Gear-shaped biodiesel catalyst and preparation method thereof

A biodiesel and catalyst technology, applied in the chemical industry, can solve the problems of large specific surface area, many active sites, and low recycling rate, and achieve the effect of large specific surface area and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

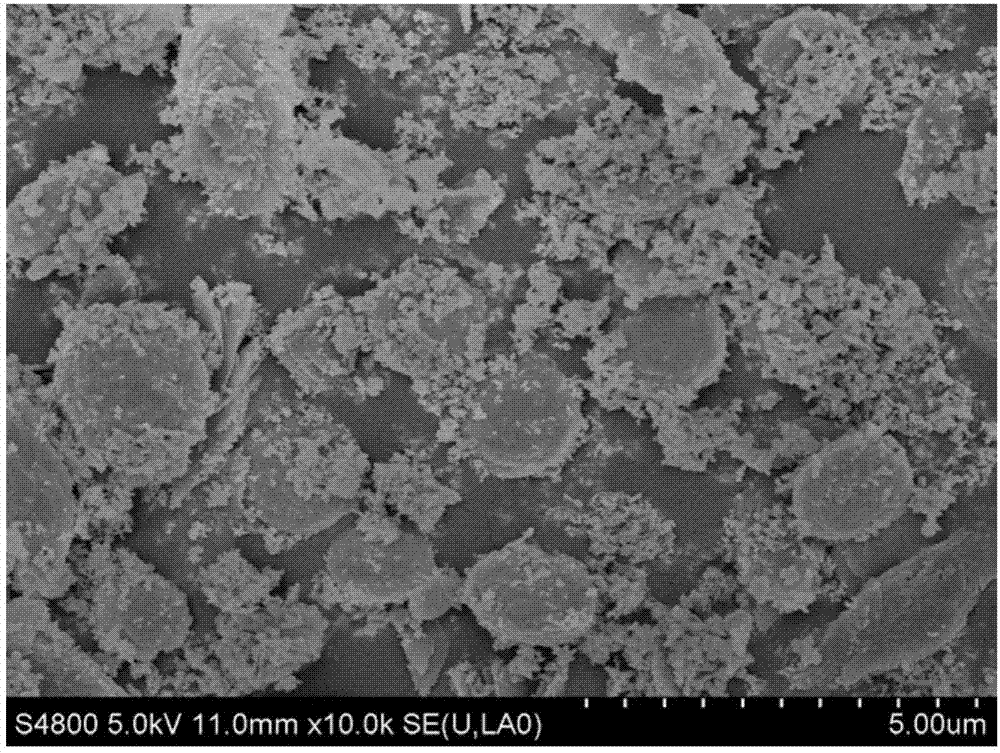

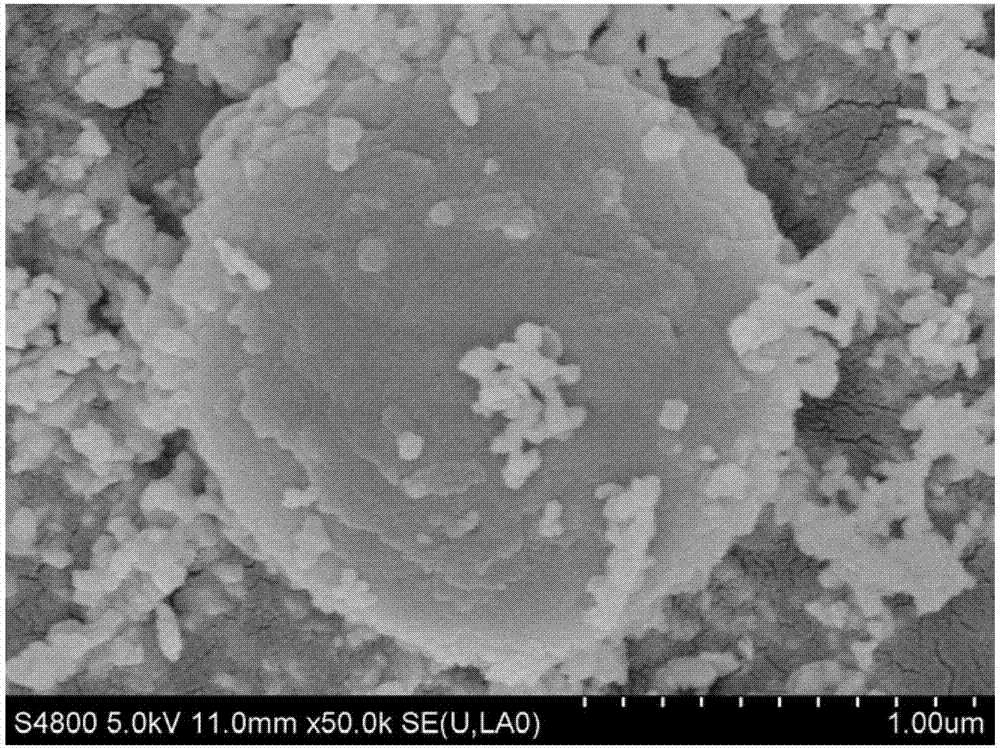

Image

Examples

Embodiment 1

[0023] A gear-shaped biodiesel catalyst and a preparation method thereof, which are prepared by the following method:

[0024] (1) Weigh a certain amount of melamine and place it in a muffle furnace to roast for 1 hour at a heating rate of 10°C / min, then cool down naturally to obtain a light yellow powder g-C 3 N 4 , grind the powder into 200 mesh for later use;

[0025] (2) Weigh a certain amount of g-C 3 N 4 Place in a beaker to make a solution and stir vigorously for 4 hours, g-C 3 N 4 The mass ratio with water is 1:80;

[0026] (3) Weigh a certain amount of CaCl 2 , Al(NO 3 ) 3 9H 2 O, La(NO 3 ) 3 ·6H 2 O is added to the above solution to dissolve, the molar ratio of the two trivalent metal ions is 1:1, and the molar ratio of divalent metal ions to trivalent particles is 3:1;

[0027] (4) Prepare a certain concentration of NaOH solution, slowly drop it in the above solution for a period of time and put it in the oven to rest. spare;

[0028] (5) Place the dr...

Embodiment 2

[0033] A gear-shaped biodiesel catalyst and a preparation method thereof, which are prepared by the following method:

[0034] (1) Weigh a certain amount of melamine and place it in a muffle furnace to roast for 1 hour at a heating rate of 10°C / min, then cool down naturally to obtain a light yellow powder g-C 3 N 4 , grind the powder into 200 mesh for later use;

[0035] (2) Weigh a certain amount of g-C 3 N 4 Place in a beaker to make a solution and stir vigorously for 2 hours, g-C 3 N 4 The mass ratio with water is 1:80;

[0036] (3) Weigh a certain amount of CaCl 2 , Al(NO 3 ) 3 9H 2 O, La(NO 3 ) 3 ·6H 2 O is added to the above solution to dissolve, the molar ratio of the two trivalent metal ions is 1:1, and the molar ratio of divalent metal ions to trivalent particles is 4:1;

[0037] (4) Prepare a certain concentration of NaOH solution, slowly drop it in the above solution for a period of time and put it in an oven to rest. spare;

[0038] (5) The dried sol...

Embodiment 3

[0041] A gear-shaped biodiesel catalyst and a preparation method thereof, which are prepared by the following method:

[0042] (1) Weigh a certain amount of melamine and place it in a muffle furnace to roast for 1 hour at a heating rate of 10°C / min, then cool down naturally to obtain a light yellow powder g-C 3 N 4 , grind the powder into 200 mesh for later use;

[0043] (2) Weigh a certain amount of g-C 3 N 4 Place in a beaker to make a solution and stir vigorously for 4 hours, g-C 3 N 4 The mass ratio with water is 1:80;

[0044] (3) Weigh a certain amount of CaCl 2 , Al(NO 3 ) 3 9H2 O, La(NO 3 ) 3 ·6H 2 O is added to the above solution to dissolve, the molar ratio of the two trivalent metal ions is 1:1, and the molar ratio of divalent metal ions to trivalent particles is 5:1;

[0045] (4) Prepare a certain concentration of NaOH solution, slowly drop it in the above solution for a period of time and put it in an oven to rest. ;

[0046] (5) The dried solid is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com