Silicon anode for lithium ion battery and preparation method thereof

A lithium-ion battery and silicon negative electrode technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems that restrict the industrialization of silicon negative electrode materials, the separation of electrode active materials from current collectors, and the reduction of battery cycle performance. Excellent reversible capacity and cycle life, stable cycle performance, and the effect of improving charge-discharge specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

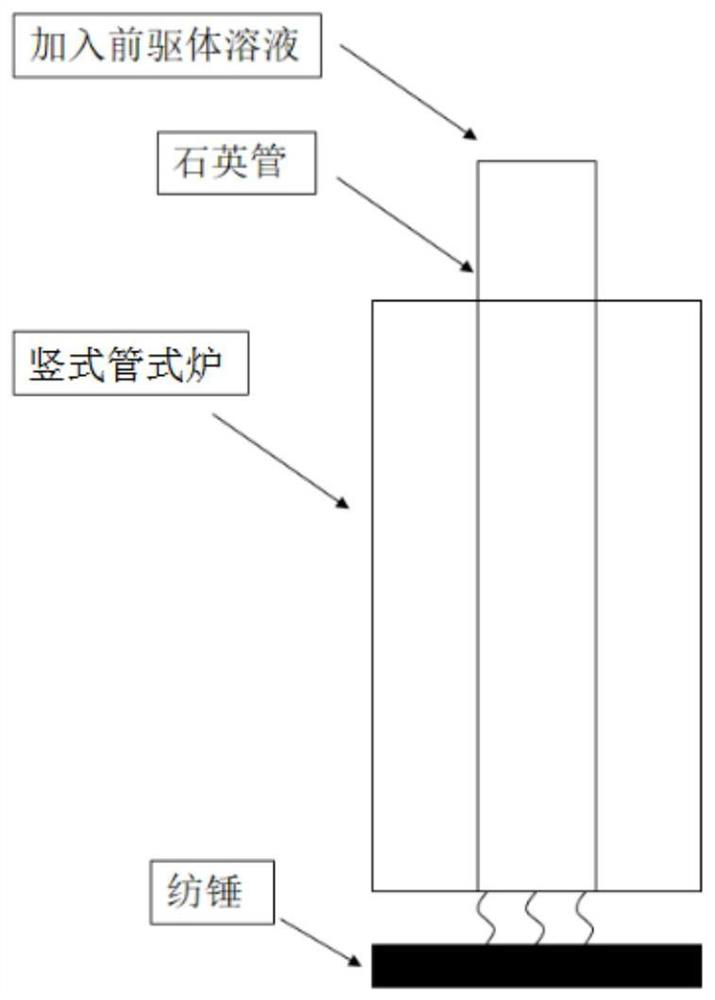

[0029] A method for preparing a silicon negative electrode, comprising the steps of: adding 18g of tetraethyl orthosilicate, 3.42g of ferrocene and 1.8g of thiophene into 200ml of ethanol, and dispersing evenly for 0.5h through magnetic stirring to obtain a mixed solution; The solution was injected into a vertical high-temperature reaction kettle containing a quartz tube at 10ml / h, and in a hydrogen atmosphere of 600ml / min, the temperature was raised to 1100°C at a rate of 10°C / min, and collected with a spindle at the outlet to prepare a silicon negative electrode electrode. The whole preparation process is as figure 1 shown.

Embodiment 2

[0031] A method for preparing a silicon negative electrode, comprising the steps of: adding 9g of tetraethyl orthosilicate, 3.42g of ferrocene and 1.8g of thiophene into 200ml of ethanol, and dispersing evenly for 2 hours by magnetic stirring to obtain a mixed solution; taking the mixed solution , injected at 20ml / h into a vertical high-temperature reaction kettle containing a quartz tube, in a hydrogen atmosphere of 1000ml / min, the temperature was raised to 1100°C at a rate of 10°C / min, and collected with a spindle at the outlet to prepare a silicon negative electrode .

Embodiment 3

[0033] A method for preparing a silicon negative electrode, comprising the steps of: adding 18g of butyl orthosilicate, 3.42g of ferrocene and 1.8g of thiophene into 200ml of toluene, and stirring for 0.5h by magnetic force to disperse evenly to obtain a mixed solution; take the mixed solution , injected at 10ml / h into a vertical high-temperature reaction kettle containing a quartz tube, in a hydrogen atmosphere of 600ml / min, the temperature was raised to 1100°C at a rate of 10°C / min, and collected with a spindle at the outlet to prepare a silicon negative electrode .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com