Well cementing slurry lightening agent and preparation method thereof

A technology of cementing cement slurry and lightening agent, which is applied in the fields of chemical instruments and methods, preparation of organic compounds, preparation of carbamic acid derivatives, etc., and can solve problems such as easy leakage layer and layer damage of long sealing section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

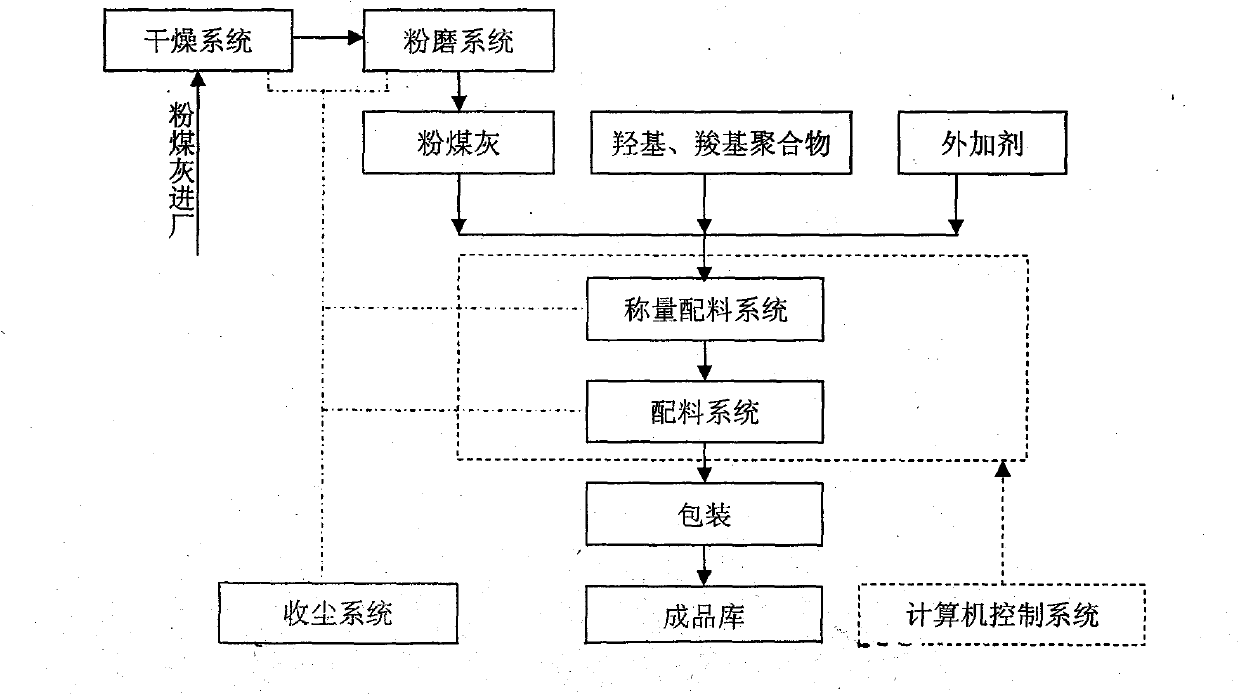

[0062] After the purchased fly ash enters the factory, it is first put into the drying system for heating, blown by blowing water and dried, and then put into the ball mill in batches for repeated grinding until the particle size is less than 20 μm. Add 450-500 kg of fly ash to the mixer each time for use.

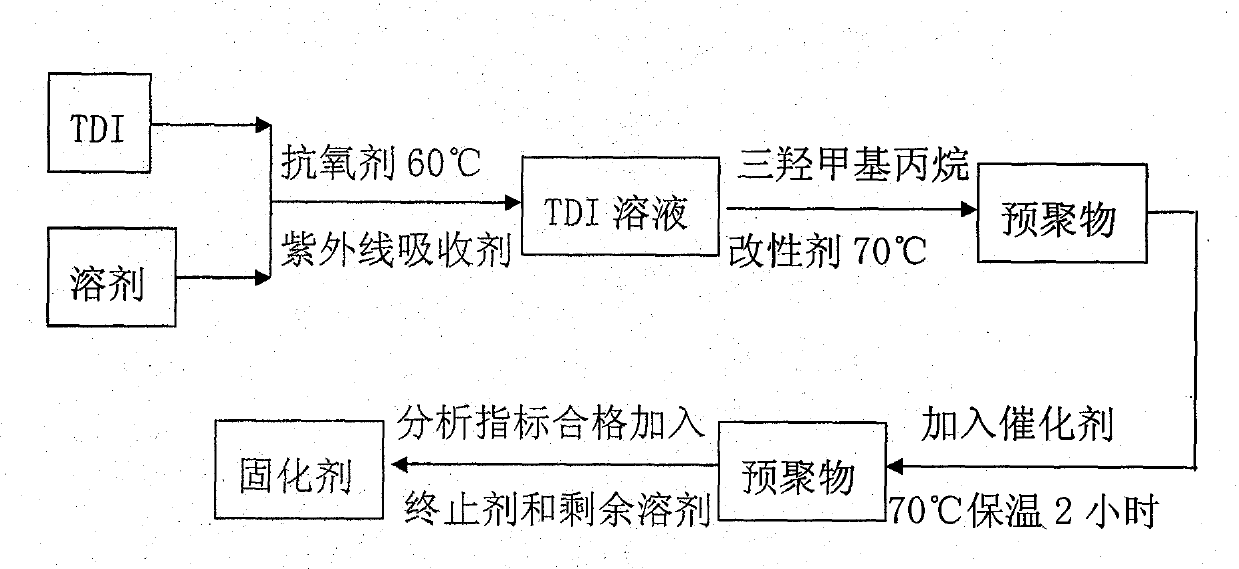

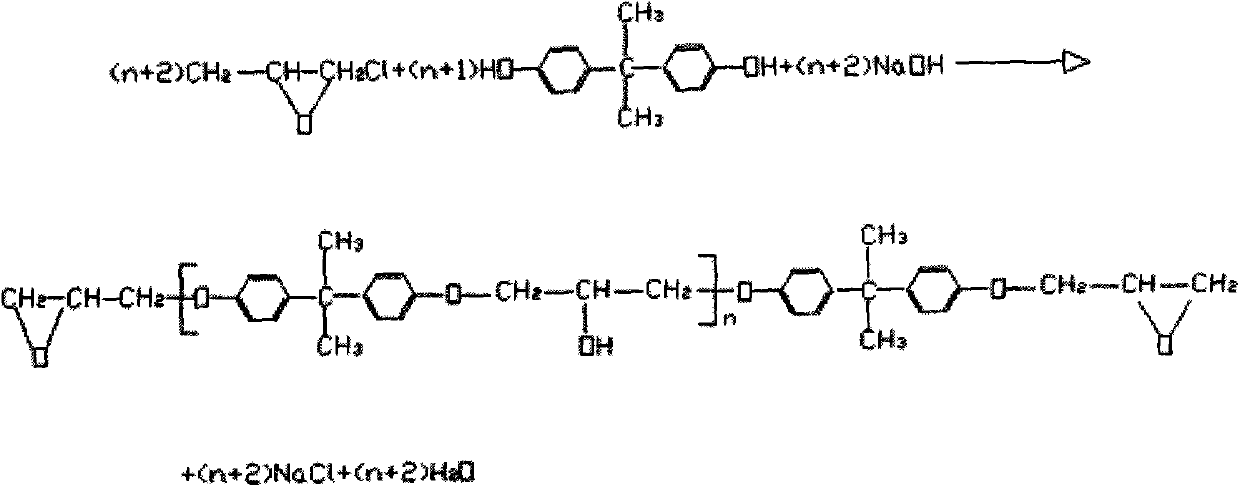

[0063] (2) Preparation of bisphenol A type epoxy resin

[0064] Stir and dissolve the bisphenol A and epichlorohydrin in the formulated amount at 80°C, then cool down to 50°C, add phenol, and then add 30% NaOH dropwise. After the base is added dropwise, keep warm for a period of time, and then recover unreacted epichlorohydrin under reduced pressure. Then the temperature was lowered to 50° C., 15% NaOH was added dropwise, and the reaction was kept warm after the addition was completed. After the reaction is complete, add benzene, raise the temperature to dissolve, then let stand and wash with water. The upper resin benzene solution is sucke...

Embodiment 2

[0083] After the purchased fly ash enters the factory, it is first put into the drying system for heating and drying, and then it is put into the ball mill in batches and repeatedly ground until the particle size is less than 20 μm. Add 450-500 kg to the mixer each time for use.

[0084] (2) Preparation of bisphenol A type epoxy resin

[0085] Add 27.8kg epichlorohydrin and 22.8kg bisphenol A to the there-necked flask equipped with stirrer, reflux condenser and thermometer. Heat the water bath to 75°C and start stirring to dissolve all the bisphenol A. Take 8 kg of sodium oxide in 20 liters of distilled water, put the solution into the dropping funnel, slowly add sodium hydroxide solution from the dropping funnel (the dropping funnel is connected to the reflux condenser), and keep the temperature at about 70°C, about 0.5h dropwise completed. Continue to react at 70-80°C for 0.5h, 1.0h, 1.5h, 2.0h, and 2.5h respectively. At this time, the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com