Fabrication of core/shell capsules of different geometries and treatment thereafter

A technology of capsules and inner shells, applied in the directions of capsule transportation, tobacco processing, chemical/physical processes, etc., can solve the problems of easy volatilization of edible spices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

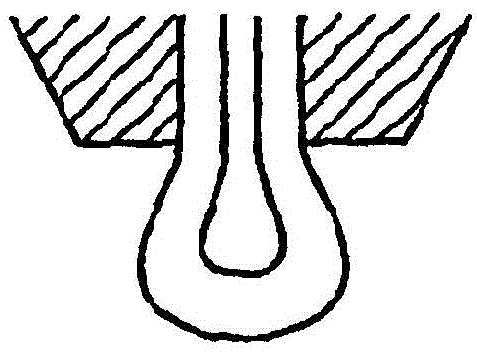

[0058] A mixture of flavorant (9670-102A) in vegetable oil was fed through the internal nozzle or nucleating nozzle (1.0 mm diameter) of a Brace GmbH Spherisator 2002 Mark II 1410-087 coextruder at a pressure of 55 mbar. A 2% by weight aqueous solution of sodium alginate (first shell-forming polymeric material) was supplied through the outer nozzle or shell-forming nozzle (2.5 mm diameter) of the coextruder at a pressure of 100 mbar. The vibration frequency is 80 Hz, and the vibration amplitude is 350 mV. The coated cores produced by coextrusion were contacted with an aqueous hardening solution containing 5% by weight calcium chloride and filtered, washed with additional aqueous hardening solution containing 5% by weight calcium chloride. A portion of the coated cores produced are undesirably small "satellite" capsules (which can be screened out or separated from desired capsules) or have cores that are not perfectly centered. A small amount of oil was observed on the surface...

Embodiment 2

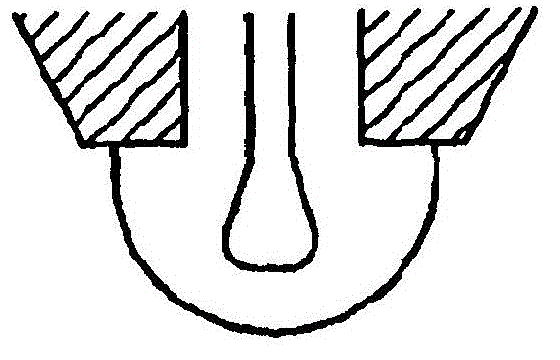

[0061] The procedure above in Example 1 was generally followed except that the flavorant was supplied through the inner nozzle at a pressure of 60 mbar and the alginate solution was supplied through the outer nozzle at a pressure of 125 mbar. A portion of the coated cores produced were satellite shaped or had cores that were not perfectly centered. After drying, several capsules burst. The weight of the capsules is about 30 mg to about 35 mg per capsule, with an average weight of about 32 mg / capsule. The burst strength of the capsules was measured and found to be from about 3.5N to about 16.7N.

Embodiment 3

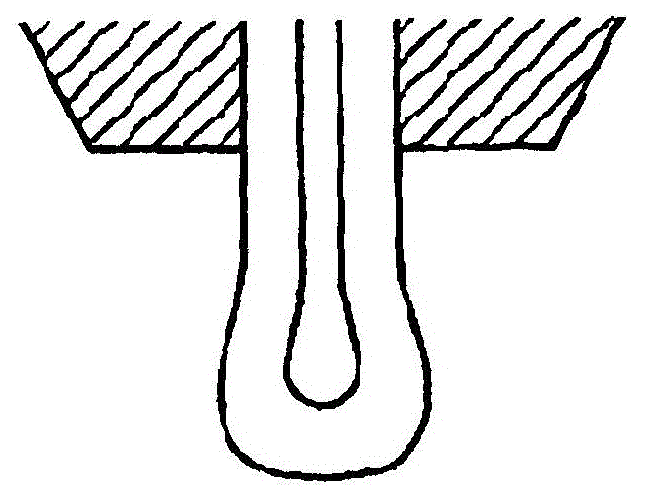

[0063] The procedure described in Example 1 was generally followed except that the vibration frequency was 100 Hz and the external nozzle pressure was 105 mbar. Few small capsules were observed, but several unencapsulated globules were observed. To an aqueous solution containing 0.25% by weight sodium alginate and 1.0% by weight polyvinylpyrrolidone ("PVP"), the filtered coated cores were added, stirred for 20 minutes, diluted with water, removed from the solution, and left without adding Filter directly under the condition of more calcium chloride. As in Example 1, the filtered capsules were dried in a tumble dryer. The average capsule weight was found to be 33.8 mg / capsule, but PVP did not prevent aggregate formation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com