Patents

Literature

39results about How to "Plug the gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-durability concrete

The invention discloses a high-durability concrete which comprises the following raw materials: cement, river sand, macadam, water, fly ash, nano microbead, natural zeolite micropowder, aluminum oxide, sodium sulfate, diethanolamine, sodium hydroxide, methyl trichlorosilane, ethanol, an air entraining agent, a lignosulfonate water reducing agent, polyvinyl alcohol, mixed fiber, sodium nitrate and polyvinylpyrrolidone. The mixed fiber is the combination of carbon fiber, steel fiber, polypropylene fiber and polyvinyl alcohol fiber in a weight ratio of 1:(2-5):(3-7):(3-6). The high-durability concrete has the advantages of high strength, favorable water impermeability, favorable freezing resistance and favorable durability, and has long service life when being applied to hydrotechnics, harbors, roads and other projects.

Owner:WUWEI HENGJI COMML CONCRETE

Temporary plugging diverting agent used for reservoir reformation, and preparation method thereof

The invention discloses a temporary plugging diverting agent used for reservoir reformation, and a preparation method thereof, and belongs to the technical field of petroleum and gas reservoir reformation. The temporary plugging diverting agent comprises, by mass, 30-45% of high-molecular polymer particles, 0-4% of a crosslinking agent, 5-12% of an expanding agent, 0.1-1% of a gel breaker, and the balance of oil, wherein the high-molecular polymer particles are at least one of polyvinyl alcohol particles, polyacrylamide particles and polyacrylamide derivative particles; the crosslinking agent is at least one of boric acid, water-soluble borate, water-soluble chromium salt, water-soluble aluminum salt, water-soluble titanium salt and water-soluble zirconium salt; the expanding agent is polyacrylamide crosslinked resin particles or acrylamide and acrylic acid copolymer crosslinked resin particles or a combination of the polyacrylamide crosslinked resin particles and the acrylamide and acrylic acid copolymer crosslinked resin particles; and the gel breaker is persulfate. The breakthrough pressure of the temporary plugging diverting agent can reach 60 MPa or above, the plugging rate can reach 99% or above, and the temporary plugging diverting agent is suitable for 80-140 DEG C reservoirs, and has good dissolving / degrading performance.

Owner:PETROCHINA CO LTD

Well cementing slurry lightening agent and preparation method thereof

ActiveCN103497747AReduce water consumptionImprove liquidityCarbamic acid derivatives preparationOrganic compound preparationFirming agentWell cementing

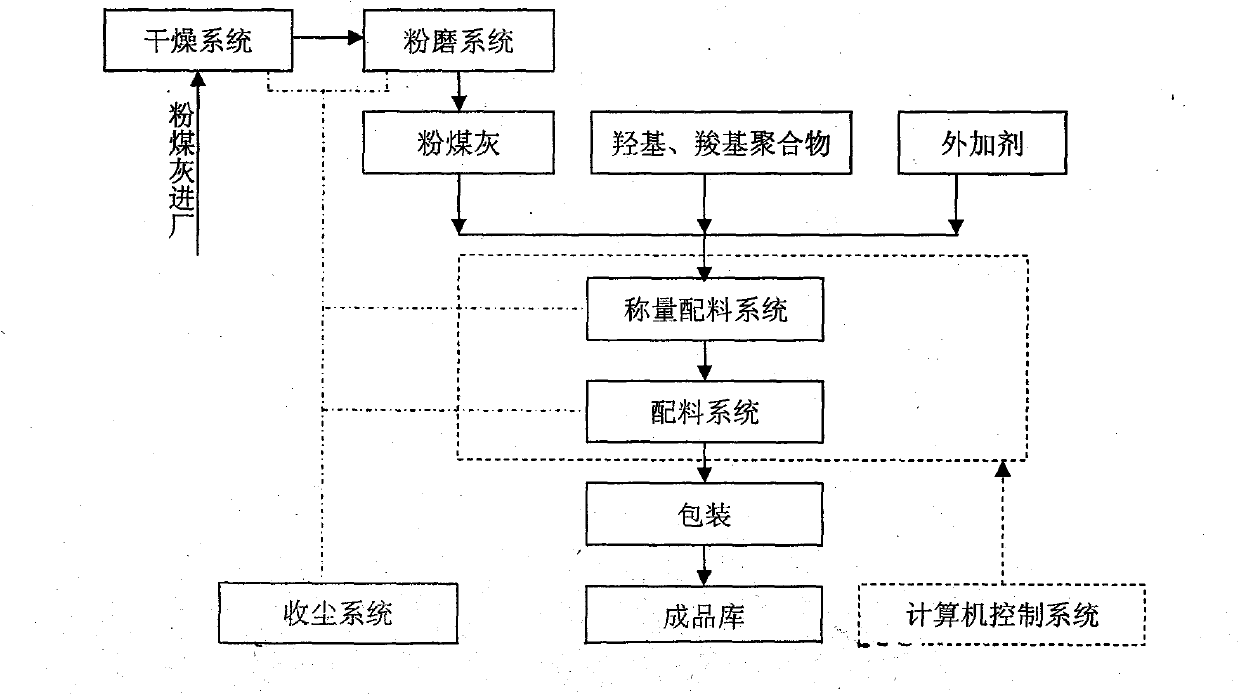

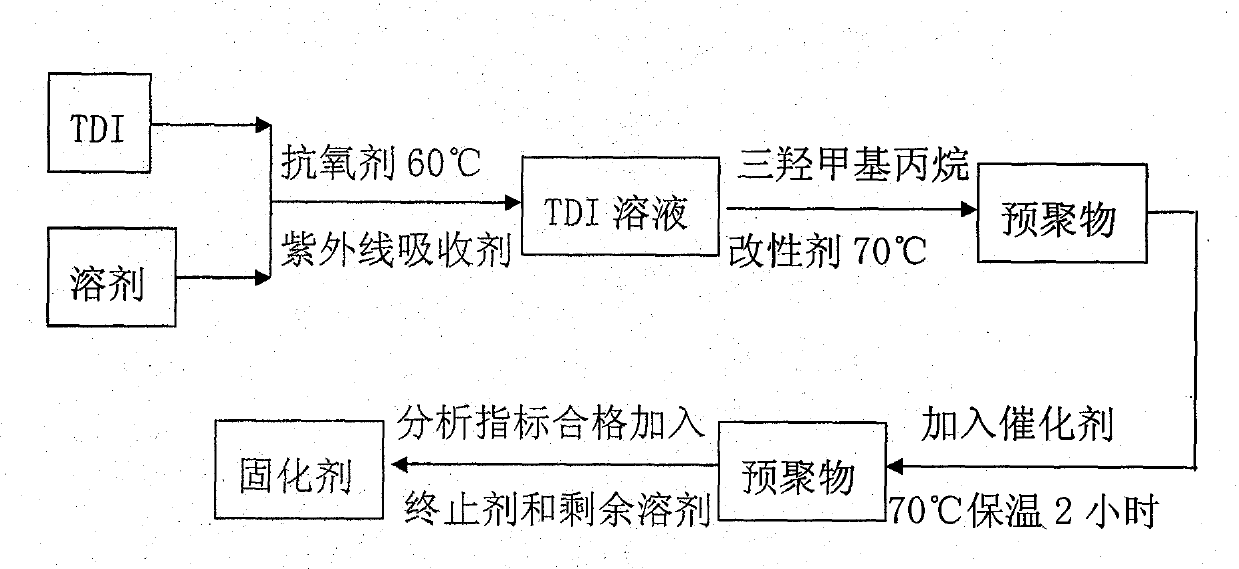

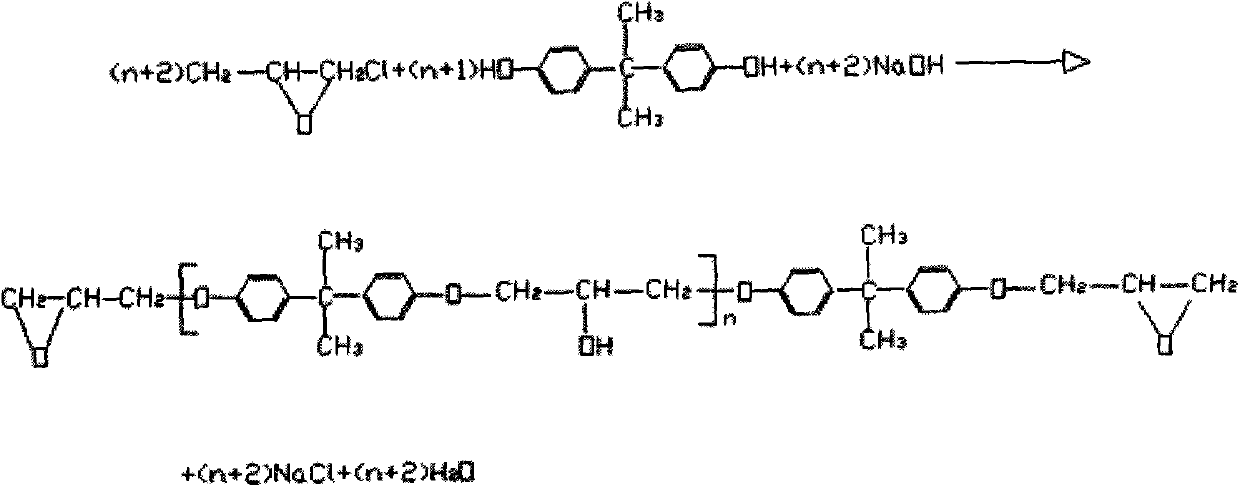

The invention relates to the technical field of well drilling and well cementing in the oil and gas fields. The lightening agent is composed of fly ash, bisphenol A epoxy resin, a TDI curing agent and an addictive, the weight percentage and particle size of each component are as follows: 45 to 50% of fly ash, wherein the particle size of fly ash is less than 20 [mu]m; 25 to 30% of bisphenol A expoxy resin, wherein the particle size of bisphenol A epoxy resin is between 0.1 and 0.2 mm; 10 to 15% of TDI curing agent; and 11 to 11.5% of addictive, wherein the addictive is a mixed glue-mixing cured product of active silicone dioxide powder and acrylate polymer, wherein the acrylate polymer is acrylate glue powder or acrylate emulsion. The well cementing low-density slurry body, which is prepared by using the lightening agent, has the characteristics of low density, good rheological property, strong stability, small dehydration rate, and high strength, can effectively solve the difficult problems of low pressure, and easy leakiness during the processes of long isolation section well cementing and oil and gas layer protection, and effectively guarantees the well cementing construction quality.

Owner:白银金奇化工科技有限公司

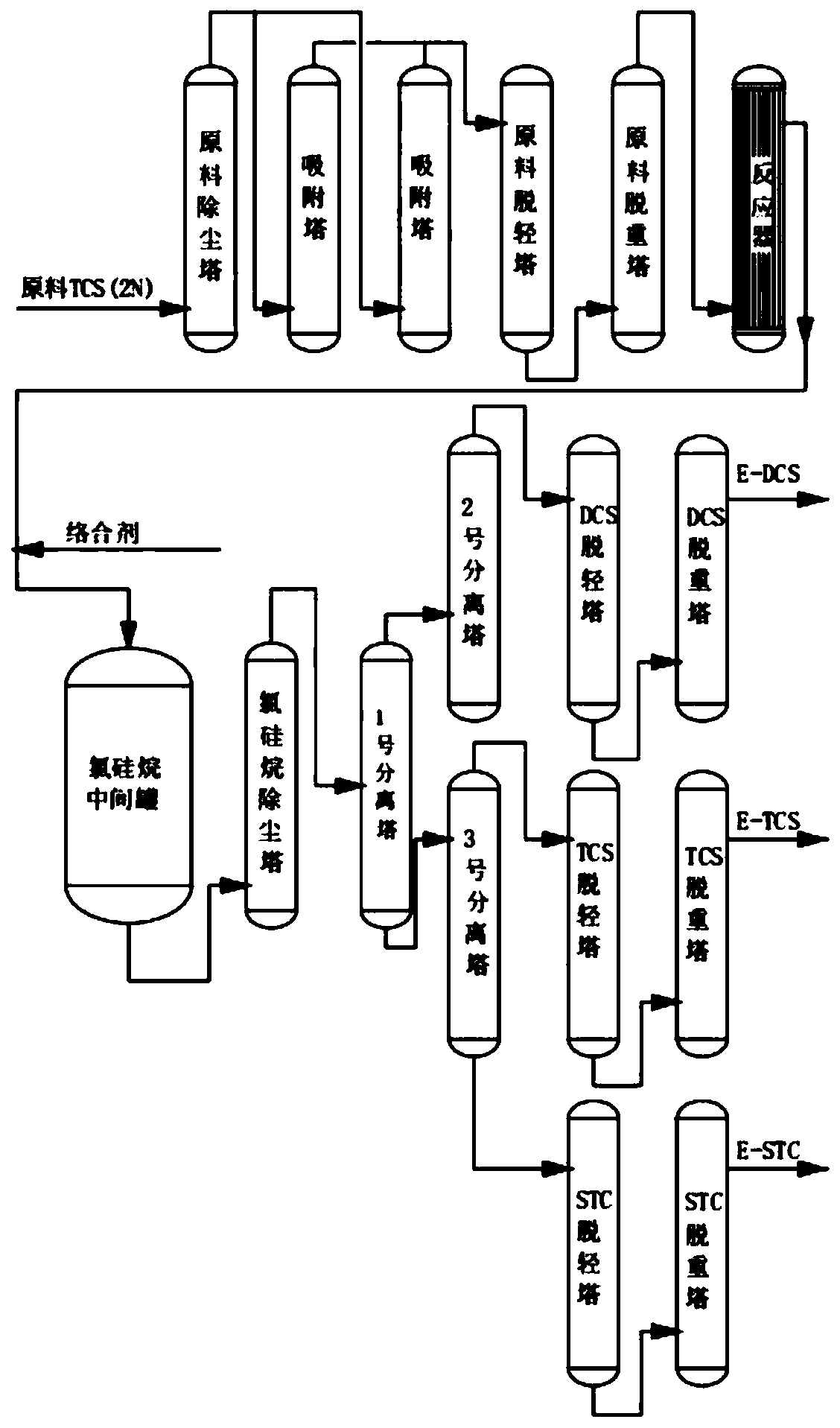

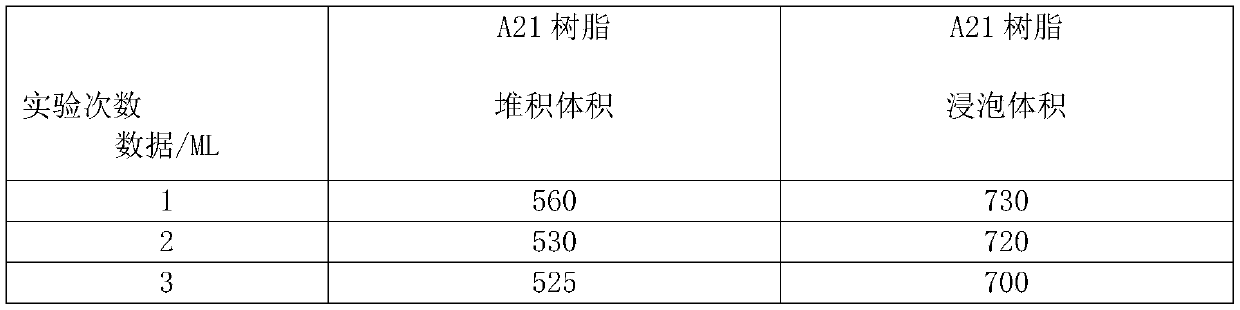

Method for simultaneously producing electronic-grade dichIorosilane, electronic-grade trichlorosilane and electronic-grade silicon tetrachloride

ActiveCN109987608ALow purity requirementLow impurity contentHalogenated silanesGas phaseSilicon tetrachloride

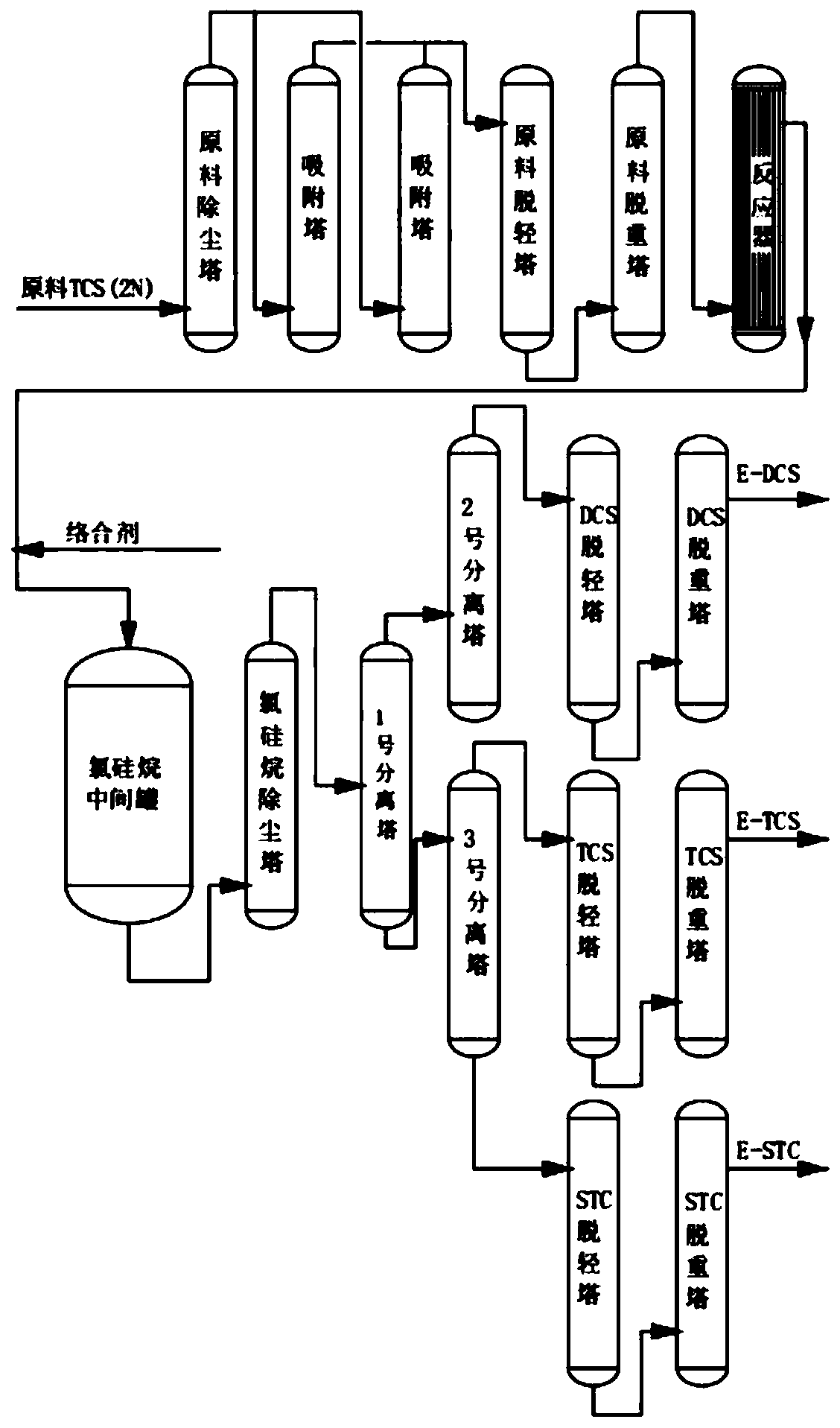

The invention relates to a method for simultaneously producing electronic-grade dichIorosilane, electronic-grade trichlorosilane and electronic-grade silicon tetrachloride. The method uses crude trichlorosilane as a raw material; and the method comprises the steps of first-stage dust removal, gas phase adsorption, first-stage light-component removal, first-stage heavy-component removal, disproportionation, addition of a complexing agent, second-stage dust removal, first-stage separation, second-stage separation treatment, second-stage light-component removal treatment, second-stage heavy-component removal treatment, third-stage separation treatment, third-stage light-component removal, third-stage heavy-component removal, fourth-stage light-component removal, and fourth-stage heavy-component removal. According to the method provided by the invention, the process route is based on a current process route of preparing electronic-grade dichIorosilane, steps are changed and adjusted, so that a requirement of purity of raw material trichlorosilane is reduced, and the electronic-grade dichIorosilane, the electronic-grade trichlorosilane and the electronic-grade silicon tetrachloride canbe simultaneously obtained; and the products have a less content of impurities such as metal impurities, chlorosilane impurities and boron impurities, and stable quality, and can meet the requirementsof large-scale integrated circuits.

Owner:唐山三孚电子材料有限公司

Water-borne high permeability crystal waterproof hardening agent

The invention discloses a water-borne high permeability crystal waterproof hardening agent. The proof hardening agent comprises the following components in percent by weight: 20 to 40 percent of alkali metal silicate, 0.25 to 1 percent of an early strength agent, 1 to 6 percent of a catalyst, 0 to 0.5 percent of a surfactant, 1 to 4 percent of a hardening accelerator, 0.5 to 2 percent of water soluble high molecular polymer, 0 to 8 percent of organic silicon, and water for the surplus. The waterproof hardening agent is moderate in cost, can realize complete localization, higher in penetration depth, higher in hardness after being reacted with substance in concrete, and higher in hydraulic pressure resistance capacity.

Owner:常州绿玛特建筑科技有限公司

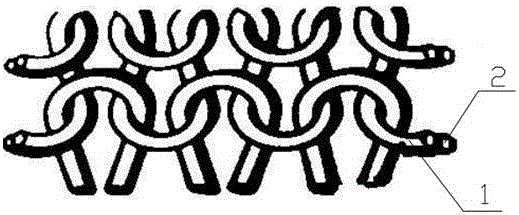

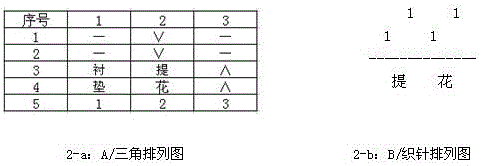

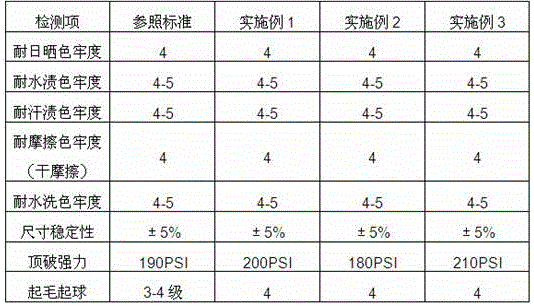

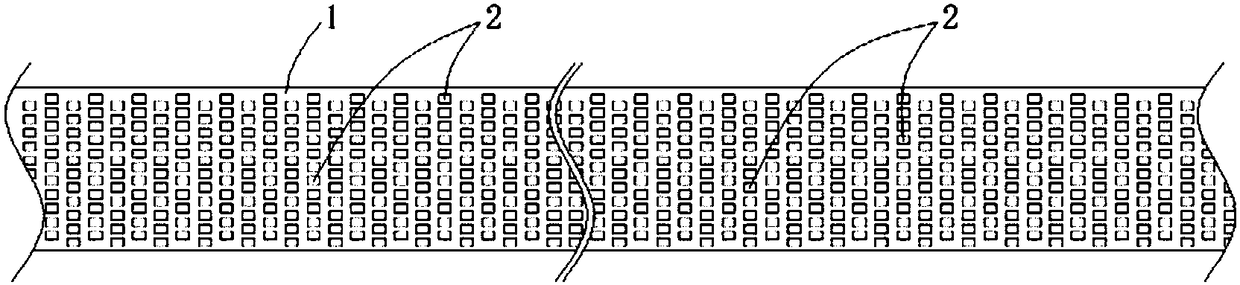

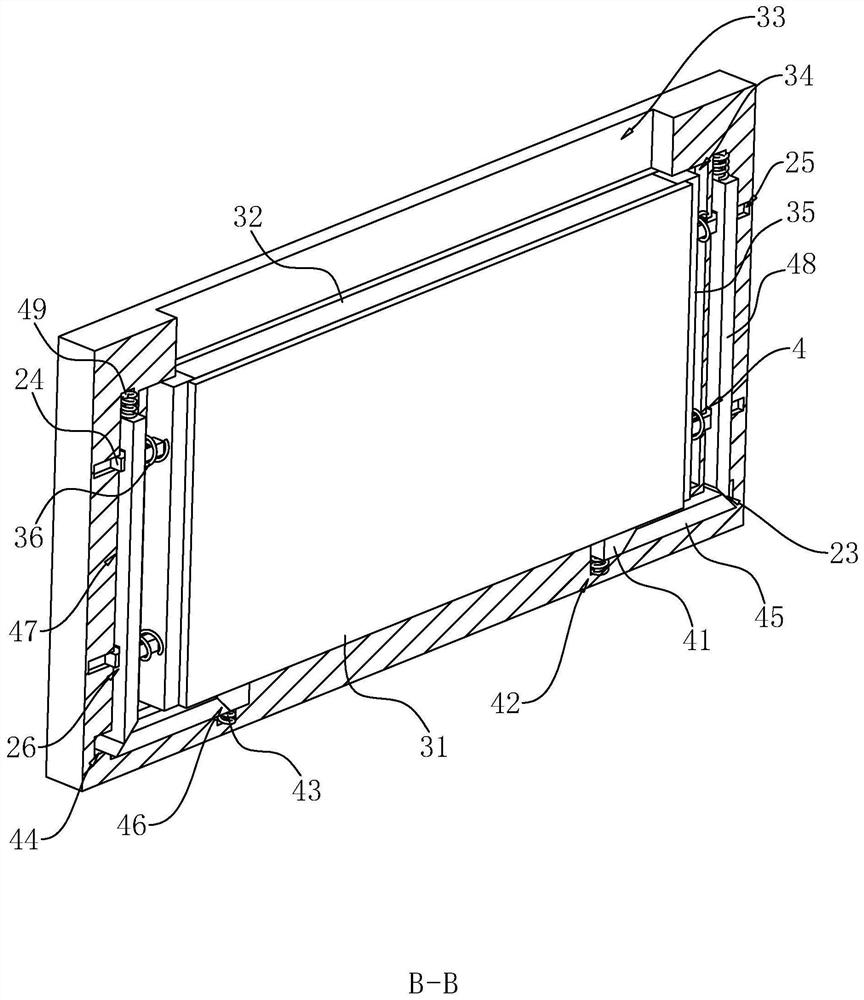

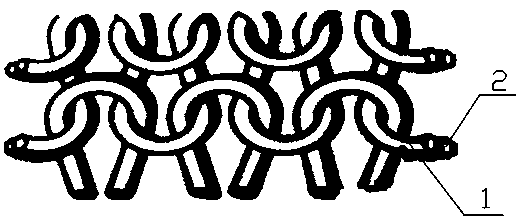

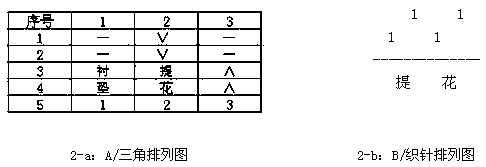

Three-dimensional pattern creasing warm keeping air layer fabric and preparation method thereof

ActiveCN105970458AImprove compactnessPlug the gapGarment special featuresWeft knittingEngineeringAir layer

The invention discloses a three-dimensional pattern creasing warm keeping air layer fabric. The fabric is of a jacquard air layer structure. Short fiber yarn and spandex or high-elastic yarn are adopted to be jacquard face yarn, short yarn is adopted to be non-jacquard face yarn, polyester filaments with hollow sections are adopted to be the air layer fabric, and according to the air layer fabric, a piece of filament bottom yarn is added below the jacquard face yarn in a lag looping mode. The air layer fabric is treated through a specific dyeing and finishing process and special auxiliaries, while the production cost is reduced and the production yield is increased, the prepared air layer fabric is strong in surface texture layering sense, obvious in pattern creasing effect and good in warm keeping effect, and the problem that yarn interlacing is prone to occurrence in a jacquard air layer jacquard face in the prior art is effectively solved.

Owner:NINGBO DAQIAN TEXTILE

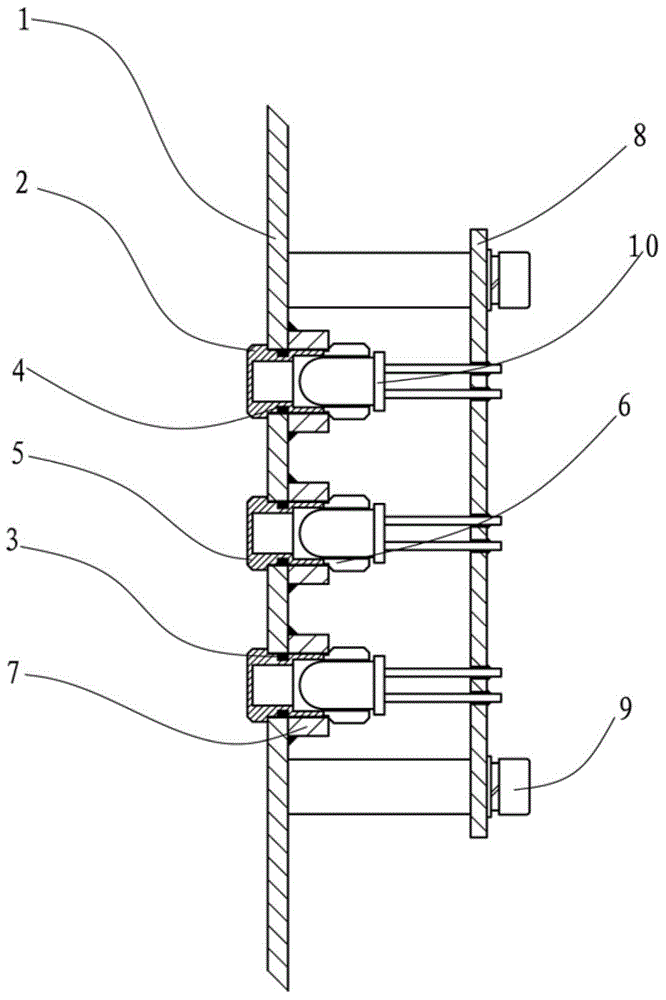

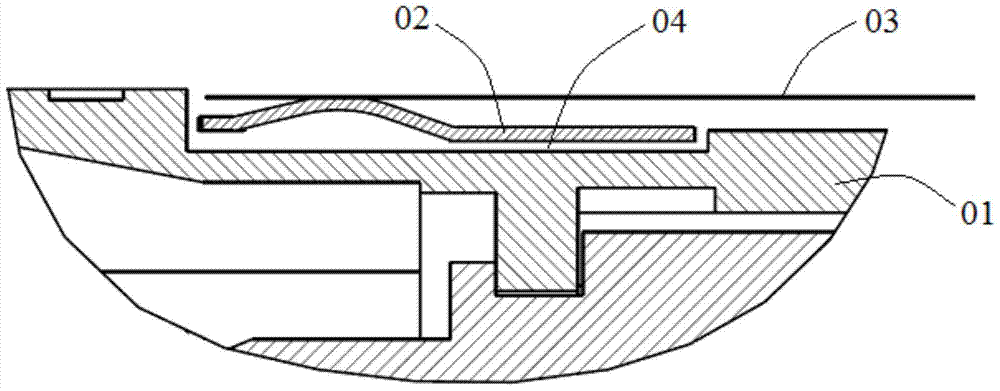

Water prevention method and water prevention structure of laser power supply indicator light and laser power supply

InactiveCN104791741ABurn out preventionDoes not affect the display effectGas-tight/water-tight arrangementsEngineeringBurning out

The invention is suitable for the field of laser power supplies, and provides a water prevention structure of a laser power supply indicator light. A laser power supply comprises a panel; a through hole is formed in the panel; a display part of the indicator light is positioned in a light transmitting device; the light transmitting device is inserted in the through hole; and a sealing device is arranged between the light transmitting device and the through hole. The invention further provides a water prevention method of the laser power supply indicator light and a corresponding laser power supply. As the transmitting device penetrating through the panel of the laser power supply is arranged at the display part of the indicator light, the display effect of the indicator light is not influenced; and the sealing device is arranged between the transmitting device and the panel to block a gap between the panel and the indicator light, so that water is prevented from entering the internal of the laser power supply to burn out the power supply.

Owner:HANS LASER TECH IND GRP CO LTD

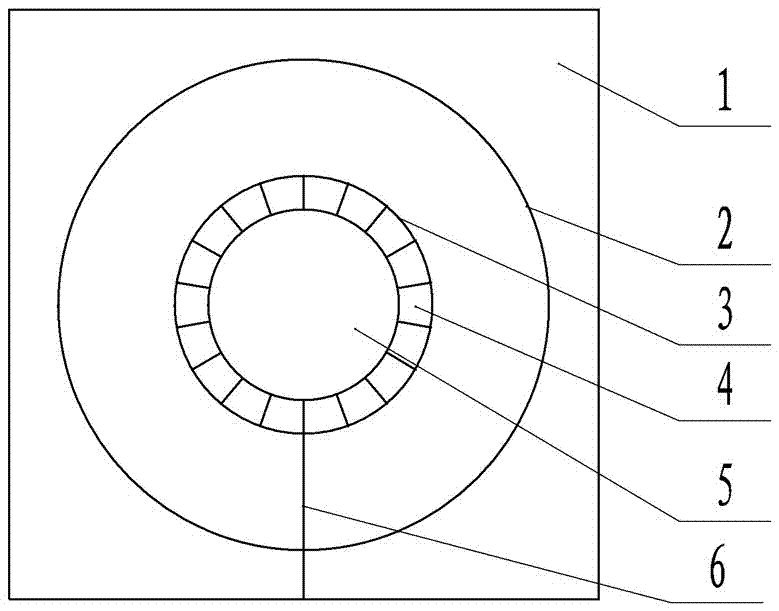

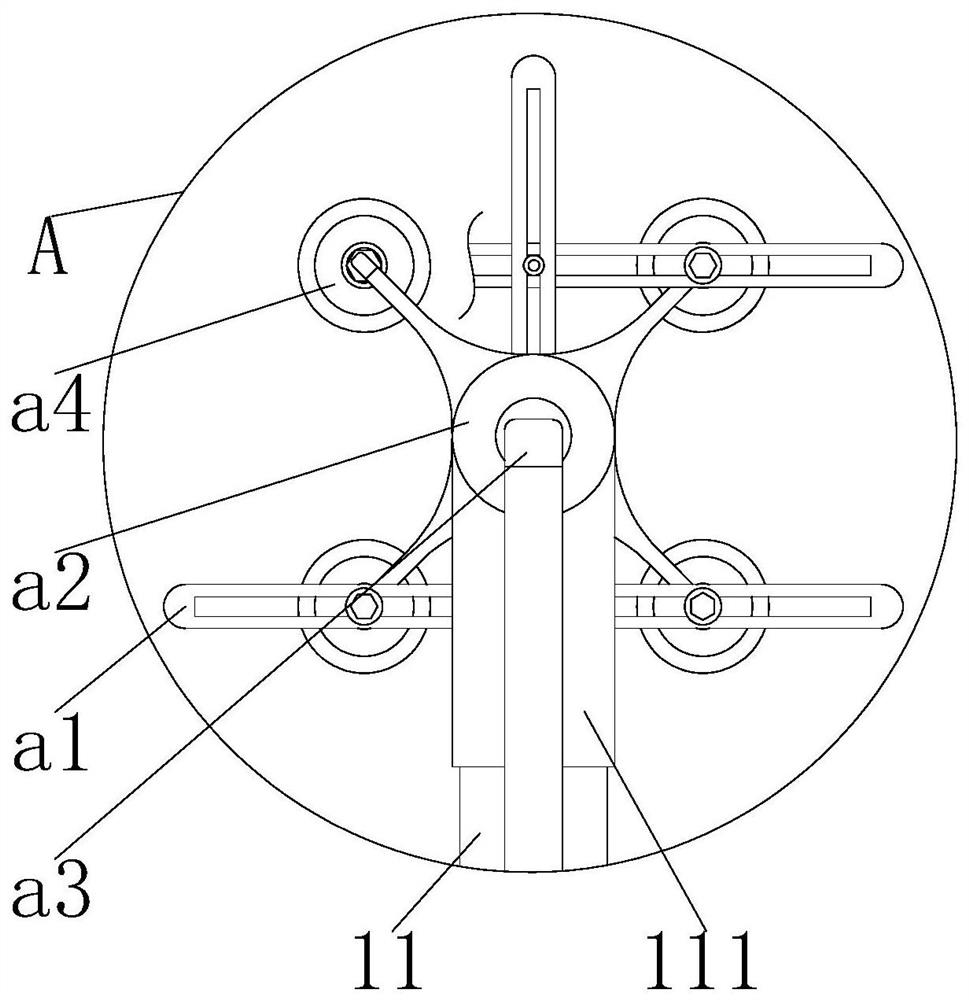

Anti-falling device special for electric pump wellhead

ActiveCN106948793APrevent falling wellPlug the gapBorehole/well accessoriesMachineCorrosion resistant

The invention relates to an anti-falling device special for an electric pump wellhead. The anti-falling device special for the electric pump wellhead comprises a lift sub seat face made of an elastic material; an alignment hole is formed in the center of the lift sub seat face; a floating blade is arranged on the inner ring of the lift sub seat face; and a sleeve opening is formed in the lift sub seat face. The anti-falling device has the characteristics of being simple in structure, convenient to machine, low in manufacturing cost and resistant to corrosion, oil, gas and water, and the phenomenon that used tools or parts fall in a well at the time of wellhead operation, so that resistance occurs in the process of wiper trip operation or unit taking out is avoided effectively.

Owner:白嘉杨

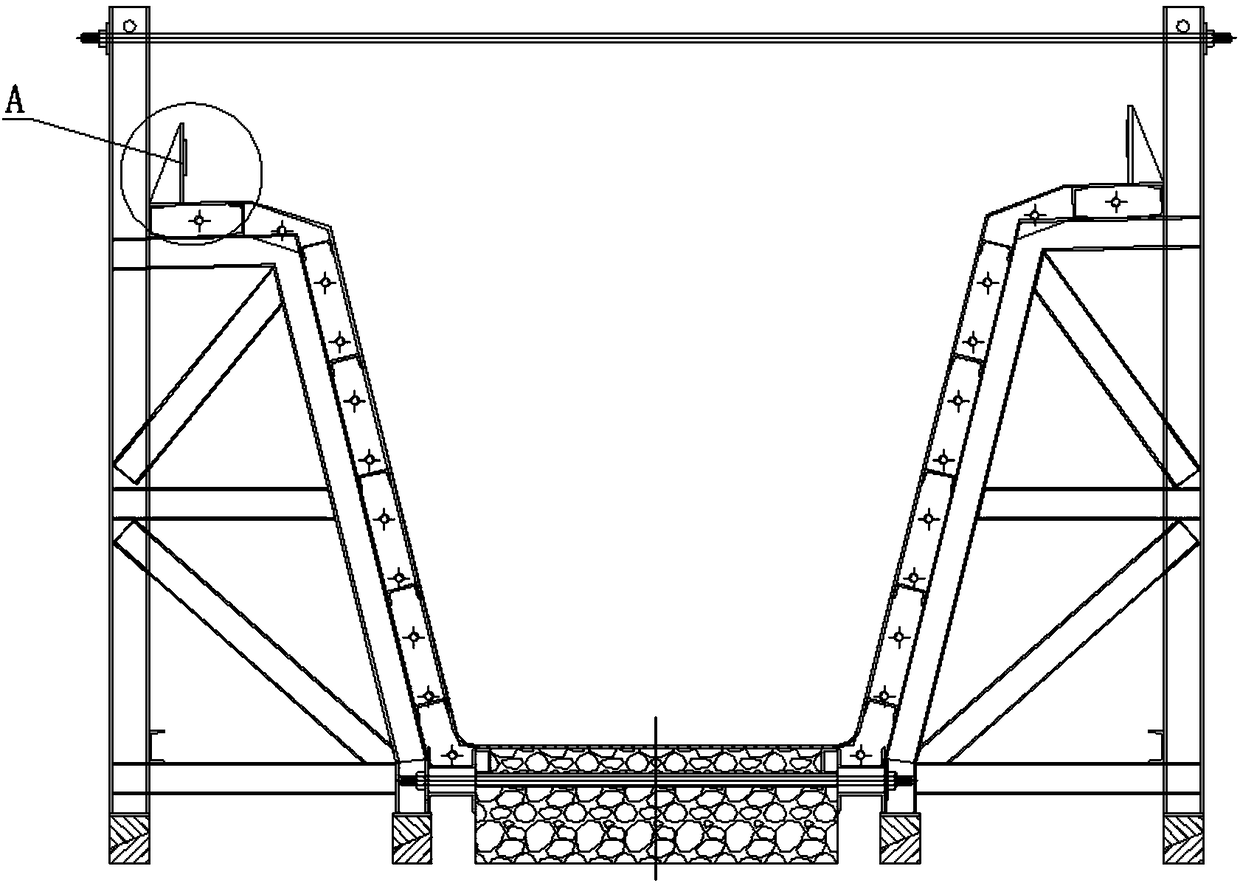

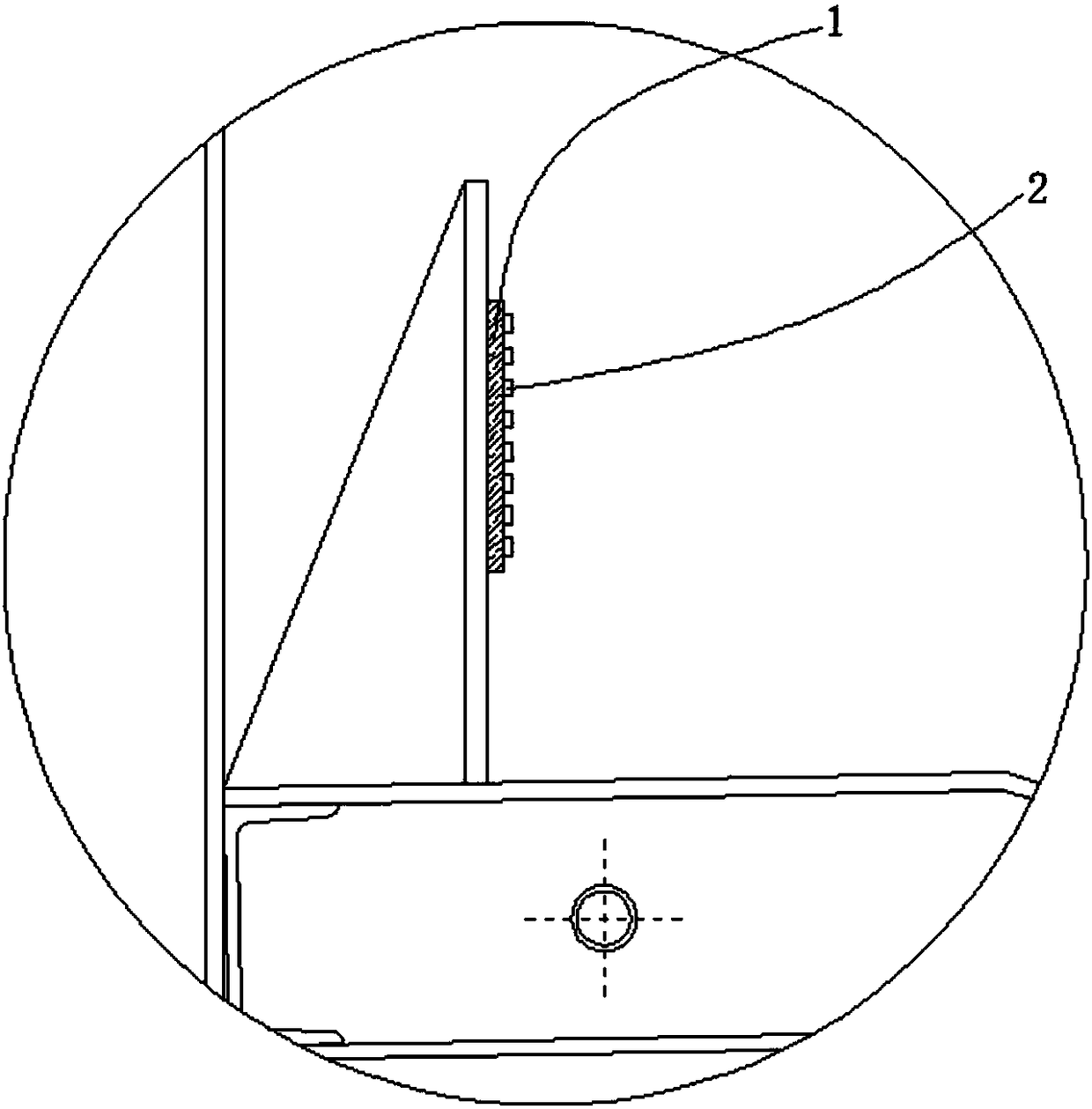

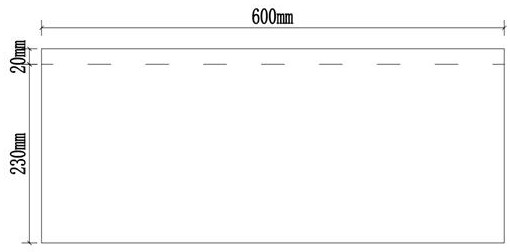

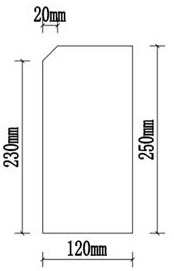

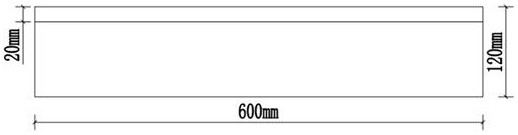

Flange isolation pad used for prefabricating box girder and construction method of flange isolation pad

InactiveCN108442234APlug the gapAvoid churnBridge structural detailsBridge erection/assemblyRough surfaceEngineering

The invention discloses a flange isolation pad used for prefabricating a box girder and a construction method of the flange isolation pad. The flange isolation pad comprises an isolation pad body madeof a wear-resisting soft material. One face of the isolation pad body is a smooth surface, and the other face of the isolation pad body is a rough surface. Protrusions are distributed on the rough surface. When the box girder is prefabricated, the smooth surface makes contact with a comb plate in a binding mode, and the protrusions face the inner side. The protrusions are evenly distributed in astaggered mode on the isolation pad body. The flange isolation pad has the remarkable beneficial effects that the pad does not need to be roughened again, energy is saved, the pad is environment-friendly, and the product quality and the production efficiency are effectively improved; concrete is prevented from running away, and the pad is quick and convenient to install and detach, economical andpractical; and the pad can be cyclically used for multiple times, and construction cost is reduced.

Owner:CHINA COMM 2ND NAVIGATIONAL BUREAU 2ND ENG

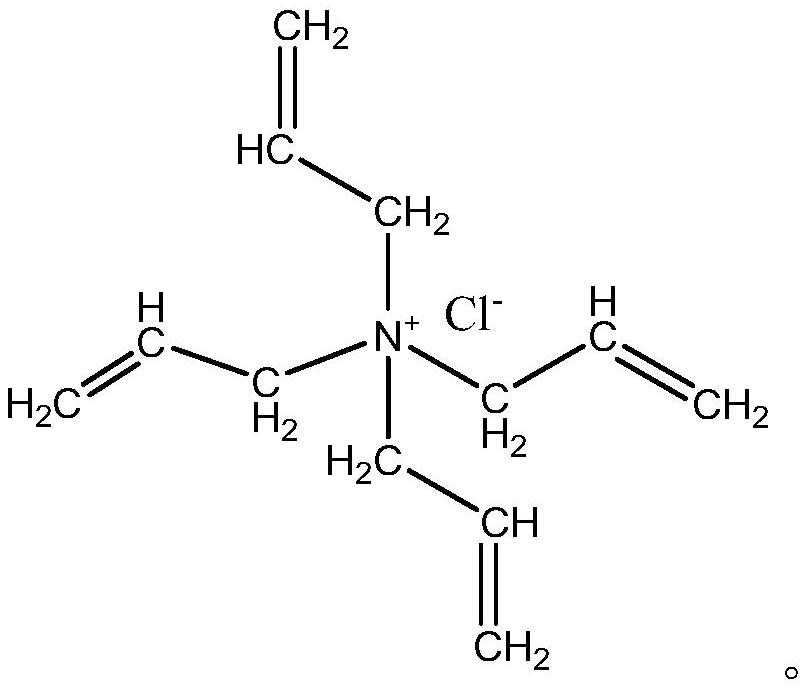

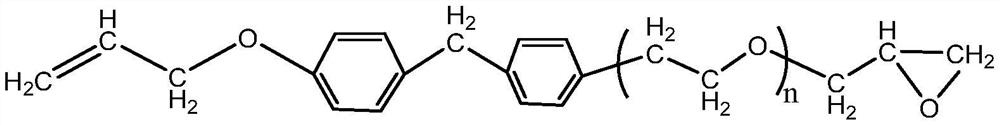

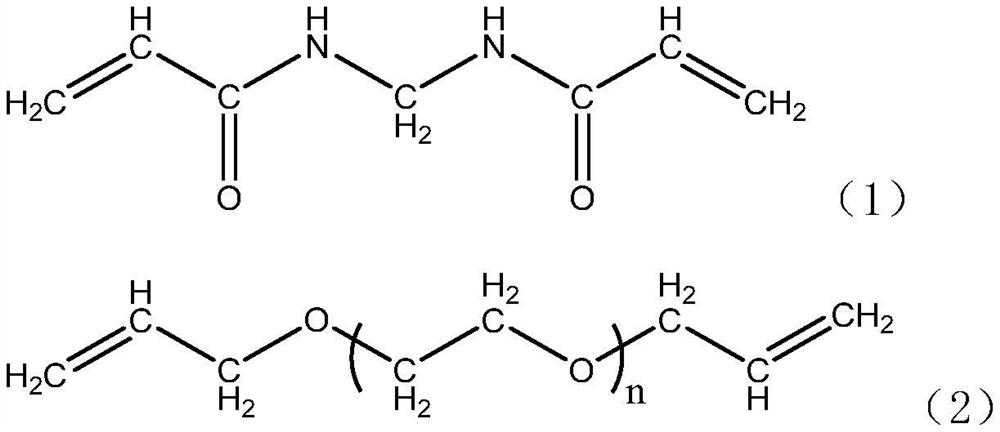

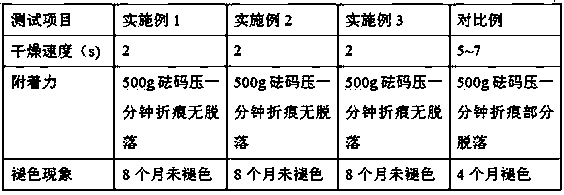

Bubble fastness improver for dyeing polyester and preparation method of bubble fastness improver

ActiveCN114657800AImproved blister fastnessPrevent water from fadingDyeing processDisperse dyePolymer science

The invention discloses a blister fastness improver for dyeing polyester and a preparation method of the blister fastness improver. The blister fastness improver comprises the following components in parts by weight: 10-20 parts of a three-terminal allyl cationic monomer, 20-60 parts of an allyl polyether epoxy end cap, 2-6 parts of a cross-linking agent, 0.2-1.0 part of an initiator and 20-50 parts of deionized water. According to the blister fastness improver for dyeing the polyester and the preparation method of the blister fastness improver, the prepared blister fastness improver for dyeing the polyester is a three-dimensional high-molecular cationic polymer with an epoxy active group, is applied to padding and sizing of a dyed polyester fabric, and can improve the blister fastness of the dyed polyester fabric, so that the blister fastness of the dyed polyester fabric is improved, and the service life of the dyed polyester fabric is prolonged. Meanwhile, the polyester fabric is endowed with antistatic property and pilling resistance, and the quality of the polyester fabric is improved.

Owner:浙江联胜新材股份有限公司

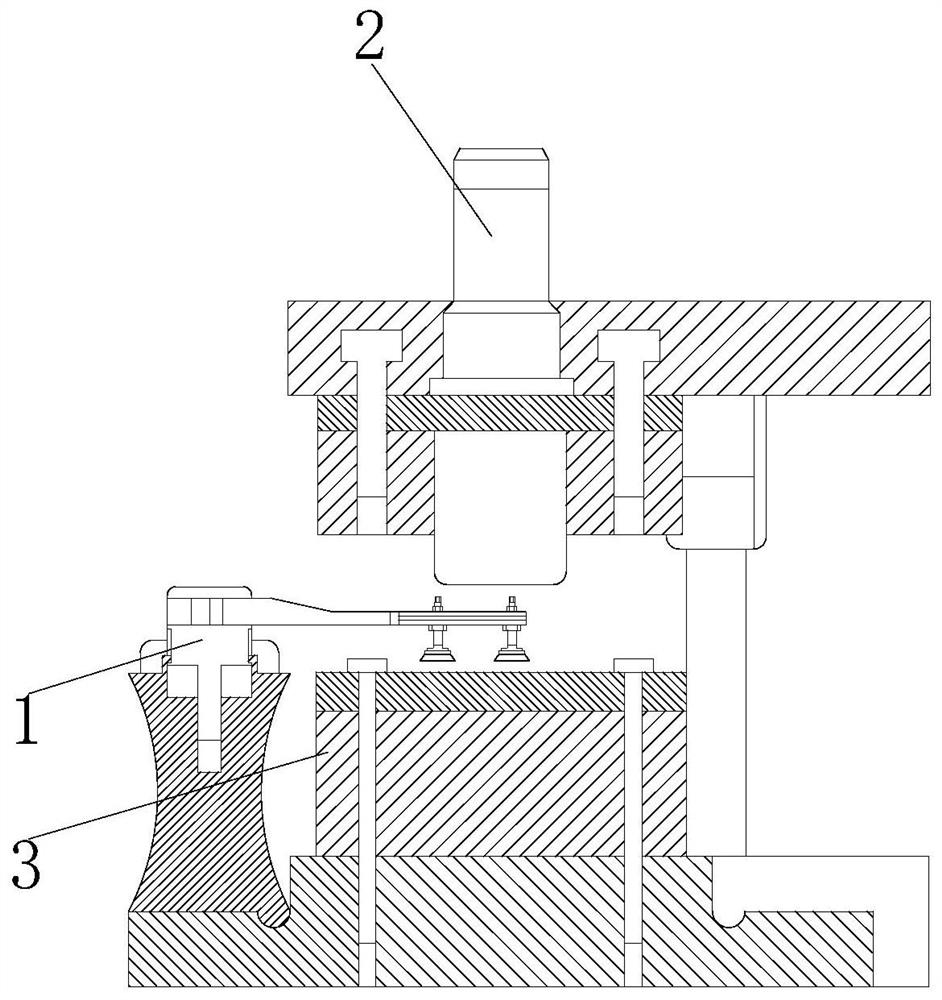

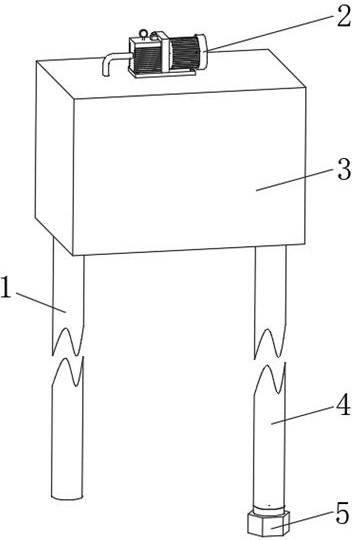

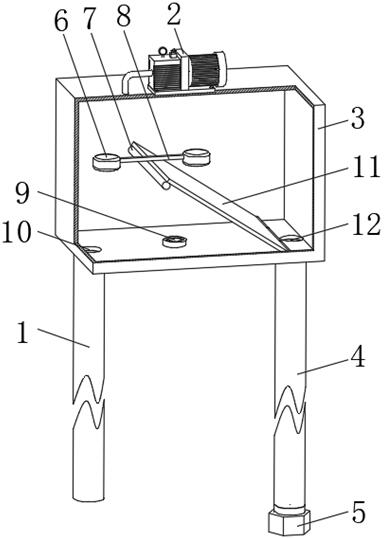

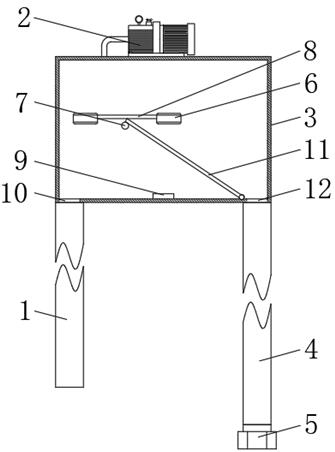

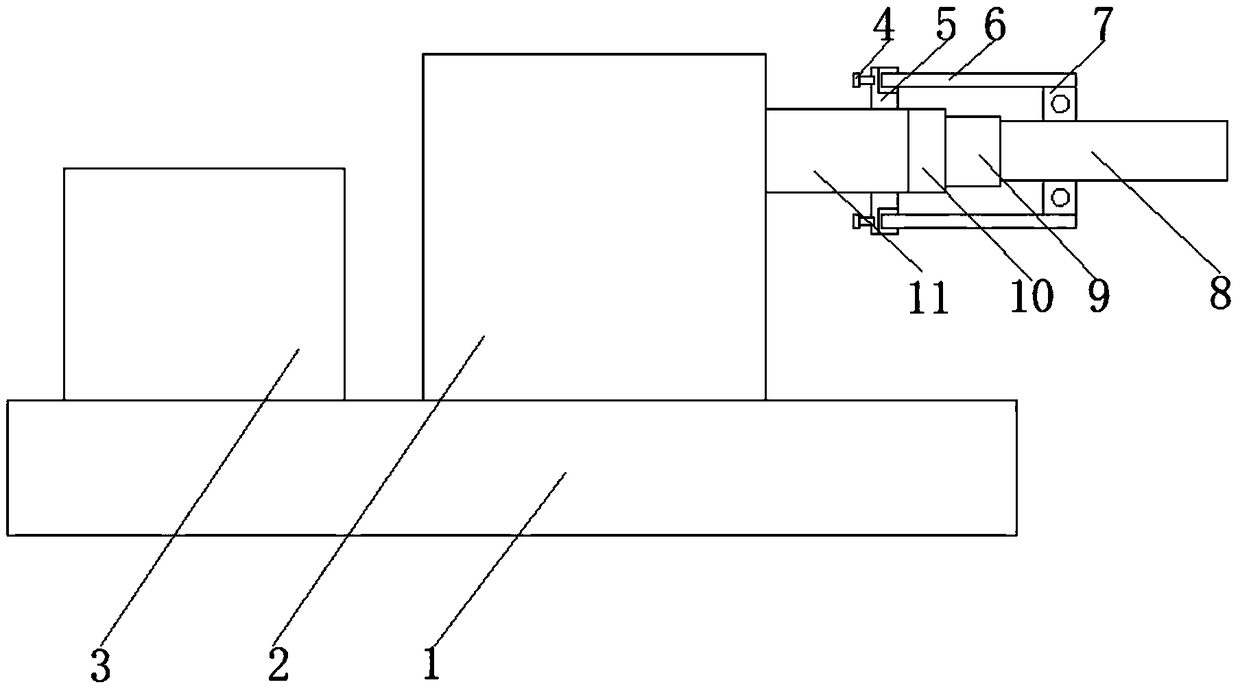

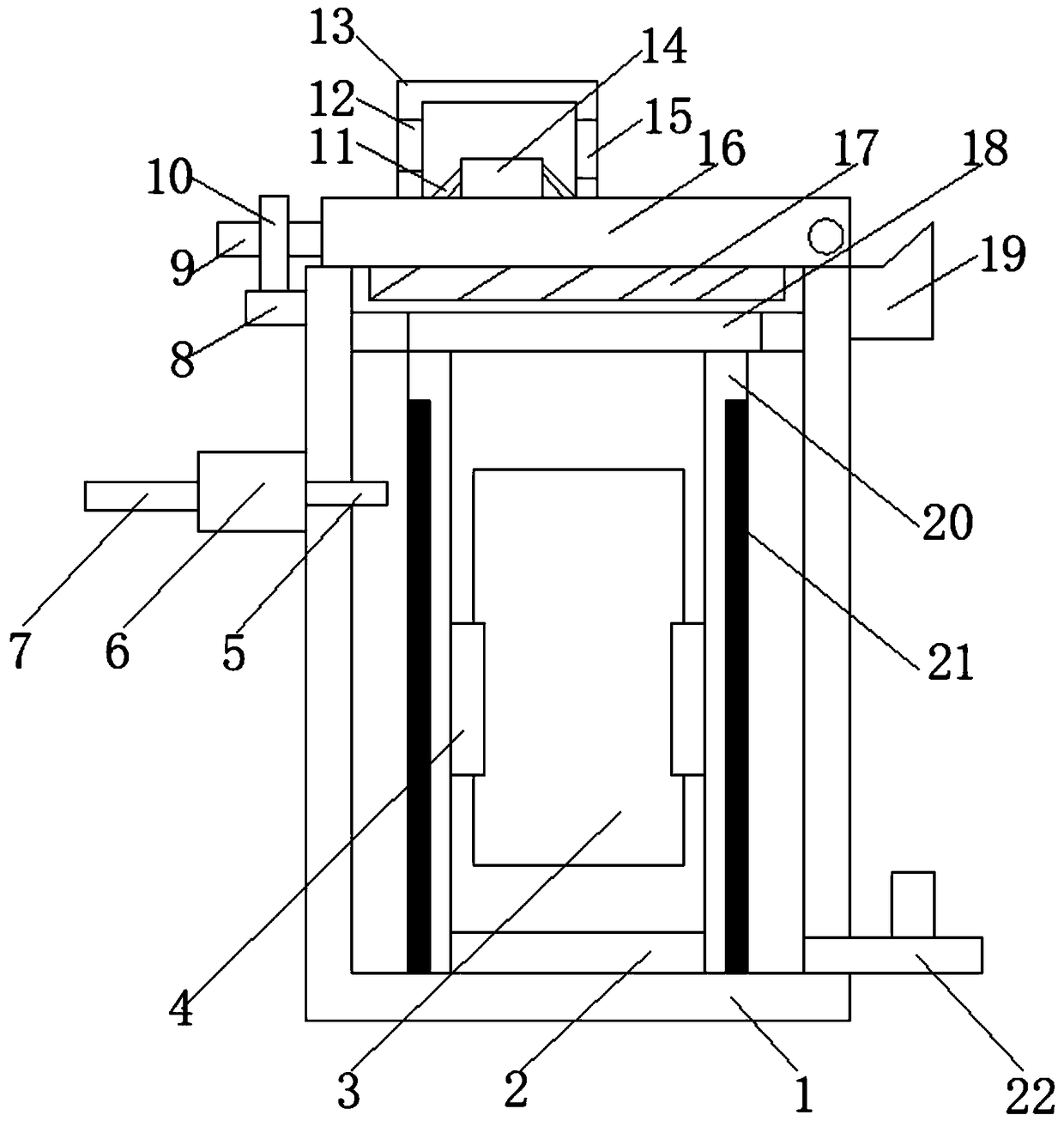

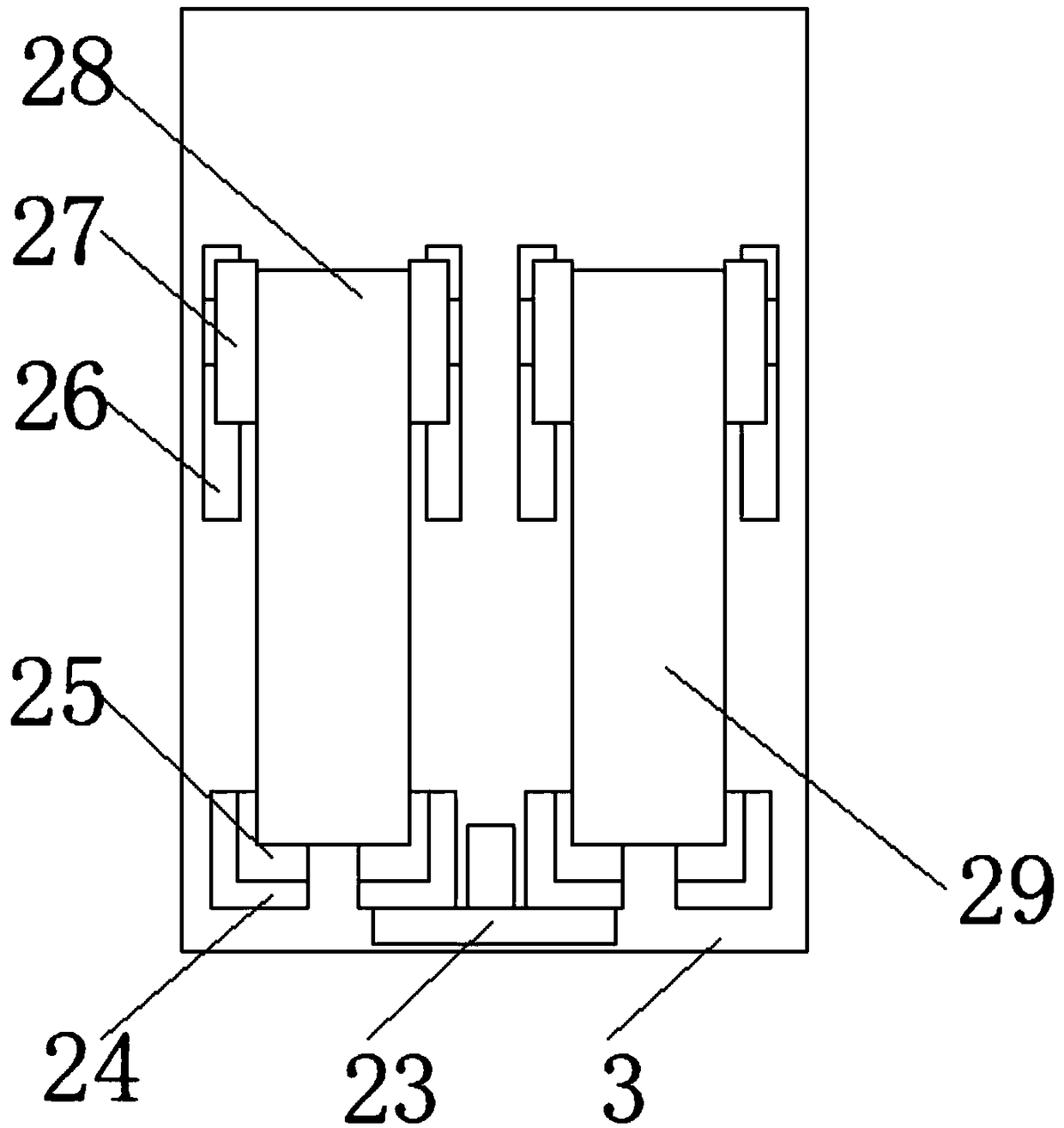

Automatic blanking device of hardware stamping die

ActiveCN112517781AAvoid drop damagePlug the gapMetal-working feeding devicesPositioning devicesSuction forceAir pump

The invention discloses an automatic blanking device of a hardware stamping die, and relates to the technical field of hardware manufacturing. The automatic blanking device of the hardware stamping die comprises an automatic feeding and discharging mechanism, a stamping head and a stamping table, wherein the bottom of the stamping head is provided with the upper surface of the stamping table; thefront end of the upper surface of the stamping table is provided with the rear end of the automatic feeding and discharging mechanism; and the lower surface of the stamping head is provided with a rear end for automatic feeding and discharging. According to the automatic blanking device of the hardware stamping die provided by the invention, by combining a silicone rubber suction bottom, a sand storage part and an air pump, fine sand in the sand storage part is sucked into a pneumatic cavity of the silicone rubber suction bottom through suction force, the fine sand is tightly stacked on the surface of a stamping part through downward pressure and air pressure extrusion, and a gap between the silicone rubber suction bottom and the surface of the stamping part is blocked; and negative pressure is generated in a sealed adsorption cavity after air is pumped out, and the silicone rubber suction bottom and the surface of the stamping part are tightly adsorbed due to the air pressure effect,so that the problem that the stamping part with the frosted surface or the uneven stamping part falls off and is damaged in the sucker transportation process is solved.

Owner:潍坊同鸣电子有限公司

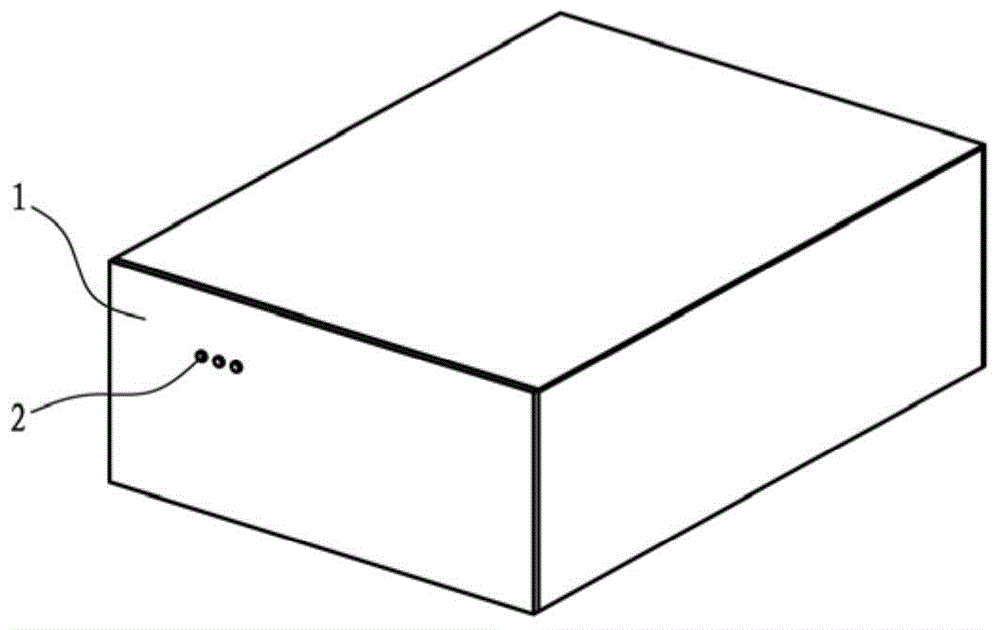

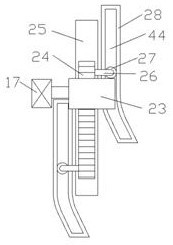

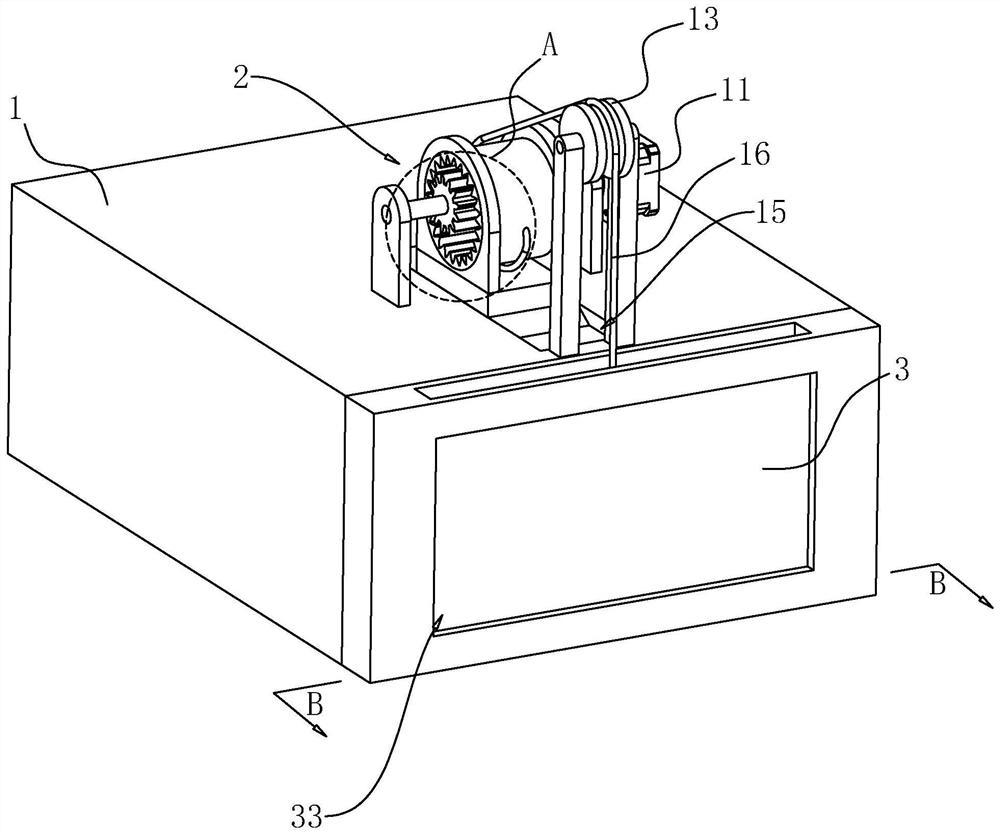

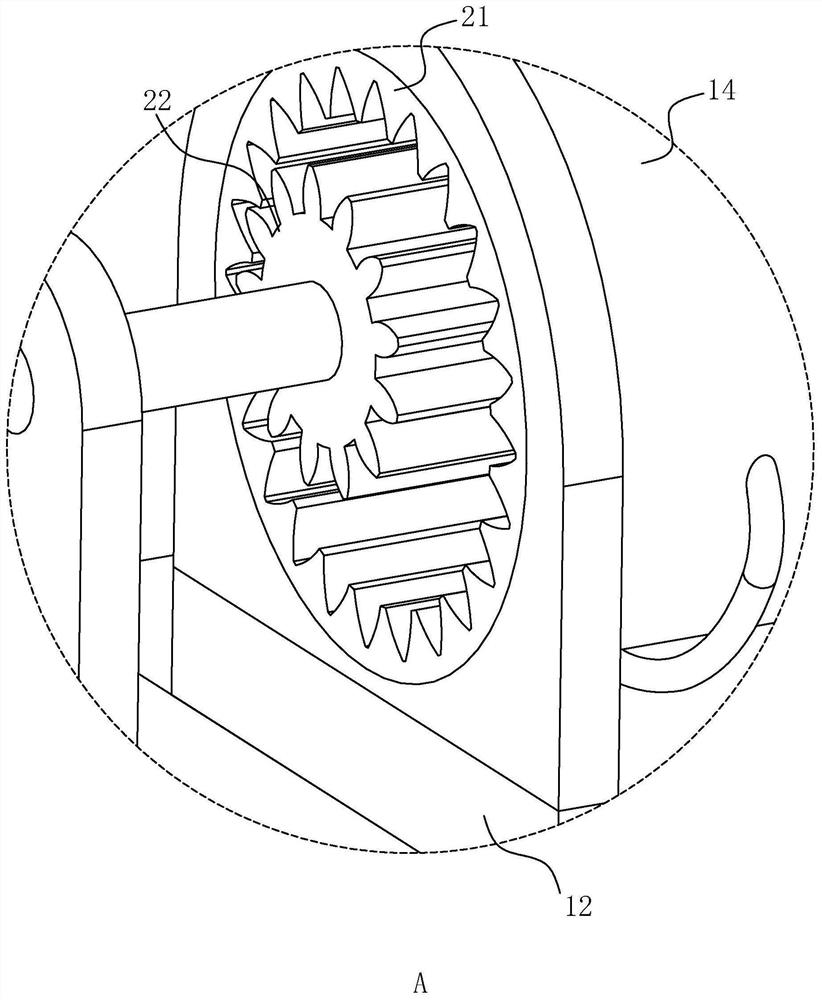

Flood-proof parking garage device with car washing function

InactiveCN111910973AEasy to rotateSimple device structureSewerage structuresCleaning apparatus for vehicle exteriorsRatchetWheelbase

The invention discloses a flood-proof parking garage device with a car washing function. The flood-proof parking garage device comprises a box body, a cavity is formed in the box body, a vertical plate is fixed to the inner wall of the upper side of the cavity, a sliding shaft is fixed between the left side of the vertical plate and the inner wall of the left side of the cavity, the sliding shaftis slidably connected with a main box, and a main cavity is formed in the main box. The device sprays water and a cleaning agent alternatively according to the steering controllability of a ratchet wheel, cleaning can be conducted more effectively, meanwhile, the device can adapt to vehicles with different axle distances, wheels can be rotated and cleaned conveniently, the conditions of the wheelscan be checked conveniently, an inflation pipe is arranged in a movable door of the device, and air inflation can be conducted to block gaps under the condition of water swelling, so that the deviceis prevented from being flooded, and the whole device is simple in structure, and maintenance of an automobile is facilitated.

Owner:宁波奉化木项洗涤科技有限公司

Gas separation device for geothermal energy recharge well

ActiveCN112624460AGuaranteed utilizationAvoid affecting the recharge effectWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsThermodynamicsEngineering

The invention discloses a gas separation device for a for geothermal energy recharge well, which comprises a negative pressure pump and a sealed shell, wherein an exhaust hole communicated with the inside and the outside of the sealed shell is formed in the upper side of the sealed shell, the exhaust hole is communicated with a gas inlet of the negative pressure pump, a water inlet hole and a water outlet hole communicated with the inside and the outside of the sealed shell are formed in the lower side of the sealed shell, the outer side of the water inlet hole is connected with the upper end of a water inlet pipe, the outer side of the water outlet hole is connected with the upper end of a drain pipe, and the height difference between the drain pipe and the sealed shell is greater than 10 m. The gas separation device for the geothermal energy recharge well is used for carrying out negative pressure gas separation treatment on the recharge water, the situation that the recharge effect is influenced due to gas phase blockage caused by air in the recharge water is avoided, and the heat utilization rate of a heat energy area is guaranteed.

Owner:中石化新星双良地热能热电有限公司

Environment-friendly pervious concrete and preparation method thereof

InactiveCN111925170AWide variety of sourcesEasy to prepareCeramicwareMicrosphereAcetic acid ammonium salt

The invention discloses environment-friendly pervious concrete. The environment-friendly pervious concrete is characterized in that the environment-friendly pervious concrete comprises the following components in parts by weight: 20-30 parts of cement, 0.5 to 1.5 parts of aluminum oxide nanotubes, 2 to 5 parts of N-(trimethoxysilyl propyl) ethylenediamine triacetic acid ammonium salt modified nanoaluminum powder, 60 to 70 parts of rough aggregate, 0.5 to 1.5 parts of nano porous hollow cage-shaped titanium oxide, 1 to 2 parts of porous polysaccharide microspheres, 0.1 to 0.4 part of sodium sulfonate-based hyperbranched poly (amine-ester) and 20 to 30 parts of water. The invention further discloses a preparation method of the environment-friendly pervious concrete. The environment-friendlypervious concrete disclosed by the invention is excellent in mechanical property, good in fatigue resistance and water permeability, good in comprehensive performance, wear resistance and durability,and safe and environment-friendly to use.

Owner:韩昌龙

Correction fluid preparation method

The invention discloses a correction fluid preparation method and belongs to the field of office supplies. The correction fluid preparation method disclosed by the invention comprises the steps: mixing styrene, butyl acrylate, methyl methacrylate and acrylic acid, adding sodium dodecyl sulphate, octyl phenol polyoxyethylene ether, sodium bicarbonate, a polyvinyl alcohol solution and distilled water, pre-emulsifying, warming, adding an initiator and cooling to room temperature to obtain an emulsion; mixing and stirring a titanate coupling agent and acetone, adding isopropyl alcohol, evenly stirring, adding nano zinc oxide, stirring, performing suction filtration to obtain filter cake and drying the filter cake to obtain a dried material; mixing and ball milling the dried material, titaniumdioxide and a surface active agent, mixing and stirring a ball milled material, deionized water and a dispersing agent and ultrasonically dispersing; adding dispersion liquid into water bath, stirring, inflating nitrogen to achieve a protection effect, heating, dropwise adding emulsion and warming and keeping warm to obtain a thermal-insulation emulsion; heating the thermal-insulation emulsion, adding an adhesive, evenly stirring and mixing, then adding glycerol, stirring, cooling to room temperature and filling into a ball milling machine to be ball milled to obtain the correction fluid.

Owner:徐冬

Petroleum refining filtering device convenient for replacement

ActiveCN108619798AEasy to replaceEasy to assemble and disassembleDispersed particle filtrationTransportation and packagingActivated carbon filtrationPetroleum engineering

The invention provides a petroleum refining filtering device convenient for replacement, and relates to the field of petroleum refining. The petroleum refining filtering device convenient for replacement comprises a base, wherein a machine body is fixedly connected to the top of the base; a storage box is fixedly connected to the top of the base and on the left side of the machine body; the storage box comprises a box body; a partition board is fixedly connected into the box body; supporting plates are fixedly connected to the left side of the partition board; storage trays are fixedly connected to the tops of the supporting plates; supporting sleeves are fixedly connected to the tops of storage trays. According to the petroleum refining filtering device convenient for replacement, throughthe arrangement of a filtering device body, a threaded section and a connecting pipe and threaded connection of a connecting sleeve and the threaded section, the filtering device body is convenient to detach and mount, and the mounting and the demounting of fans on mounting plates are facilitated; due to unified arrangement of multiple layers of filtering components, the overall replacement is facilitated; a butting unit guide is easy to fail so an activated carbon filter rod is required to be replaced in time, through the separated arrangement of a filter structure, independent replacement can be performed, and replacement by personnel is convenient.

Owner:DONGYING LIANHE PETROCHEMICAL CO LTD

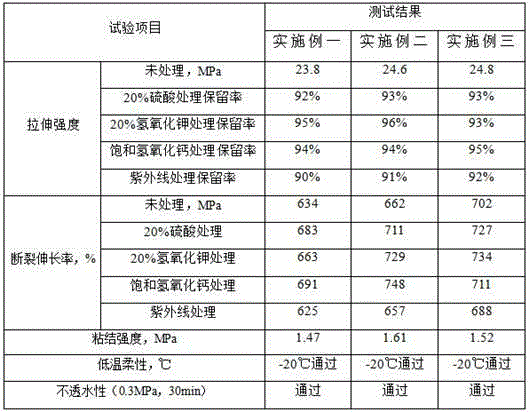

A kind of transparent water-based waterproof paint for building and preparation method thereof

ActiveCN103614063BThe composition formula is reasonableSimilar refractive indexPolyurea/polyurethane coatingsWater basedUltraviolet

The invention discloses a transparent waterborne waterproof coating for a building and a preparation method thereof. The transparent waterborne waterproof coating comprises the following components in percentage by mass: 70-80% of water soluble high polymer material, 0.8-1.6% of coalescing agent, 0.8-1.6% of accelerant, 0.5-1.0% of nano material, 0.02-0.06% of penetrating agent, 0.3-0.8% of ultraviolet absorbent, 0.5-1.2% of thickening agent, 0.1-0.3% of defoaming agent and the balance of water. The coating disclosed by the invention is pollution resistant, good in weather fastness, excellent in physical and mechanical properties, acid and alkali resistance and waterproof performance, and good in transparency, and the coating does not cover the bottom, so that the coating can maintain the appearance and feature of the building when in use; and meanwhile, the coating is simple to prepare, environment-friendly, free of pollution and convenient to use and can be both spray coated and crush coated, so that the coating can be widely applied to water resistance of building periphery or exterior wall so as to provide long-term waterproof protection for the building.

Owner:苏州市姑苏新型建材有限公司

Antibacterial and low-toxin modified corn starch powdery adhesive

InactiveCN107815271AEasy to buyLow commercial priceNon-macromolecular adhesive additivesStarch adhesivesSodium acetateAdhesive

An antibacterial and low-toxic modified corn starch powdery adhesive, comprising the following components in parts by weight: 120-140 parts of corn starch, 6-10 parts of montmorillonite, 20-30 parts of casein, 22 parts of sodium acetate ‑24 parts, 3‑5 parts of hydrochloric acid, 7‑9 parts of crosslinking agent, 1‑3 parts of coupling agent, 7‑9 parts of defoaming agent, 25‑35 parts of composite preservative, 13‑17 parts of antibacterial agent, urea 18-22 parts, 17-25 parts of cetyltrimethylammonium bromide; the present invention also discloses a preparation method of an antibacterial and low-toxic modified corn starch powdery adhesive: first corn starch, compound Preservatives and organically modified montmorillonite are mixed evenly, then urea and casein are added for heating reaction to obtain mixture B, then dispersant, coupling agent and defoamer are added to obtain jelly C, and finally spray drying and centrifugation are carried out. Obtain powdery kudzu root starch adhesive. The invention has the characteristics of high bonding strength, water resistance, antibacterial, long environmental protection storage period, etc., effectively reduces the harm to the environment, reduces the production cost, and improves the production benefit of the enterprise.

Owner:李琛璞

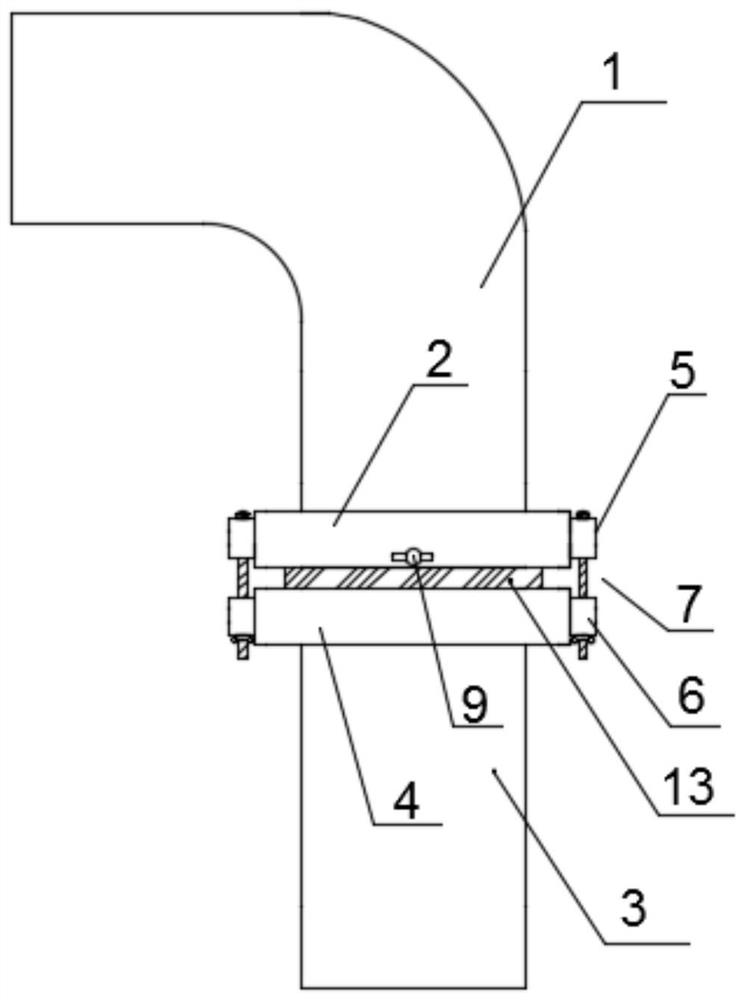

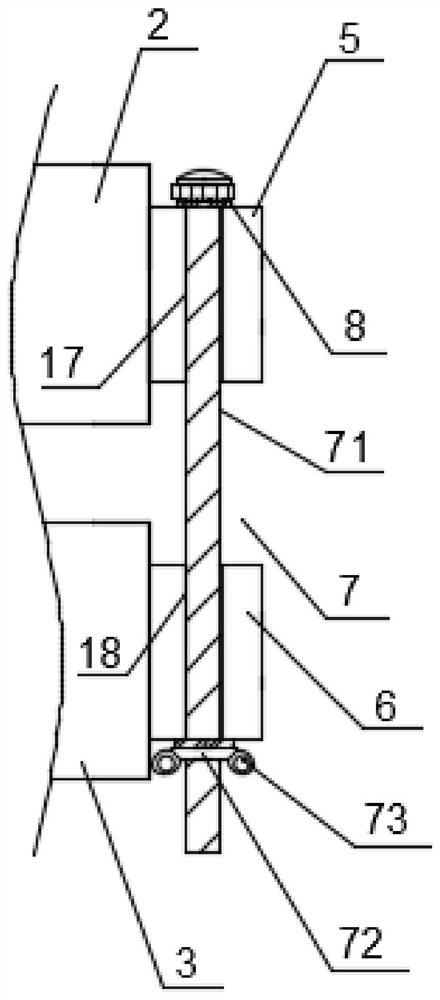

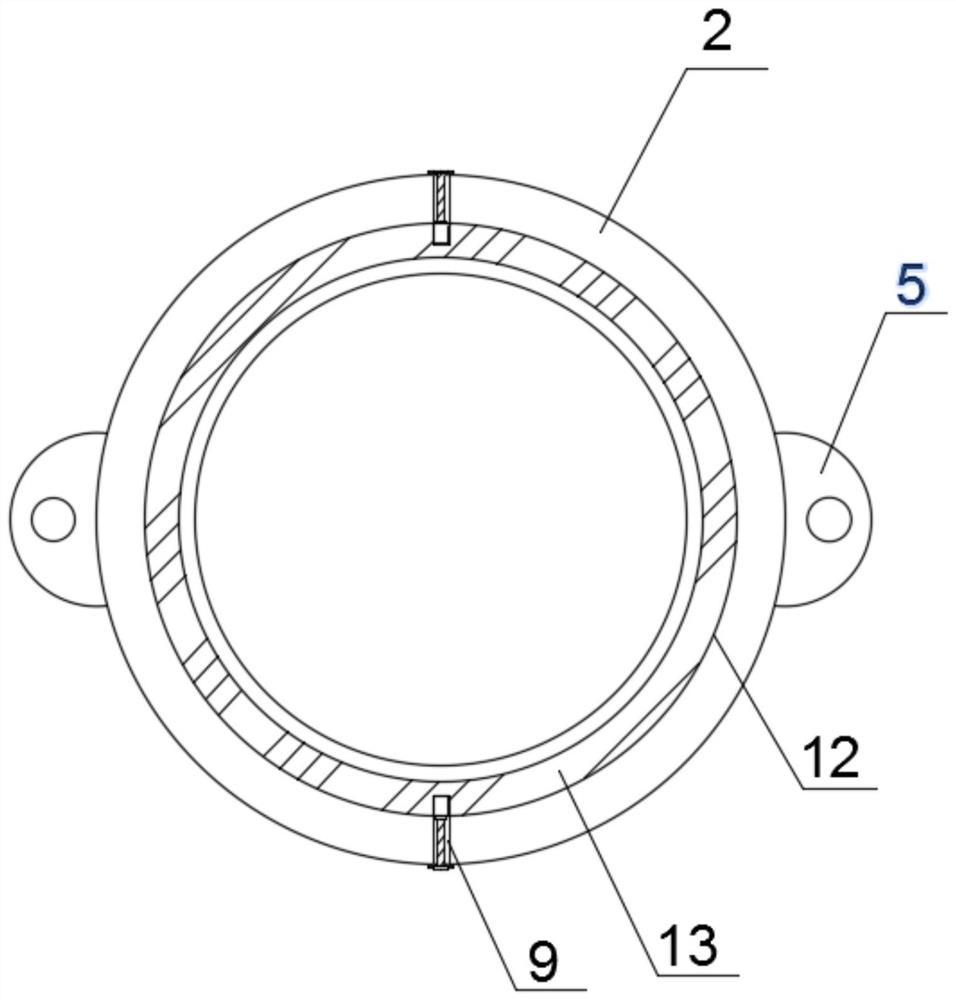

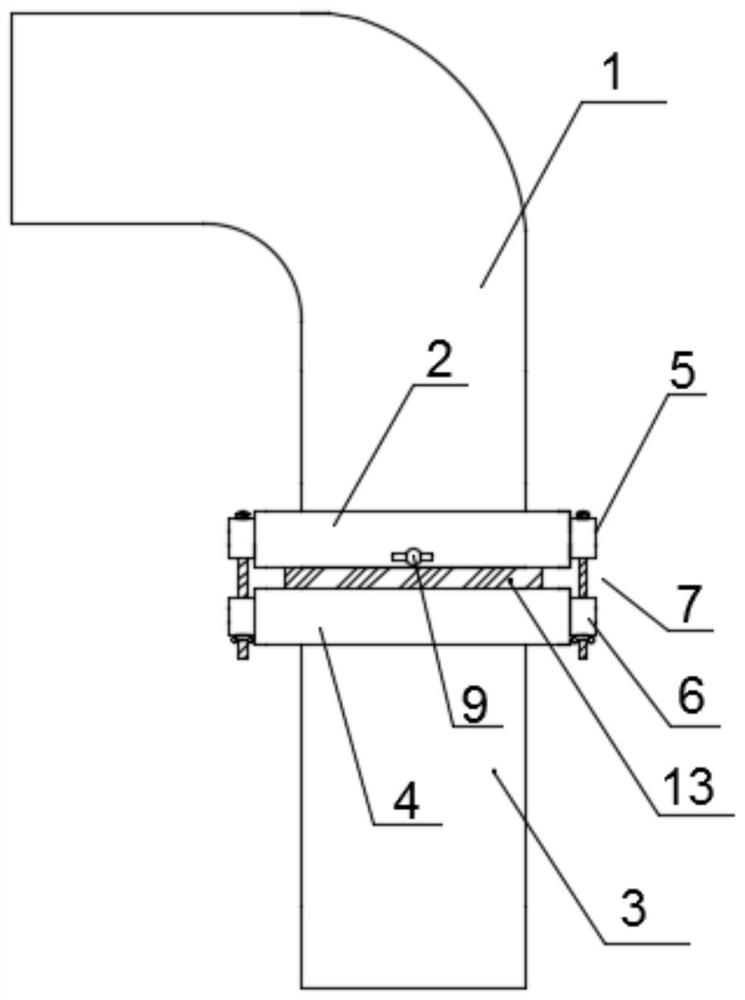

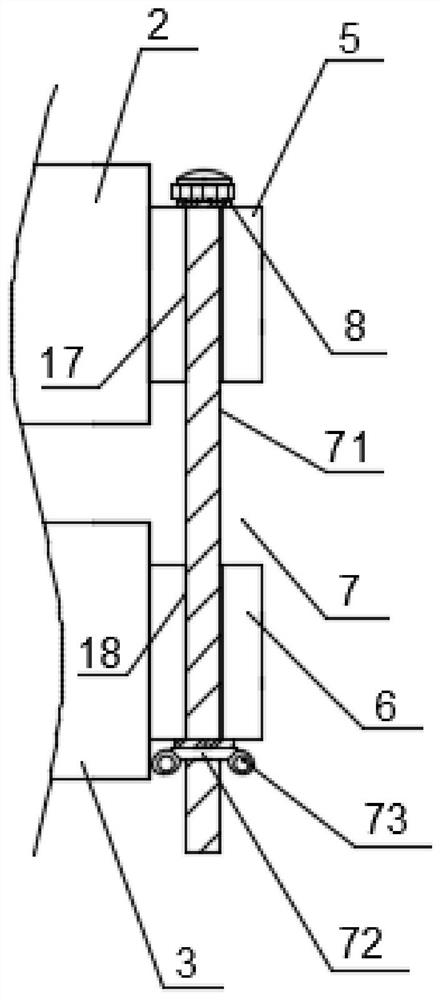

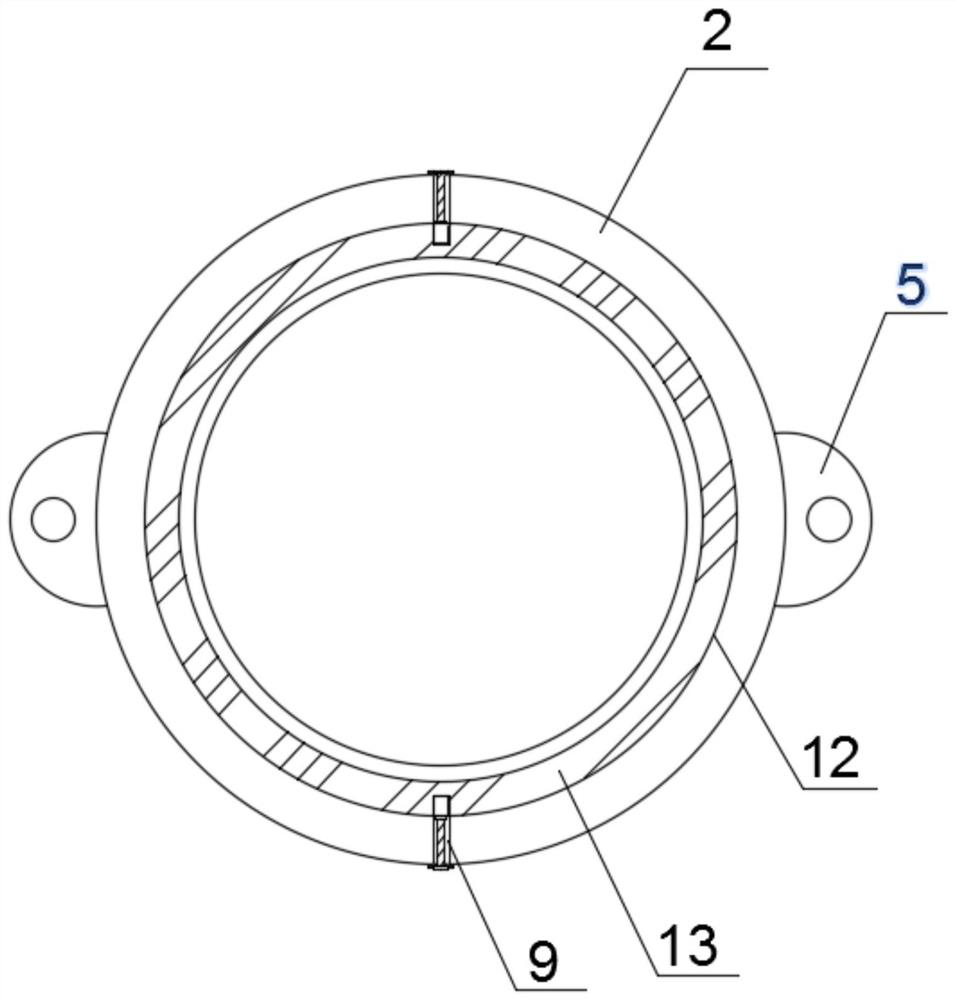

Loading arm pipeline connecting structure convenient to disassemble and assemble

The invention discloses a loading arm pipeline connecting structure convenient to disassemble and assemble. The loading arm pipeline connecting structure comprises a bent pipe, wherein a first connecting flange is welded to one end of the bent pipe; a vertical pipe is connected to the lower end of the bent pipe; a second connecting flange is welded to one end, opposite to the bent pipe, of the vertical pipe; first side blocks are fixedly connected to two sides of the first connecting flange; second side blocks are fixedly connected to two sides of the second connecting flange; and limiting mechanisms are connected between the first side blocks and the second side blocks which are opposite in pairs, and the limiting mechanisms comprise bolts. The loading arm pipeline connecting structure has the beneficial effects that through the arrangement of the limiting mechanisms, the bolts of the limiting mechanisms are twisted between the first side blocks and the second side blocks, by holding limiting rings of adjusting nuts, due to the fact that the middles of the limiting rings are of a hollow structure, fingers can conveniently stretch into the limiting rings to hold the limiting rings, the adjusting nuts are twisted to be in threaded connection with the corresponding bolts, so that installation can be completed by fixing the first connecting flange and the second connecting flange, a special tool is not needed, and the loading arm pipeline connecting structure is very convenient.

Owner:连云港华鑫石化机械设备有限公司

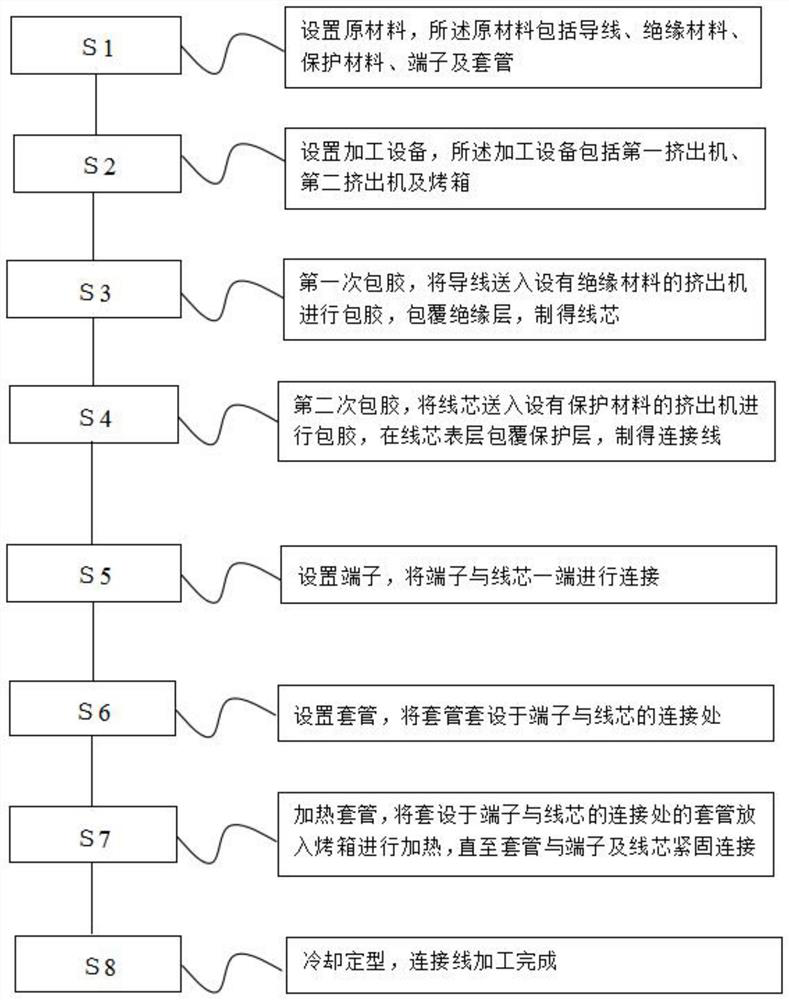

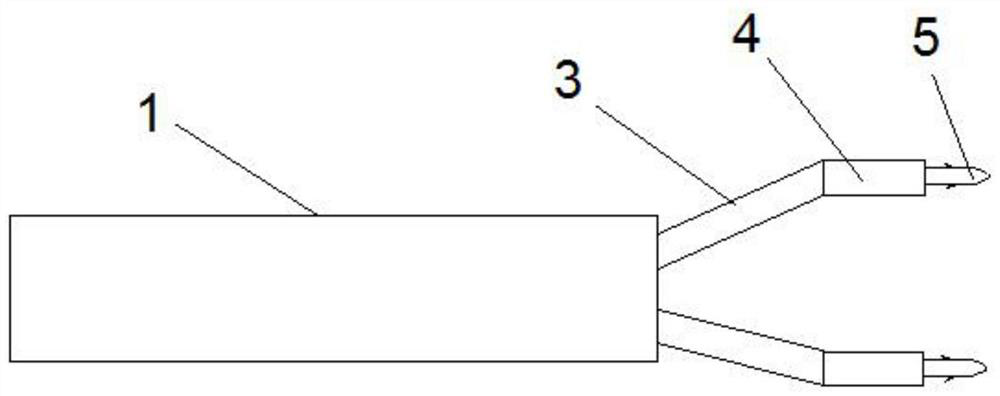

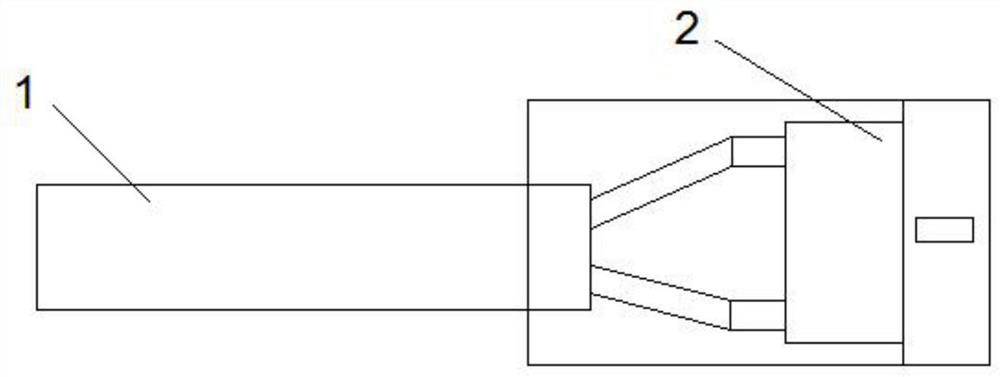

Connecting line processing method and connecting line

PendingCN114079214AImprove connection stabilityReduce lossContact member assembly/disassemblyInsulated cablesManufactured materialProcess engineering

The invention discloses a connecting line processing method and a connecting line. The connecting line processing method comprises the following steps: S1, setting raw materials; S2, arranging machining equipment; S3, conducting first rubber coating, namely feeding a wire into an extruder provided with an insulating material for rubber coating to prepare a wire core; S4, conducting secondary rubber coating, namely feeding the wire core into an extruder provided with a protective material for rubber coating to prepare a connecting wire; S5, arranging a terminal, and connecting the terminal with one end of the wire core; S6, arranging a sleeve, and arranging the sleeve at the joint of the terminal and the wire core in a sleeving mode; S7, heating the sleeve, and putting the sleeve arranged at the joint of the terminal and the wire core in a sleeving mode into an oven for heating; and S8, conducting cooling and shaping. The sleeve is arranged at the joint of the terminal and the wire core, the sleeve is tightly connected with the terminal and the wire core through heating, a gap in the shell is blocked, the situation of glue flushing in the forming process is prevented, the reject ratio is reduced, the loss of raw materials is reduced, and the processing efficiency is improved.

Owner:DONGGUAN SHUNHUI ELECTRONICS

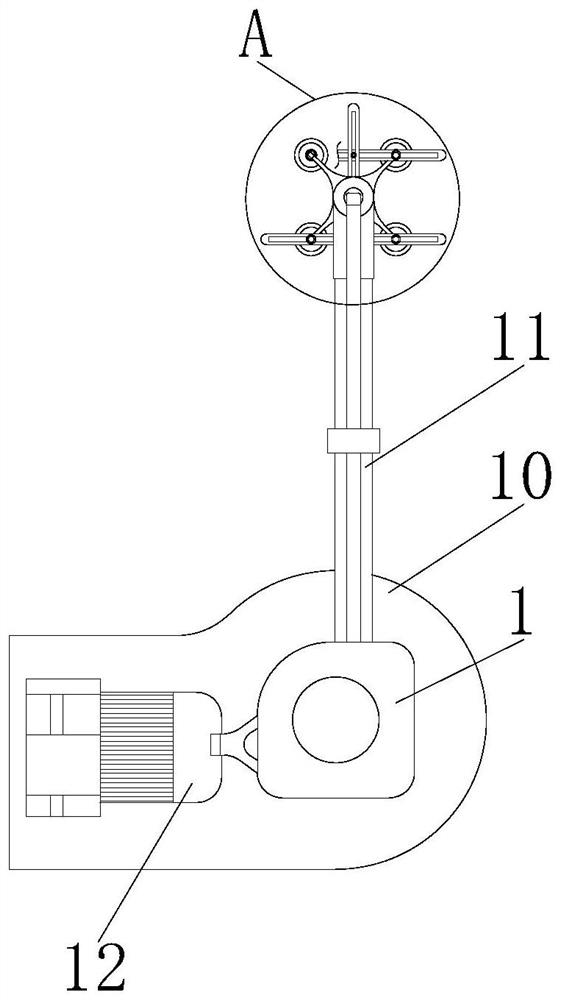

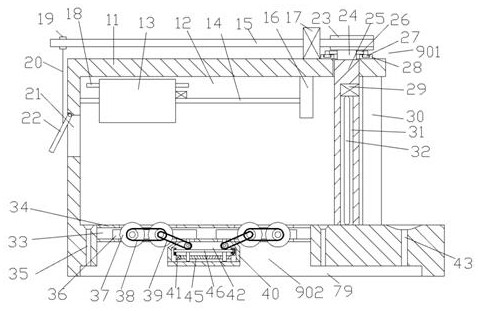

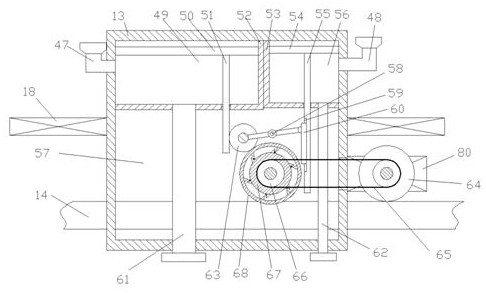

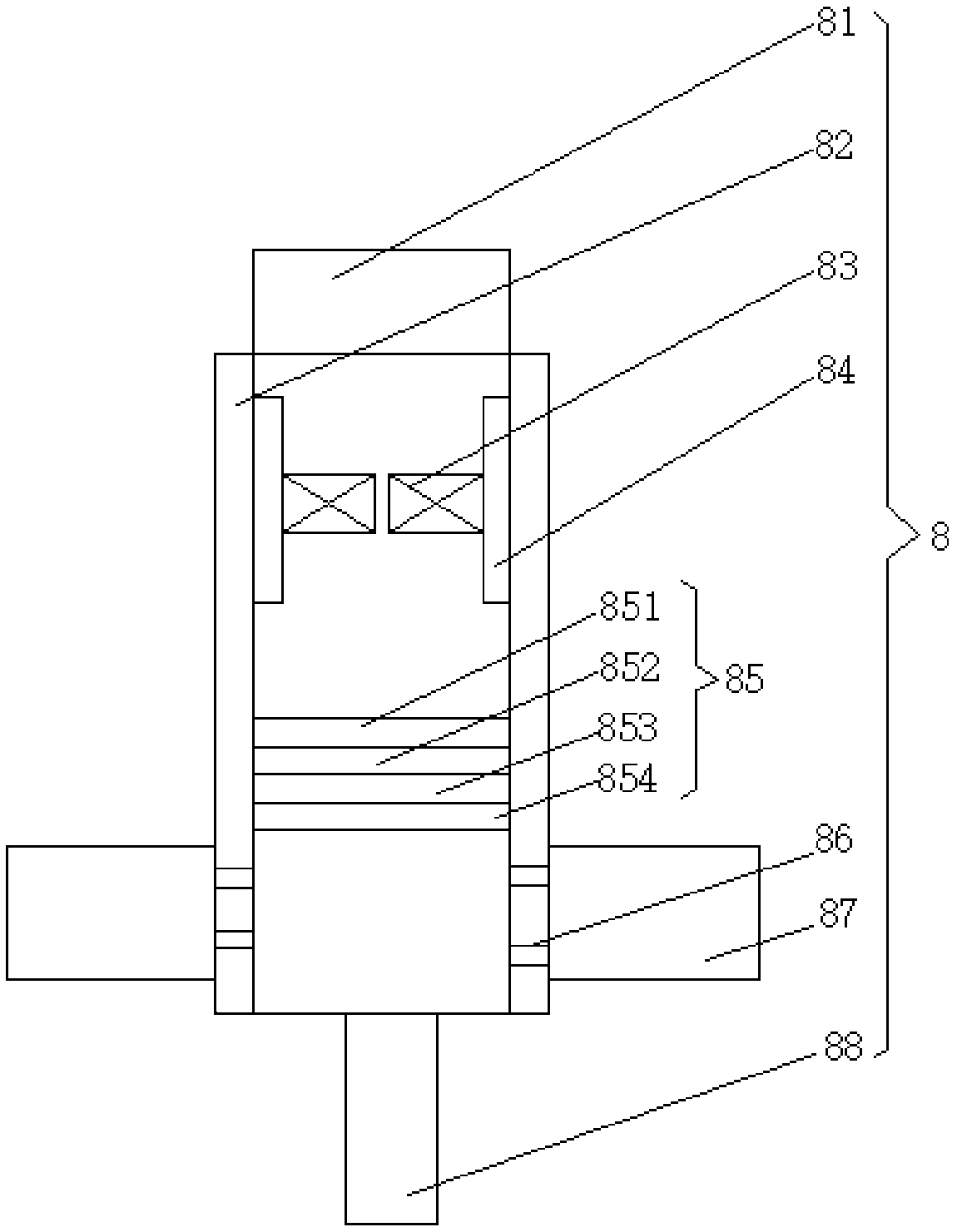

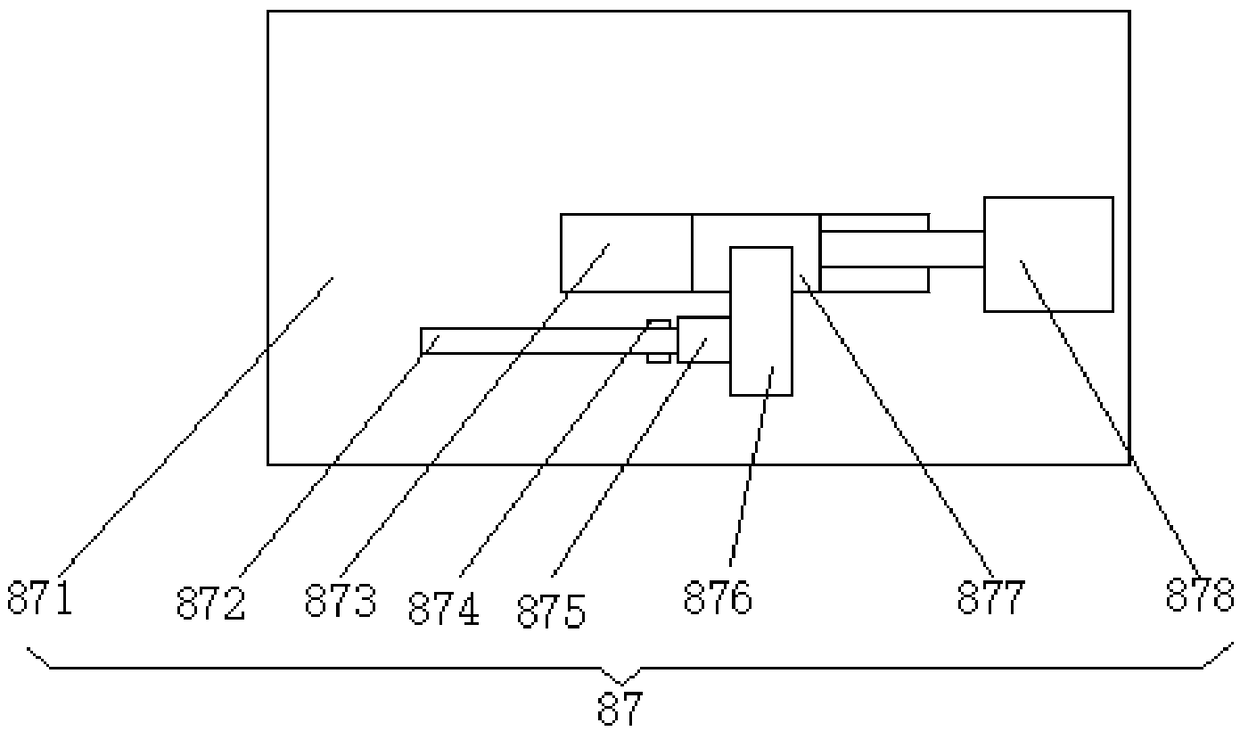

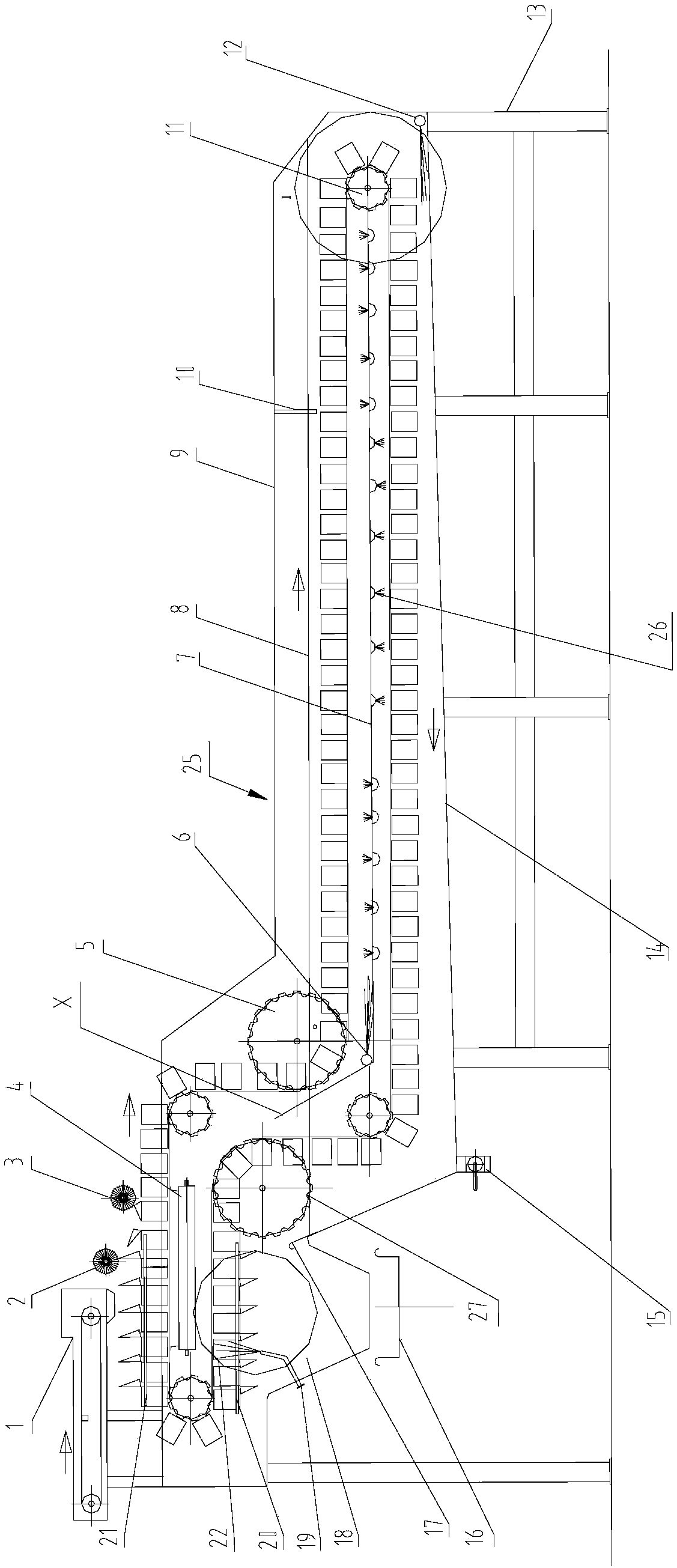

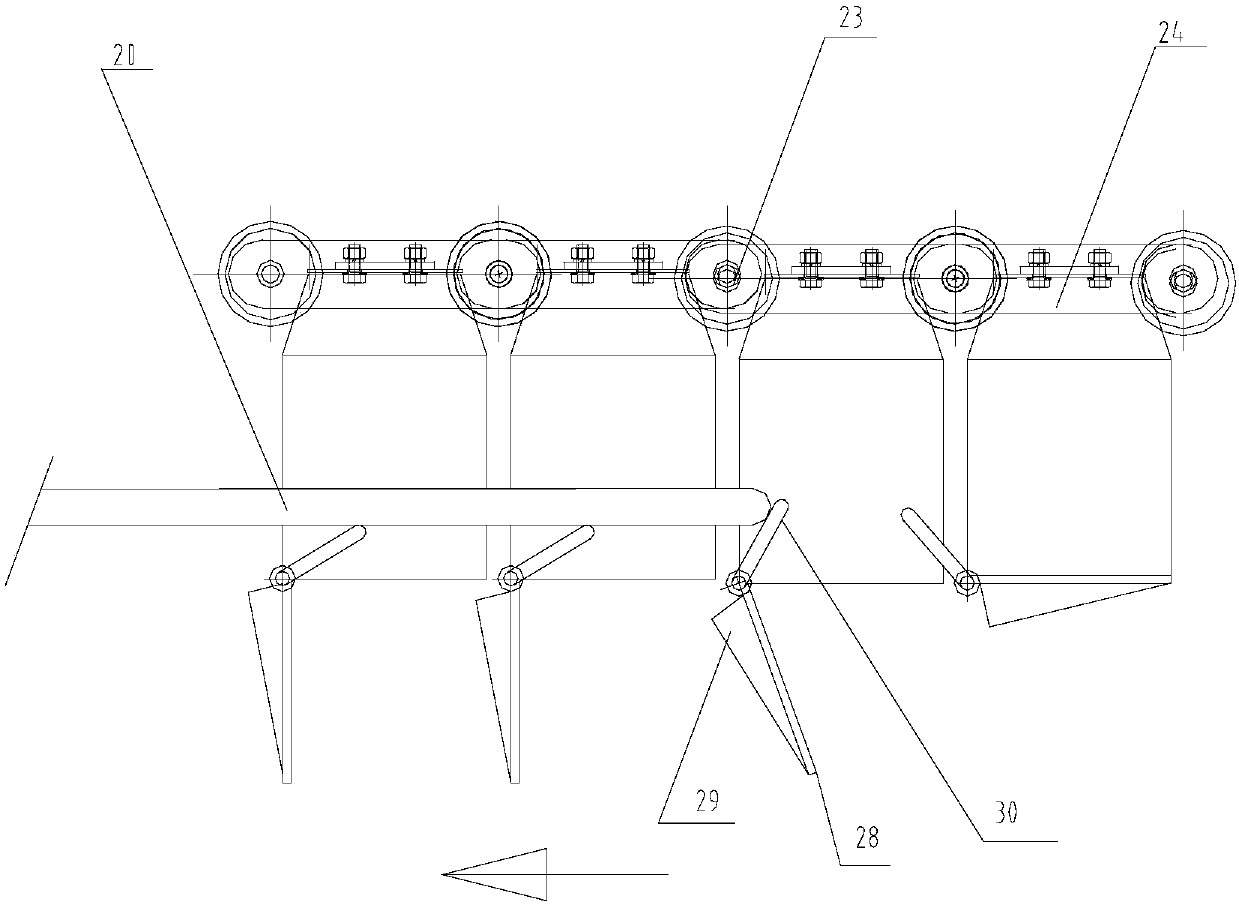

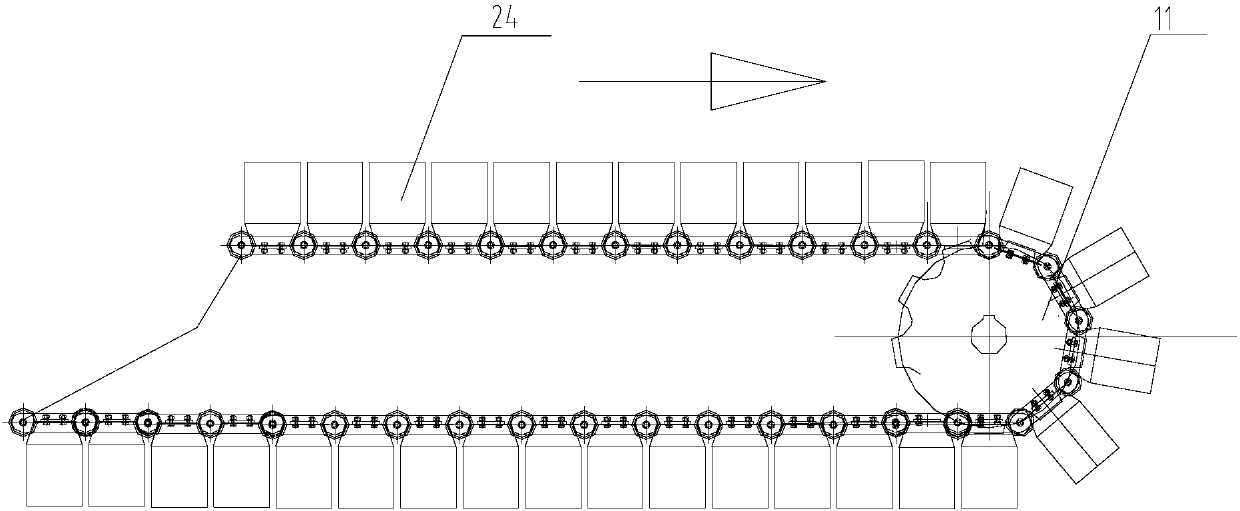

Soaking extraction processing equipment and soaking extraction processing method

ActiveCN106235381BImprove the level of homogenization and soaking extractionAvoid breakingTobacco treatmentSolution crystallizationEngineeringMechanical engineering

The invention provides a soaking extracting processing device and a soaking extracting processing method. The soaking extracting processing device comprises a machine frame. A feeding device, a discharging device and a box are installed on the machine frame, an annular conveying device is installed in the box, and a plurality of water-permeable soaking boxes are installed on the annular conveying device; the annular conveying device comprises a feeding end and a discharging end, the feeding end corresponds to the feeding device, and the discharging end corresponds to the discharging device; the feeding end and the discharging end of the annular conveying device are located at the upper portion of the liquid level of the box; a water adding device is also arranged in the box. According to the soaking extracting processing device and the soaking extracting processing method, under the condition that breaking and waste of tobacco materials are reduced, soluble substances in the tobacco materials can be evenly and efficiently soaked and extracted, and the good basis is established for processing of the follow-up tobacco materials.

Owner:ZHISI HLDG GRP

Asphalt concrete prefabricated part based on solid waste material and preparation method of asphalt concrete prefabricated part

ActiveCN113998923AIncrease profitReduce the area occupied by cultivated landSolid waste managementProcess engineeringPavement milling

The invention belongs to the field of recycling of renewable resources (road engineering), and particularly relates to an asphalt concrete prefabricated part based on a solid waste material and a preparation method of the asphalt concrete prefabricated part. According to the invention, after the waste pavement reclaimed material and the waste plastic powder are mixed according to a certain proportion, microwave heating is carried out to prepare the asphalt concrete prefabricated part, so that 100% utilization of the pavement milling material is realized, the waste fine material with high asphalt content is fully utilized, the use amount of new asphalt is saved, and the production cost is greatly reduced; the microwave heating mode is adopted, compared with the traditional heating mode, the microwave heating mode has the advantages that the heating speed of the mixture is high, the secondary aging of the new and old asphalt is reduced, the softening and melting effects of the heated waste plastic powder can be improved, the heating uniformity is good, and the curing effect is prevented from being influenced by non-uniform heating of the waste materials. The emulsified asphalt slurry seal mixture is used for carrying out surface treatment on the prefabricated part, so that the water resistance and corrosion resistance of the prefabricated part can be improved, and meanwhile, the mechanical property of the prefabricated part is also improved.

Owner:山东高速工程咨询集团有限公司 +1

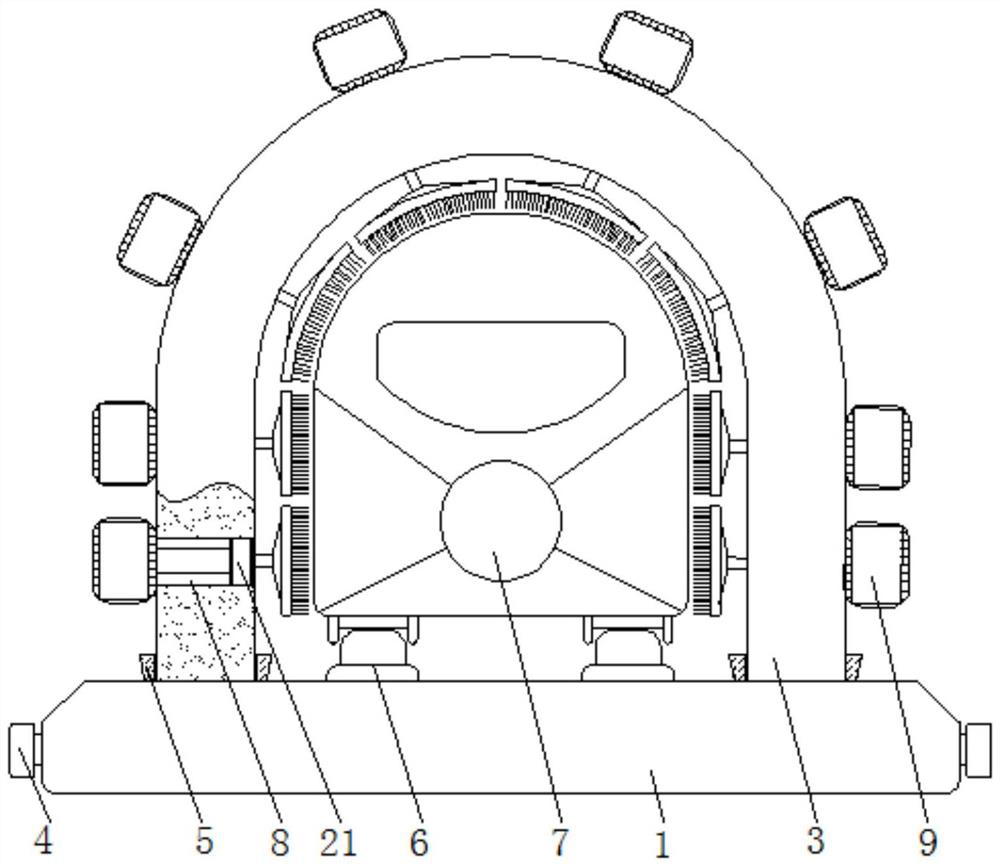

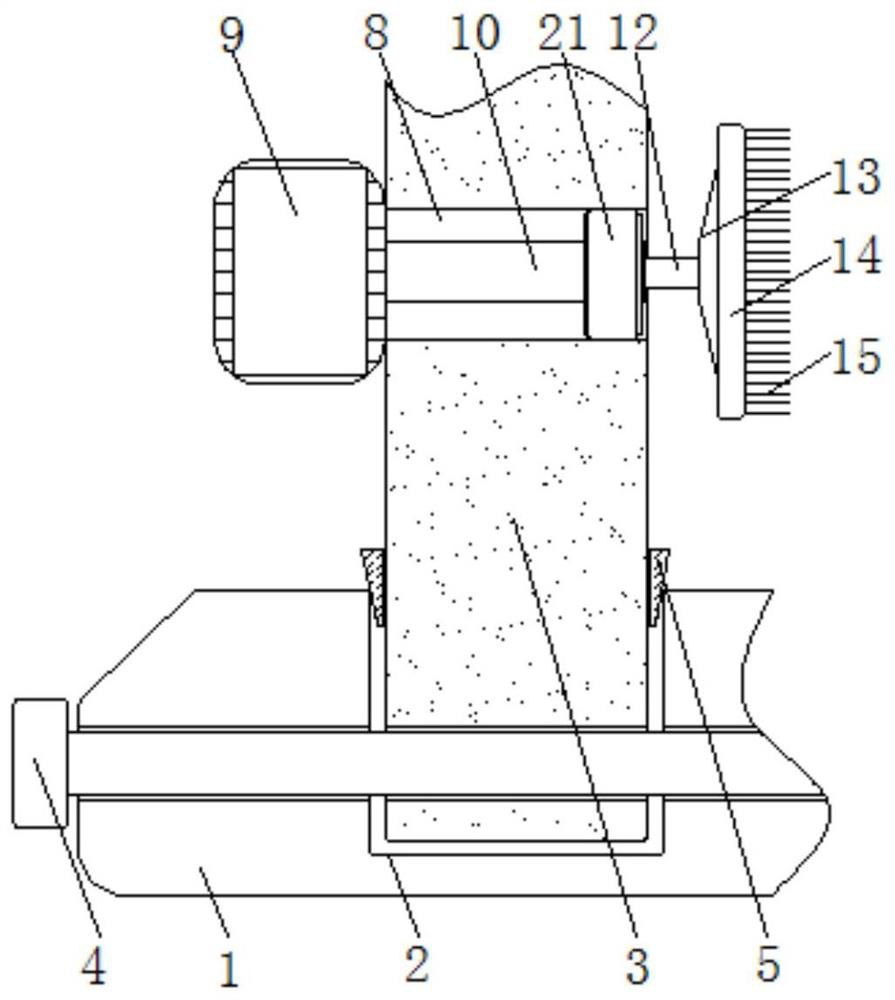

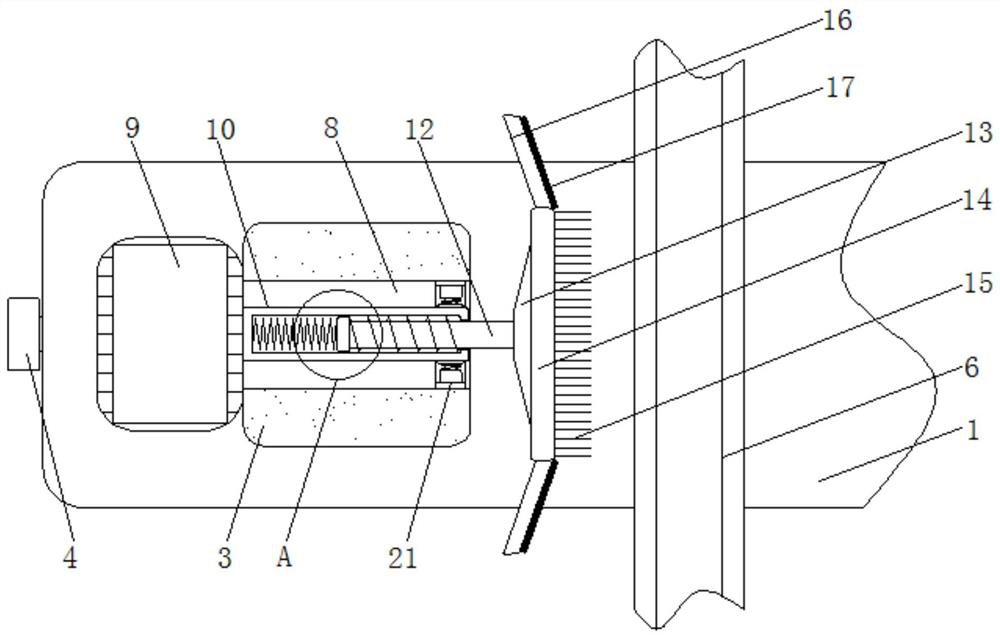

Control method of vehicle cleaning device for rail transit

InactiveCN112519722AAvoid scratchesEasy to cleanCleaning apparatus for railwaysCleaning apparatus for vehicle exteriorsBristleElectric machinery

The invention relates to the technical field of rail transit vehicle cleaning, and discloses a control method of a vehicle cleaning device for rail transit. The vehicle cleaning device comprises a foundation, square grooves are formed in the two sides of the top of the foundation, a cleaning arch is arranged between the interiors of the two square grooves, and square rods are arranged on the two sides of the foundation in a penetrating mode; and wedging blocks are arranged on the inner side and the outer side of the cleaning arch and located at the openings of the square grooves. The control method comprises the steps that when the rail transit vehicle passes through the cleaning arch, eight vibration motors are started to drive a fixing plate and cleaning bristles to vibrate, dust and attachments on the outer surface of the rail transit vehicle can be washed and brushed, a telescopic rod and a limiting plate are arranged in a vibrating shaft, then the cleaning brush bristles are matched with a first opening spring and a second pushing spring for use, the cleaning brush bristles can be tightly close to the outer surface of the rail transit vehicle, formation of redundant gaps is reduced, and the outer surface of the rail transit vehicle is effectively cleaned and maintained.

Owner:周丽英

A crane tube pipe connection structure that is easy to disassemble

The invention discloses a crane tube pipe connection structure which is easy to assemble and disassemble. For the second connecting flange, first side blocks are fixedly connected to both sides of the first connecting flange, and second side blocks are fixedly connected to both sides of the second connecting flange. The blocks are connected with a limit mechanism, and the limit mechanism includes bolts. The beneficial effects achieved by the present invention are: the present invention is provided with a limit mechanism, and the bolts of the limit mechanism are twisted into the space between the first side block and the second side block. , by holding the limit ring of the adjusting nut, because the middle part of the limit ring is hollow, it is convenient for fingers to reach in and hold the limit ring, and the adjusting nut is screwed to the bolt by twisting the adjusting nut, so that the first connecting flange and the second The two connecting flanges can be fixed to complete the installation without using special tools, which is very convenient.

Owner:连云港华鑫石化机械设备有限公司

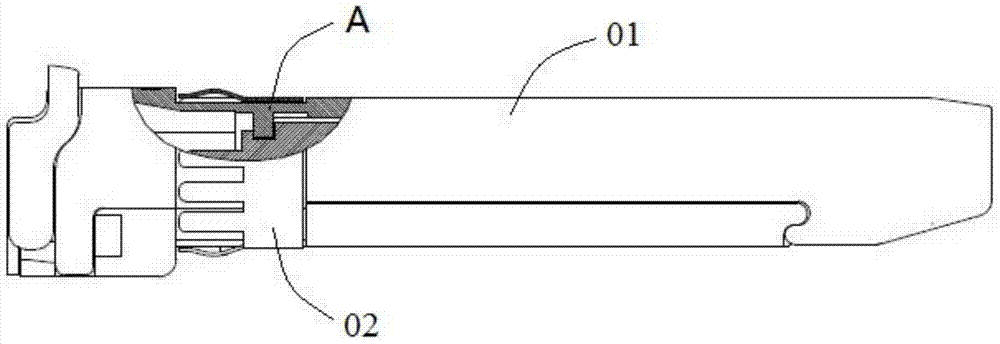

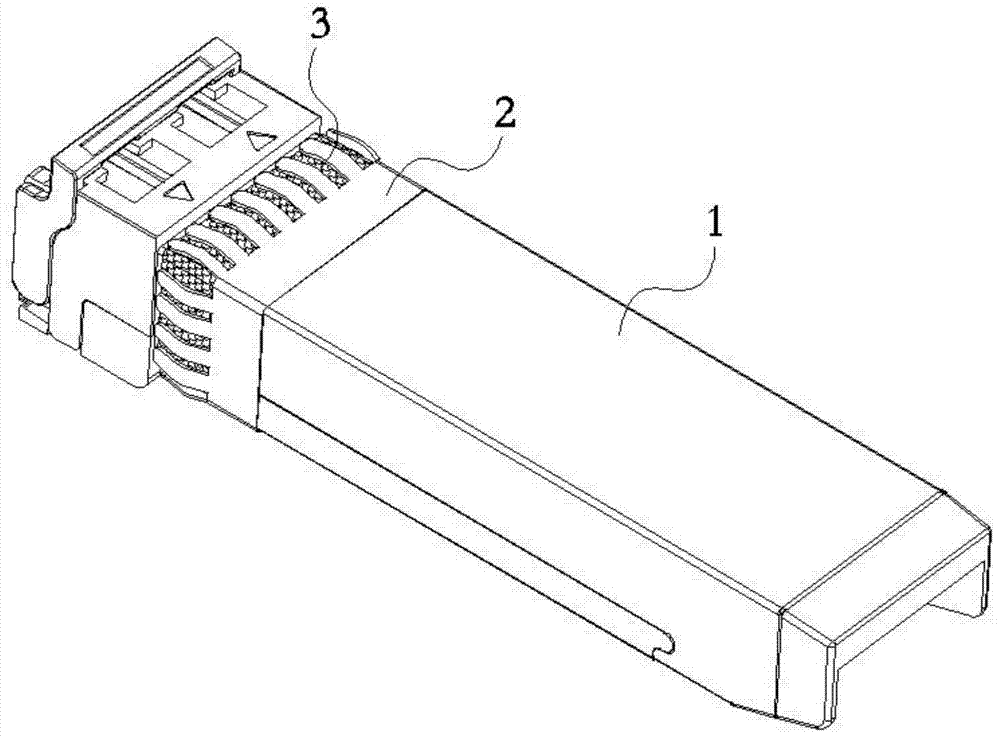

A pluggable optical module

ActiveCN105403964BPrevent leakageAvoid interferenceMagnetic/electric field screeningCoupling light guidesOptical ModuleComputer module

Owner:HISENSE BROADBAND MULTIMEDIA TECH

A single-piece non-heat-insulating fire-resistant glass-type smoke-shielding vertical wall

This application relates to a single-piece non-heat-insulating fire-resistant glass-type smoke-blocking vertical wall, which belongs to the technical field of smoke-blocking curtain walls. It includes a wall seat and a motor fixed on the top of the wall seat. The base is slidably connected through the sliding groove; the top of the base is rotatably connected with the drum; the side of the base away from the reversing wheel is fixed with a return spring, and the side away from the base is fixedly connected with the wall seat through the sliding groove; There is a suspension rope around the outer circumference of the drum, and a smoke-stop vertical wall is fixed at the bottom of the suspension rope; a driving wheel is fixed at the output end of the motor, and a gear ring is fixed on the side of the drum close to the motor; the driving wheel is used to connect with the inner peripheral surface of the gear ring. engage. The present application has the effect of reducing the possibility of the spool idling.

Owner:安徽钟南消防科技有限公司

A kind of three-dimensional wrinkle warm liner air layer fabric and its preparation method

Owner:NINGBO DAQIAN TEXTILE

Ceramic coating for protecting electrode substrate against high temperature melt erosion and its preparing method

InactiveCN1218064CPrevent penetrationImprove bindingMolten spray coatingElectric discharge heatingCeramic coatingComposite ceramic

The ceramic coating is agglomerated composite ceramic powder coating made of zirconium silicate or high-purity zirconite powder, and there may be molybdenum silicide underlayer and intermediate transition layer of composite powder including zirconium silicate or high-purity zirconite powder and molybdenum silicide. Through thermal spraying process, high temperature melt erosion resisting coating with thickness smaller than 0.7 mm is prepared on the surface of electrode base made of molybdenum alloy or other high temperature alloy. The molybdenum electrode with the coating has high temperature pore self-sealing effect, and thus 3-4 times higher melt erosion resisting capacity and prolonged service life. The technological process is simple and low in cost and can produce coating with stable performance.

Owner:WUHAN UNIV OF TECH

Precision filter of water system for pharmacy

InactiveCN108751497APlug the gapEasy to observeTreatment involving filtrationWater/sewage treatment by ion-exchangePharmacyEngineering

The invention provides a precision filter of a water system for pharmacy, and relates to the field of water systems for pharmacy. The precision filter of the water system for pharmacy comprises a filter body, wherein the bottom part of the interior of the filter body is fixedly connected with a bottom plate; the interior of the filter body is fixedly connected with a fixed plate; a filtering net is clamped at the inner side of the fixed plate; an installation plate is arranged at the inner side of the filter body; the outer surface of the installation plate is provided with a sliding groove; asliding block is arranged in the sliding groove; the outer surface of the sliding block is fixedly connected with a jacket; the jacket is glidingly connected with the sliding groove through the sliding block. The precision filter of the water system for pharmacy has the advantage that by arranging the installation plate, multiple fixed seats, a first resin plate and a second resin plate, the fixed seat and the groove are used for supporting and clamping the first resin plate and the second resin plate to install, the jacket slides down along the sliding groove to clamp the first resin plate and the second resin plate in an assisting way, the installation plate is clamped and falls down, and the installation plate is clamped between a guide rod and a back plate of the filter body to fix.

Owner:江苏德佳机电科技有限公司

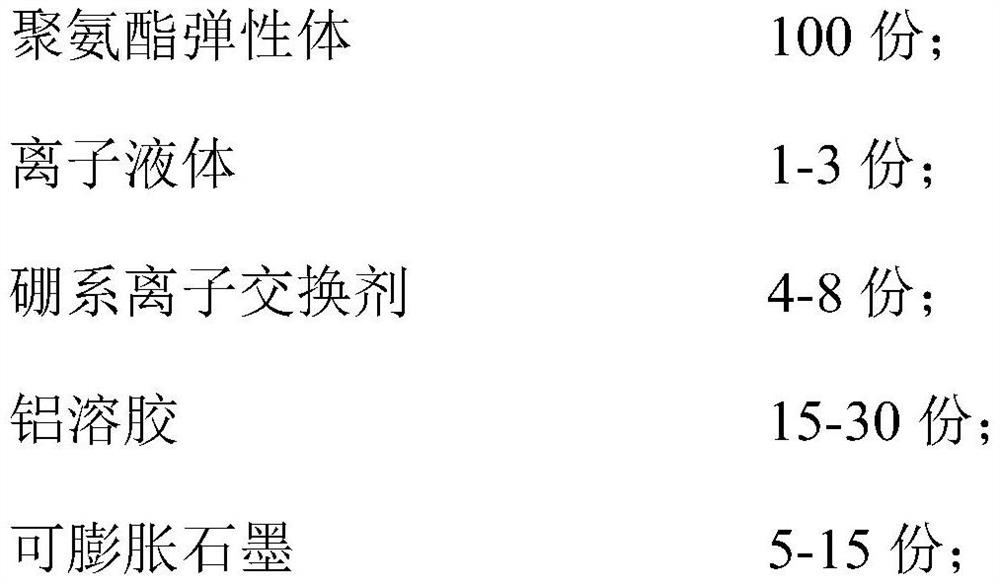

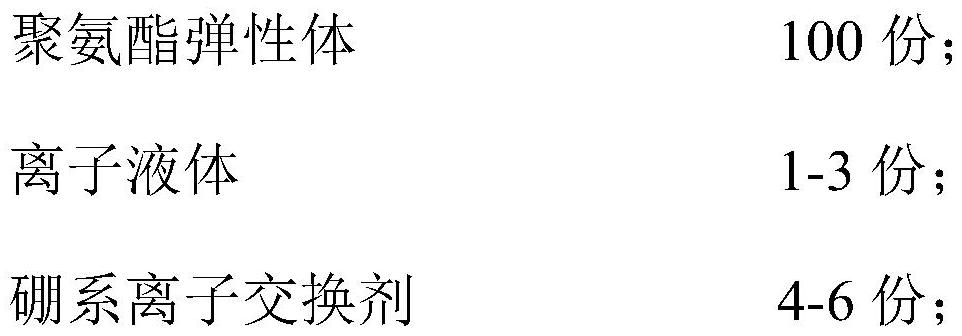

A kind of flame retardant polyurethane elastomer material for furniture and preparation method thereof

ActiveCN108017898BAvoid migration and precipitationSmall particle sizePolyurethane elastomerPolymer science

The invention provides a flame-retardant polyurethane elastomer material for furniture and a preparation method thereof. The flame-retardant polyurethane elastomer material includes the following raw material components in parts by mass: 100 parts of polyurethane elastomer, 1-3 parts of ionic liquid, 4-8 parts of boron ion exchanger, 15-30 parts of aluminum sol and 5 parts ‑15 parts expandable graphite. The flame-retardant polyurethane elastomer material is prepared by first mixing and reacting ionic liquid, boron ion exchanger, aluminum sol and expandable graphite, and then melting and blending the obtained solid component with polyurethane elastomer. The flame-retardant polyurethane elastomer material provided by the present invention has high flame-retardant performance, no small-molecule flame-retardant is precipitated during use, and the flame-retardant performance is effective for a long time. It is especially suitable for furniture such as sofas, mattresses, and chair armrests. .

Owner:DONGGUAN XIONGLIN NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com