Novel winding machine winding method and device thereof

A winding machine and a new type of technology, applied in the direction of winding strips, external support, transportation and packaging, etc., can solve the problems of rotating film deviation, difficult to control the tension of packaging film, insufficient winding tightness of objects, etc., to avoid offset effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

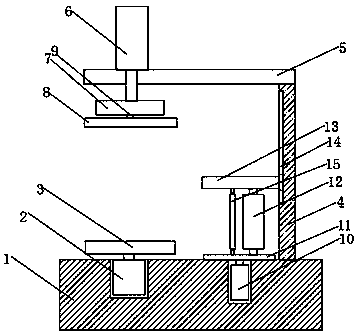

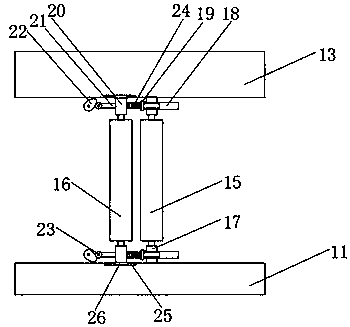

[0029] Such as Figure 1-2 As shown, the embodiment of the present invention provides a new type of winding machine winding method and its equipment, including a base 1, a vertical plate 4 is welded on the top side of the base 1, and a top seat 5 is welded vertically on the top of the vertical plate 4, and the base 1 The inner side of the base 1 is embedded with a servo motor 2, and the driving end of the servo motor 2 passes through the top of the base 1 and is fixedly connected with a turntable 3, and the inside of the base 1 near the side of the vertical plate 4 is embedded with a first cylinder 10, and The piston end of the first cylinder 10 passes through the base 1 and is fixedly connected with a bottom plate 11, a top plate 13 is arranged above the bottom plate 11, a winding drum 12 is arranged between the top side of the bottom plate 11 and the top plate 13, and the two ends of the winding drum 12 Rotately connected with the bottom plate 11 and the top plate 13 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com