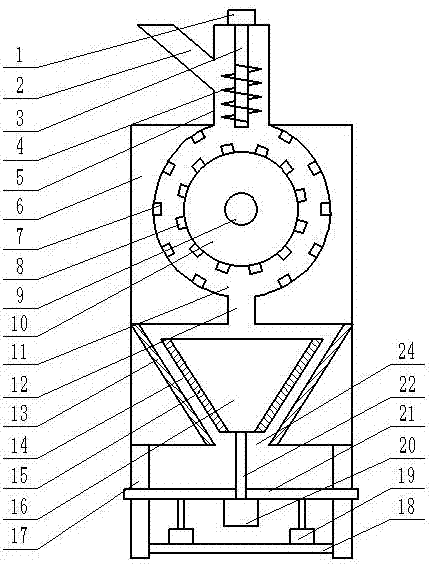

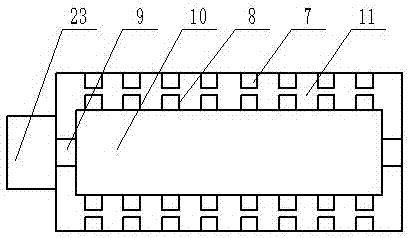

[0018] see Figure 1-3 , a multi-stage high-efficiency soybean refiner, comprising a casing 6, a feeding cylinder 5 and a support column 17, a crushing bin 11 and a grinding bin 14 are respectively arranged above and below the casing 6, the crushing bin 11 and the grinding bin The bins 14 are connected through the feeding pipe 12; the inner side wall of the crushing bin 11 is fixedly connected with a plurality of fixed breaking hammers 7, and the coaxial center of the crushing bin 11 is provided with a crushing shaft 9, and one end of the crushing shaft 9 passes through the The casing 6 is connected with the output shaft of the first motor 23, the crushing shaft 9 is fixedly connected with a fixed cylinder 10, and the fixed cylinder 10 is fixedly connected with a plurality of dynamic crushing hammers 8; the upper part of the crushing bin 11 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com