A kind of lifepo4-v2o5-graphene composite cathode material and its preparation method

A composite positive electrode material, V2O5 technology, applied in the field of high-performance lithium iron phosphate composite materials and its preparation, can solve the problems of low electrical conductivity, limit the development of high specific energy lithium ion batteries, low specific capacity, etc., and achieve the suppression of electrode structure damage , good flexibility and elasticity, the effect of good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

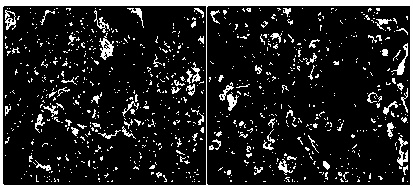

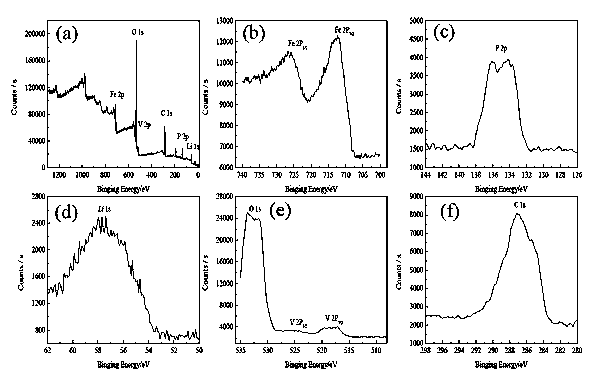

[0039] For Nano LiFePO 4 The two major defects of low electrical conductivity and low specific capacity of the material, through the relationship with V 2 o 5 With the compound of Graphene, this embodiment provides a kind of LiFePO 4 -V 2 o 5 ―Graphene composite cathode material and its preparation method, using its outstanding synergistic effect, exerts excellent comprehensive electrochemical performance.

[0040] The LiFePO provided by this embodiment 4 -V 2 o 5 ―Graphene composite cathode material is made of LiFePO 4 Nanoparticles, V 2 o 5 A composite material composed of nanowires and Graphene nanosheets with a mass ratio of 6:3:1, and its structural characteristics are LiFePO 4 nanoparticles and V 2 o 5 LiFePO composed of nanowires uniformly supported on the surface of Graphene nanosheets 4 Nanoparticles—V 2 o 5 Nanowire - Graphene nanosheet multi-dimensional heterogeneous nanostructure, its preparation method is as follows:

[0041] (1) Add natural graphi...

Embodiment 2

[0047] The difference between this example and Example 1 is that in step (4), the three components are mixed with LiFePO 4 :V 2 o 5 :Graphene=7:2:1 weight ratio mixed and ultrasonicated at 140W for 8 hours. During ultrasonication, LiFePO 4 nanoparticles and V 2 o 5 Nanowires will spontaneously assemble on the exposed surface of Graphene nanosheets to reduce the free energy of the whole system, resulting in a weight ratio of three components of 7:2:1 (LiFePO 4 :V 2 o 5 :Graphene) LiFePO 4 Nanoparticles—V 2 o 5 Nanowire-Graphene nanosheet composite cathode material.

Embodiment 3

[0049] The LiFePO provided by this embodiment 4 -V 2 o 5 ―Graphene composite cathode material is made of LiFePO 4 Nanorods, V 2 o 5 A composite material composed of nanowires and Graphene nanosheets with a mass ratio of 6:3:1, and its structural characteristics are LiFePO 4 Nanorods and V 2 o 5LiFePO composed of nanowires uniformly supported on the surface of Graphene nanosheets 4 Nanorod-V 2 o 5 Nanowire—Graphene nanosheet multi-dimensional heterogeneous nanostructure, its preparation method is different from Example 1 in steps (2) and (4), which are described in detail as follows:

[0050] (2) Add 0.34 mL of 85% H to 20 mL of ethylene glycol solution 3 PO 4 and 1.389g FeSO 4 7 hours 2 O, after ultrasonication for 30 minutes, add 0.5238g LiOH·H 2 O, stirred for 20 minutes, transferred to a polytetrafluoroethylene autoclave, and heated at 200 ° C for 14 hours. The obtained product was washed with deionized water, added to tetrahydrofuran and ultrasonicated to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com