PVC tub recycling pulverizer with drying function

A technology of PVC pipe and drying function is applied in the field of pulverizers for recycling PVC pipes, which can solve the problems of low pulverization efficiency, high labor intensity and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

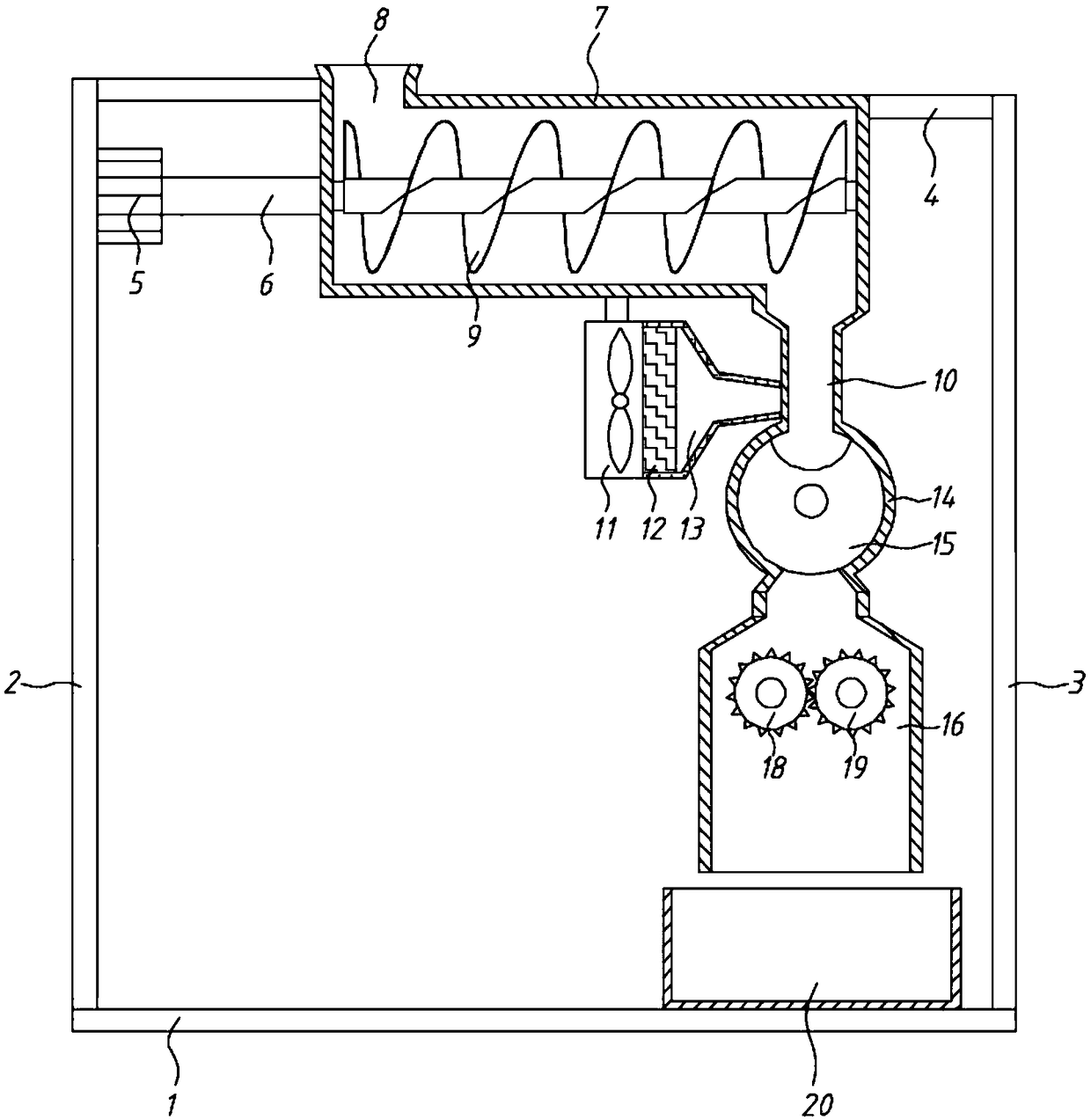

[0042] A pulverizer for recycling PVC pipes with a drying function, including a support frame, a primary pulverization component, a drying component, a blanking component and a secondary pulverization component,

[0043] The support frame includes a base 1, a left vertical plate 2 and a right vertical plate 3 fixedly connected to both ends of the base, and a drive motor 5 is installed on the upper part of the inner side of the left vertical plate 2;

[0044]The primary crushing assembly includes a primary crushing cylinder 7 arranged horizontally between the left and right vertical plates. The end is provided with feeding port 8; the output end of drive motor 5 stretches out to the right and is connected with driving shaft 6, and driving shaft 6 stretches into the primary pulverizing cylinder 7 and is equipped with screw auger 9, and screw auger 9 follows The rotation of the driving shaft 6 drives the material to move to the right; the lower right end of the side wall of the f...

Embodiment 2

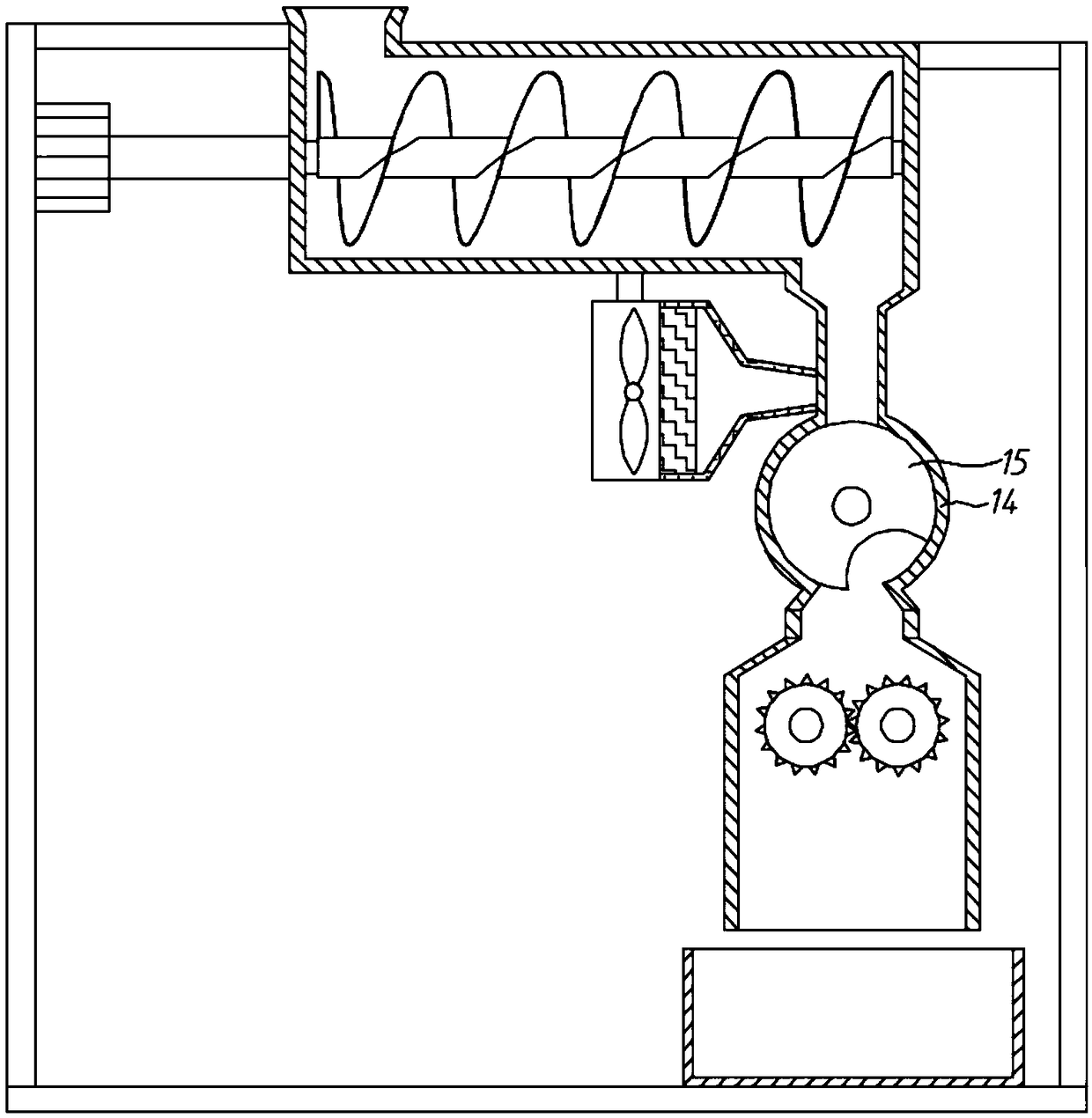

[0049] A pulverizer for recycling PVC pipes with a drying function, including a support frame, a primary pulverization component, a drying component, a blanking component and a secondary pulverization component,

[0050] The support frame includes a base 1, a left vertical plate 2 and a right vertical plate 3 fixedly connected to both ends of the base, and a drive motor 5 is installed on the upper part of the inner side of the left vertical plate 2;

[0051] The primary crushing assembly includes a primary crushing cylinder 7 arranged horizontally between the left and right vertical plates. The end is provided with feeding port 8; the output end of drive motor 5 stretches out to the right and is connected with driving shaft 6, and driving shaft 6 stretches into the primary pulverizing cylinder 7 and is equipped with screw auger 9, and screw auger 9 follows The rotation of the driving shaft 6 drives the material to move to the right; the lower right end of the side wall of the ...

Embodiment 3

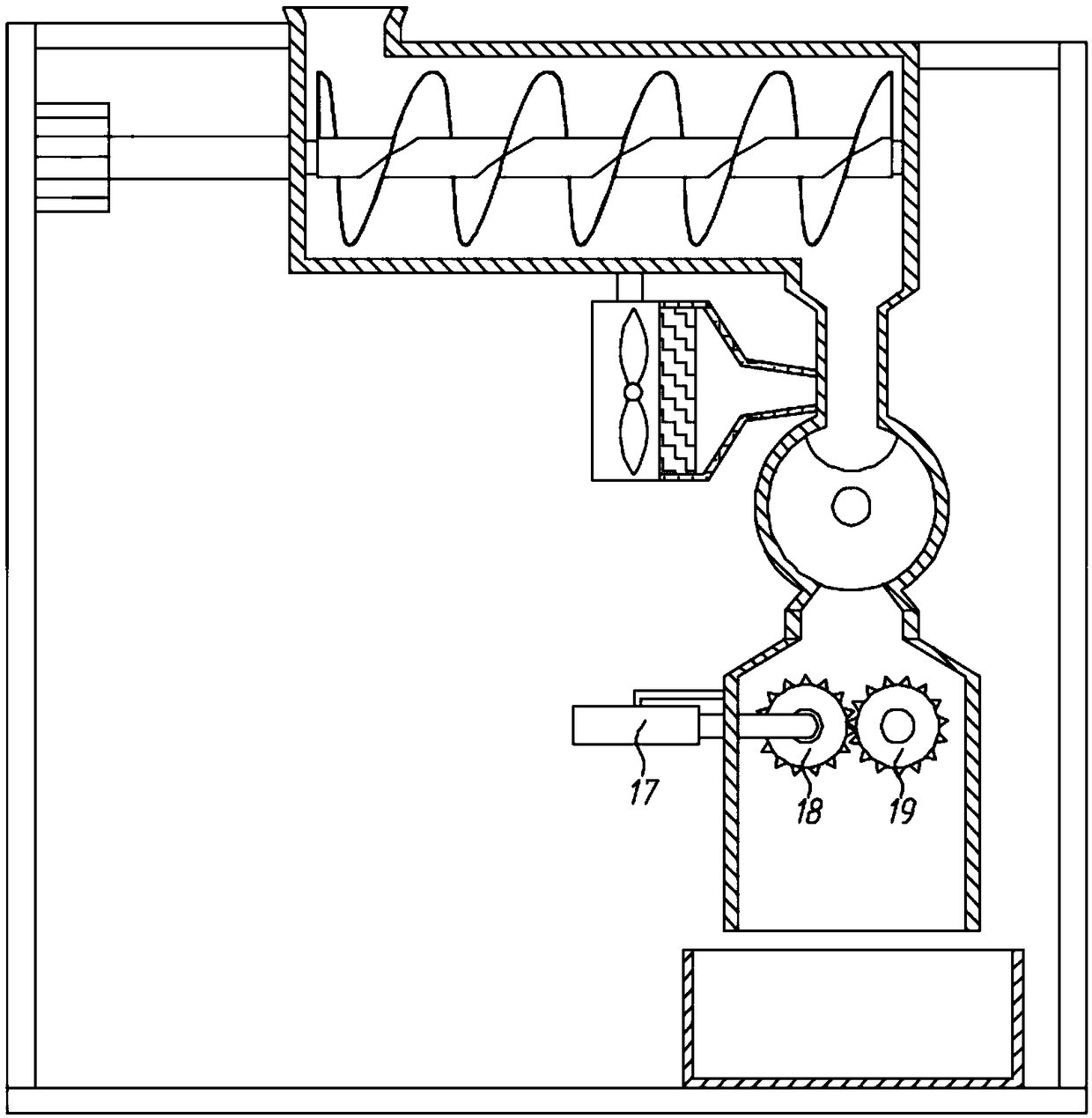

[0057] A pulverizer for recycling PVC pipes with a drying function, including a support frame, a primary pulverization component, a drying component, a blanking component and a secondary pulverization component,

[0058] The support frame includes a base 1, a left vertical plate 2 and a right vertical plate 3 fixedly connected to both ends of the base, and a drive motor 5 is installed on the upper part of the inner side of the left vertical plate 2;

[0059] The primary crushing assembly includes a primary crushing cylinder 7 arranged horizontally between the left and right vertical plates. The end is provided with feeding port 8; the output end of drive motor 5 stretches out to the right and is connected with driving shaft 6, and driving shaft 6 stretches into the primary pulverizing cylinder 7 and is equipped with screw auger 9, and screw auger 9 follows The rotation of the driving shaft 6 drives the material to move to the right; the lower right end of the side wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com