Silicon-carbon negative electrode material and preparation method thereof

A negative electrode material, silicon carbon technology, applied in the field of silicon carbon negative electrode materials and its preparation, can solve the problems of poor cycle stability, severe volume expansion and contraction, low conductivity, etc., to improve conductivity, ensure effective performance, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

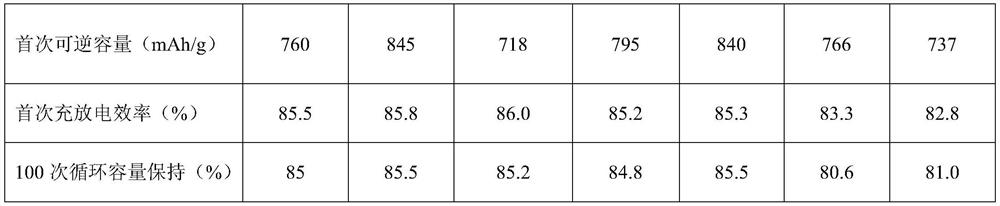

Embodiment 1

[0029] Dissolve a certain amount of polyaniline into N-methylpyrrolidone (NMP) and then add nano-silicon with a particle size of 200nm (polyaniline: silicon mass ratio is 2%:25%) and stir for a certain period of time, and use a rotary evaporator at 70°C Solvent is evaporated to dryness, obtains the nano-silicon material of one deck conductive carbon film on the surface; The nano-silicon material, graphene, spherical graphite, polyvinylpyrrolidone and sodium alginate are according to a certain ratio (27%: 6%: 45: 0.5 :0.5) Add ball milling pot to mill for 120min, wherein the ratio of ball to material is 8:1, the rotating speed is 500rpm, and the solid content is 30%. +25%. The ball-milled product was formulated to have a solid content of 60% for spray drying treatment, the feed flow rate was 15mL / min, and the inlet and outlet temperatures were 150°C and 100°C, respectively, to obtain the first precursor material. The first precursor material and a certain bitumen (10%) were st...

Embodiment 2

[0031]Dissolve a certain amount of polypyrrole in N-methylpyrrolidone (NMP) and then add nano-silicon with a particle size of 80nm (polypyrrole: silicon mass ratio is 4%:30%) and stir for a certain period of time, using a rotary evaporator at 90°C Solvent is evaporated to dryness, obtains the nano-silicon material of one deck conductive carbon film on the surface; The nano-silicon material, graphene, spherical graphite, polyethyleneimine and sodium alginate are according to a certain ratio (34%: 4%: 35: 1:1) into the ball mill tank for 300min, where the ball-to-material ratio is 6:1, the rotation speed is 300rpm, and the solid content is 40%. %+30%. The ball-milled product was formulated to have a solid content of 60% for spray drying treatment, the feed flow rate was 10mL / min, and the inlet and outlet temperatures were 180°C and 60°C, respectively, to obtain the first precursor material. The first precursor material and a certain bitumen (10%) were stirred and uniformly disp...

Embodiment 3

[0033] Dissolve a certain amount of polyacetylene in N-methylpyrrolidone (NMP) and then add nano-silicon with a particle size of 300nm (polyacetylene:silicon mass ratio is 4%:25%) and stir for a certain period of time, and use a rotary evaporator at 120°C Evaporate the solvent to obtain a nano-silicon material whose surface is coated with a conductive carbon film; add the nano-silicon material, graphene, spherical graphite, and polyvinylpyrrolidone to a ball mill according to a certain ratio (29%:4%:30:2) Medium ball milling for 60 minutes, wherein the ball-to-material ratio is 8:1, the rotation speed is 1000rpm, and the solid content is 20%. Here, the proportion of nano-silicon material is equal to the sum of the proportions of polyacetylene and silicon, that is, 28%=3%+25%. The ball milled product was formulated to have a solid content of 60% and spray-dried, the feed flow rate was 6mL / min, and the inlet and outlet temperatures were 200°C and 100°C, respectively, to obtain th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com