Fan frame structure

A fan and frame technology, which is applied in the field of fan frame, can solve the problems of shortened or damaged shell life, high internal stress, and insufficient bending strength of the side wall, so as to improve fan efficiency, reduce internal stress, and improve bending resistance Insufficient strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The detailed description and technical content of the present invention are described as follows in conjunction with the accompanying drawings. However, the accompanying drawings are only for reference and description, and are not used to limit the present invention.

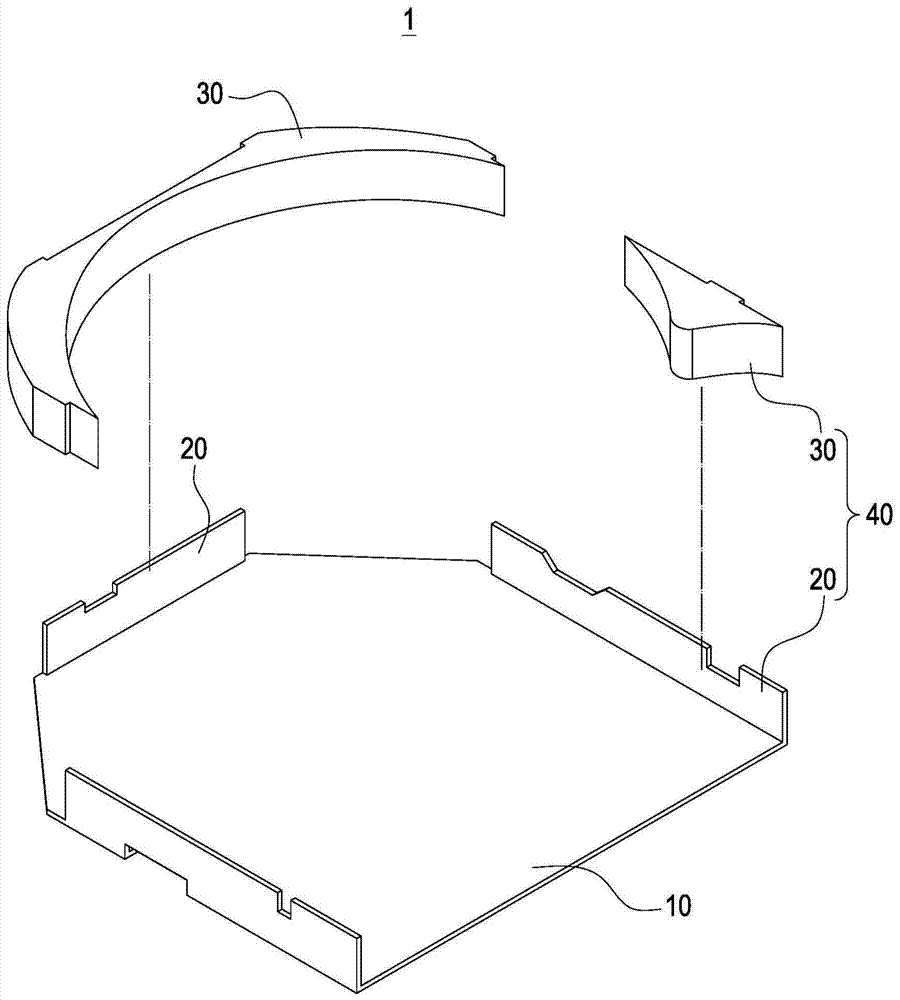

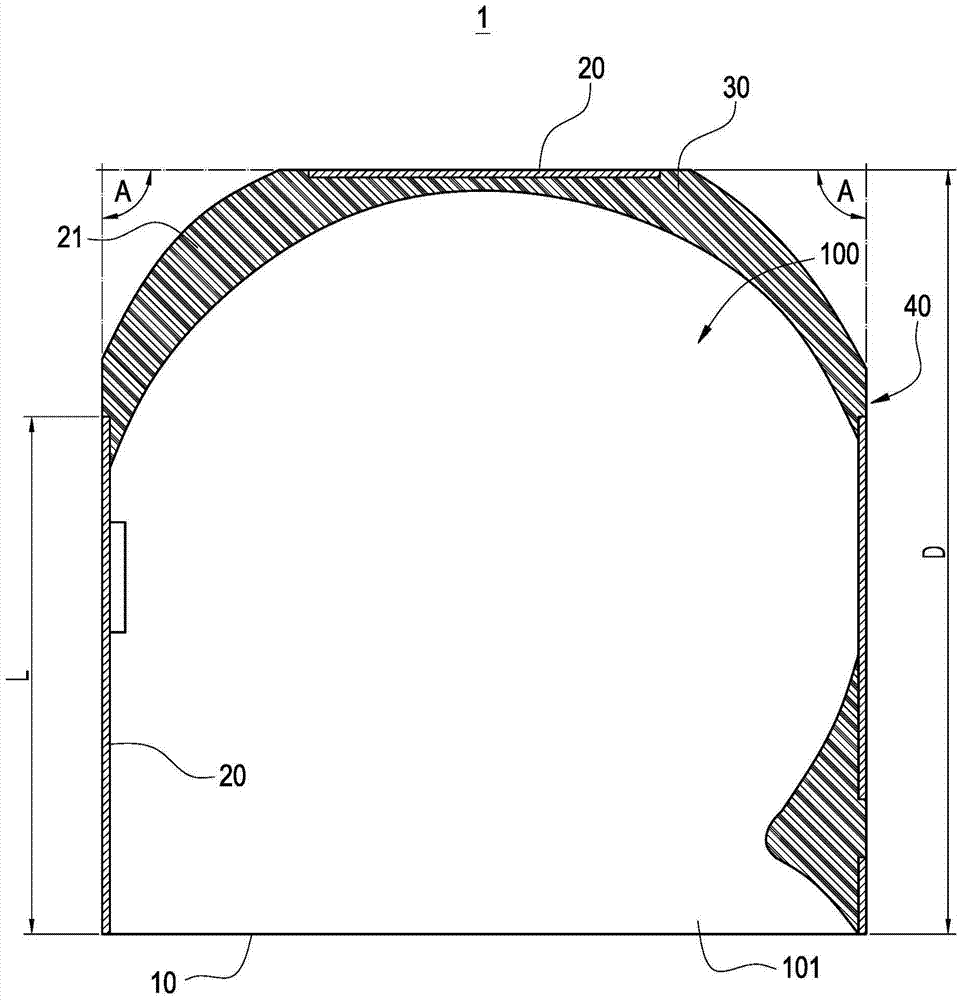

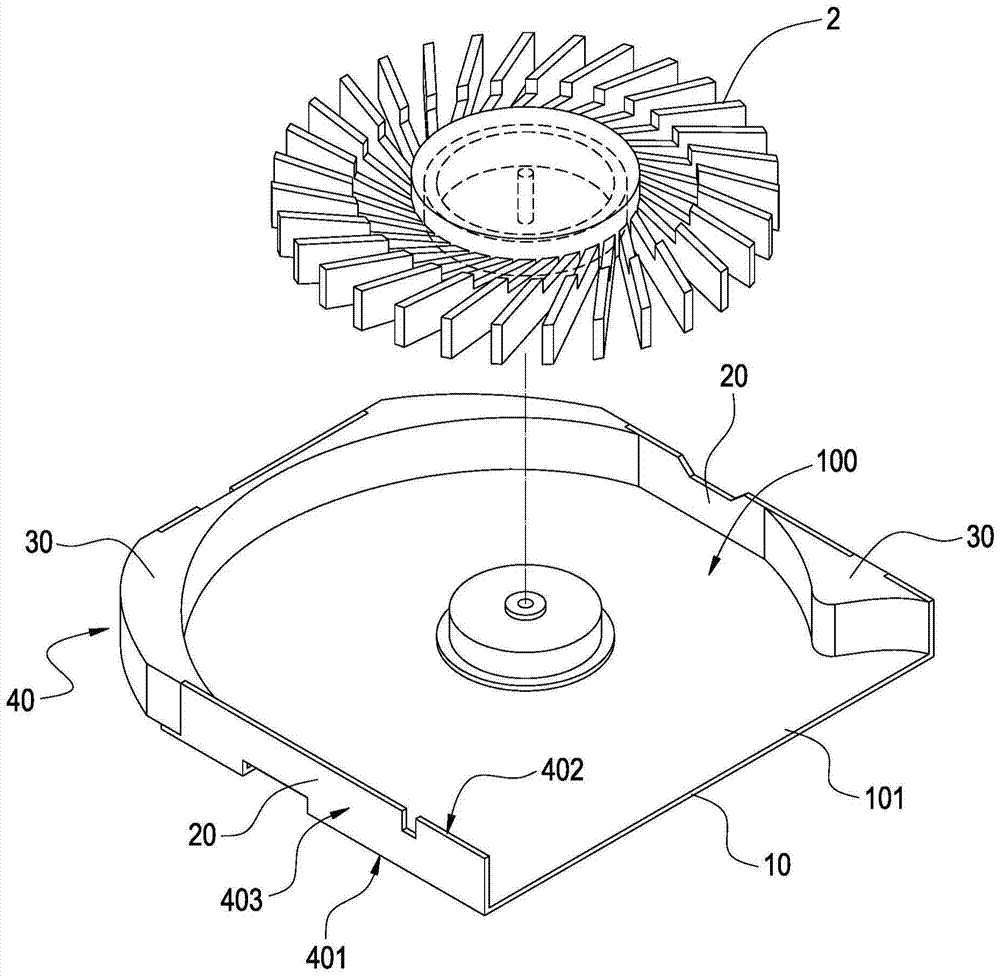

[0039] Please refer to Figure 1 to Figure 3 , Are respectively a three-dimensional exploded schematic view, a combined cross-sectional view, and a schematic view of a combined fan of the fan frame seat structure of the present invention. The present invention provides a fan frame base structure 1 for arranging a fan blade 2. The fan frame structure 1 includes a metal bottom plate 10 and at least one non-metal side wall 30. The metal bottom plate 10 includes at least two metal side plates 20, each of the metal side plates 20 is formed by bending the sides of the metal bottom plate 10, and the at least two metal side plates 20 are flat.

[0040] Furthermore, the at least one non-metal side wall 30 is adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com