Gradient-doped manganese iron oxalate precursor and preparation method thereof

A technology of iron-manganese oxalate and gradient doping, which is applied in the direction of carboxylate preparation, electrical components, battery electrodes, etc., can solve the problems that cannot effectively solve the defects and existing problems of lithium iron-manganese phosphate, and achieve easy large-scale industrial production, Good rate performance and cycle performance, the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

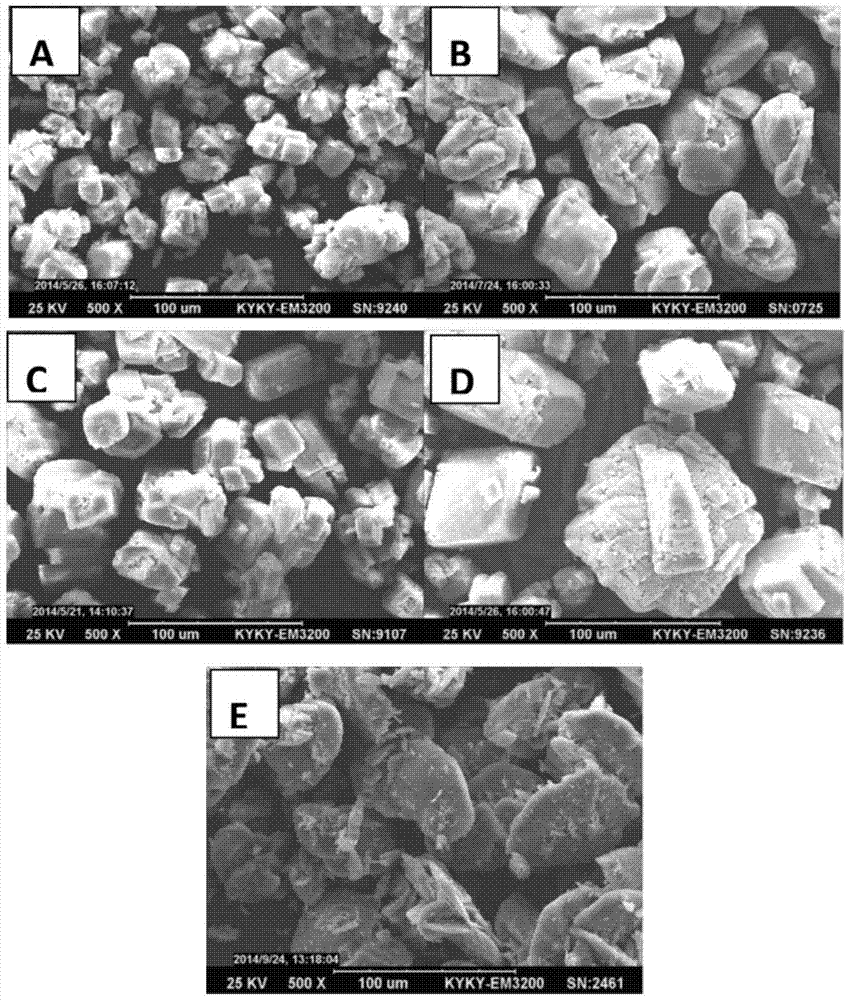

[0044] Embodiment 1 (comparative example, undoped):

[0045] Weigh 144.59g of ferrous sulfate heptahydrate and 351.52g of manganese sulfate monohydrate, dissolve them in an appropriate amount of water, and prepare iron-manganese mixed solution A. Add 402g of ammonium oxalate and water to the reaction kettle, the concentration of ammonium oxalate is 1.0mol / L, feed nitrogen into the reaction kettle, set the flow meter to 600ml / min, the pH of the system is 6, control the temperature of the reaction kettle at 65°C, heat until the ammonium oxalate is completely dissolved. Then add iron-manganese mixed solution A to the system concurrently and dropwise. Solution A is added at a rate of 1 L / h. After the dropwise addition, it is aged for 3 hours under stirring at a rate of 1500 r / min. The intermediate was washed with water and ethanol respectively, dried at 85°C for 5 hours, and the chemical composition was Fe 0.2 mn 0.8 C 2 o 4 2H 2 O.

[0046] The granular ferromanganese oxal...

Embodiment 2

[0048] Weigh 475.29g of manganese sulfate monohydrate and 150.15g of ferrous sulfate heptahydrate, and dissolve them in an appropriate amount of water to obtain mixed solution A of iron and manganese; 23.82g of nickel nitrate is dissolved in water to form solution B. Add 523g of ammonium oxalate and water to the reactor, the concentration of ammonium oxalate is 1.2mol / L, feed argon into the reactor, set the flow meter to 600ml / min, the pH of the system is 3, and the temperature of the reactor is controlled at 80°C. Heat until the ammonium oxalate is completely dissolved. In a stirring state, iron-manganese mixed solution A and nickel nitrate solution B are added dropwise to the system in a co-current manner. The dropping speed of the iron-manganese mixed solution A is 4L / h, and the dropping speed of the nickel sulfate solution B is gradually increased by 0.05L / h, 0.5L / h, and 1L / h. After the dropwise addition, continue aging for 3h under stirring , the stirring speed is 1200r / ...

Embodiment 3

[0051] Weigh 117g of ferrous oxalate dihydrate and 337.84g of manganese oxalate dihydrate and dissolve them in an appropriate amount of water to obtain mixed solution A of iron and manganese; weigh 17.69g of tetrabutyl titanate, 9.69g of absolute ethanol, and 1.04g Acetylacetone, add appropriate amount of water dropwise, and magnetically stir to make titanium sol B. Add 402g of ammonium oxalate and water into the reactor, the concentration of ammonium oxalate is 1.1mol / L, feed hydrogen into the reactor, set the flow meter to 600ml / min, the pH of the system is 6, control the temperature of the reactor at 65°C, heat until the ammonium oxalate is completely dissolved. In the stirring state, adopt the method of co-current addition to dropwise add iron-manganese mixed solution A and titanium sol B to the system, the dropping speed of iron-manganese mixed solution A is 2L / h, and at the same time slowly add titanium sol B, the dropping speed is according to 0.005L / h, 0.025L / h, 0.05L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible capacity | aaaaa | aaaaa |

| Reversible capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com