Preparation method of v2(po4)o/c material, negative electrode and method for making lithium ion battery

A lithium-ion battery and negative electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as no precedent, and achieve the effects of low production cost, simple and easy-to-control methods, and excellent reversible capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a V 2 (PO 4 ) The preparation method of O / C material, comprises the following steps:

[0029] (1) Dissolve vanadium pentoxide and oxalic acid in deionized water in proportion, and stir for 1 hour under oil bath conditions to form a blue transparent solution. Subsequently, ammonium dihydrogen phosphate and glucose were added in sequence and stirred until the solution was uniform. The temperature of the oil bath is 60°C-100°C, and the molar concentration of vanadium pentoxide is 0.05-0.08mol L -1 . The feed ratio of vanadium pentoxide, oxalic acid, and ammonium dihydrogen phosphate is: V 2 o 5 : H 2 C 2 o 4 2H 2 O: NH 4 h 2 PO 4 =1:3:1. Among them, glucose and ethylene glycol can be distributed in appropriate amounts, generally the amount of glucose is 0.6-2 times the mass of vanadium pentoxide, and the volume fraction of ethylene glycol in the above mixed solution is 3%-6%.

[0030] (2) Put the mixed solution into a 100mL hydr...

no. 1 example

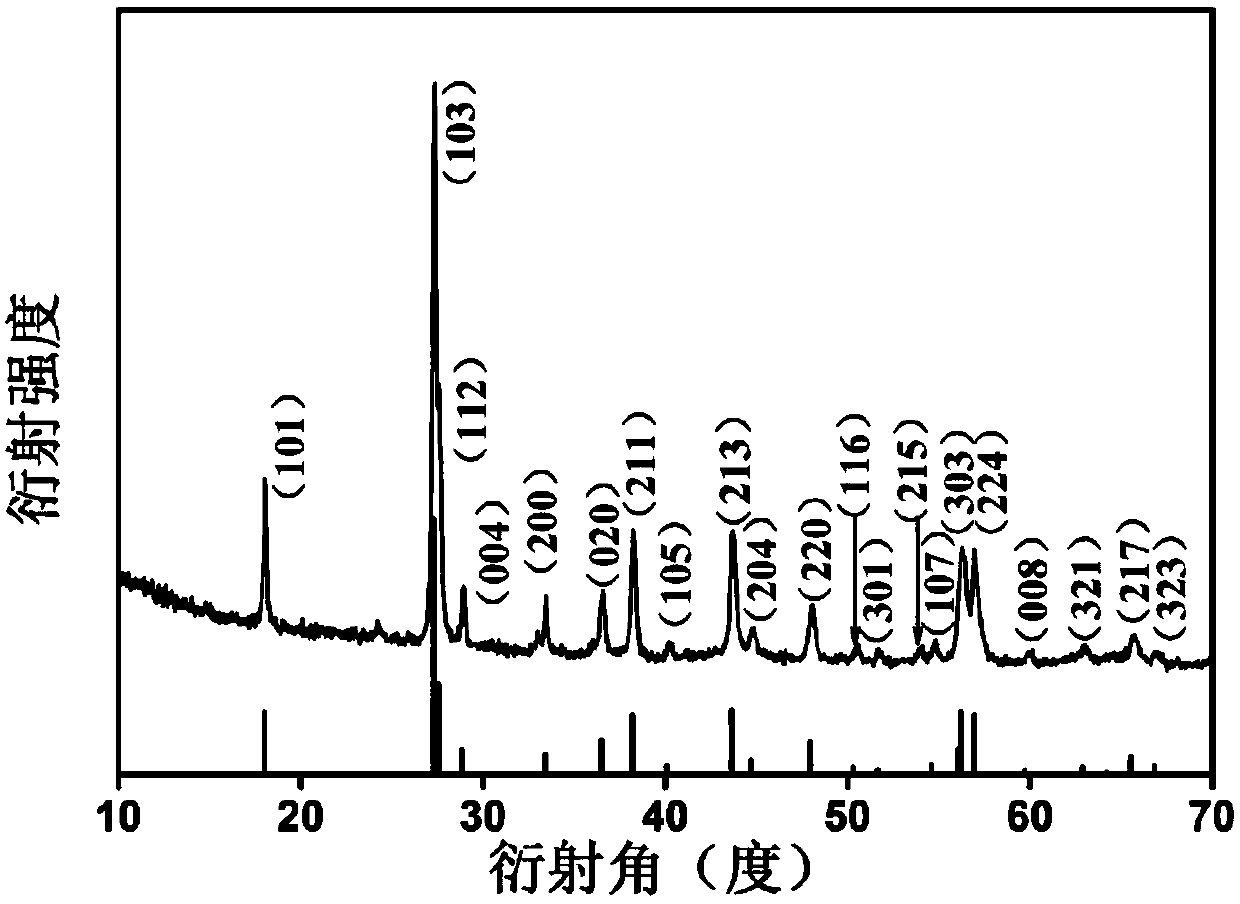

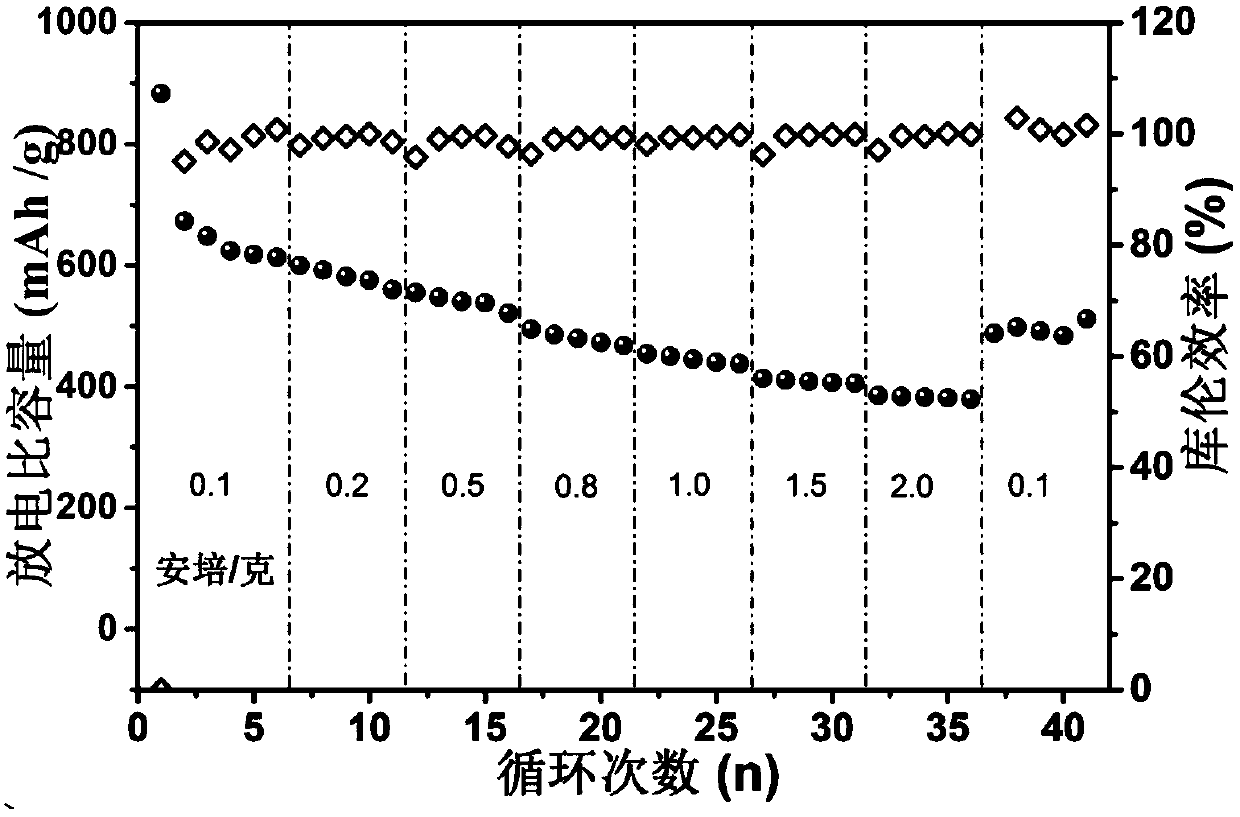

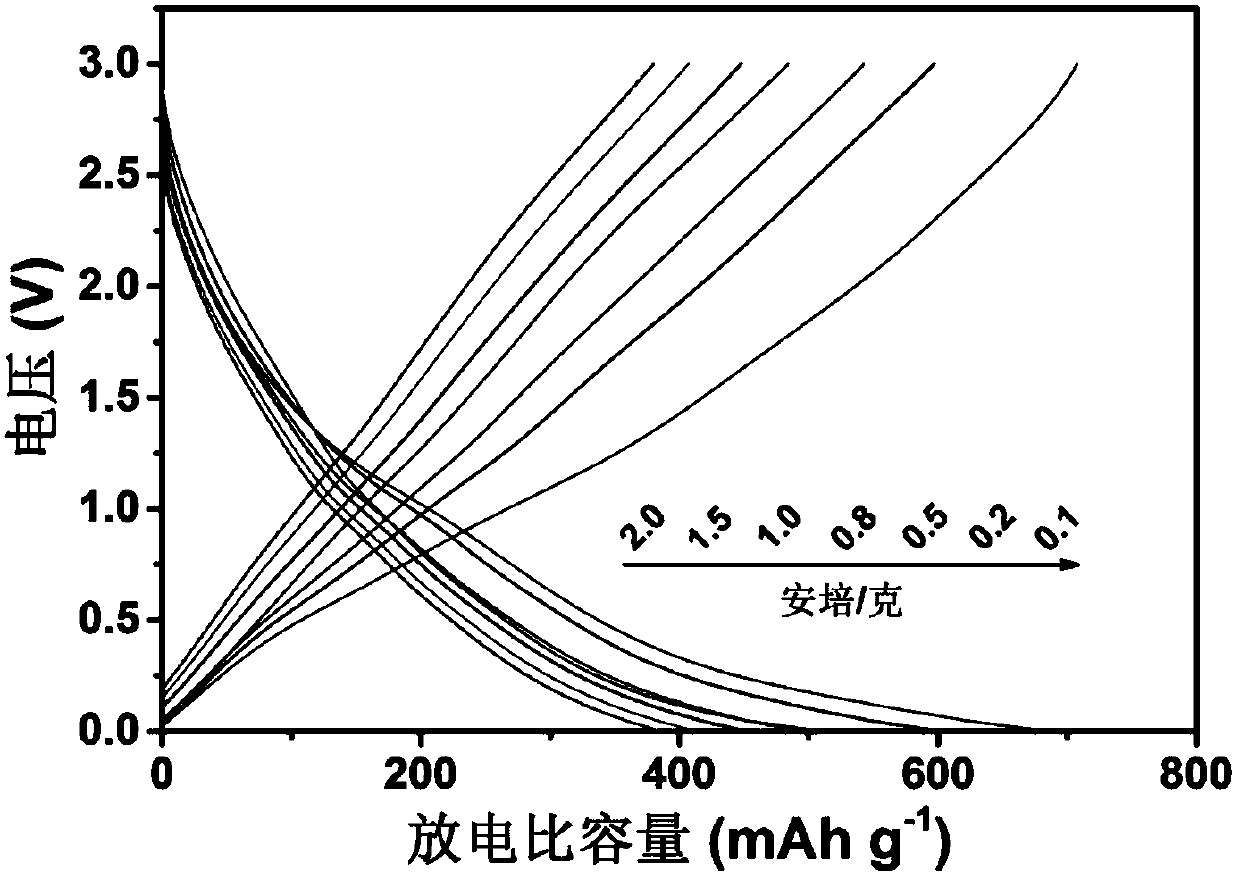

[0041] Place 0.752g of V 2 o 5 (vanadium pentoxide) and 1.512g of H 2 C 2 o 4 (oxalic acid) was dissolved in 70 mL of deionized water and stirred for 60 minutes in an oil bath at 70°C. Subsequently, 0.46 g of NH 4 h 2 PO 4 (ammonium dihydrogen phosphate) and 0.6g of glucose were stirred for 5 minutes after adding the medicine each time to ensure that the medicine was fully dissolved and mixed evenly. Then, 3 mL of ethylene glycol (EG) was added to the reaction system, and further stirred for 10 min. Finally, the solution was transferred into a 100 mL polytetrafluoroethylene-made hydrothermal liner, and sealed in a stainless steel hydrothermal kettle. Under the condition of hydrothermal reaction for 10 hours. The product after hydrothermal reaction was dried at 80°C for 10 hours, then pre-sintered at 350°C for 4 hours, and finally sintered at 750°C for 8 hours to obtain the final product V 2 (PO 4 )O / C.

[0042] The battery casing used for electrochemical testing in ...

no. 2 example

[0046] 0.752g of V2O5 and 1.512g of H 2 C 2 o 4 (oxalic acid) was dissolved in 70 mL of deionized water and stirred for 60 minutes in an oil bath at 100°C. Then sequentially add 0.46 g of NH 4 h 2 PO 4 (ammonium dihydrogen phosphate) and 1g of glucose were stirred for 5 minutes after adding the medicine each time to ensure that the medicine was fully dissolved and mixed evenly. Then, 2 mL of ethylene glycol (EG) was added to the reaction system, and further stirred for 10 min. Finally, the solution was transferred into a 100 mL polytetrafluoroethylene-made hydrothermal liner, and sealed in a stainless steel hydrothermal kettle. Under the condition of hydrothermal reaction for 20 hours. The product after hydrothermal reaction was dried at 80°C for 15 hours, then pre-sintered at 350°C for 4 hours, and finally sintered at 750°C for 8 hours to obtain the final product V 2 (PO 4 )O / C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com