Miniaturized extracting concentrating machine set and formulation production technique thereof

A technology of concentrating units and extraction tanks, which is applied in the direction of making medicines into special physical or ingestible devices, solid solvent extraction, etc., which can solve the problems affecting the retention and extraction of active ingredients of medicines, large production space, and production process capacity. Consumption and other problems, to achieve the effect of energy-saving and high-efficiency preparation process, small footprint and low input cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

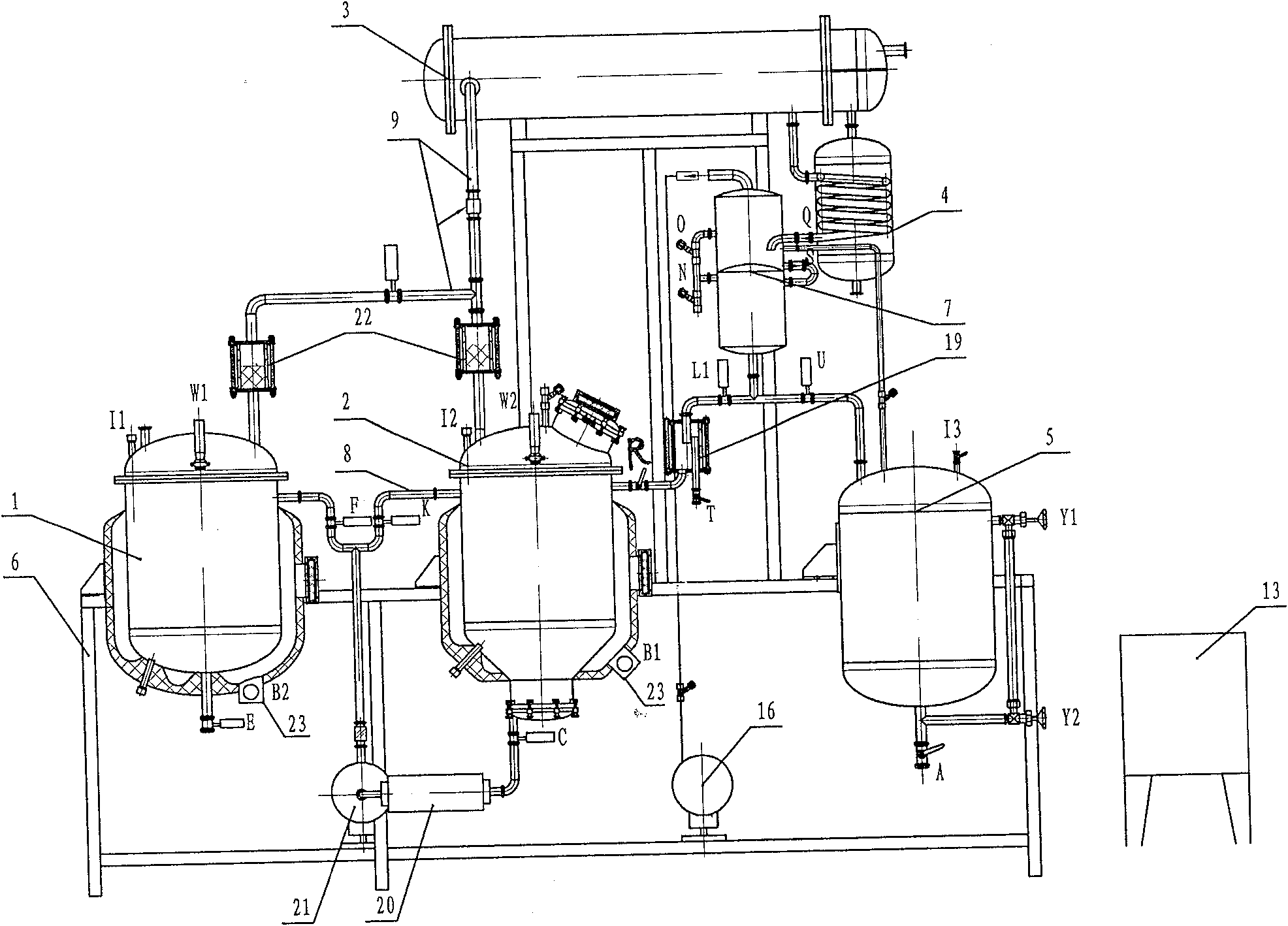

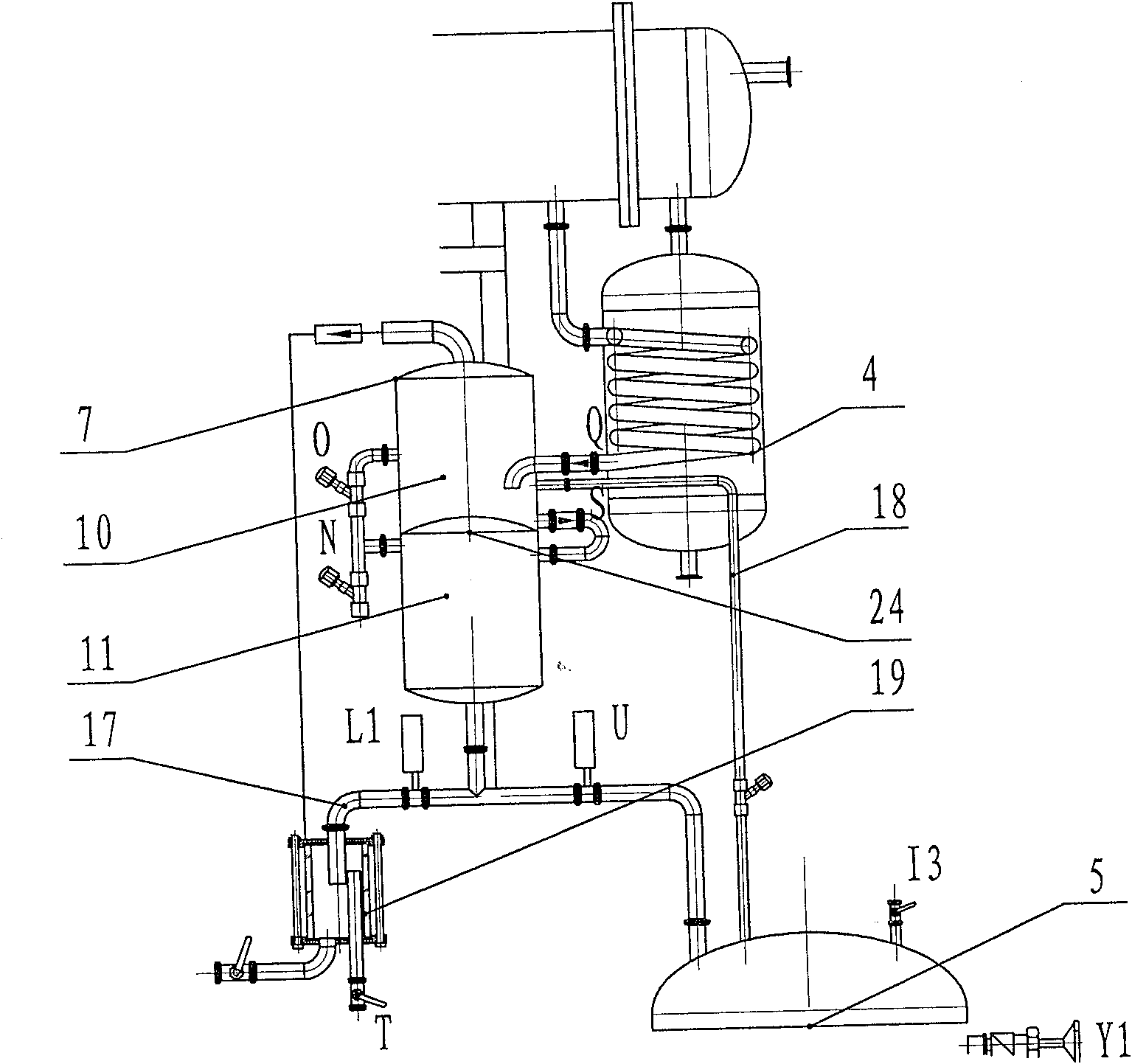

[0014] refer to figure 1 , figure 2 It can be seen that the miniaturized extraction and concentration unit of the present invention includes a concentration tank 1, an extraction tank 2, a condenser 3, a cooler 4, a liquid receiving tank 5 (temporarily storing the solvent and solvent recovered by condensation) and a support 6, and the concentration tank 1. The extraction tank 2 and the liquid receiving tank 5 are installed side by side on the bracket 6 in sequence (the distance between the three is relatively small), the concentration tank 1 and the extraction tank 2 are connected through a pipeline 8, and are connected to the condenser through another pipeline 9 3 connected, between the extraction tank 2 and the concentration tank 1 connecting pipeline 8 and the bottom of the extraction tank 2 are connected with a suction pump 21 and a pipeline filter 20 in sequence, between the cooler 4 and the extraction tank 2 A vacuum converter 7 is installed between them; the vacuum co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com