A kind of preparation method of chromium-based lithium ion battery composite negative electrode material

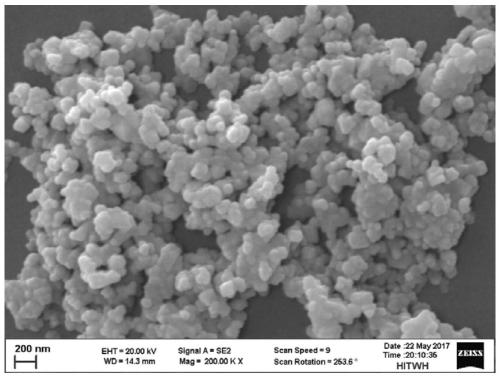

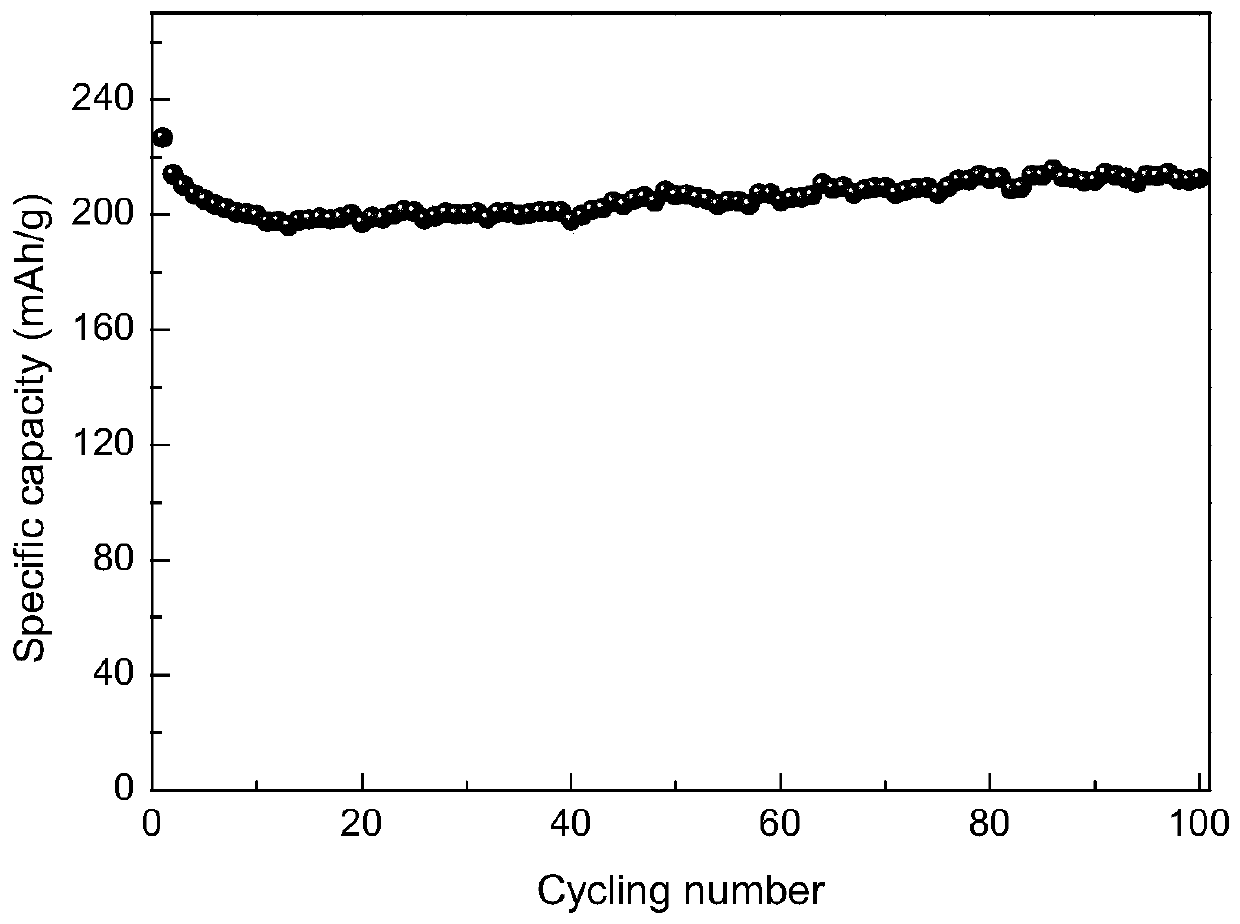

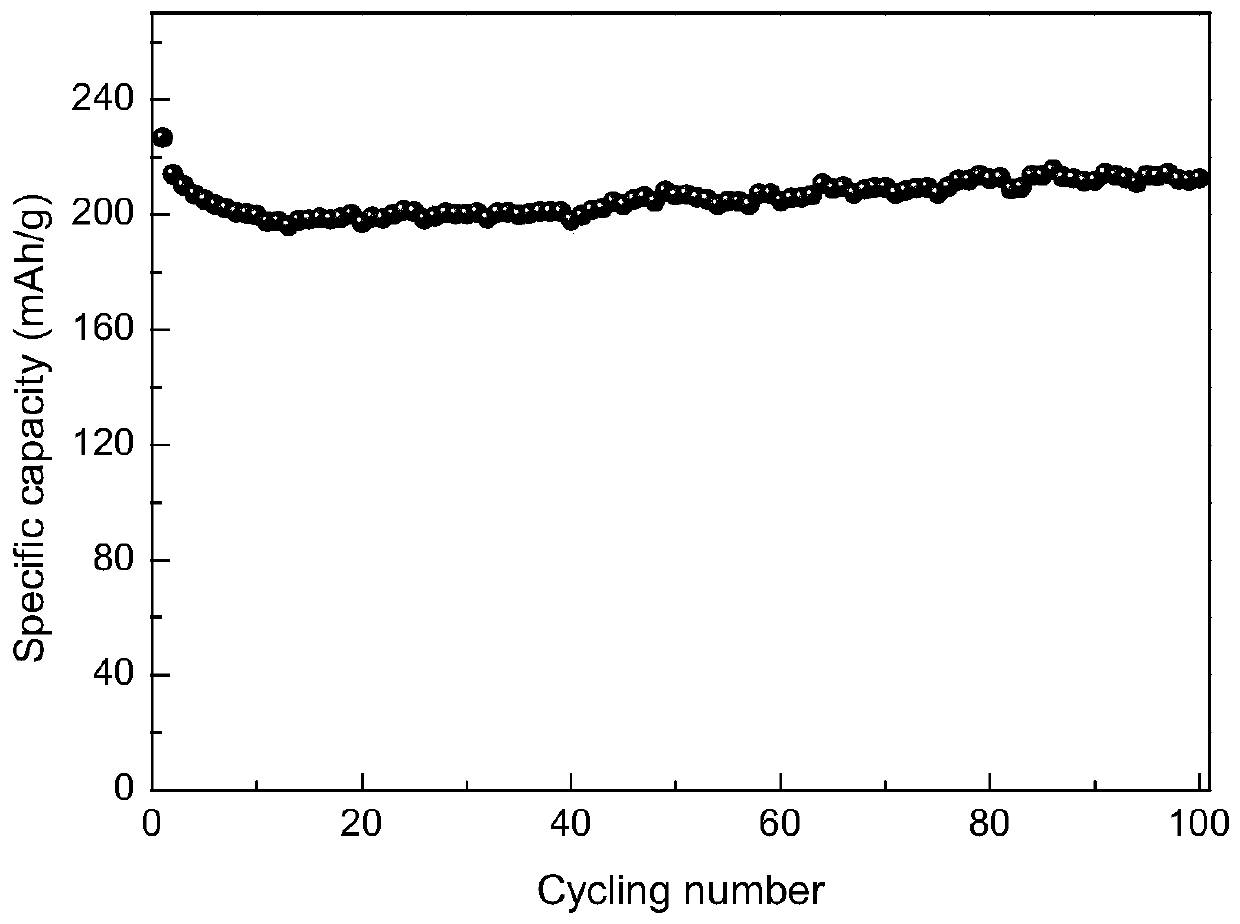

A negative electrode material and ion battery technology, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problems of poor rate performance, fast capacity decay, low electronic conductance and ion conductance, etc. Achieve stable cycle life, uniform particles, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Dissolve 0.06mol tetrabutyl titanate, 0.0501mol lithium nitrate and 0.07mol chromium nitrate in a mixed solution of 500mL ethanol and benzyl alcohol (volume ratio is 1:1), add adipic acid as a chelating agent, wherein adipic acid The molar ratio to the metal cation is 1.8:1, then add 25 grams of a mixture of N,N-acrylamide and acrylamide (the mass ratio of the two is 1:6), and stir in a constant temperature water bath at 80°C until it forms Then put the gel at room temperature for 12h, then put the gel into a vacuum drying oven at 160°C and dry it for 24h to obtain a precursor. Treat for 6h, then take out the ball mill for 2h, dry and sieve, and then calcined at 800°C for 10h to obtain the target product Li 5 Cr 7 Ti 6 o 25 Material. 0.2071g of ferric nitrate (Fe(NO 3 ) 3 9H 2 O) be dissolved in deionized water, add 2.5g Li 5 Cr 7 Ti 6 o 25 Disperse and ultrasonically stir for 30 minutes, then slowly add 0.0590 g of ammonium dihydrogen phosphate aqueous solut...

Embodiment 2

[0022] Dissolve 0.06mol of isopropyl titanate, 0.0502mol of lithium acetate and 0.07mol of chromium acetate in a mixed solution of 500mL of ethanol and benzyl alcohol (1:1 by volume), and add adipic acid as a chelating agent, wherein adipic acid The molar ratio to the metal cation is 1.5:1, then add 25 grams of a mixture of N,N-acrylamide and acrylamide (the mass ratio of the two is 1:6), and stir in a constant temperature water bath at 70°C until it forms Gel, then put the gel at room temperature for 10h, then put the gel in a vacuum oven at 120°C and dry for 24h to obtain a precursor. Treat for 5 hours, then take out the ball mill for 2 hours, dry and sieve, and then calcined at 800°C for 8 hours to obtain the target product Li 5 Cr 7 Ti 6 o 25 Material. 0.0678g of ferric nitrate (Fe(NO 3 ) 3 9H 2 O) be dissolved in deionized water, add 2.5g Li 5 Cr 7 Ti 6 o 25 Disperse and ultrasonically stir for 30 minutes, then slowly add 0.0193 g of ammonium dihydrogen phospha...

Embodiment 3

[0024] Dissolve 0.06mol isopropyl titanate, 0.0502mol lithium hydroxide and 0.07mol chromium nitrate in a mixed solution of 500mL ethanol and benzyl alcohol (volume ratio is 1:1), add adipic acid as a chelating agent, wherein adipic acid The molar ratio of acid to metal cation is 2.0:1, then add 25 grams of a mixture of N,N-acrylamide and acrylamide (the mass ratio of the two is 1:6), in a constant temperature water bath at 70-100°C Stir until a gel is formed, then place the gel at room temperature for 15 hours, then put the gel in a vacuum drying oven at 180°C for 24 hours to obtain a precursor, ball mill the precursor for 3 hours, put it in a muffle furnace in air Pretreatment at 600°C for 8h, then take out the ball mill for 2h, dry and sieve, and then calcined at 800°C for 12h to obtain the target product Li 5 Cr 7 Ti 6 o 25 Material. 0.3525g of ferric nitrate (Fe(NO 3 ) 3 9H 2 O) be dissolved in deionized water, add 2.5g Li 5 Cr 7 Ti 6 o 25 Disperse and ultrason...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com