Ultrahigh-speed horizontal band sawing machine

An ultra-high-speed, band sawing machine technology, used in sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve the problems of difficulty in high-speed operation, short service life, high noise, etc., to improve repeat accuracy and reliability, The effect of improving sawing accuracy and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

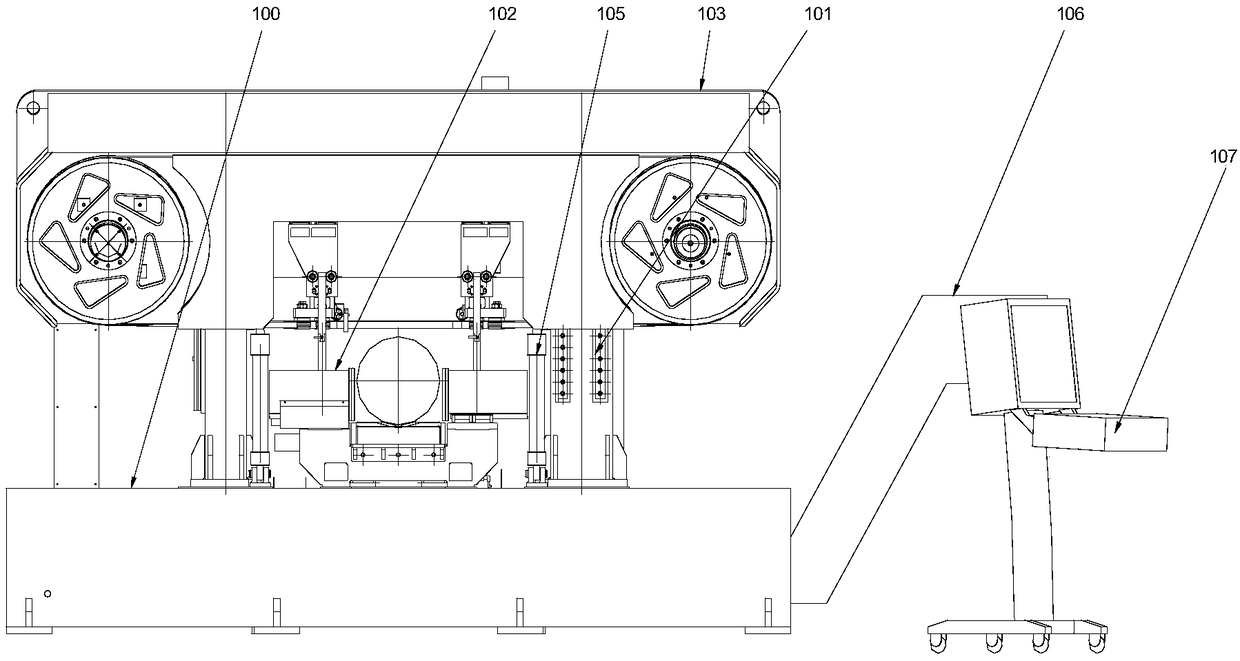

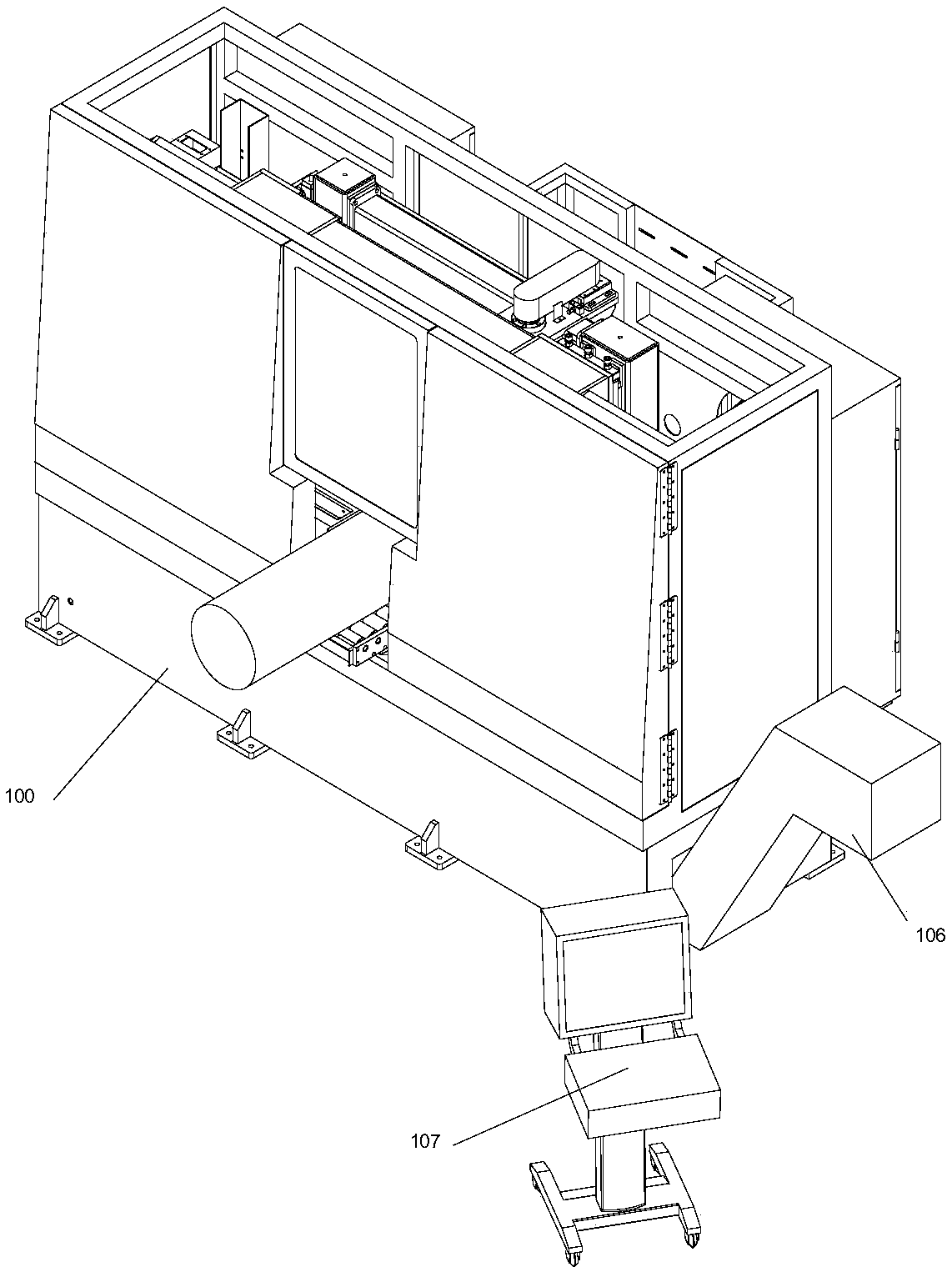

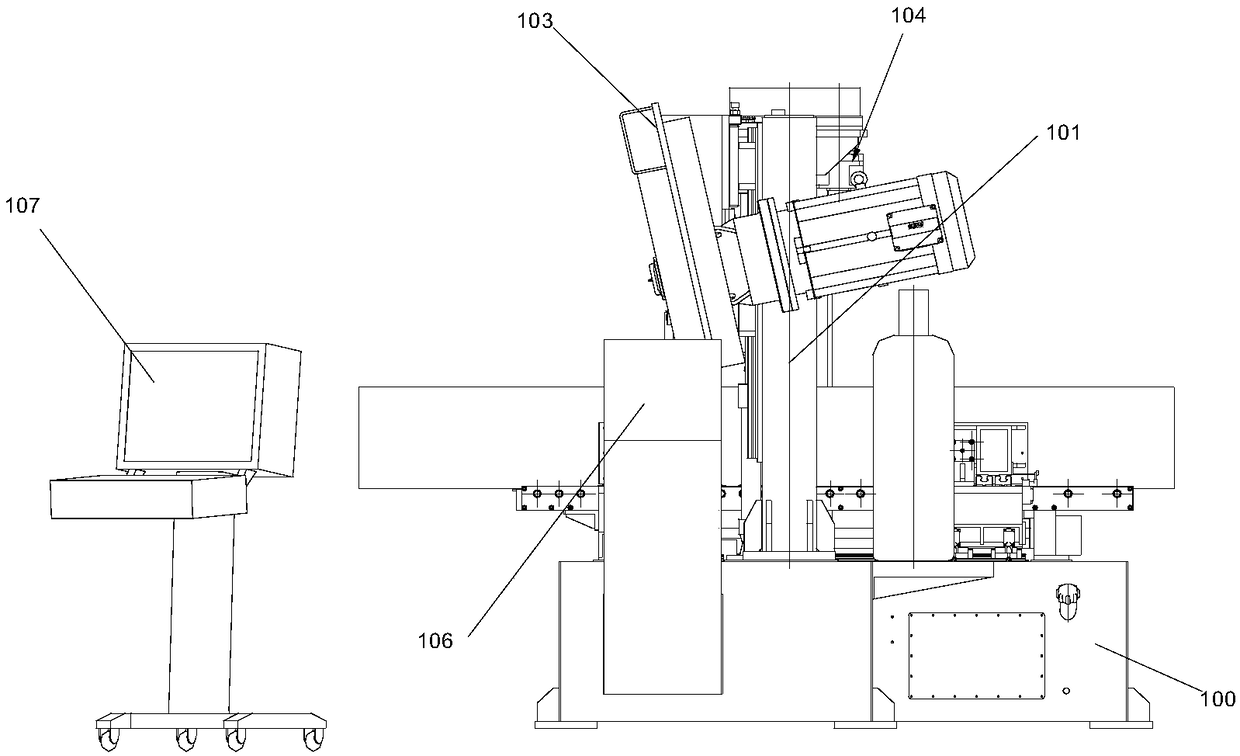

[0030] Please also refer to Figures 1 to 3 , an ultra-high-speed horizontal band sawing machine, including a base 100, a column 101, a bed 102, a saw frame 103, a servo drive system 104, a saw frame lifting and balancing system 105, a chip removal machine 106 and a controller 107. The saw frame 103 is inclined forward relative to the column 101, and its inclination angle is 12°.

[0031] Wherein, the bed platform 102 is installed on the base 100 for arranging and clamping sawing materials, and the columns 101 are arranged on the left and right sides of the bed platform 102 .

[0032] The saw frame 103 can be lifted up and down along the column 101, and it includes a driving wheel 91, a driven wheel 92, a saw band 93, a tensioning device 94, and a saw band guiding device 95 for turning and clamping the saw band. The saw band 93 is sheathed on the driving wheel 91 and the driven wheel 92 , and the tensioning device 94 is used to increase the distance between the driving wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com