A kind of preparation method of double metal oxide composite negative electrode material with multi-level structure

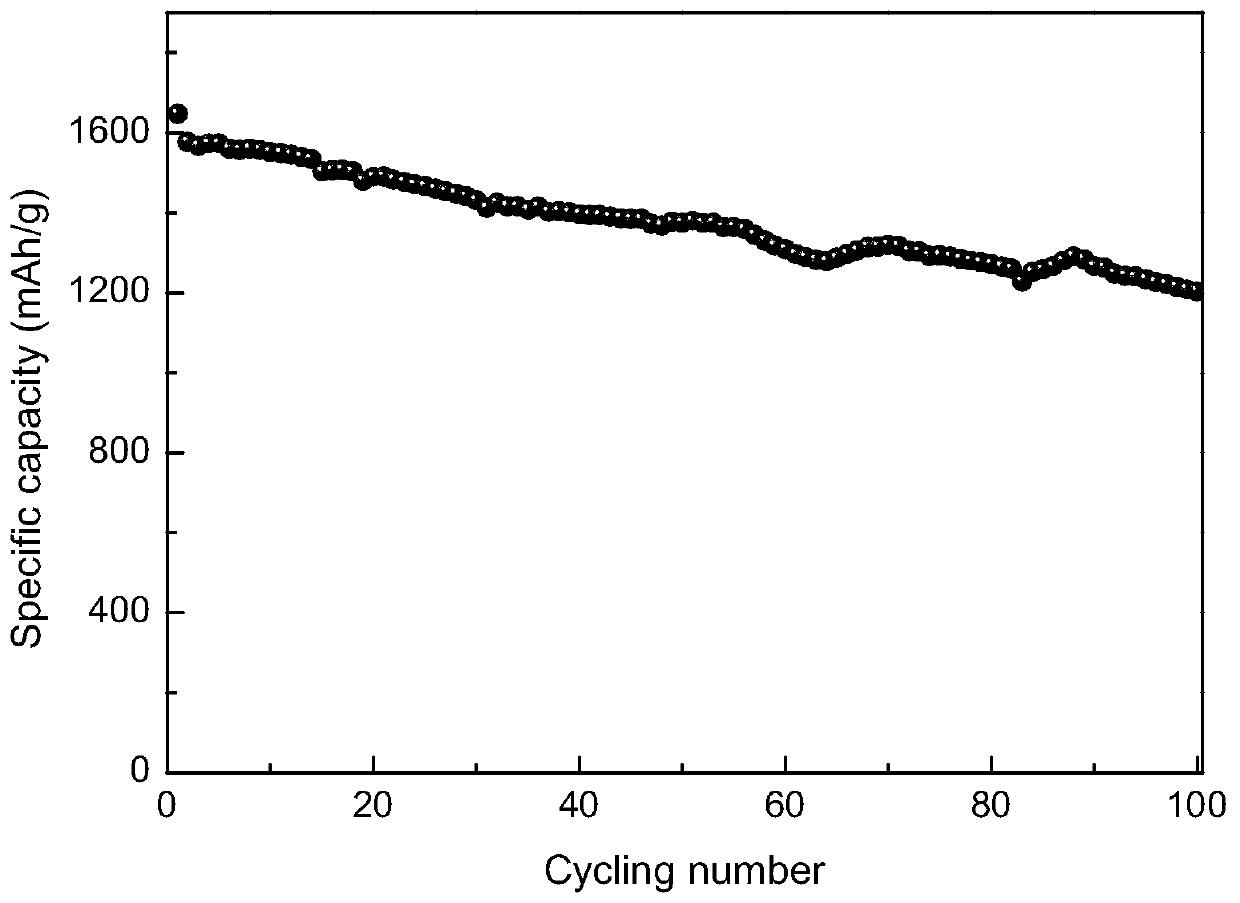

A bimetallic oxide and negative electrode material technology, applied in the field of lithium ion batteries, can solve the problem of low reversible lithium storage capacity, and achieve the effects of excellent rate performance, improved electrochemical performance, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

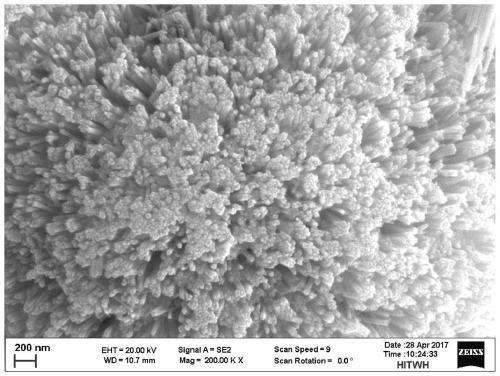

[0021] 1mmol Ni(NO 3 ) 2 ·6H 2 O, 2mmol Co(NO 3 ) 2 ·6H 2 O, 3mmol NH 4 Dissolve F and 5mmol of urea in 70mL of deionized water, stir for 1h, transfer to a 100mL polytetrafluoroethylene reactor and add an appropriate amount of nickel foam (14mm in diameter, 1mm in thickness, 120PPI in diameter), and then react in an oven at 120°C 12h. After cooling to room temperature, filter, wash and dry, then transfer to a tube furnace under N 2 Continuous heat treatment at 600 °C for 2 h under atmosphere to obtain NiCoO grown on nickel foam 2 -Co 3 o 4 Bimetallic anode materials. Then NiCoO grown on nickel foam 2 -Co 3 o 4 Place the bimetallic negative electrode material in a small beaker, then add 50mL of 0.1g / L sodium dodecylsulfonate aqueous solution, and sonicate for 9 minutes, then mechanically stir for 10h, then add 0.035mL of pyrrole, 0.5mL of 1mol· L -1 Hydrochloric acid solution and 0.114g of oxidizing agent (NH 4 ) 2 S 2 o 8 , and at the same time stirred in an...

Embodiment 2

[0023] 1mmol Ni(NO 3 ) 2 ·6H 2 O, 2mmol Co(NO 3 ) 2 ·6H 2 O, 3mmol NH 4 F and 5mmol of urea were dissolved in 70mL of deionized water, stirred for 1h, transferred to a 100mL polytetrafluoroethylene reactor and an appropriate amount of nickel foam (120PPI) was added, and then reacted in an oven at 110°C for 10h. After cooling to room temperature, filter, wash and dry, then transfer to a tube furnace under N 2 Continuous heat treatment at 400°C for 5h under atmosphere to obtain NiCoO grown on foamed nickel (14mm in diameter, 1mm in thickness, 120PPI in pore size) 2 -Co 3 o 4 Bimetallic anode materials. Then NiCoO grown on nickel foam 2 -Co 3 o 4 Place the bimetallic negative electrode material in a small beaker, then add 70mL of 0.1g / L sodium dodecylsulfonate aqueous solution, and sonicate for 3 minutes, then mechanically stir for 15h, then add 0.03mL pyrrole, 0.43mL 1mol· L -1Hydrochloric acid solution and 0.1g of oxidizing agent (NH 4 ) 2 S 2 o 8 , and at the...

Embodiment 3

[0025] 1mmol Ni(NO 3 ) 2 ·6H 2 O, 2mmol Co(NO 3 ) 2 ·6H 2 O, 3mmol NH 4 F and 5mmol of urea were dissolved in 70mL of deionized water, stirred for 3h, transferred to a 100mL polytetrafluoroethylene reactor and an appropriate amount of nickel foam (120PPI) was added, and then reacted in an oven at 130°C for 10h. After cooling to room temperature, filter, wash and dry, then transfer to a tube furnace under N 2 Continuous heat treatment at 600°C for 1 h under atmosphere to obtain NiCoO grown on nickel foam (diameter 14mm, thickness 1mm, pore size 120PPI) 2 -Co 3 o 4 Bimetallic anode materials. Then NiCoO grown on nickel foam 2 -Co 3 o 4 Place the bimetallic negative electrode material in a small beaker, then add 60mL of 0.1g / L sodium dodecylsulfonate aqueous solution, and sonicate for 9 minutes, then mechanically stir for 10h, then add 0.15mL of pyrrole, 2.1mL of 1mol· L -1 Hydrochloric acid solution and 0.2g of oxidizing agent (NH 4 ) 2 S 2 o 8 . At the same t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com