Oil pressing device

A technology of an oil pressing device and a processing box, which is applied in the directions of fat oil/fat production, fat oil/fat refining, and fat generation, etc., can solve the problems of reducing oil efficiency, oil quality, reducing pressing efficiency, and unfavorable oil filtration, etc. Improve oil extraction efficiency and oil extraction quality, ensure quality and filtration efficiency, and improve the effect of oil extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

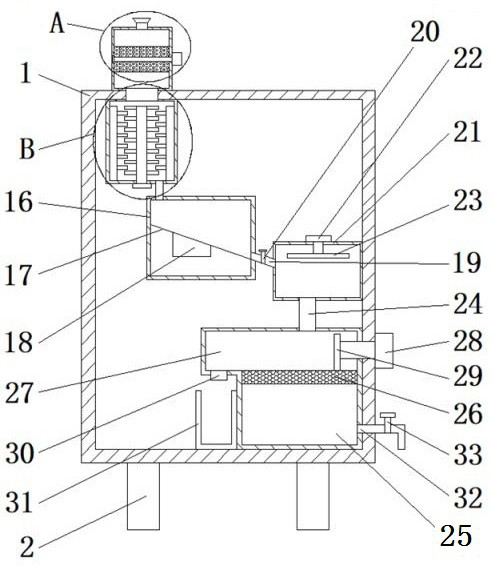

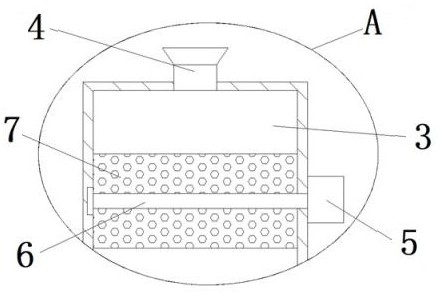

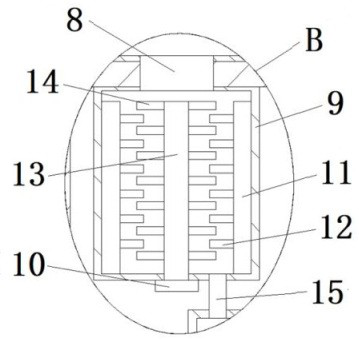

[0021] See Figure 1 ~ 4As shown, an oil pressing device comprises a processing box 1, wherein support legs 2 are arranged at four corners of the lower side of the processing box 1, a feed box 3 is arranged at the left end of the top of the processing box 1, a discharge pipe 32 is arranged at the right bottom of the processing box 1, a second electromagnetic valve 33 is arranged on the discharge pipe 32, a feed hopper 4 is arranged at the top of the feed box 3, a first motor 5 is arranged at the outer wall of the middle part of the right side of the feed box 3, and a rotating shaft 6 is arranged at the output end of the first motor 5. The other end of the rotating shaft 6 is connected with the inner wall of the feed box 3 through a bearing, the rotating shaft 6 is provided with a baffle 7, the bottom end of the feed box 3 is provided with a feed inlet 8, the inner wall of the top left end of the processing box 1 is provided with a cutting box 9, and the top end of the cutting box 9...

Embodiment 2

[0026] On the basis of Example 1, refer to Figure 4 The outer wall of the front top of the processing box 1 is provided with a control panel 34, the outer wall of the front bottom of the processing box 1 is embedded with a cover plate 35, and the outer wall of the cover plate 35 is embedded with a transparent glass window 36; By setting the control panel 34, intelligent control can be realized, manual operation can be reduced, and work efficiency can be improved; The cover plate 35 can facilitate the inspection and maintenance of the inside of the processing box 1, and the transparent glass window 36 can facilitate the observation of the working condition of the inside of the processing box 1.

[0027] Working principle: In the process of use, by setting the feed box 3, the raw materials are poured into the feed box 3 from the feed funnel 4. By the cooperation of the first motor 5, the rotating shaft 6, the baffle 7 and the feed inlet 8, the feeding speed can be controlled, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com