Preparation and application of graphdiyne material modified diaphragm

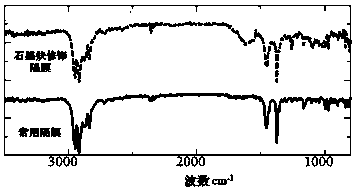

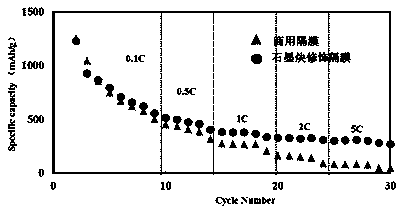

A technology of graphyne and diaphragm, which is applied in the field of preparation of lithium-sulfur battery diaphragm, can solve problems such as uneven diaphragm coating, increased diaphragm thickness, and reduced cycle stability, so as to achieve maximum play space and control possibility, energy density and Improved cycle performance and improvement of insulation defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

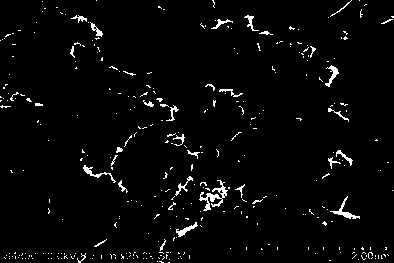

[0024] Ultrasonic wash the copper foil-wrapped diaphragm (copper foil 4×12 cm, 10 pieces of diaphragm 3×10 cm) with hydrochloric acid with a concentration of 1 mol / L for 10 minutes, and then ultrasonically wash with water, ethanol and acetone for 10 minutes before using Blow dry with argon. The dried copper foil-wrapped septum was placed in a 100 mL three-neck flask loaded with 80 mL of anhydrous pyridine solvent, and the gas in the bottle was replaced with an argon atmosphere. Dissolve 36mg of hexaynylbenzene monomer with 20mL of pyridine and inject it into the argon-protected constant pressure funnel through a syringe, drop into the septum filled with solvent and copper foil that has been kept at 50°C (preferably 50°C). In the three-necked flask, the drop was completed within 2 hours; the system was kept at 50°C for 12 hours. After the reaction, take out the aluminum sheet, wash the copper sheet several times with ethanol and acetone in turn, and finally dry it under vacuum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com