Silicon carbon composite material and preparation method and application thereof

A silicon-carbon composite material, nano-silicon technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of complex preparation process, poor repeatability, high cost, reduce volume expansion effect, improve pulverization, battery High stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] To sum up, the preparation method of the silicon-carbon composite material of the present invention includes: (1) adopting the chemical precipitation method to prepare a double-layer structure material of Bernalite ferric hydroxide-coated nano-silicon in a heterogeneous nucleation mode; (2) The double-layer structure material is mixed with the ethanol solution of phenolic resin, evaporated to dryness, and subjected to high-temperature sintering treatment to obtain three-layer coating structure particles of amorphous carbon-Bernalite iron hydroxide-nano-silicon in sequence from the outside to the inside; ( 3) Treat the three-layer coating structure particles of amorphous carbon-Bernalite iron hydroxide-nano-silicon in acid solution, remove the Bernalite iron hydroxide in the middle layer, and prepare a three-dimensional layered petal-shaped porous amorphous carbon coating Composite structural material coated with nano-silicon.

[0046] Its basic principle and operation p...

Embodiment 1

[0056] (1)Fe(OH) 3 - Preparation of nano-Si composite materials:

[0057] a. Mix 0.5g of nano-Si powder with FeCl 2 4H 2 O is dissolved in 200ml of water according to the mass ratio of 1:1; the particle size of the nano-Si powder is 80nm-300nm.

[0058] b. Add 1ml of concentrated ammonia water to 100ml of water, then slowly add the solution dropwise to the above solution with a peristaltic pump, so that the nucleation is heterogeneous, and the crystal nuclei grow up to form particle precipitation;

[0059] c. After stirring for 2 hours, a three-dimensional lamellar petal-like Fe(OH) was obtained 3 - The nano-Si precipitate was centrifuged at a speed of 4500 r / min to obtain a precipitate, which was dried at 40° C. for 5 hours.

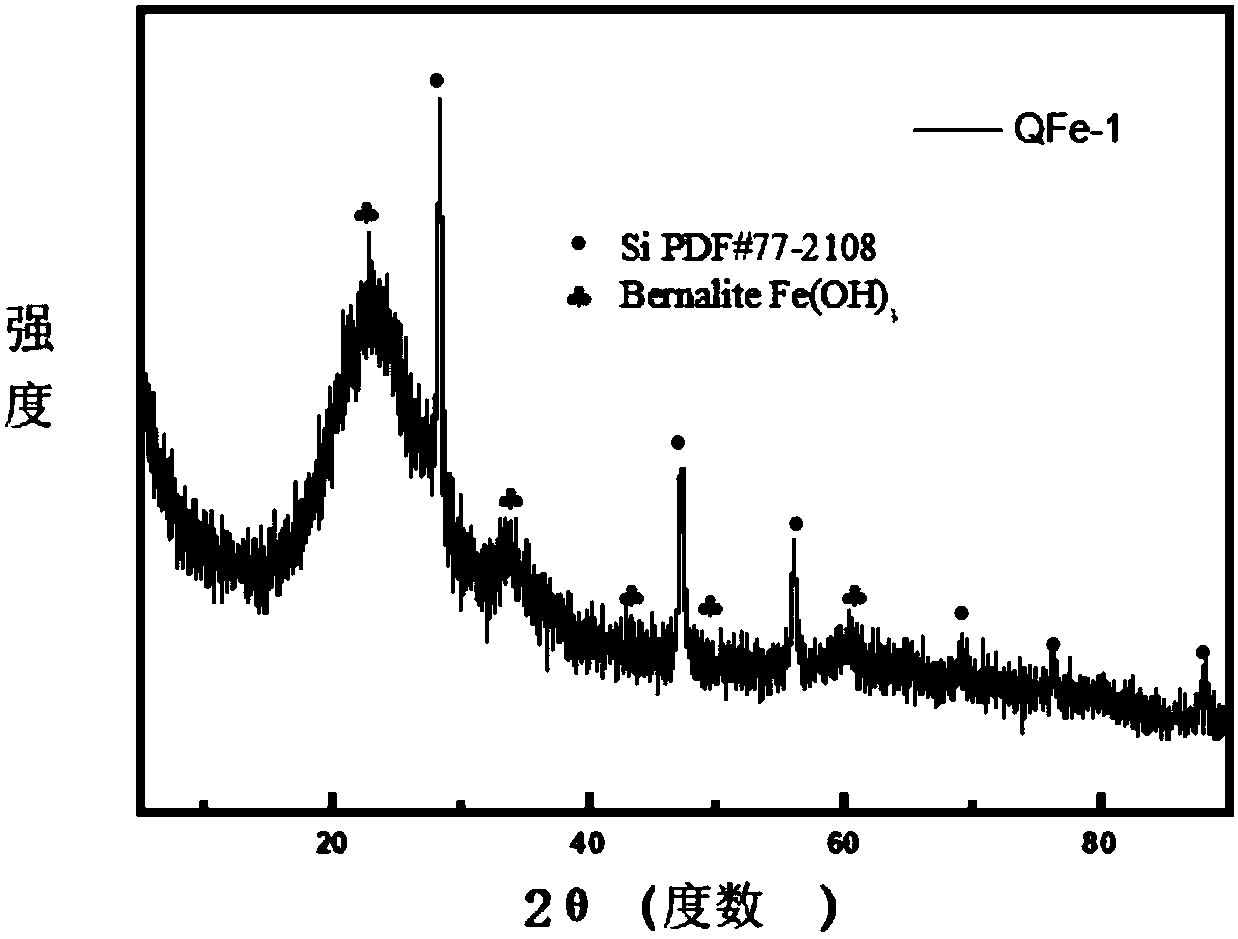

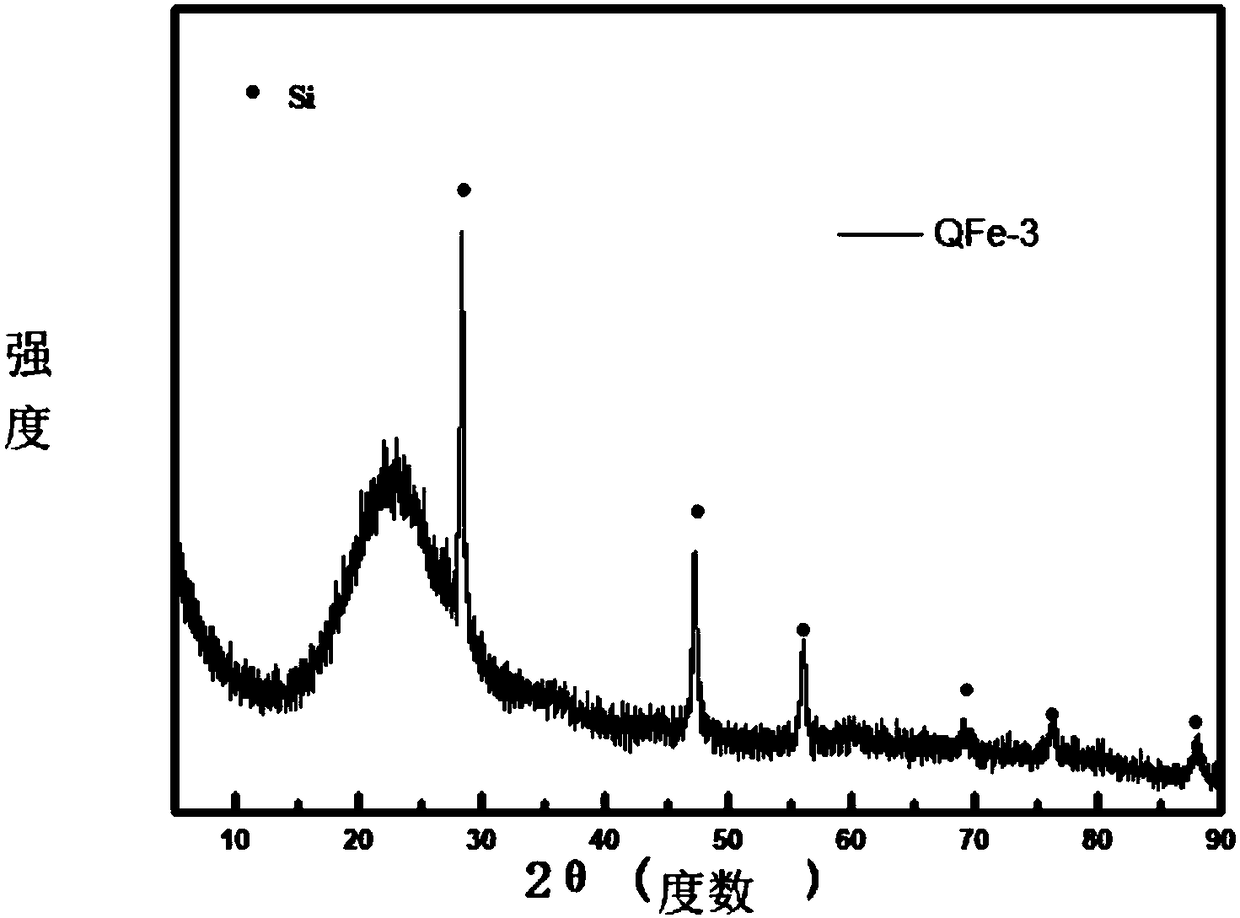

[0060] figure 2 For the precipitate Fe(OH) 3 - XRD powder diffraction pattern of nano-Si. From figure 2 It can be seen from the figure that the diffraction peaks in the XRD powder diffraction patterns of the samples before and after coating co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com