Multi-functional-tooth-form integrated high-crushing-ratio type fine crushing machine

A technology of crushing ratio and crusher, which is applied in the field of crushing device and fine crusher with large crushing ratio, to achieve the effect of compact structure, convenient maintenance and high production capacity per unit volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings and embodiments.

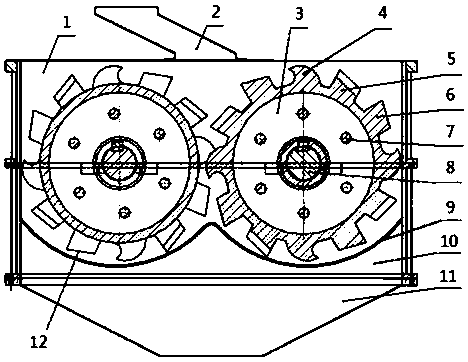

[0024] Such as Figure 1-3 Shown.

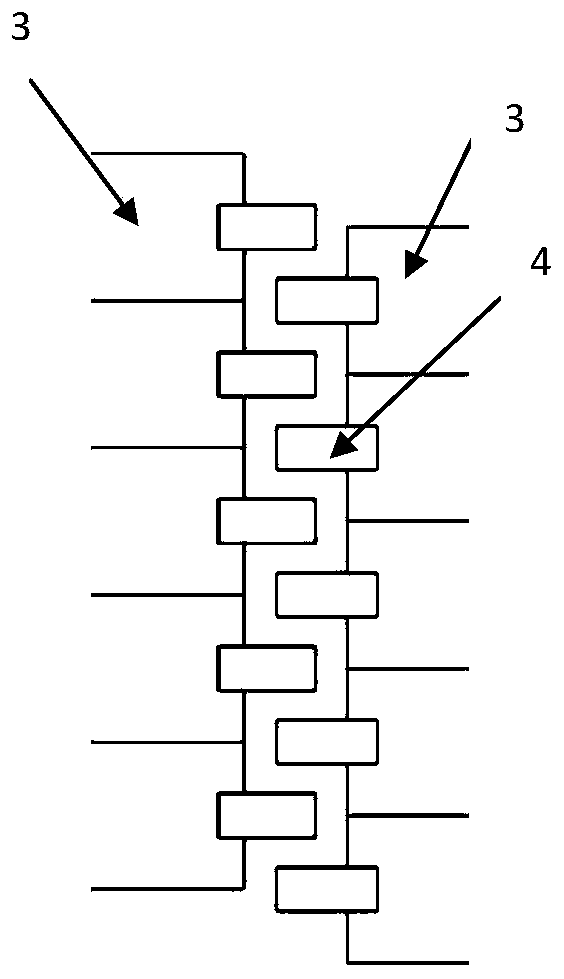

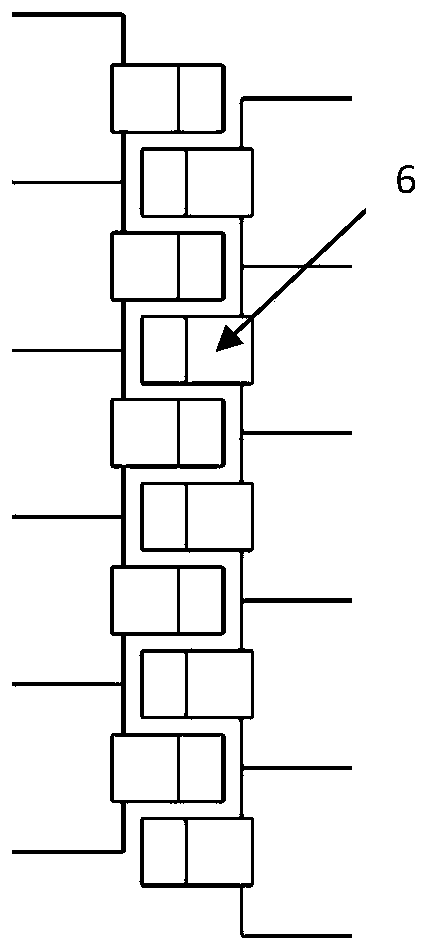

[0025] A large crushing ratio fine crusher with multiple functional tooth shapes, which includes a machine body and two crushing rollers; among them, the machine body is composed of an inlet 2, an upper box body 1, a sieve plate 9, a lower box body 10 and an output The crushing roller is composed of the material port 11, and the crushing roller is composed of the main shaft 8, the toothed disk 3 and the connecting bolt 7. The outer cylindrical surface of the toothed disk 3 is evenly distributed with four groups of crushing teeth, and each group of crushing teeth includes the primary crushing teeth 4, Cutting and crushing teeth 5 and trapezoidal teeth 6; the primary crushing teeth 4 are olecranon-shaped, and the end of the cutting and crushing teeth 5 is a blade with an apex angle of 55-65 degrees (60 degrees is best), and the long sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com