Novel active air foil bearing based on PZT and SMA

A foil bearing, active technology, applied in the direction of shafts and bearings, sliding contact bearings, bearing components, etc., can solve the problems of applying preload, small mechanical deformation, etc., to improve stiffness characteristics, increase structural damping, and improve damping The effect of the characteristic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. However, it can be understood that the following specific embodiments are only preferred technical solutions of the present invention, and should not be construed as limiting the present invention.

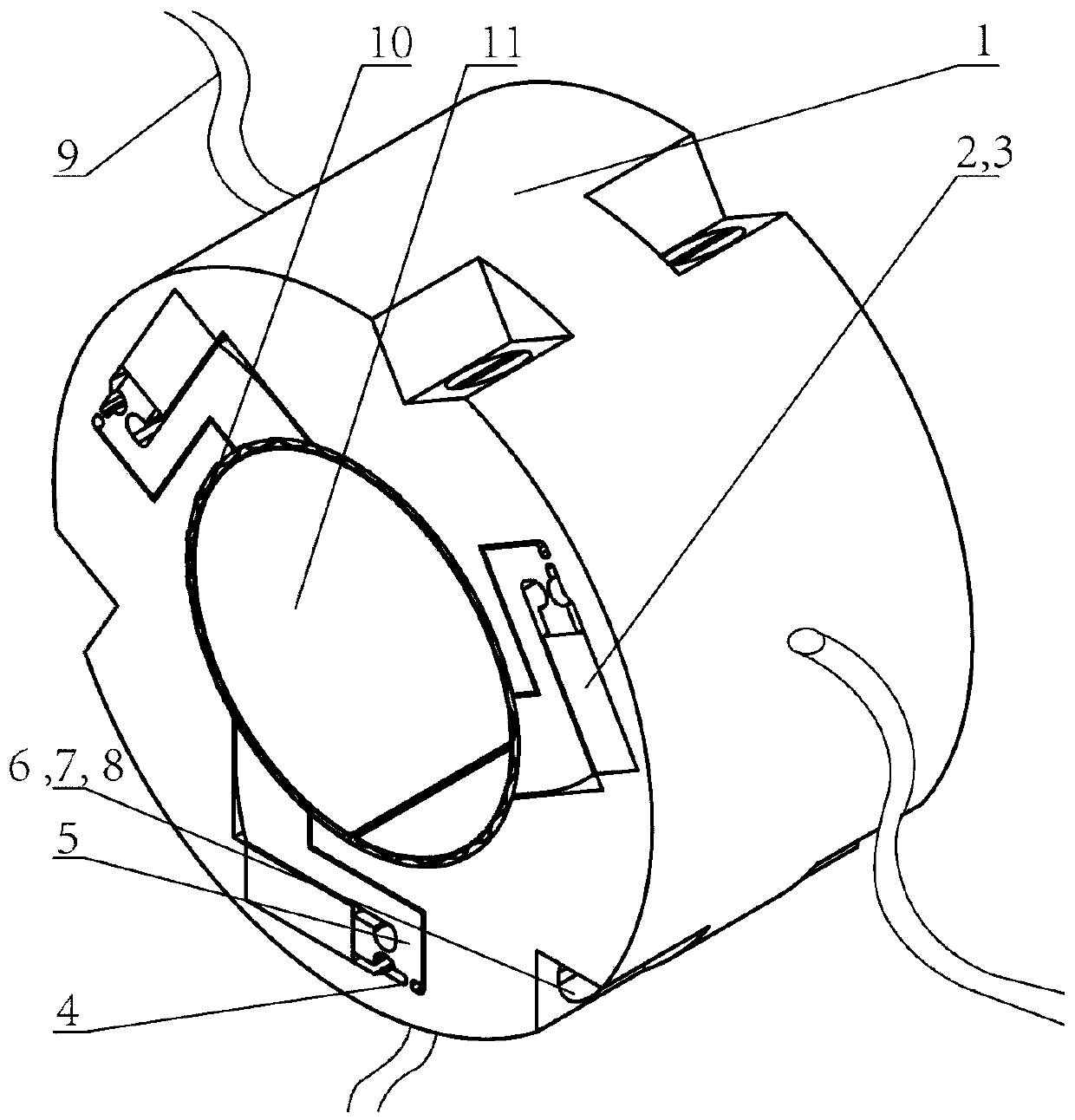

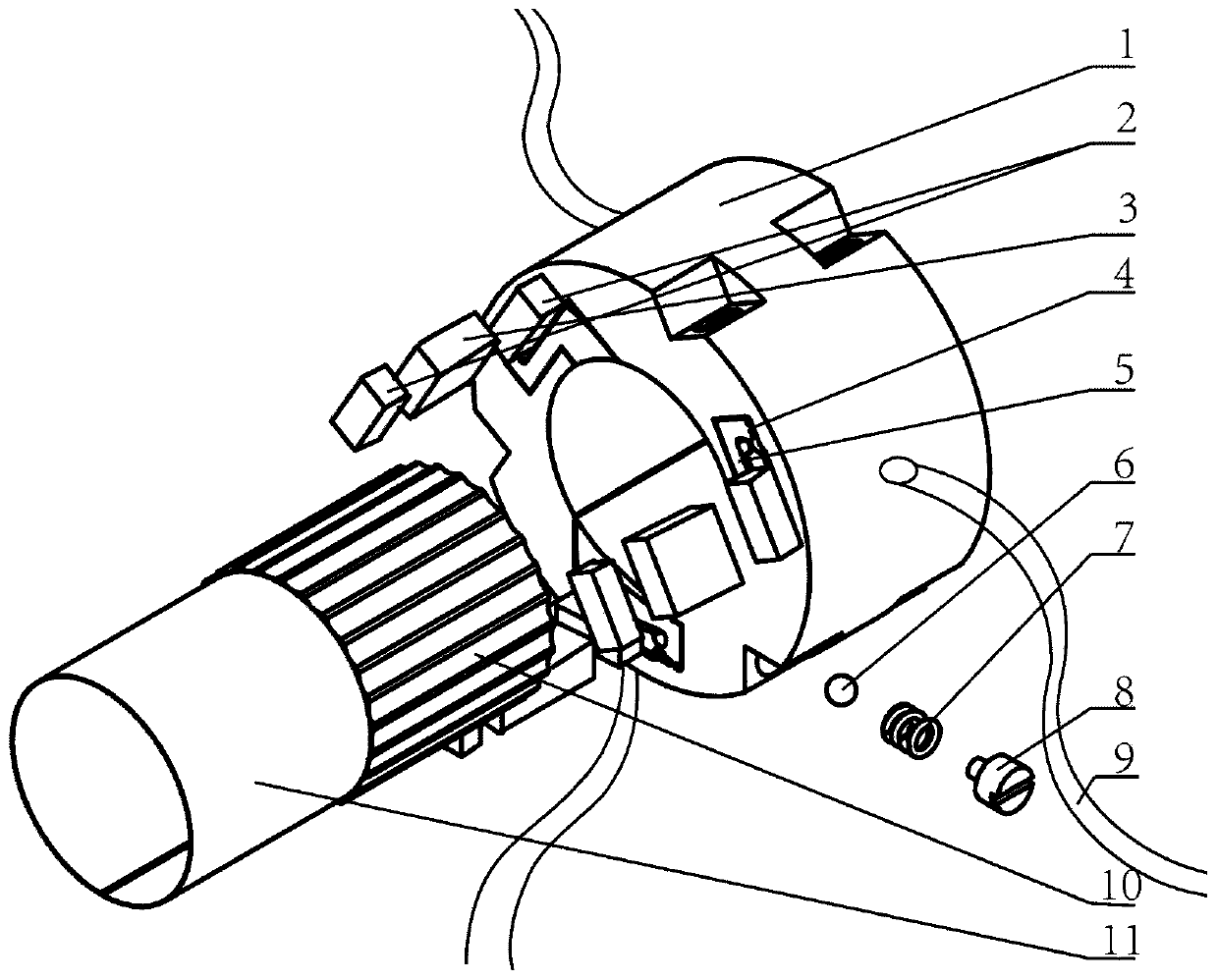

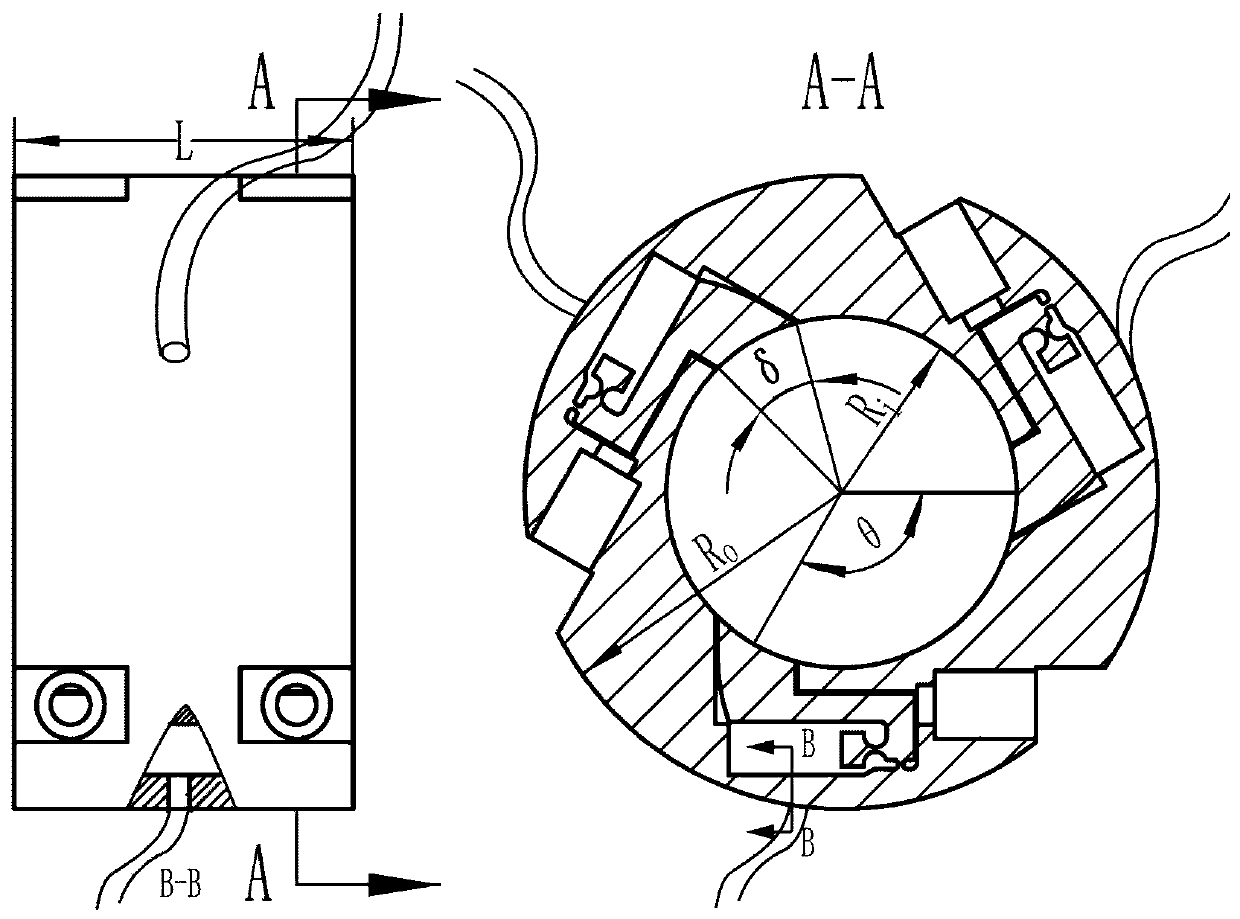

[0024] Such as figure 1 and figure 2 As shown, the new active air foil bearing based on PZT and flexible hinge includes: bushing (1), PZT (2), SMA block (3), flexible hinge (4), rigid push rod (5), steel ball ( 6), spring (7), screw (8), cooling pipe (9), wave foil (10) and top foil (11) constitute. Such as figure 2 As shown, the shaft sleeve (1) is processed by wire cutting to obtain three pairs of PZTs (six PZTs) and three SMA block (3) installation through slots uniformly distributed along the circumferential direction and the corresponding flexible hinges (4) and rigid push rod (5), the top of the rigid push rod (5) and the shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com