Ultrasonic wave and dry air combined production line drying equipment

A drying equipment and combined technology, applied in the direction of food ultrasonic treatment, lighting and heating equipment, drying solid materials, etc., can solve the problems of loss of flavor, heat damage of vegetables, loss of effective ingredients, etc., to reduce damage, reduce costs, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

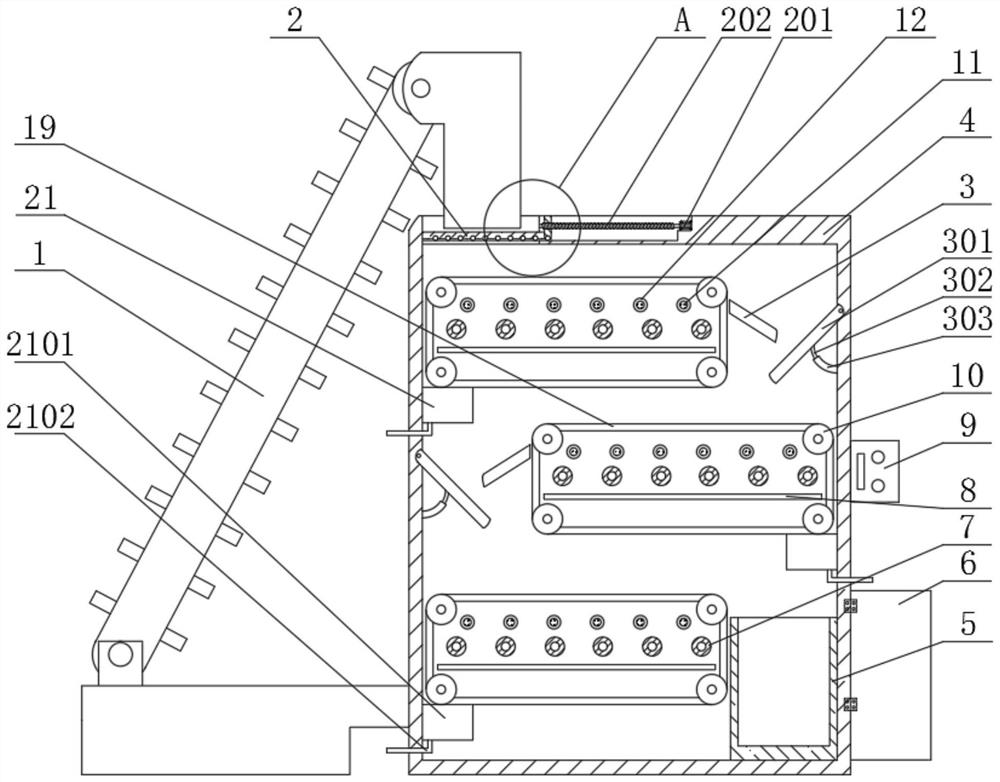

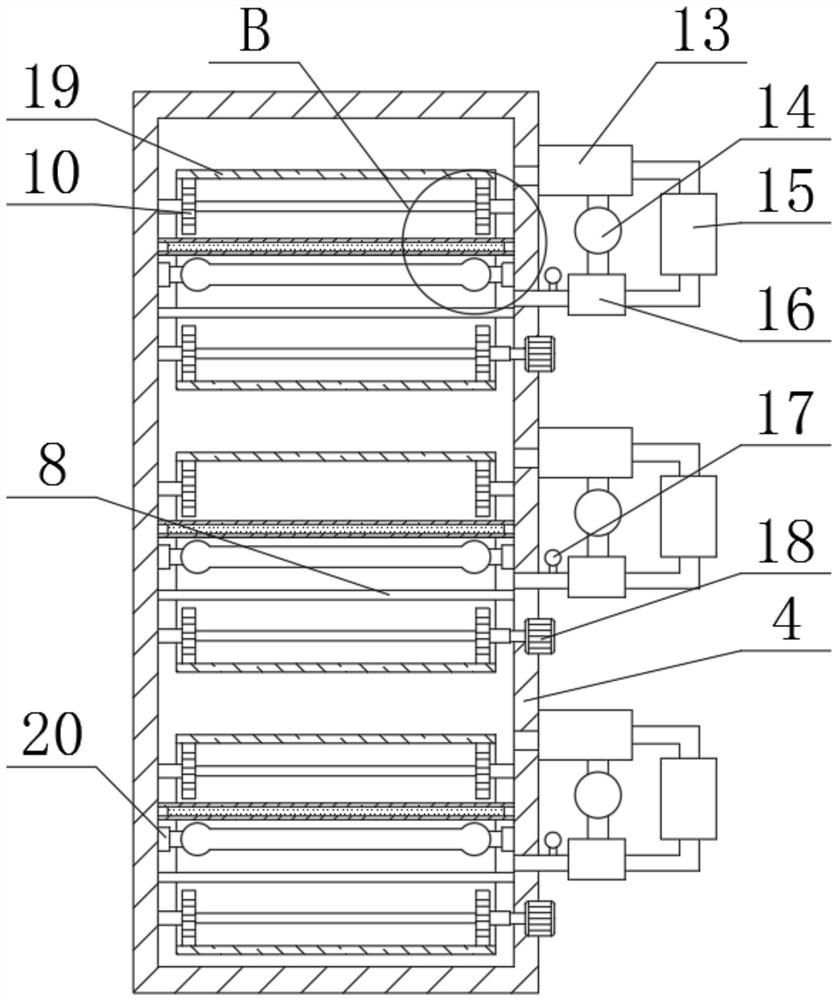

[0029] see Figure 1-8 , the present invention provides a technical solution:

[0030] An assembly line drying equipment combining ultrasonic waves and dry air, including a hoist 1 and a drying shell 4, the right end of the hoist 1 is fixedly connected with a drying shell 4, and the inside of the top end of the drying shell 4 is fixedly connected with a dustproof device 2, and the drying shell 4 The inner side of the drying shell 4 is fixedly connected with a buffer device 3, the right end of the drying shell 4 is fixedly connected with a controller 9, the right end of the drying shell 4 is connected with a door panel 6 through a hinge, the bottom of the drying shell 4 is provided with a collection box 5, and the drying shell 4 The inner side is connected with a sprocket 10 for rotation, and the outer side of the sprocket 10 is meshed with a stainless steel mesh belt 19, and the rear end of the sprocket 10 on the right side is fixedly connected with a first motor 18, and the f...

Embodiment 2

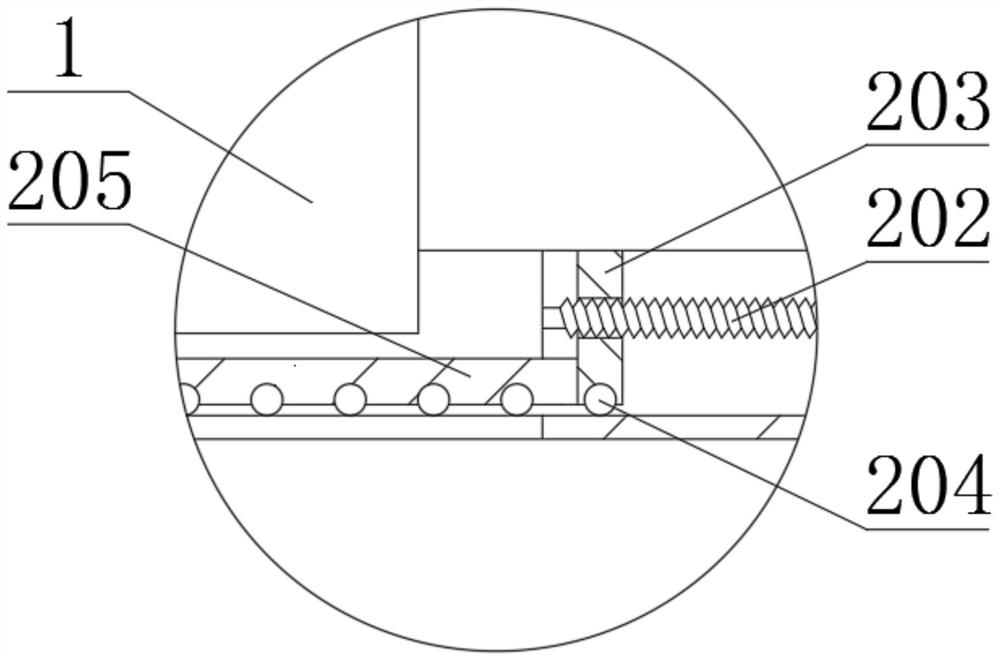

[0033] Embodiment 2 and Embodiment 1 will not repeat the same parts. The difference is that when the staff does not use the drying shell 4 to dry the food, the staff first makes the dust suppression plate 205 below the discharge port of the hoist 1, The staff controls the second motor 201 to rotate clockwise through the controller 9, and then the second motor 201 drives the adjustment screw 202 to rotate clockwise, and then the adjustment screw 202 drives the slider 203 and the dust suppression plate 205 to move to the left along the ball 204, Make the dust suppression plate 205 not at the lower end of the discharge port of the hoist 1, that is, block the feed port of the drying shell 4 by the dust suppression plate 205 to prevent external dust from entering the inside of the drying shell 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com