Preparation method of composite heterojunction photocatalyst and application thereof

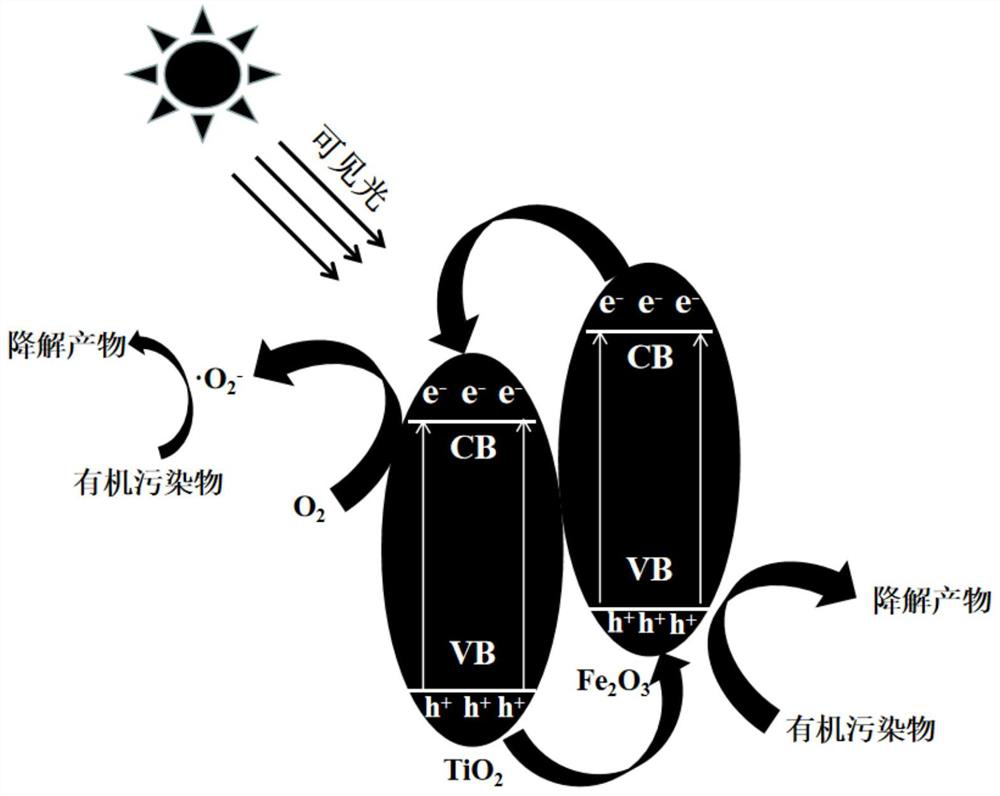

A composite heterojunction, photocatalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problem that photocatalysts cannot be promoted and widely used, and cannot be effectively recycled. , low photocatalytic efficiency and other problems, to achieve the effect of economical and feasible raw materials, sufficient raw materials, and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

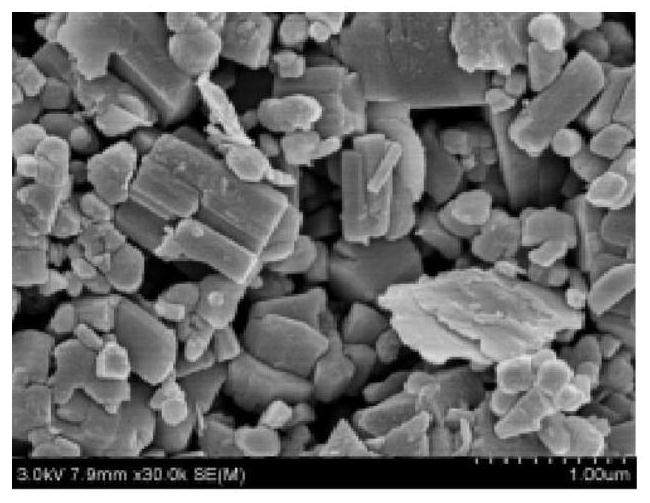

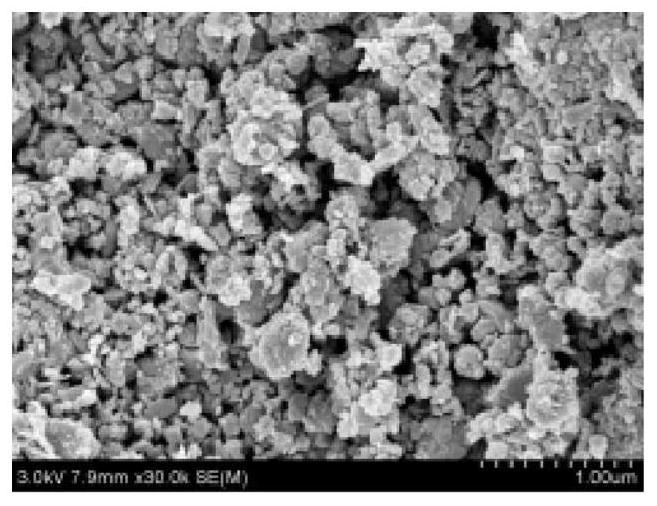

Embodiment 1

[0034] 85 parts of high-iron red mud and 15 parts of wheat stalks were ground to below 150 mesh, and the two were mixed and formed into a cylindrical shape with a pressure of 2 MPa. Then put the mixture into a crucible, put the crucible into a tube furnace, calcinate at 400°C for 20 minutes, keep it warm for 20 minutes, and take it out after cooling. Grinding the calcined cylinder to a 150-mesh sieve to obtain a composite heterojunction photocatalyst. Put 50mg of composite heterojunction photocatalyst into 100ml of methylene blue solution with a concentration of 10mg / L, reach adsorption equilibrium in the dark, and then put it in sunlight for degradation. After the degradation is completed, use a magnet to light the composite heterojunction The catalyst is separated from the aqueous solution.

Embodiment 2

[0036]70 parts of high-iron red mud and 30 parts of bamboo powder are ground to below 180 mesh, and the two are mixed and formed into a cylindrical shape with a pressure of 3 MPa. Then put the mixture into a crucible, put the crucible into a tube furnace, calcinate at 300°C for 30 minutes, keep it warm for 15 minutes, and take it out after cooling. Grinding the calcined cylinder to a 180-mesh sieve to obtain a composite heterojunction photocatalyst. Put 50mg of composite heterojunction photocatalyst into 100ml of methylene blue solution with a concentration of 10mg / L, reach adsorption equilibrium in the dark, and then put it in sunlight for degradation. After the degradation is completed, use a magnet to light the composite heterojunction The catalyst is separated from the aqueous solution.

Embodiment 3

[0038] 95 parts of high-iron red mud and 5 parts of sawdust are ground to below 200 mesh, and the two are mixed and formed into a cylindrical shape with a pressure of 1.5 MPa. Then put the mixture into a crucible, put the crucible into a tube furnace, calcinate at 300°C for 25 minutes, keep it warm for 25 minutes, and take it out after cooling. Grinding the calcined cylinder to a 200-mesh sieve to obtain a composite heterojunction photocatalyst. Put 50mg of composite heterojunction photocatalyst into 100ml of methylene blue solution with a concentration of 10mg / L, reach adsorption equilibrium in the dark, and then put it in sunlight for degradation. After the degradation is completed, use a magnet to light the composite heterojunction The catalyst is separated from the aqueous solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com