An aqueous solution-based zinc-based battery cathode material, its preparation and application

A cathode material, zinc-based battery technology, applied in aqueous electrolyte batteries, battery electrodes, secondary batteries, etc., can solve the problems of low reversible capacity, low battery energy density, non-rechargeable limited application occasions, etc., to achieve high reversible capacity , high energy density, high reversible capacity and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044]The present invention also provides a method for preparing the positive electrode material. After the active material and the conductive material are mixed, they are heated to 50-500° C. under vacuum airtight conditions to obtain the positive electrode material.

[0045]The above-mentioned cathode material provided by the present invention can be used as a cathode material for aqueous zinc-based batteries. In particular, it can be used as a cathode material for rechargeable aqueous zinc-based batteries, which can release ultra-high reversible capacity and exert its high energy density performance.

[0046]The present invention also provides a zinc-based battery based on an aqueous solution, which includes a positive electrode material, a negative electrode material, and an electrolyte, wherein the positive electrode material is the composite of the active material and the conductive material as described above, and the negative electrode material and electrolyte are based on the aqu...

Embodiment 1

[0049]Weigh 1.0g sulfur powder and 1.0g carbon nanotubes (pore diameter 50nm, specific surface area 543m2g-1), grind and mix in an agate mortar for 30 minutes, then vacuum-sealed in a quartz tube, and then heat to 160°C for 24 hours. After cooling, the elemental sulfur and carbon nanotube composite material in this embodiment is cooled.

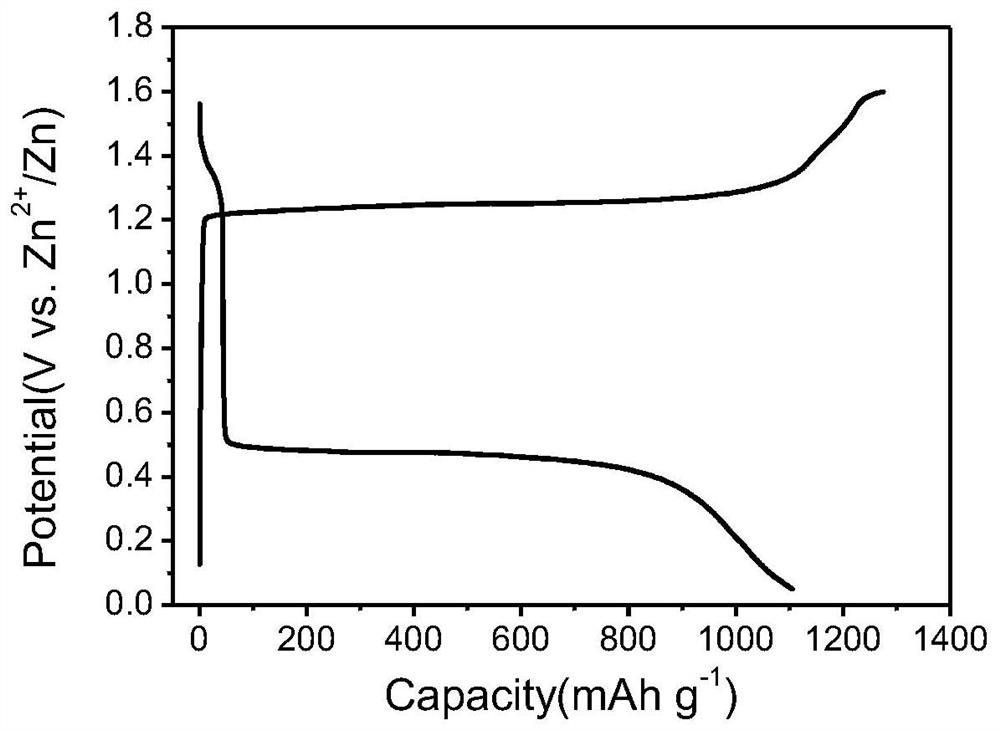

[0050]Weigh the above-mentioned composite material and PTFE according to a mass ratio of 8:2, mix them in isopropanol, and then roll them into a film with a pair of rollers, cut them into discs with a diameter of 8mm, and press them on a titanium mesh. electrode. The obtained electrode was used as the positive electrode, and the zinc sheet was used as the negative electrode. 1mol / L Zn(CH3COO)2As the electrolyte, the button cell is assembled to test its electrochemical performance. The charge-discharge curve is asfigure 1 Shown.

[0051]figure 1 Shows that the prepared electrode is 0.05Ag-1The current density is 0.05-1.6V(vs.Zn2+ / Zn) charge and discharge ...

Embodiment 2

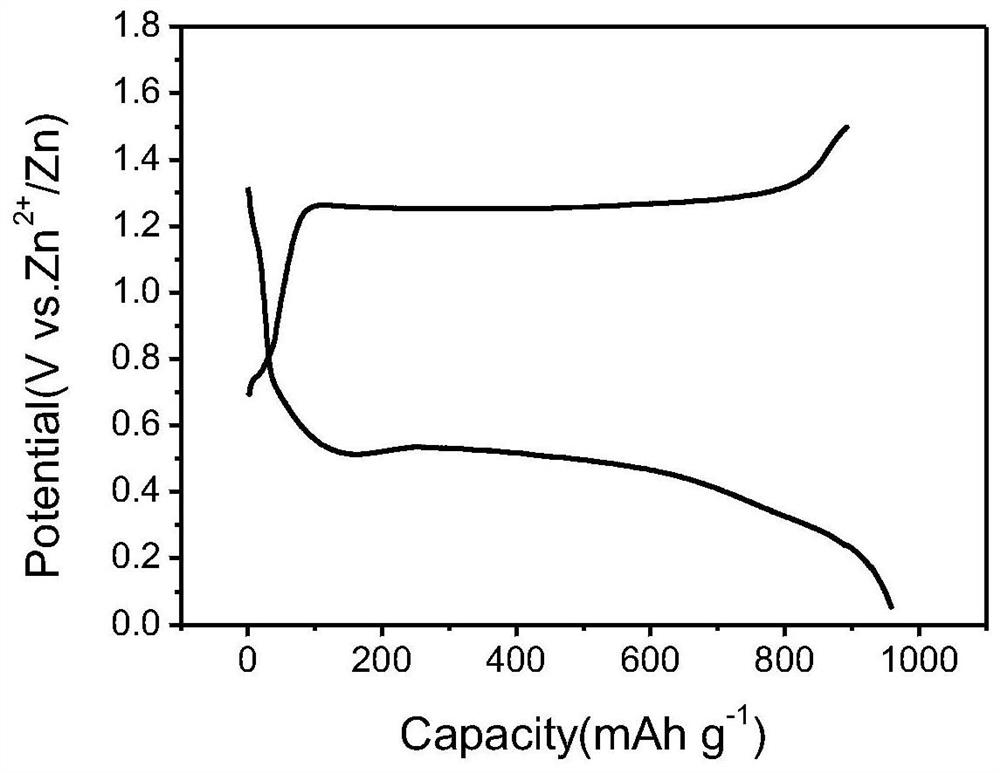

[0053]Weigh 1.0g sulfur powder and 1.0g activated carbon (particle size 5μm, specific surface area 1623m2g-1), after grinding and mixing in an agate mortar for 30 minutes, then vacuum sealing in a quartz tube, then heating to 160° C. for 24 hours, and cooling to obtain the elemental sulfur and activated carbon composite material in this example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com