Self-supporting carbon-based TiO2 electro-catalytic material as well as preparation method and application thereof

An electrocatalytic material and self-supporting technology, applied in the field of electrocatalysis, can solve the problems of uneven distribution of TiO2, increase of contact resistance between active material and carrier mass transfer, decrease of charge transfer efficiency and mass transfer efficiency, etc., to improve electrochemical performance , enhanced electron transfer rate, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

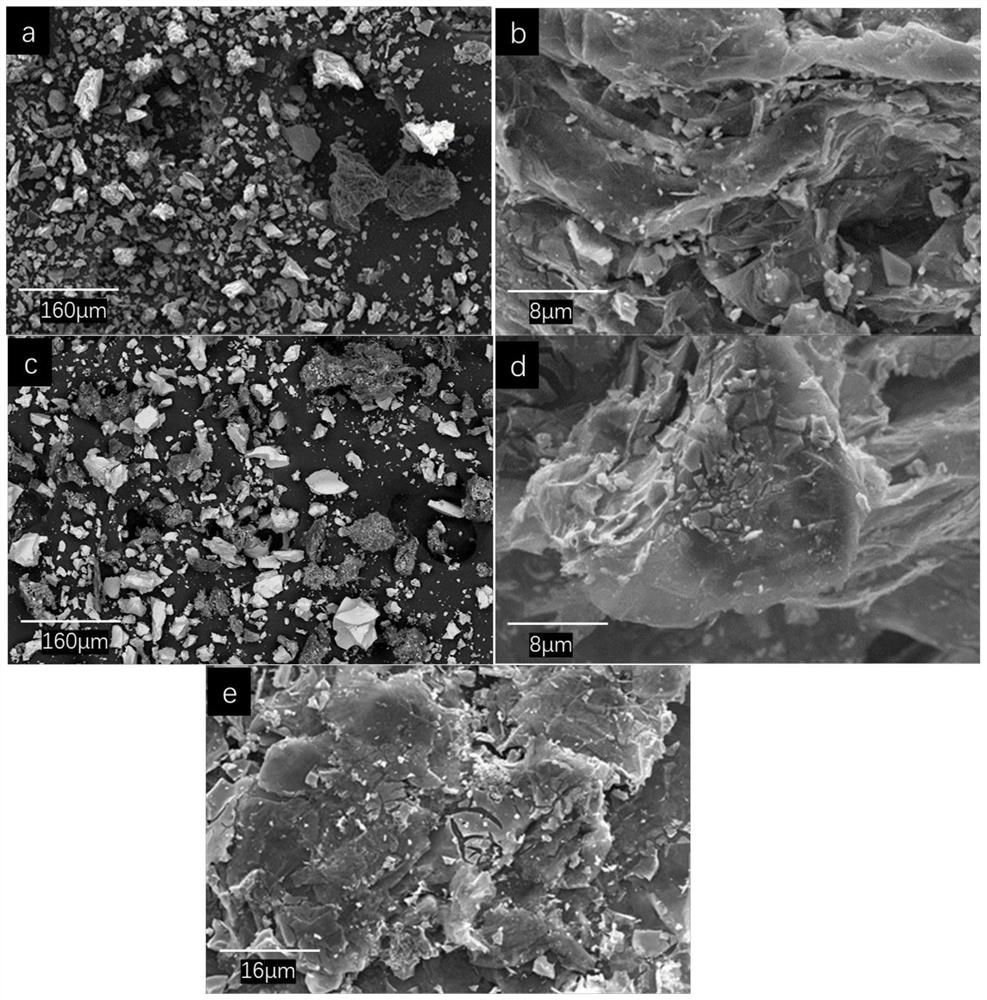

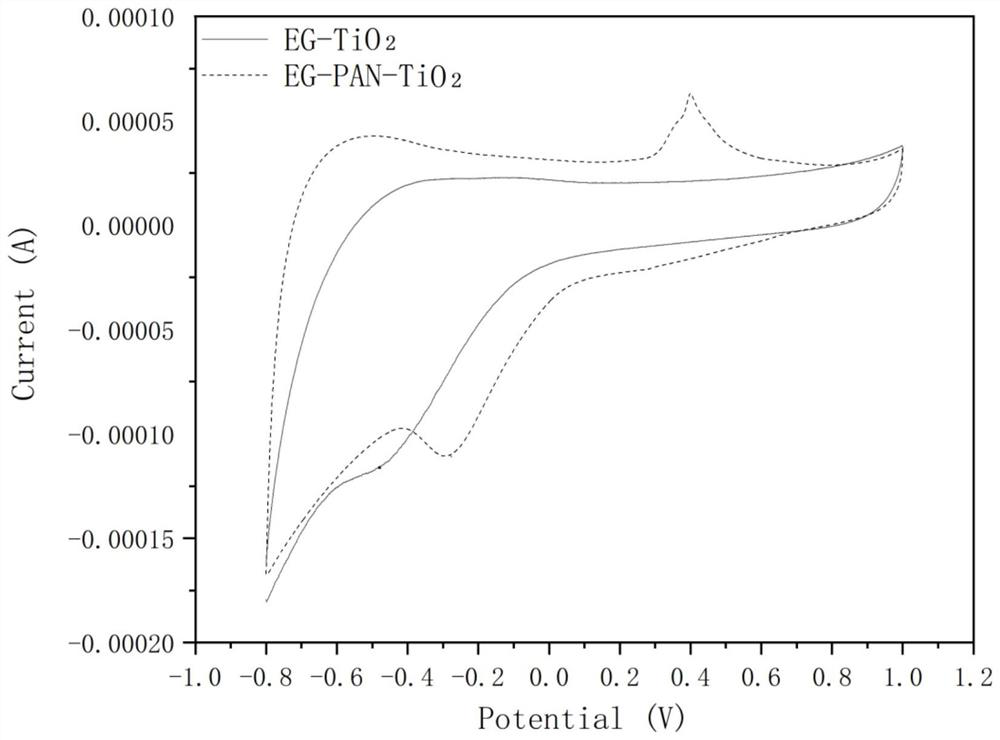

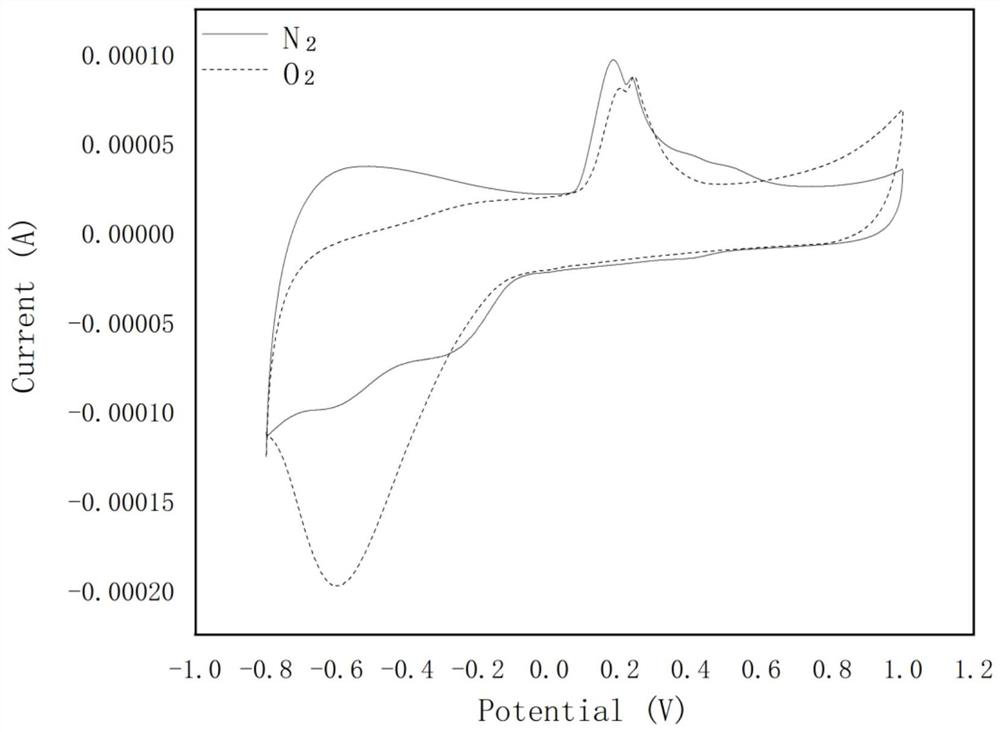

[0040] (1) The expanded graphite powder was ultrasonically cleaned with ultrapure water and absolute ethanol for 30 minutes, then placed in a vacuum drying oven, and dried at 80° C. for 8 hours.

[0041] (2) Put 1 g of pretreated expanded graphite powder into aniline-ethanol (volume ratio 1:4) solution, and ultrasonically treat it at 60 Hz for 30 min.

[0042](3) Add the expanded graphite powder cleaned with ultrapure water into 75mL of HCl / H2SO4 (0.5M / 1M) mixed acid solution, add 7.6325g of ammonium persulfate while stirring, and continue stirring at 6°C for 10h Filter and dry at 80°C for 10 hours to obtain EG-PAN powder.

[0043] (4) Mix 1 g of EG-PAN powder, 7.5 ml of tetrabutyl titanate, and 22.5 ml of absolute ethanol, and stir for 20 min with a magnetic stirrer to form a mixed solution A.

[0044] (5) Mix 22.5ml of absolute ethanol, 3ml of deionized water, and 0.6ml of concentrated nitric acid, and stir with a magnetic stirrer for 20min to form a mixed solution B.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com