High-rate lithium ion battery cathode material and preparation method and application thereof

A technology of lithium-ion batteries and positive electrode materials, applied in the field of electrode materials, to achieve the effects of excellent electrochemical performance, easy purchase, and easy large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0080] A preferred preparation method comprises the steps of:

[0081] The positive electrode material is uniformly mixed with the conductive agent and the binder in the solution (such as nitrogen methyl pyrrolidone (NMP)), and the mass ratio of the suitable positive electrode material, conductive agent and binder is adjusted (such as 80-90:5- 10:5-10, preferably 90:5:5, 80:10:10 or 85:10:5), then coated and pressed on an aluminum foil, dried, and pressed to obtain a positive electrode sheet.

[0082] secondary battery

[0083] The secondary battery provided by the present invention includes a positive electrode material and a negative electrode material, wherein the positive electrode material includes the lithium nickel cobalt manganese oxide solid solution battery positive electrode material of the present invention, and the battery contains the battery positive electrode of the present invention .

[0084] The secondary battery provided by the invention also includes a...

Embodiment 1

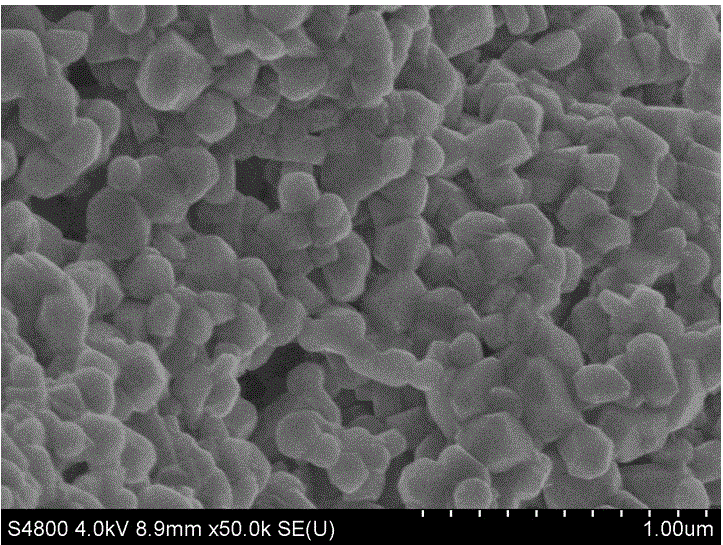

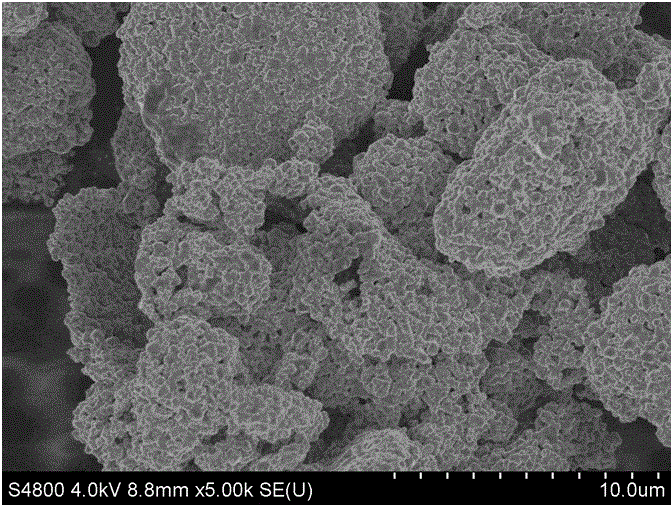

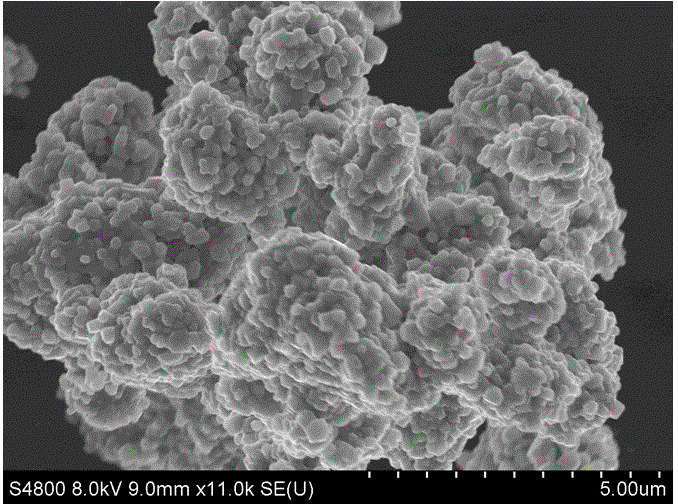

[0095] Embodiment 1: Take nickel sulfate, cobalt sulfate, and manganese sulfate according to the molar ratio of nickel, cobalt, and manganese of 0.35:0.33:0.32, add deionized water to fully dissolve and prepare a transparent solution with an ion concentration of 1mol / L, and place it in a water bath constant temperature at 70 0 C, slowly and evenly add sodium hydroxide solution of the same concentration, and stir at the same time, the rotating speed is 600 rpm, until the sodium hydroxide solution is added, the color of the suspension obtained by the reaction will no longer change, stop adding sodium hydroxide, and continue After stirring at a constant speed for more than 30 minutes, the co-precipitation reaction was completed. The reaction suspension was centrifuged to obtain a co-precipitated solid, which was repeatedly washed with deionized water and filtered 4 times, then placed in a blast drying oven, and dried at 120°C for 16 hours to obtain a precursor. After taking it o...

Embodiment 2

[0097] Embodiment 2: Take by weighing nickel nitrate, cobalt nitrate, manganese nitrate according to nickel, cobalt, manganese molar ratio 0.45:0.23:0.32, add deionized water and fully dissolve and prepare the transparent solution that ion concentration is 1mol / L, place in water bath constant temperature at 60 0 C, slowly and evenly add sodium carbonate solution of the same concentration, and stir at the same time, the rotating speed is 1200 rpm, until the sodium carbonate solution is added, the color of the reaction suspension does not change, stop adding sodium carbonate, continue to stir at a constant speed for more than 60 minutes After that, the co-precipitation reaction was ended. The precursor was mixed with LiOH at a molar ratio of 1:1.09. All the other are identical with embodiment 1, and its X-ray diffraction figure (XRD) and SEM figure are similar to Figures 1A-1D .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com