Preparation method for polyurethane polishing material by using network interpenetration

A technology of polishing materials and network interpenetration, which is applied in the direction of polishing compositions containing abrasives, etc., can solve the problems of poor mold fit between polishing pads and workpieces, hard polyurethane matrix materials, lack of toughness and elasticity, etc., and achieve porosity Effects of increase, long storage time at room temperature, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

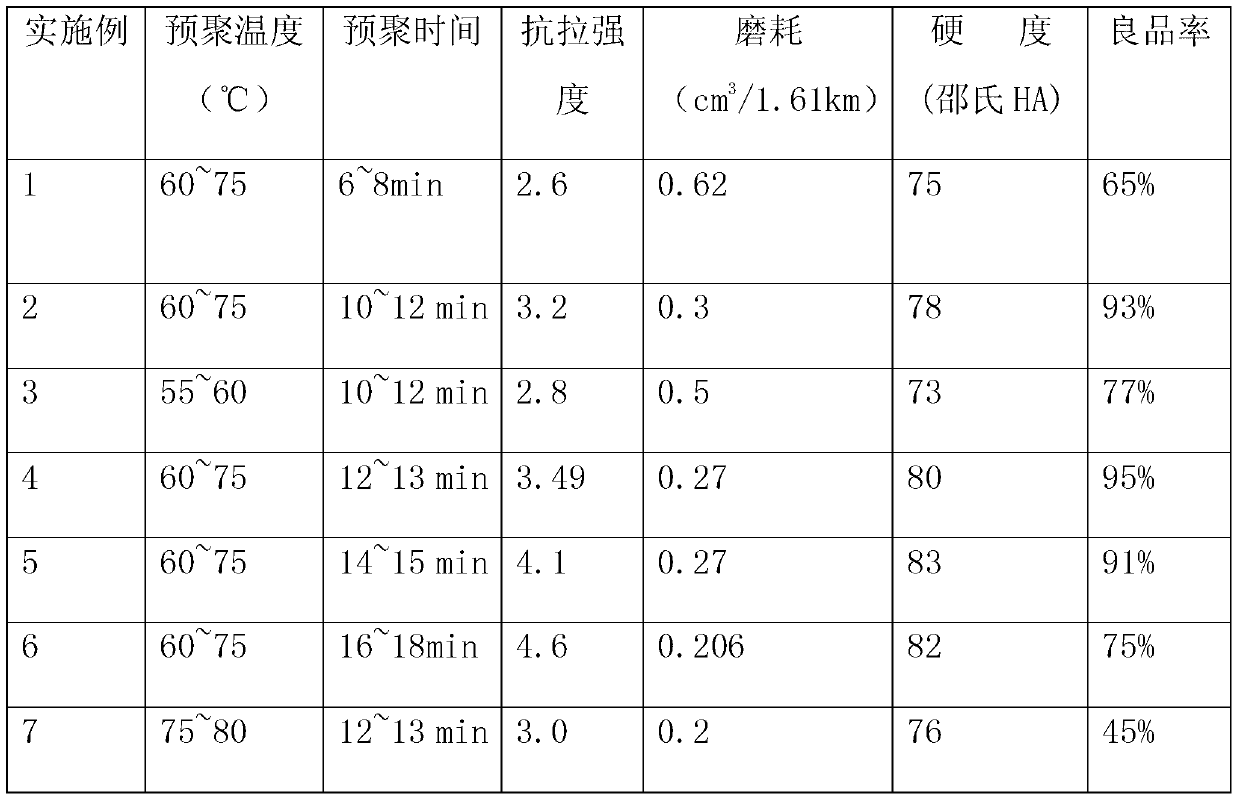

Examples

Embodiment 1

[0016] This embodiment provides a method for making polyurethane polishing material by network interpenetrating method, comprising the following steps:

[0017] a. Mix a total of 35kg of polymer polyol, epoxy resin, and polyether polyol mixture in a weight ratio of 5:2:3, and heat to 60-75°C. The weight ratio of polyether 210 and polyether 330 2:3, the molecular weight of the polymer polyol and the epoxy resin is 3000-4500, and the molecular weight of the polyether polyol is 100-300;

[0018] b. Add 26kg of toluene diisocyanate and 0.5kg of composite catalyst, and stir rapidly for 6-8 minutes to make the viscosity of the mixture reach 1600-1800cp.s / 25°C, then add 14kg of ethylene glycol by weight for chain extension ;

[0019] c. Stir for 2-3 minutes, the reaction viscosity reaches 2600-3000cp.s / 25°C, the reaction temperature is 110-115°C, add 0.5kg of water, 20kg of cerium oxide, zirconia mixture polishing powder, cerium oxide, zirconia The weight ratio is 3:1, high-speed s...

Embodiment 2

[0021] Same conditions as in Example 1, step b was stirred rapidly for 10-12 minutes.

Embodiment 3

[0023] a. Mix a total of 40kg of polymer polyol, epoxy resin, and polyether polyol mixture in a weight ratio of 5:2:3, and heat it to 55-60°C. The weight ratio of polyether 210 and polyether 330 is The ratio is 2:3, the molecular weight of the polymer polyol is 3000-4500 and the epoxy resin is 300-800, and the molecular weight of the polyether polyol is 100-300;

[0024] b. Add 24kg of toluene diisocyanate and 0.6kg of composite catalyst, stir rapidly for 10-12 minutes to make the viscosity of the mixture reach 1600-1800cp.s / 25°C, then add 16kg of ethylene glycol by weight for chain extension ;

[0025] c. Stir for 2-3 minutes, the reaction viscosity reaches 2600-3000cp.s / 25°C, the reaction temperature is 110-115°C, add 0.5kg of water, 24kg of polishing powder of a mixture of cerium oxide and zirconia, cerium oxide, zirconia The weight ratio is 3:1, high-speed stirring at 100-115°C for 10-15s, injection molding, curing at 120°C for 16 hours, demoulding, and slicing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com