Fatigue performance testing machine for piston rod detection

A fatigue performance and piston rod technology, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, measuring devices, strength characteristics, etc., can solve problems that affect the efficiency of fatigue performance detection, waste of manpower, piston rod rotation or sliding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

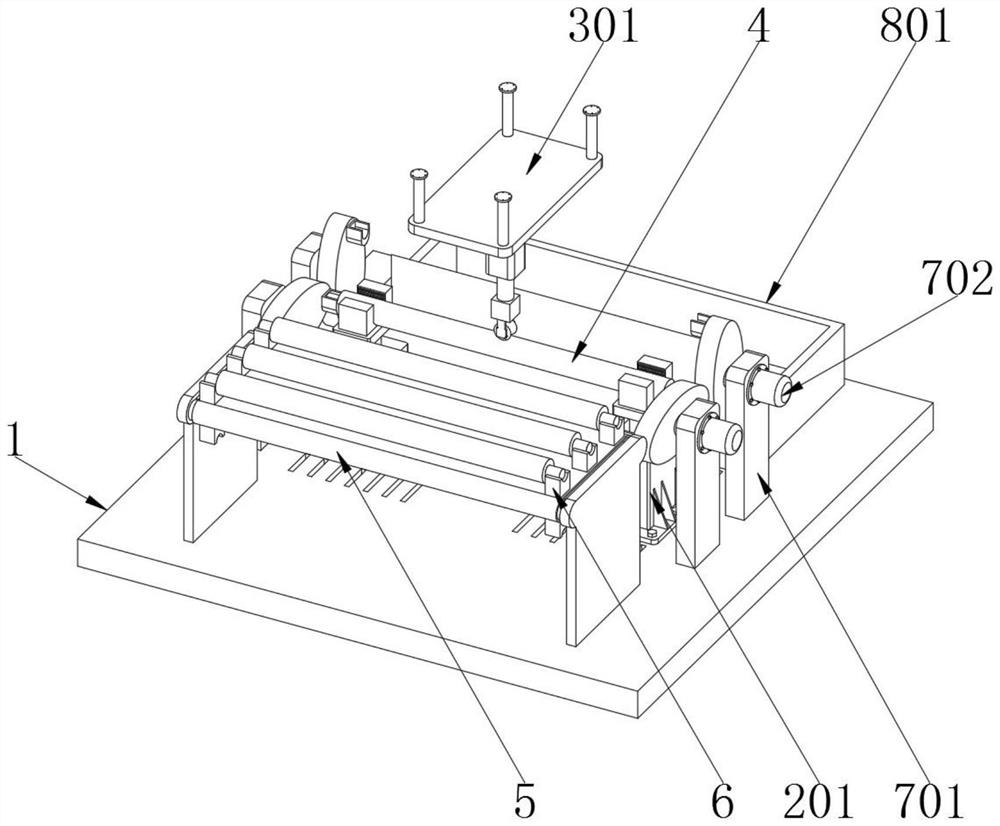

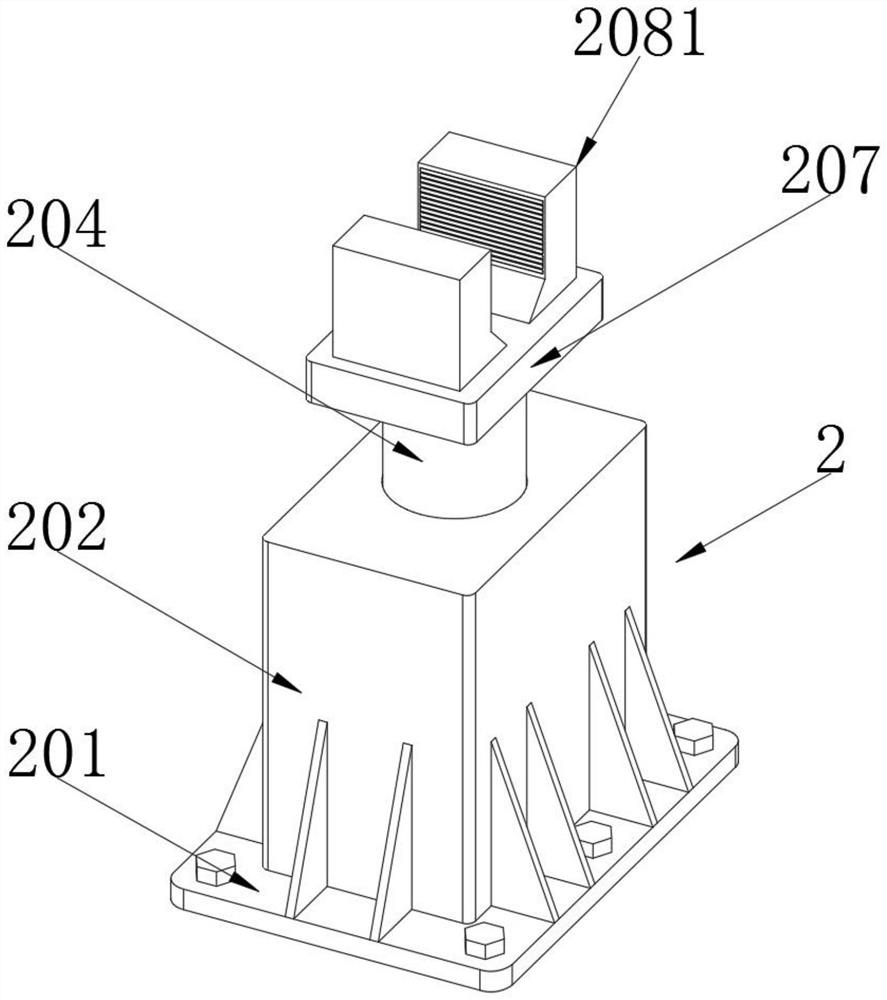

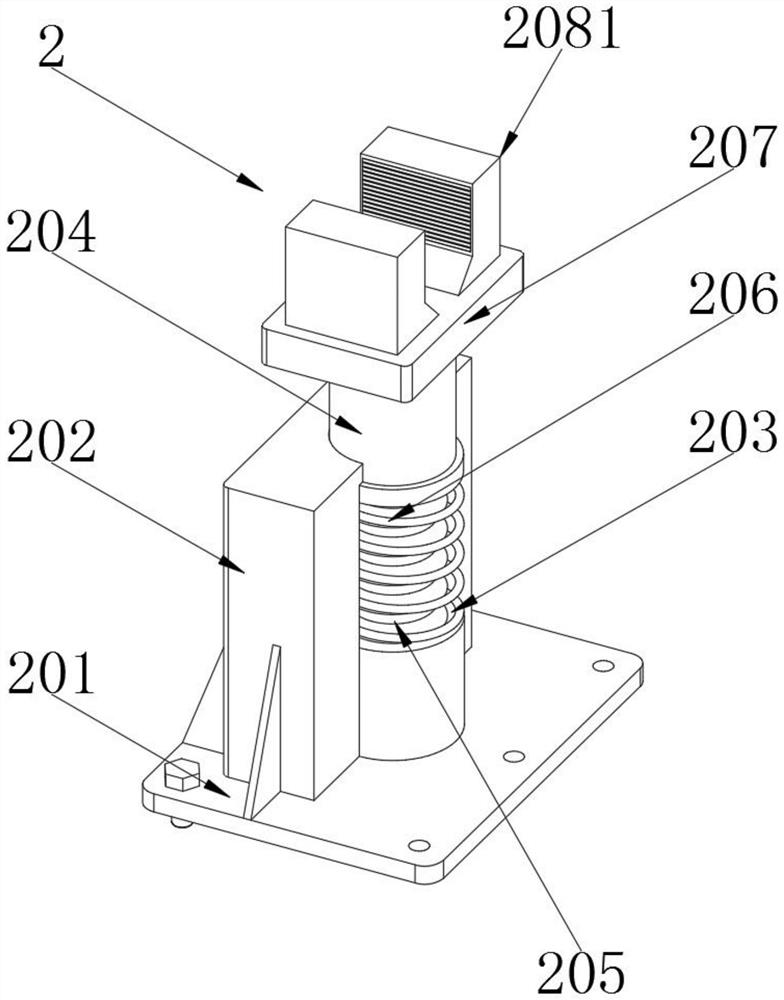

[0046] Example: such as Figure 1 to Figure 11 As shown, the present invention provides the following technical solutions, a fatigue performance testing machine for piston rod detection. A pressurizing mechanism 3 is provided above the middle part, and the pressurizing mechanism 3 is used to pressurize the piston rod 4 to facilitate the detection of the bending fatigue performance of the piston rod 4. A conveyor belt 5 is provided on one side of the piston rod 4 on the support mechanism 2 to transport The belt 5 is provided with a fixed seat 6, the conveyor belt 5 is used to transport the piston rod 4 to be tested for fatigue performance, the fixed seat 6 is used to fix the piston rod 4 transported by the conveyor belt 5, and the two ends of the support mechanism 2 are Two loading and unloading mechanisms 7 are provided, one of the two loading and unloading mechanisms 7 is used to load the piston rod 4 conveyed by the conveyor belt 5 onto the support mechanism 2, and the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com