Volute tongue and centrifugal fan comprising same

A technology of centrifugal fan and volute tongue, which is applied to parts of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc. It can solve complex gas flow, air volume and static pressure drop, and great influence on fan performance, etc. problem, achieve the effect of improving fan performance and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

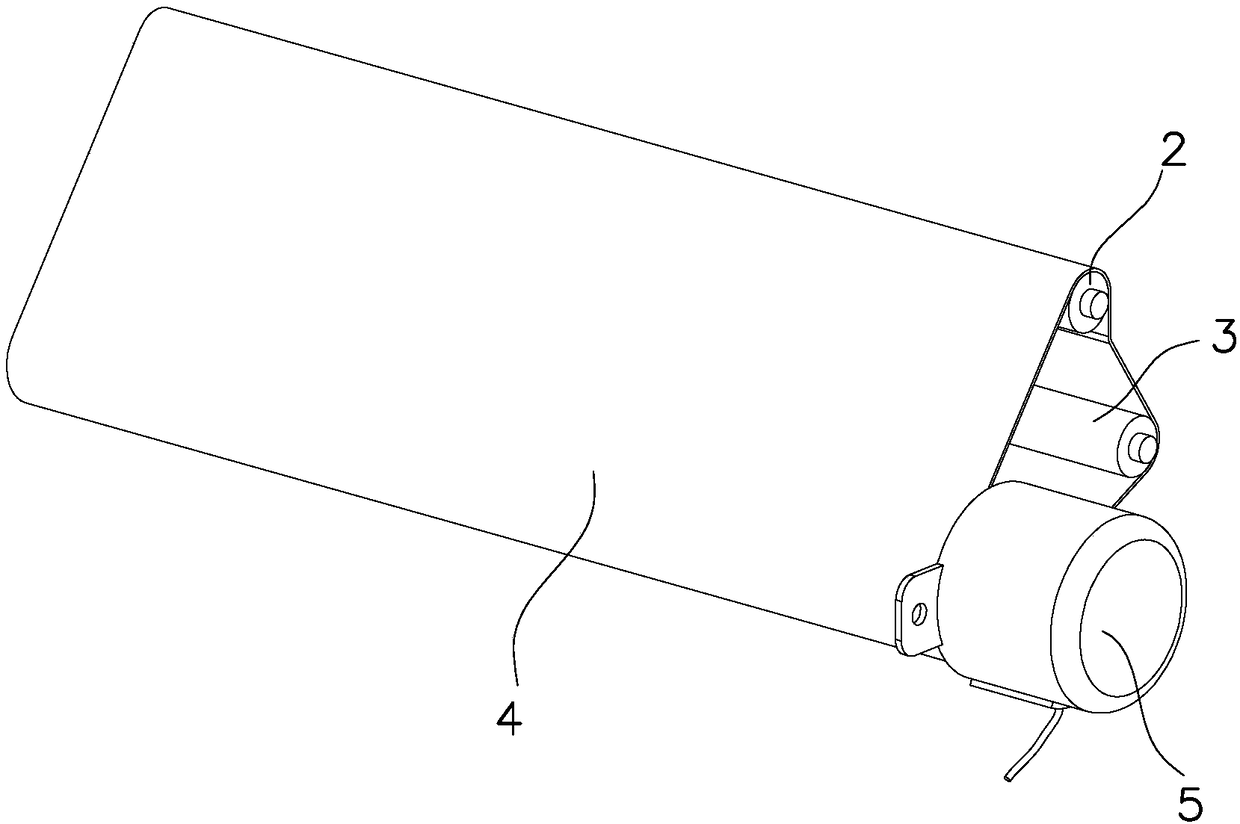

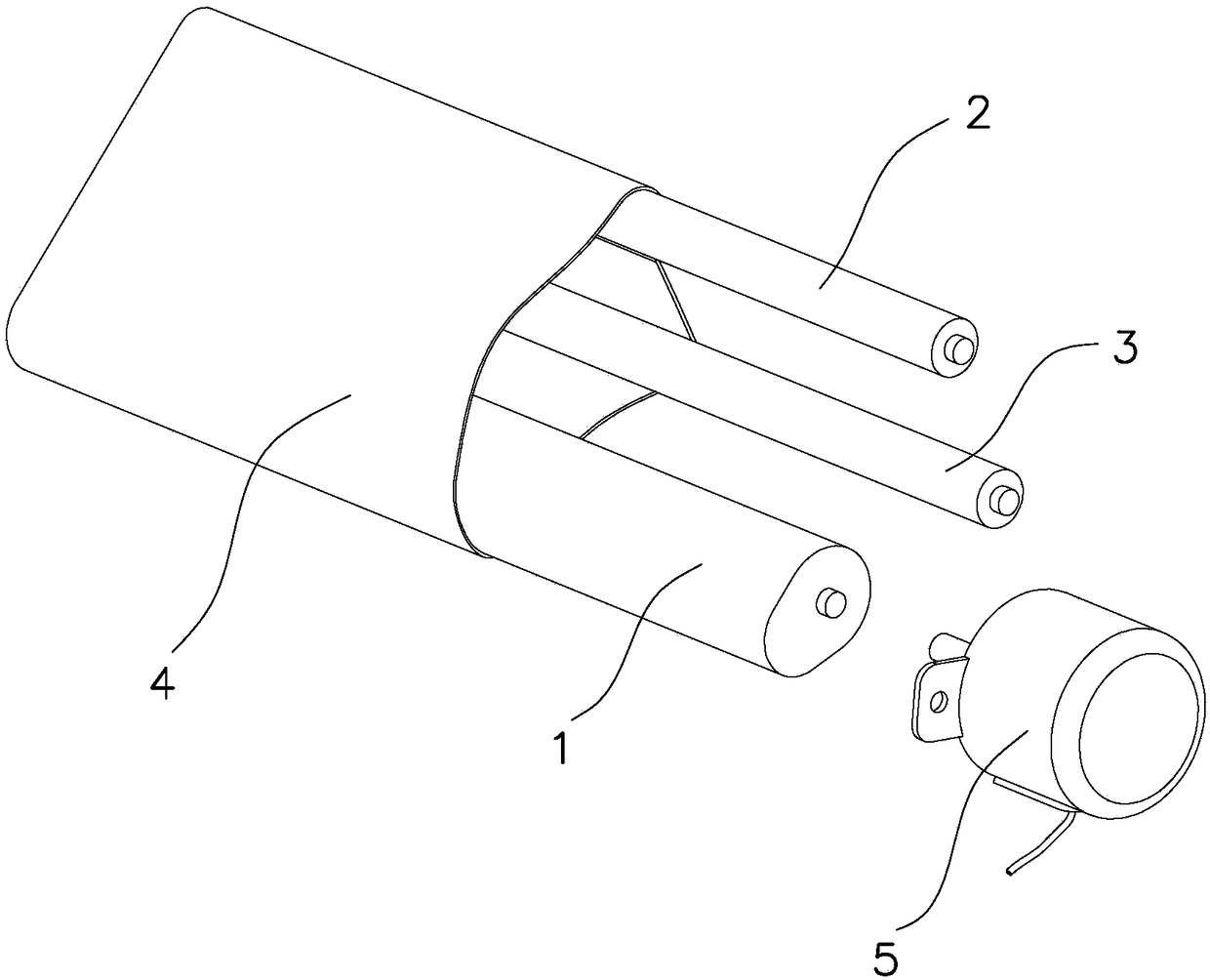

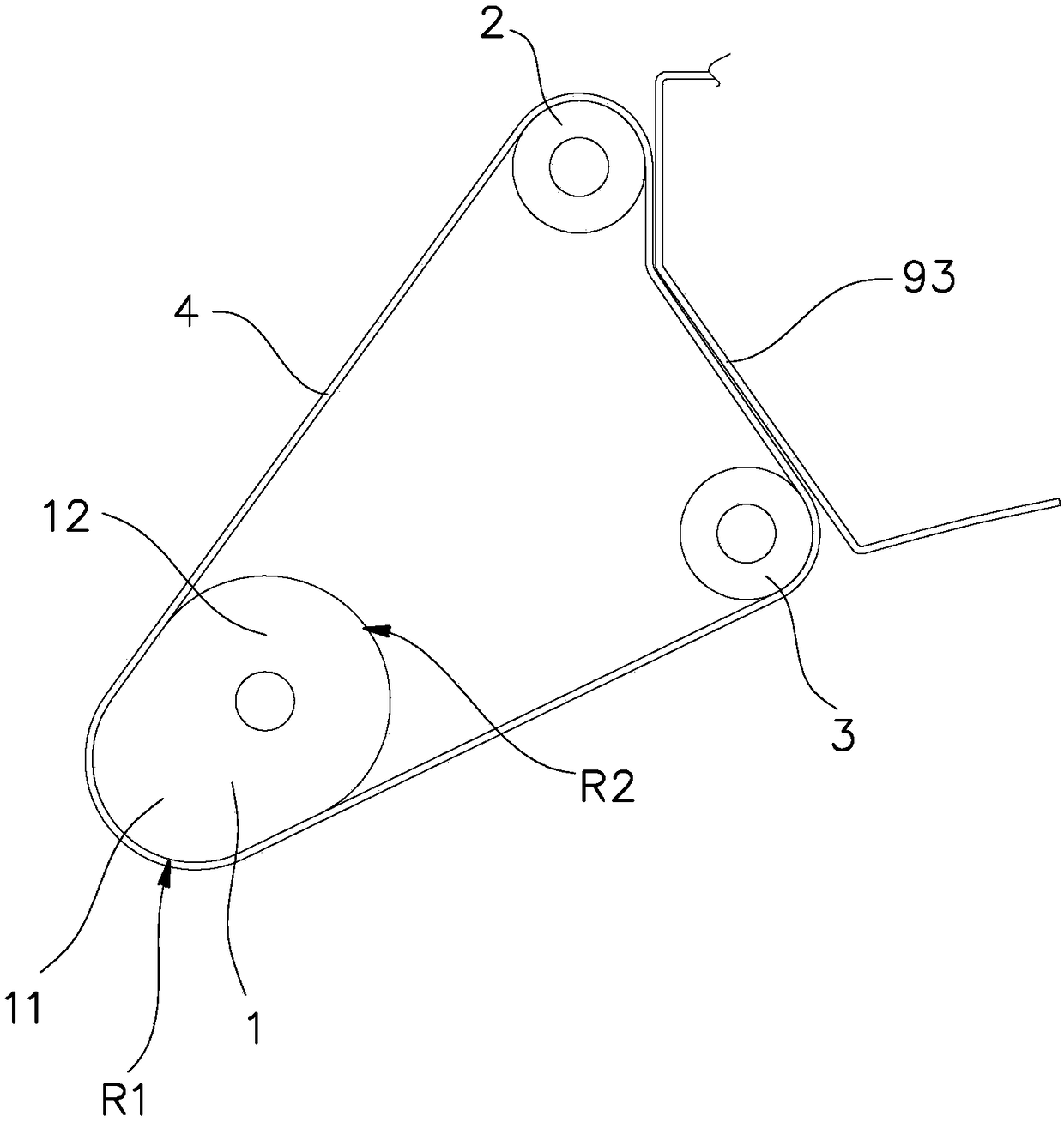

[0029] Such as Figure 1 to Figure 4 As shown, the volute tongue in this embodiment includes variable R cylinder 1 , upper support shaft 2 , lower support shaft 3 , flexible volute tongue wall 4 and motor 5 . Wherein, the upper supporting shaft 2 and the lower supporting shaft 3 are arranged at the root of the volute tongue, and the variable R cylinder 1 is arranged at the head of the volute tongue. The upper support shaft 2 is arranged on the front top of the lower support shaft 3, and the variable R cylinder 1 is arranged on the front and bottom of the lower support shaft 3, so that the upper support shaft 2, the lower support shaft 3 and the variable R cylinder 1 are triangularly distributed and each axes are parallel to each other.

[0030] The upper support shaft 2 constitutes the upper support body of the volute tongue, the lower support shaft 3 constitutes the lower support body of the volute tongue, the upper support shaft 2, the lower support shaft 3 and the variable...

Embodiment 2

[0036] Such as Figure 10 As shown, the upper support body of the volute tongue is the upper support bar 6, the lower support body is the lower support bar 7, the upper support bar 6 and the lower support bar 7 are parallel to each other and distributed along the axial direction of the variable R cylinder 1, flexible The rear end of the volute tongue wall 4 is fixed on the upper support bar 6 and the lower support bar 7 . When installing the volute tongue, the upper support bar 6 and the lower support bar 7 are all fixed on the ring wall 93 of the volute by screws 10, and the rear end of the flexible volute tongue wall 4 is clamped on the upper support bar 6 and the ring wall 93 and the lower support bar 6. Between the support bar 7 and the ring wall 93, the installation is very reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com