Automatic cleaning device for canned bottle

A technology for automatic cleaning and canning bottles, which is applied to spray devices, spray devices, cleaning hollow objects, etc., can solve the problems of high labor intensity, poor cleaning effect, time-consuming and laborious, etc., achieve good cleaning effect, improve sterilization efficiency and Sterilization effect, effect of improving cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

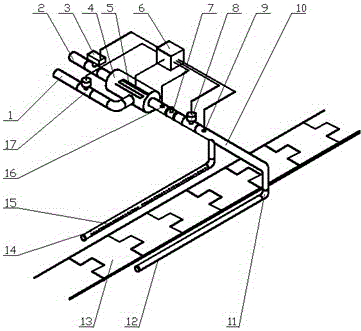

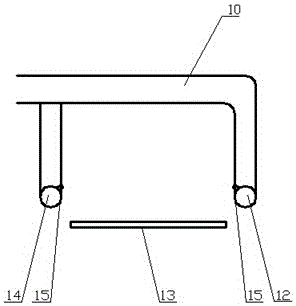

[0030] like Figure 1~3 As shown, the automatic cleaning device for cans includes a water inlet pipe 1, a steam pipe 2, a heating chamber 4, a connecting pipe 10, a water spray pipe, and a controller 6; the heating chamber 4 is provided with a water inlet, a steam inlet and a water outlet, The water inlet and the steam inlet are respectively connected with the water inlet pipe 1 and the steam pipe 2, and the first regulating valve 17 is installed on the steam pipe 2, and the water outlet is connected with the water spray pipe through the connecting pipe 10, and the connecting pipe 10 is installed with the controller 6 The connected thermal probe 16 and the controller 6 control the opening of the first regulating valve 17 on the steam pipe 2 so that the water temperature at the outlet of the water spray pipe is 75°C. The water spray pipe is installed on both sides of the conveying chain 13 to spray water There are several spray holes distributed on the pipe.

[0031] When the ...

Embodiment 2

[0042] Compared with Example 1, the filling slurry pipeline resistance increasing device of this example has the following differences:

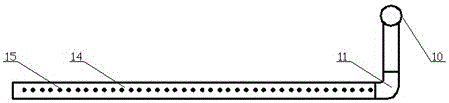

[0043] like Figure 3~4 As shown, the water spray holes are distributed on the water spray pipe in a W shape. The horizontal distance between adjacent water spray holes is 10cm, and the vertical distance between adjacent water spray holes is 5cm. The water spray hole adopts non-linear setting, which can clean the can bottles from different angles, and the cleaning effect is better.

[0044] Working principle and using method of the present invention:

[0045] After starting to work, the controller 6 opens the first regulating valve 17 and closes the third regulating valve 8 at the same time, cold water enters from the water inlet pipe 1 and fills the heating chamber 4, then the controller 6 opens the second regulating valve 3 and the heating device 5, The controller 6 receives the temperature measured value of the cleaning water flow sent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com