Process for extracting bacterial cell coenzyme Q10

A technology of bacterial cells and coenzymes, applied in the field of microbial engineering, can solve the problems of low volume efficiency of extraction tanks, increase the load of concentration equipment, and lose the driving force of mass transfer, etc. It is conducive to safe production, low overall height, and overall height low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

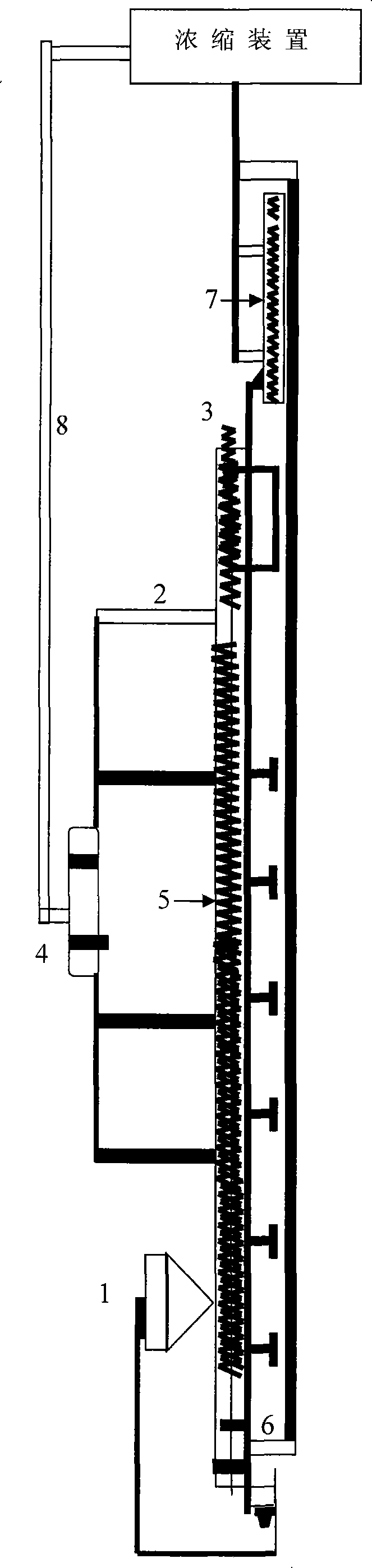

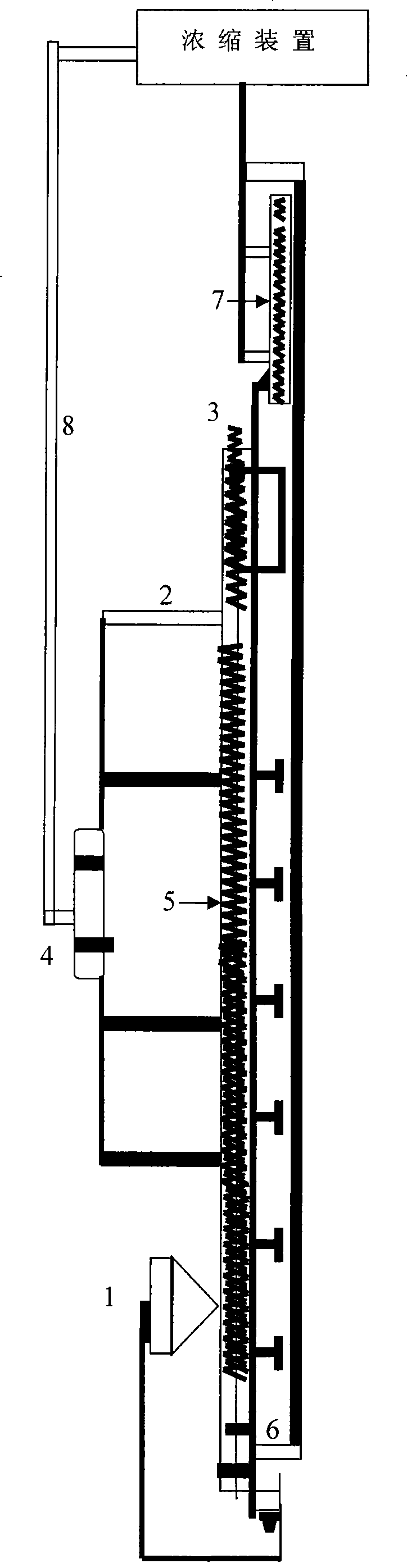

Image

Examples

example 1

[0036] Process parameters:

[0037] (1) Cells: photosynthetic bacteria or Agrobacterium cells, 80Kg.

[0038] (2) Solvent: n-hexane for food.

[0039] (3) Outlet coefficient: 1:3 (solid-liquid ratio)

[0040] (4) Temperature: room temperature.

[0041] (5) Extraction time: 4 hours.

[0042] Extraction method: (1) continuous countercurrent extraction scheme; (2) multifunctional tank extraction scheme

[0043] Extraction efficiency: (1) continuous countercurrent extraction scheme: 90%; (2) multifunctional tank extraction scheme: 72%.

[0044] Attached:

[0045] The method of calculating the result:

[0046] Standard method: Take 1g of bacteria (or dried bacteria residue after extraction), add 100mL of absolute ethanol, ultrasonically extract for 1 hour, and measure its CoQ10 content.

[0047] Result: Expressed as a percentage of extraction

[0048] (CoQ10 content of bacteria - CoQ10 content in bacteria residue)*100 / CoQ10 content of bacteria

example 2

[0050] Process parameters:

[0051] (1) Cells: photosynthetic bacteria or Agrobacterium cells, 80Kg.

[0052] (2) Solvent: n-hexane for food.

[0053] (3) Solid-to-liquid ratio: 1:6.

[0054] (4) Temperature: 40°C.

[0055] (5) Extraction time: 4 hours.

[0056] Extraction method: (1) continuous countercurrent extraction scheme; (2) multifunctional tank extraction scheme

[0057] Extraction efficiency: (1) continuous countercurrent extraction scheme: 95%; (2) multifunctional tank extraction scheme: 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com