A device for extrusion molding of lipstick packaging tube

A technology for extrusion molding and packaging tubes, which is applied in the field of extrusion molding and blanking devices for lipstick packaging tubes, can solve the problems of low production efficiency, low degree of automation, time-consuming and labor-intensive, etc., and achieves high work efficiency, high degree of automation, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

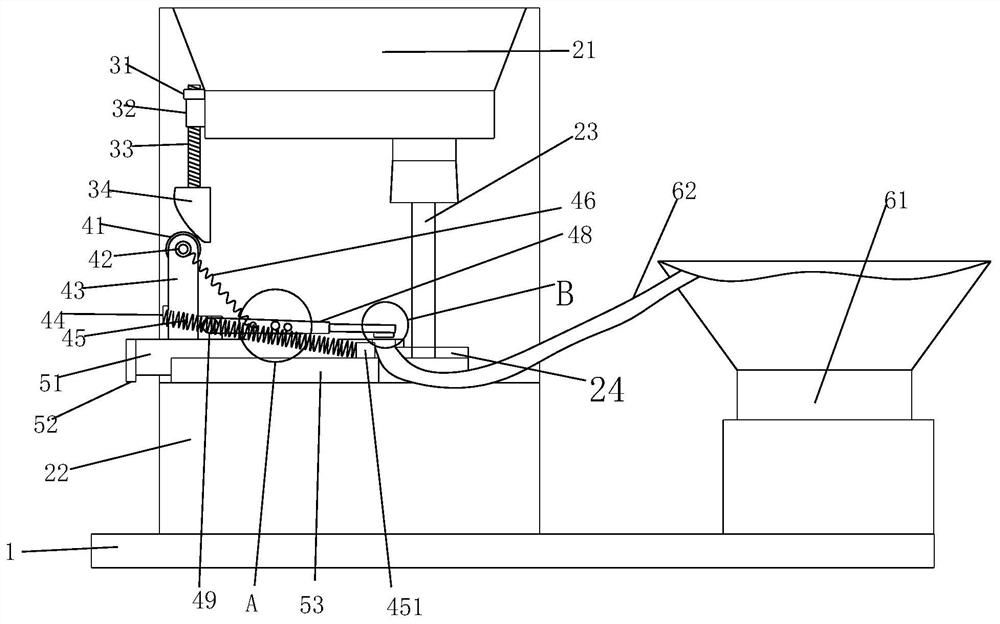

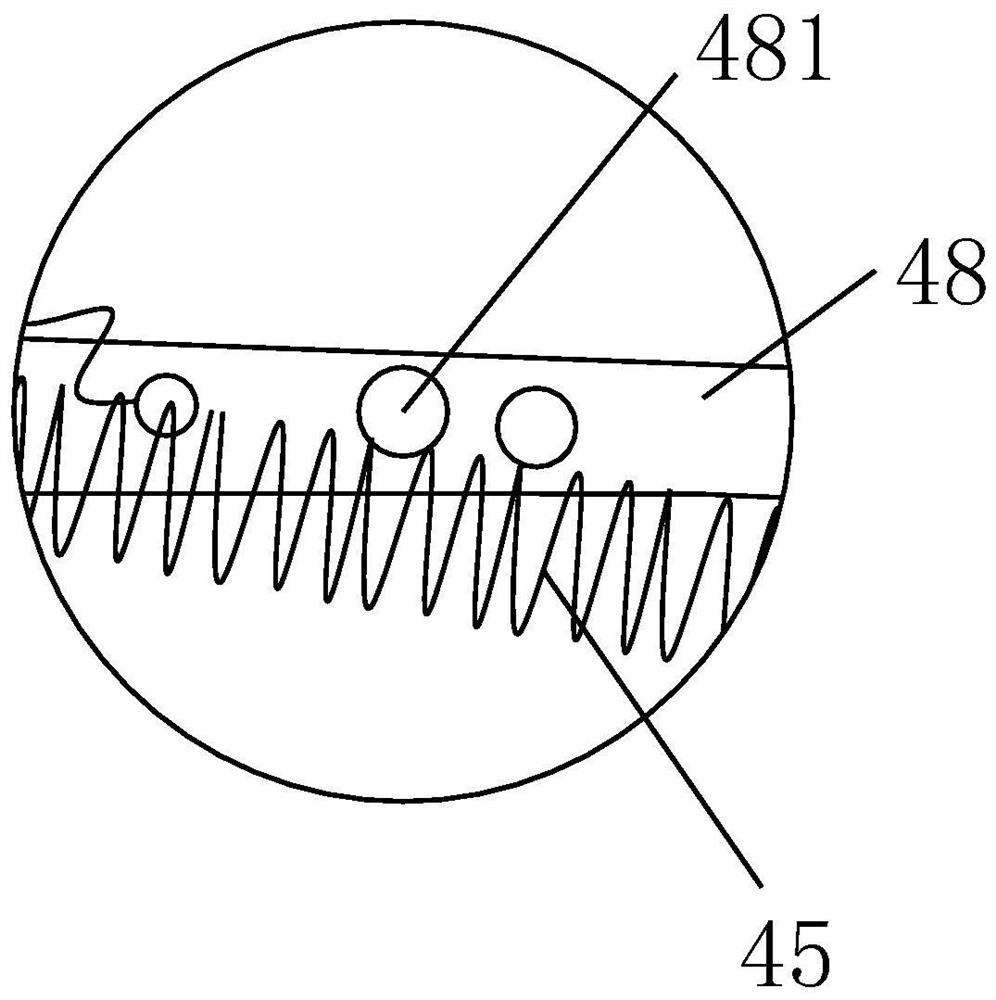

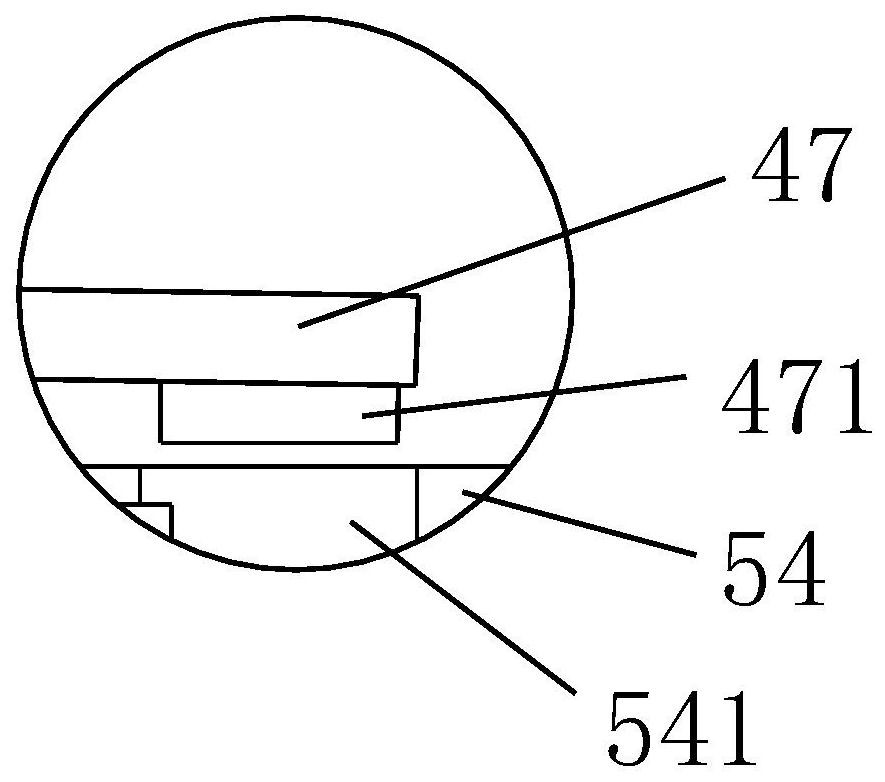

[0028] A blanking device for extrusion molding of lipstick packaging tubes, characterized in that it comprises:

[0029] Rack 1, used to carry work objects;

[0030] Extrusion molding machine, the extrusion molding machine is arranged on the frame 1, and the extrusion molding machine includes a workbench 22 arranged at one end of the frame 1, an extrusion mechanism 21 arranged on the workbench 22, and the conveying mechanism of the extrusion mechanism 21 An extruding head 23 is arranged at the end, and an extruding die 24 is arranged under the extruding head 23 on the workbench 22, and an extruding hole 241 is arranged in the center of the extruding die 24, and one part of the extruding die 24 corresponds to the extruding die 24 on the workbench 22. The side is equipped with a feeding device;

[0031] Vibrating plate 61, the vibrating plate 61 is arranged on the other end of the frame 1, and the vibrating plate 61 is connected with the feeding device through the feeding pipel...

Embodiment 2

[0039] A blanking device for extrusion molding of lipstick packaging tubes, characterized in that it includes:

[0040] Rack 1, used to carry work objects;

[0041] Extrusion molding machine, the extrusion molding machine is arranged on the frame 1, and the extrusion molding machine includes a workbench 22 arranged at one end of the frame 1, an extrusion mechanism 21 arranged on the workbench 22, and the conveying mechanism of the extrusion mechanism 21 An extruding head 23 is arranged at the end, and an extruding die 24 is arranged under the extruding head 23 on the workbench 22, and an extruding hole 241 is arranged in the center of the extruding die 24, and one part of the extruding die 24 corresponds to the extruding die 24 on the workbench 22. The side is equipped with a feeding device;

[0042] Vibrating plate 61, the vibrating plate 61 is arranged on the other end of the frame 1, and the vibrating plate 61 is connected with the feeding device through the feeding pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com