Copper strip surface degreasing device

A technology for copper strips and cleaning devices, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve problems affecting production costs and yields, limited, and no dwell time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

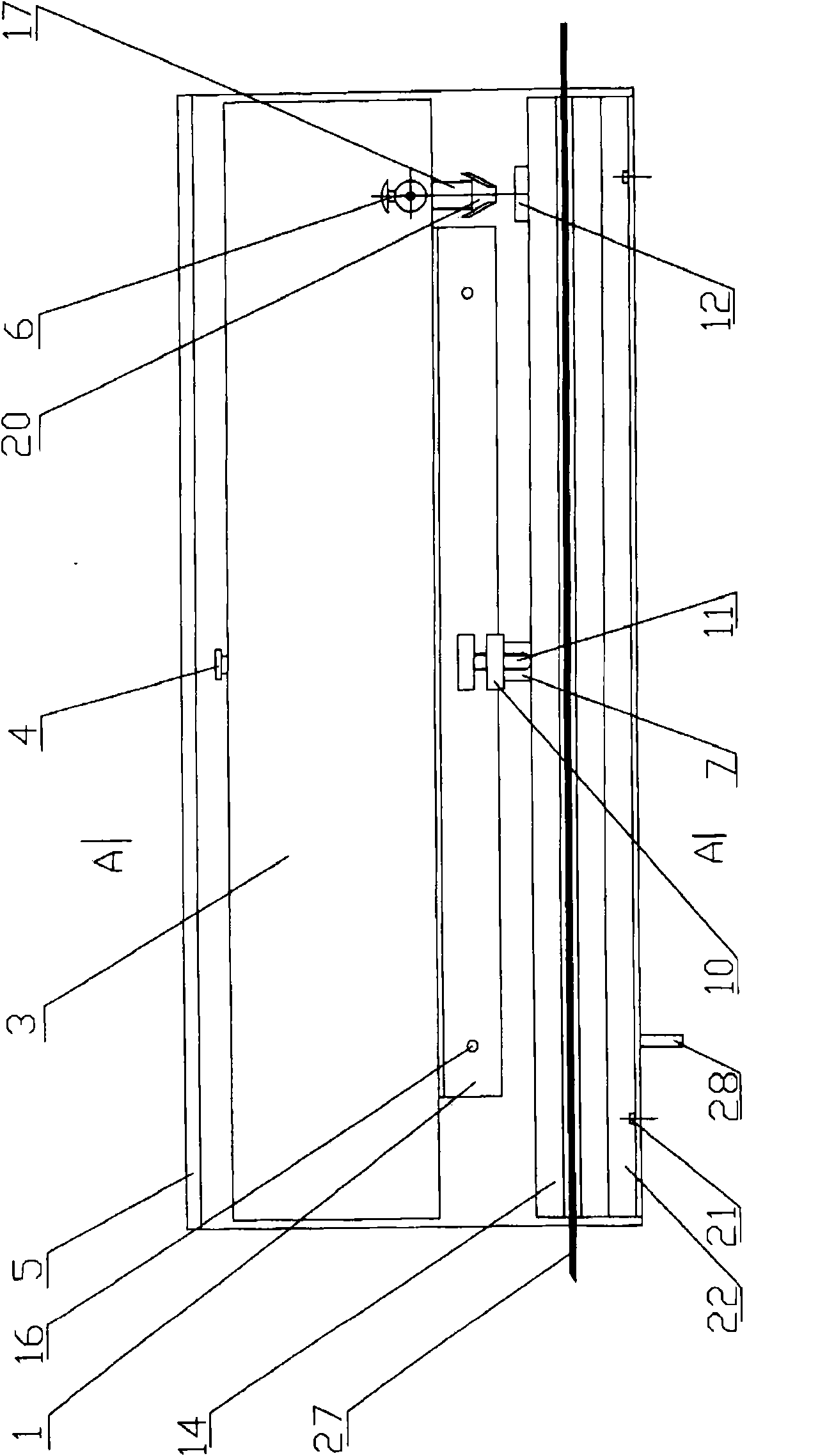

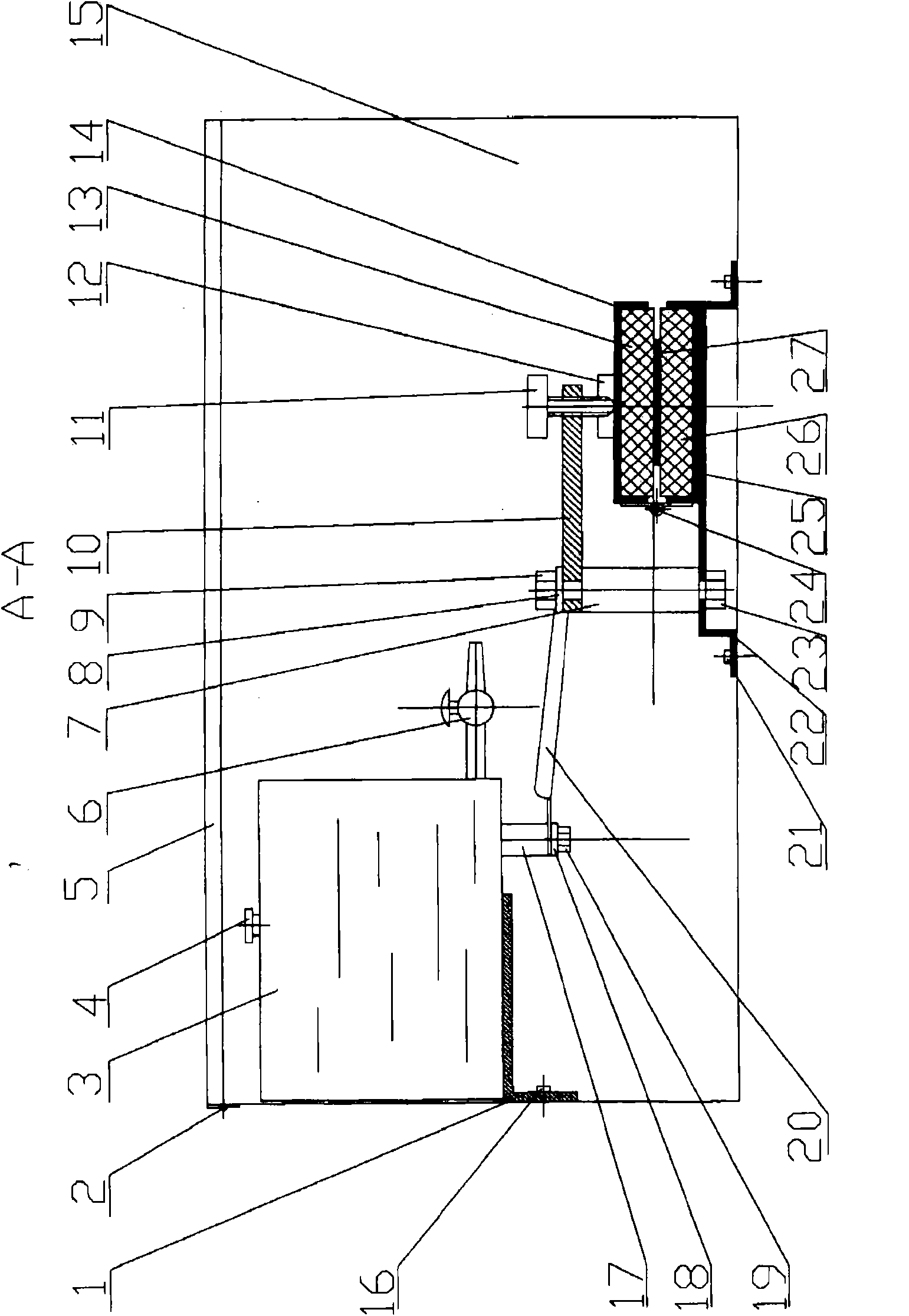

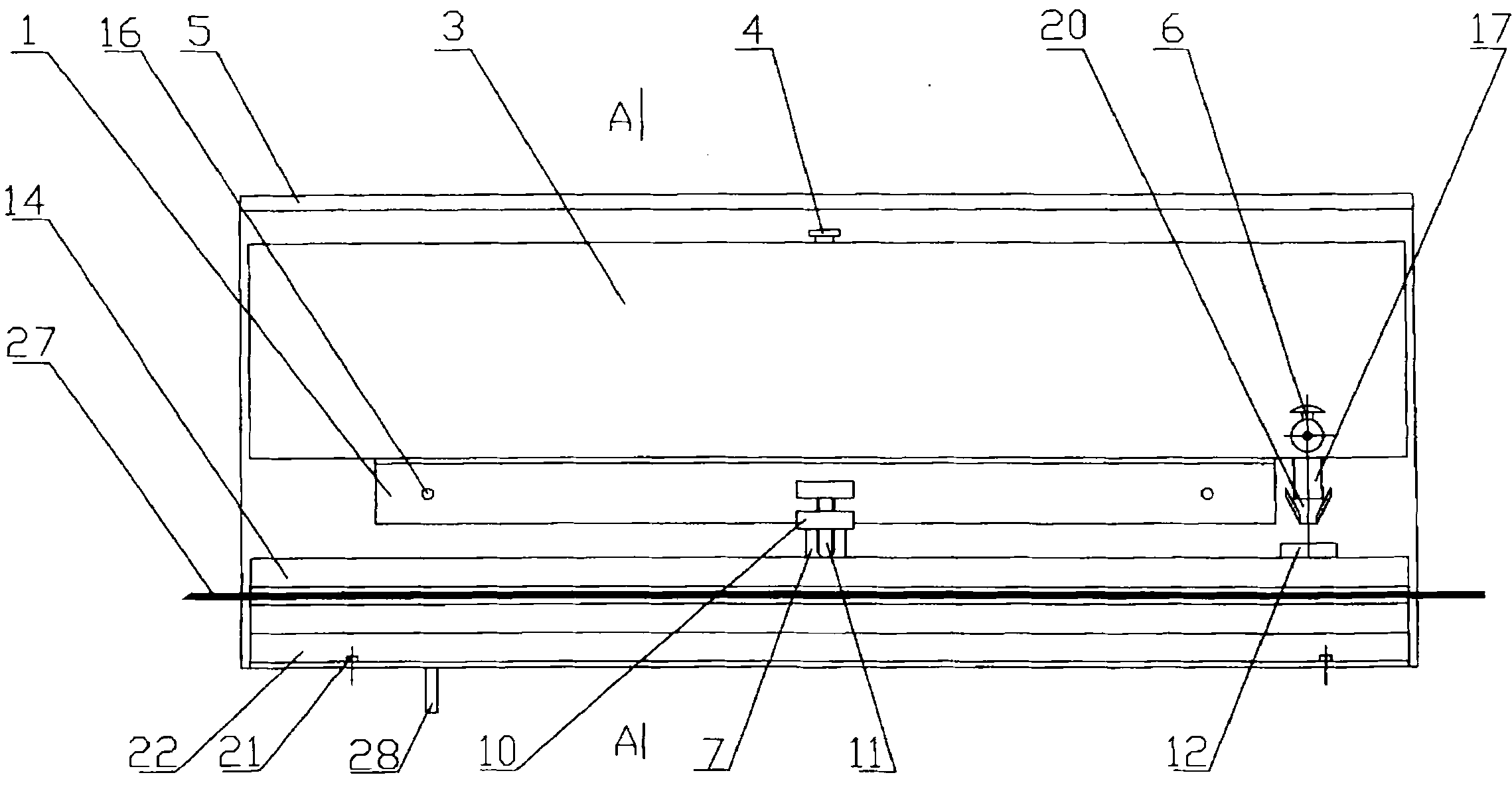

[0012] refer to figure 1 and figure 2 , the copper strip surface degreasing device of the present invention comprises the container 3 that fills cleaning agent, and described container is fixed in a box body 15, and box body is provided with box body upper cover 5, and this box body upper cover passes hinge 2 is hinged with the side wall of the box body 15. The container 3 is provided with a container cover 4, and the cleaning agent can be added through the container cover. Container 3 is connected on the support 1 of L shape, and this support 1 is fixed on the wall surface of container by screw 16. The box body 15 is provided with a friction cleaning device, and the container 3 is provided with a delivery device for delivering the cleaning agent to the friction cleaning device. The delivery device includes a flow limiting valve 6 connected to the container and a guide groove 20 below the flow limiting valve. , the end of the guide groove 20 extends to the top of the frict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com