Patents

Literature

31results about How to "Low commercial price" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

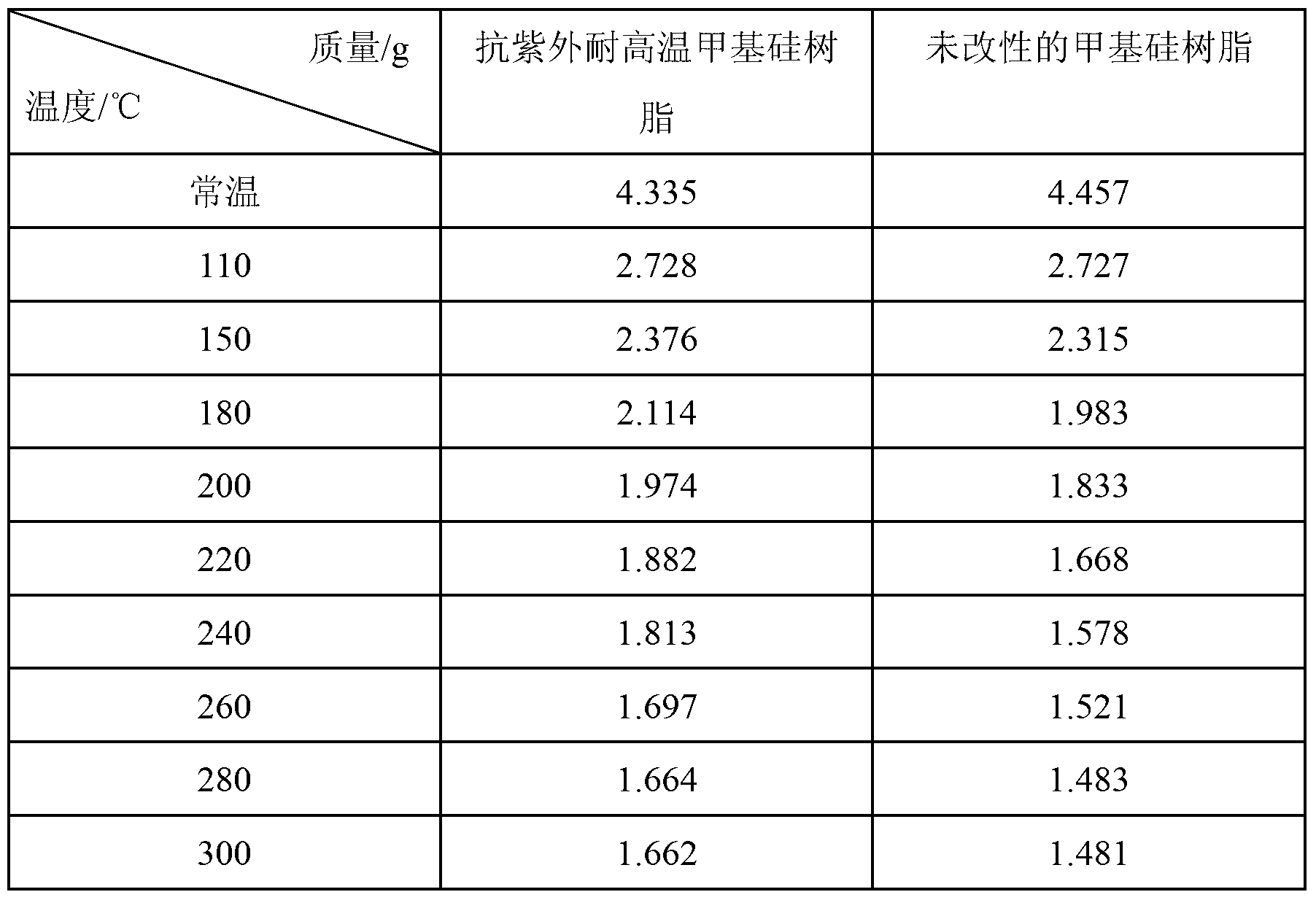

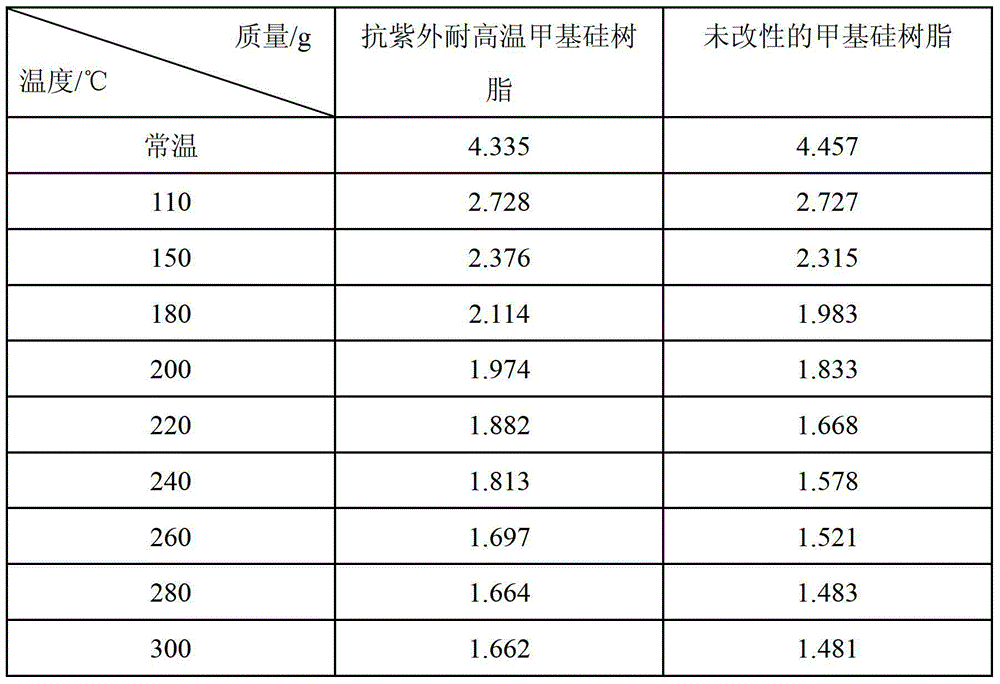

Preparation method of ultraviolet-resistant and high-temperature-resistant methyl silicone resin

The invention relates to a preparation method of ultraviolet-resistant and high-temperature-resistant methyl silicone resin, relates to the preparation method of modified methyl silicone resin, and is used for solving the problems that the existing methyl silicone resin is poor in high temperature and ultraviolet resistance, complicated in preparation method and high in cost. The preparation method comprises the following steps of:1, dispersing ethyl orthosilicate in anhydrous ethanol and then adding a mixing solution of deionized water, the anhydrous ethanol and ammonia, thereby obtaining a silica ethanol solution; 2, dispersing tetrabutyl titanate in the anhydrous ethanol and then adding the mixing solution of the deionized water, the anhydrous ethanol and hydrochloric acid, thereby obtaining a titania ethanol solution; 3, dispersing methyl triethoxysilane and diethoxydimethylsilane in the anhydrous ethanol, thereby preparing a methyl silicone resin prepolymer; and 4, regulating the pH values of the solutions obtained in the steps 1 and 2 to be 7 and performing a refluxing operation after adding the prepolymer, thereby obtaining the methyl silicone resin. The method is conventional in raw material preparation as well as simple and easy to implement. The thermal weight loss rate of the modified methyl silicone resin at the temperature of 300 DEG C is 0.6, so that the modified methyl silicone resin is good in ultraviolet resistance.

Owner:HARBIN INST OF TECH

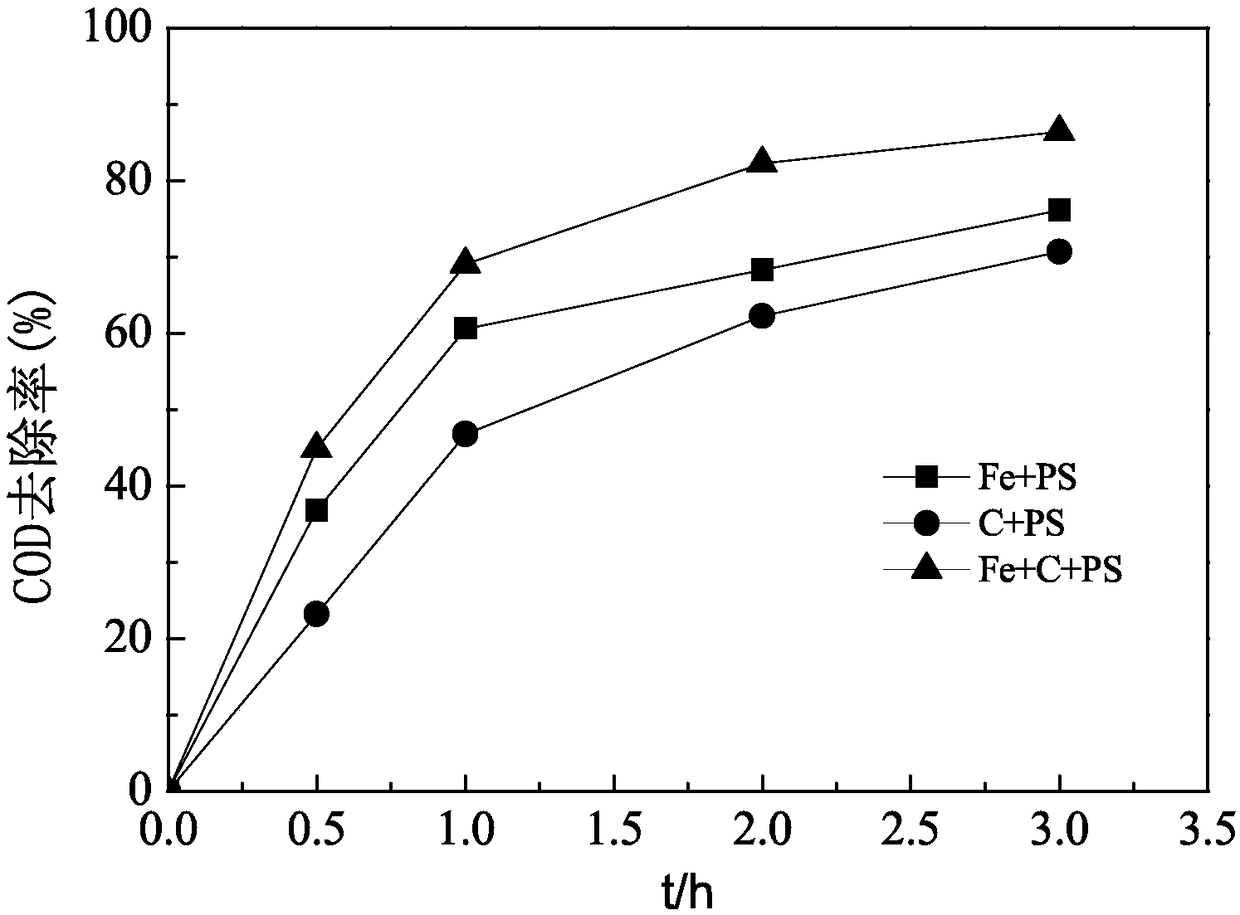

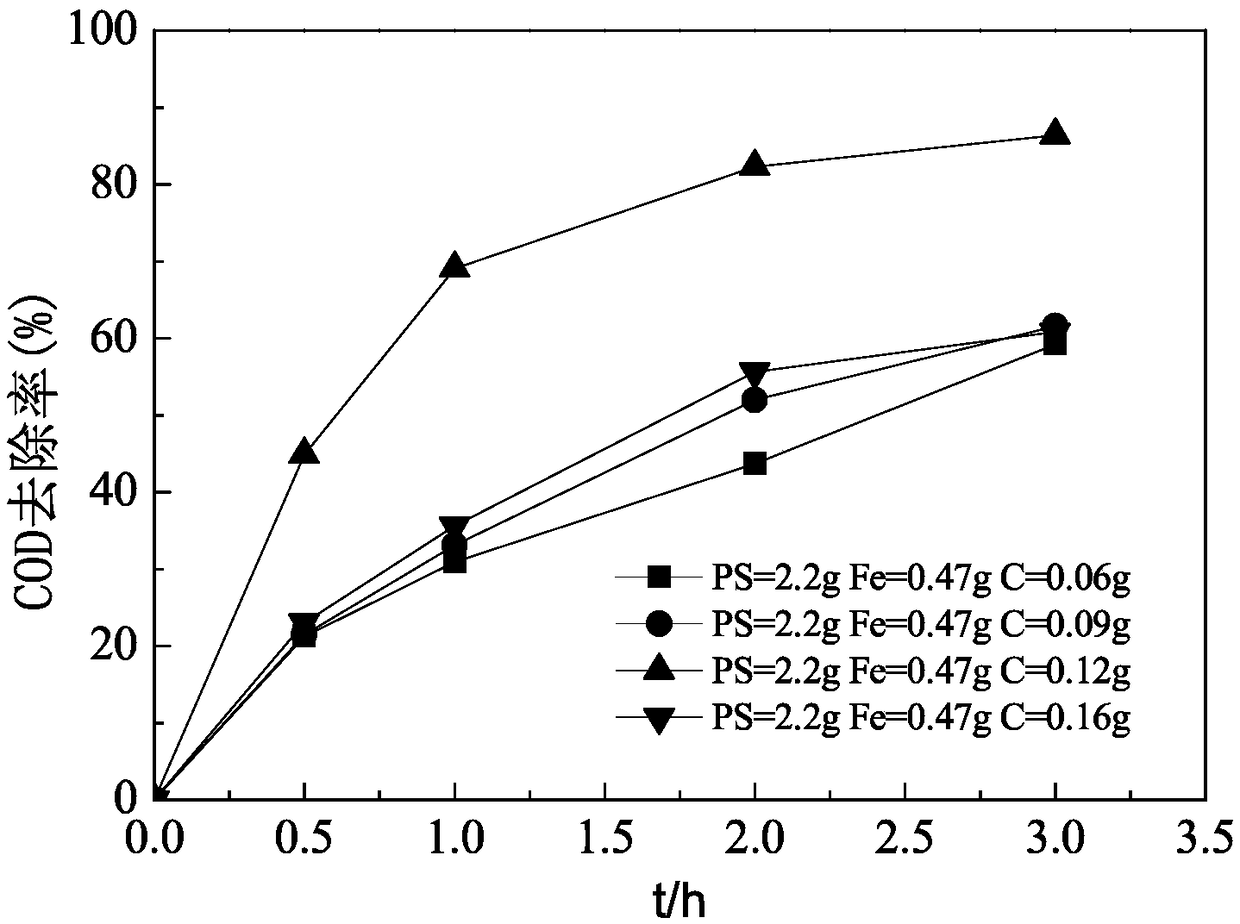

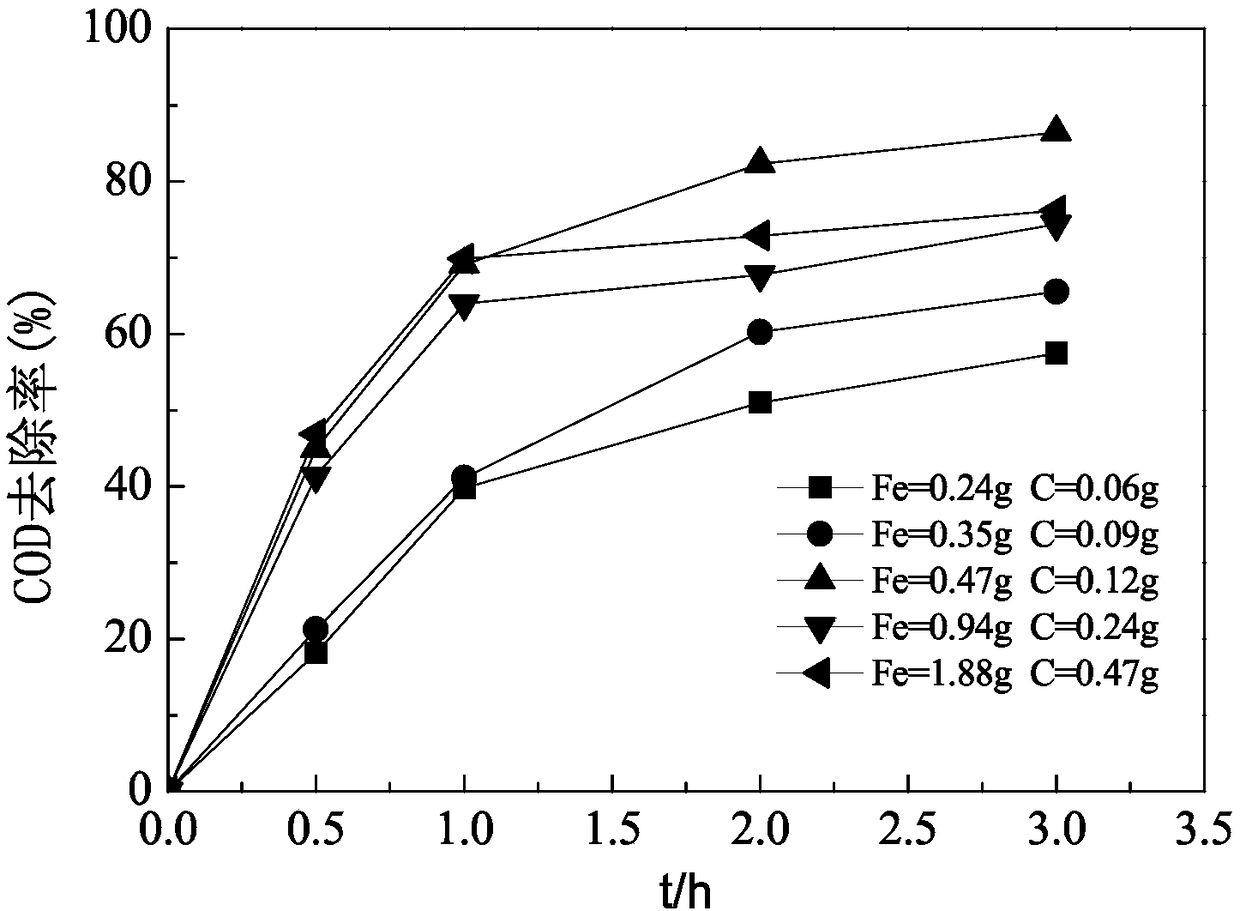

Method for treating high-concentration difficulty-degradable alkaline waste liquid by using iron carbon activated persulfate

InactiveCN108059229AGood adsorbentAvoid competitionWater contaminantsWater/sewage treatment by sorptionHigh concentrationBiological activation

The invention relates to a method for treating high-concentration difficulty-degradable alkaline waste liquid by using iron carbon activated persulfate. The method comprises the following steps: adding a certain amount of zero-valent iron (Fe0), activated carbon (AC) and persulfate (PS) into high-concentration difficulty-degradable organic matter containing alkaline waste liquid at normal temperature and pressure, uniformly stirring, and reacting for 2-3h under the condition that the initial pH is alkaline to oxidatively degrade contaminants. A synergistic activating oxidant is obtained by adding the zero-valent iron and the activated carbon into the alkaline basic waste liquid, and sulfate and hydroxyl radicals are produced to oxidize the contaminants so as to degrade the alkaline waste liquid; compared with the conventional Fenton oxidation technology, the method has the advantages as follows: the pH application range is wider, the step of adding acid for neutralizing is omitted, removal of the contaminants is facilitated, and the economic cost is reduced; in addition, with the Fe0 and the AC as a catalyst, the efficiency of producing SO4- through activation of PS is significantly improved, so that efficient treatment to the alkaline waste liquid is facilitated better.

Owner:SUZHOU UNIV OF SCI & TECH

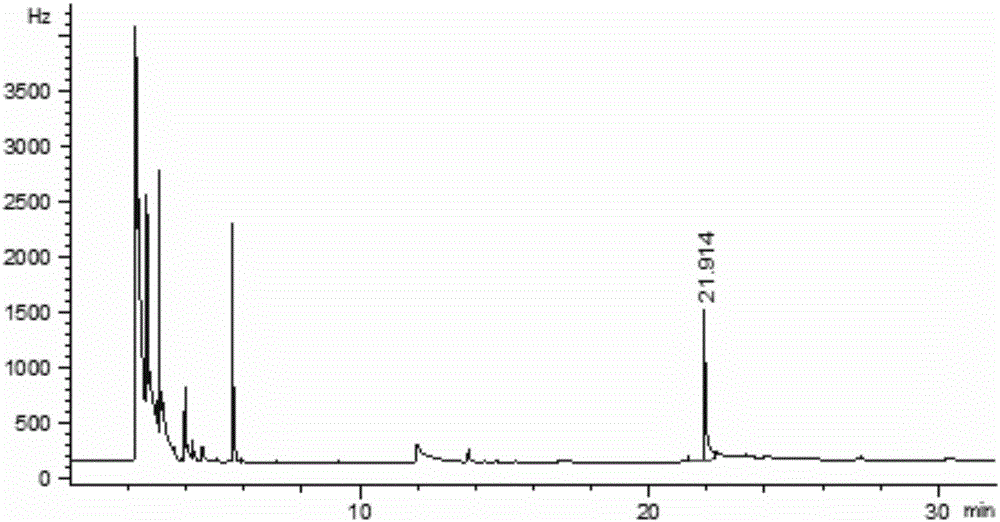

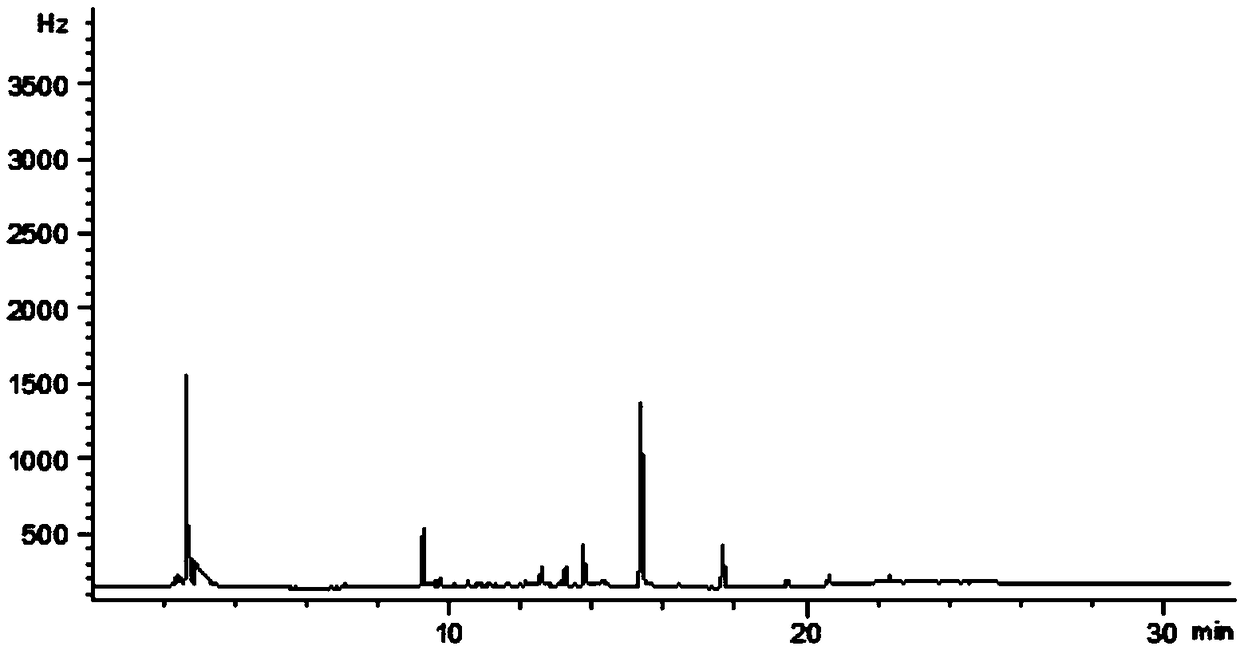

Preparation method of 2, 3, 3, 3-tetrafluoropropene

ActiveCN102675038AAccurate control of volume ratioReduce the probability of exposureHalogenated hydrocarbon preparationRetention timeProduct gas

The invention provides a preparation method of 2, 3, 3, 3-tetrafluoropropene, which comprises the following steps: taking monochlorodifluoromethane (R22) and methane chloride (methyl chloride) as raw materials and carrying out thermal cracking reaction at a high temperature of 600-1000 DEG C under the condition that N2 exits to prepare the 2, 3, 3, 3-tetrafluoropropene, wherein the volume ratio of the monochlorodifluoromethane to the methane chloride is 1-3:1, and the retention time of a reactant is 0.01-0.2 seconds. The reaction raw material used in the preparation method is easy to obtain, the defect of high cost of the used raw material in the prior art is overcome, the production cost is greatly reduced, and the reaction process is simple. The prepared 2, 3, 3, 3-tetrafluoropropene has the advantages of zero ODP and low GWP and can be used as a substitute of an automotive air-conditioning refrigerant.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

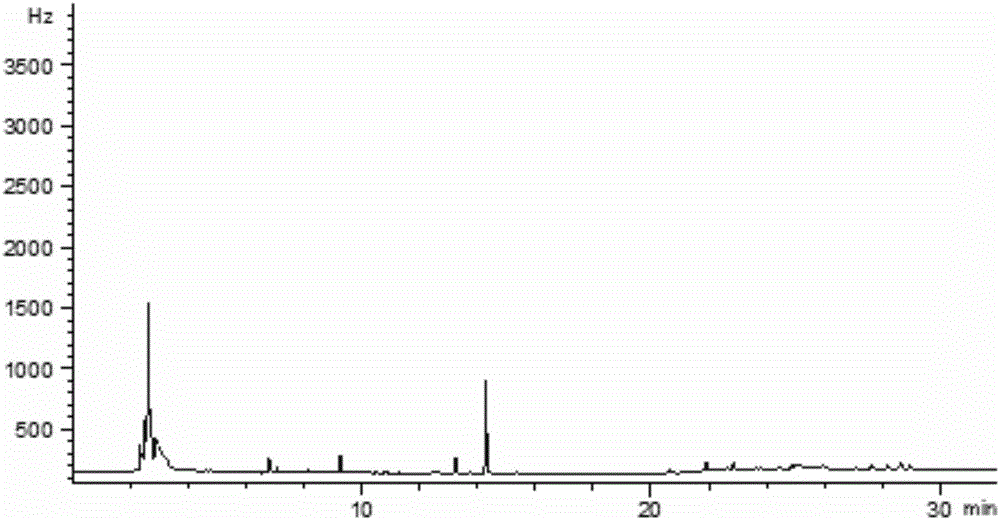

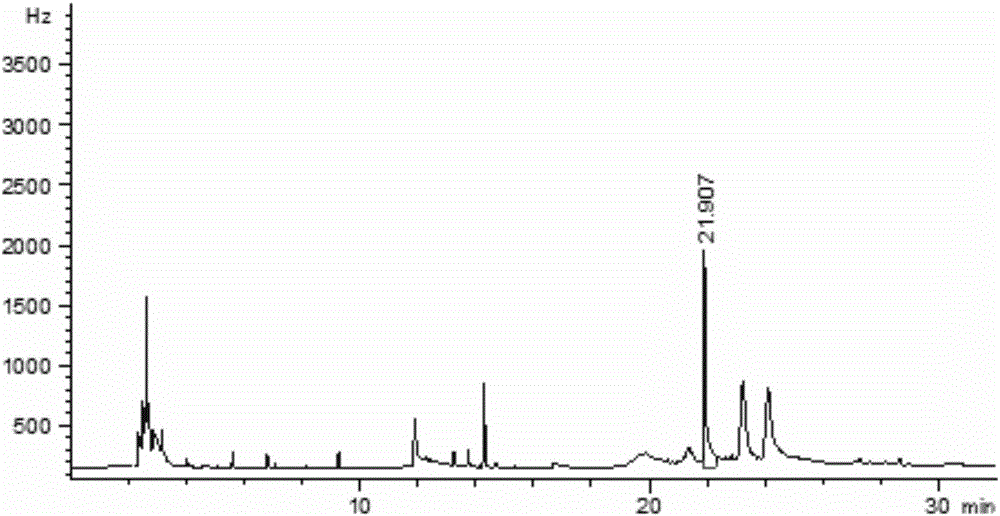

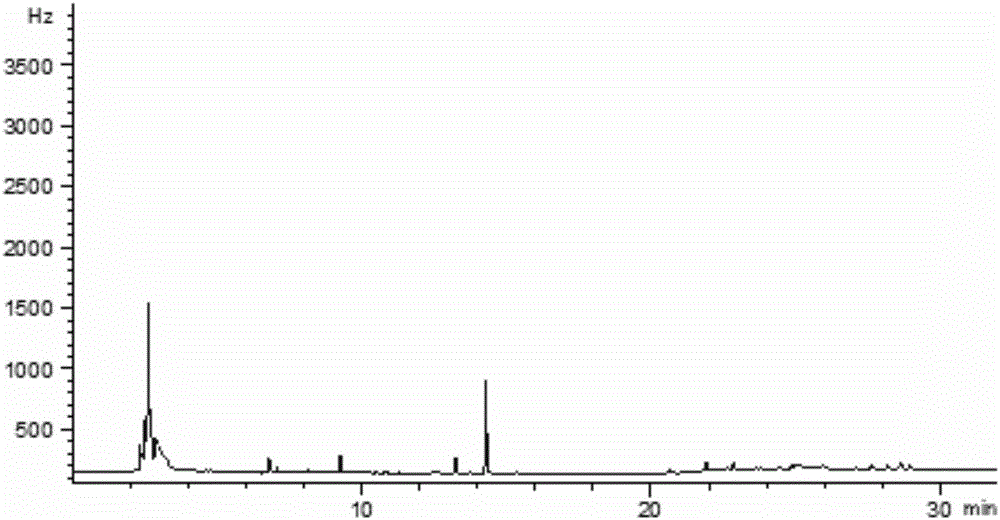

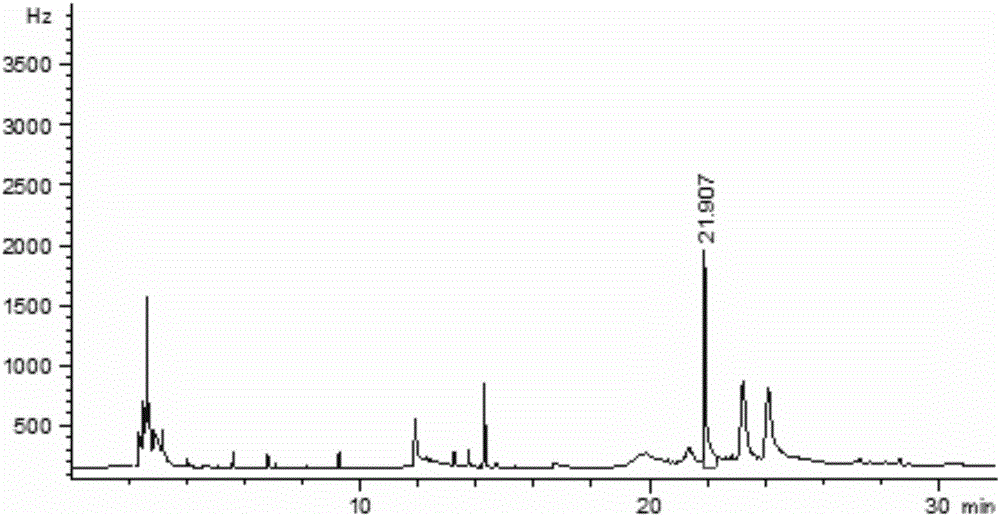

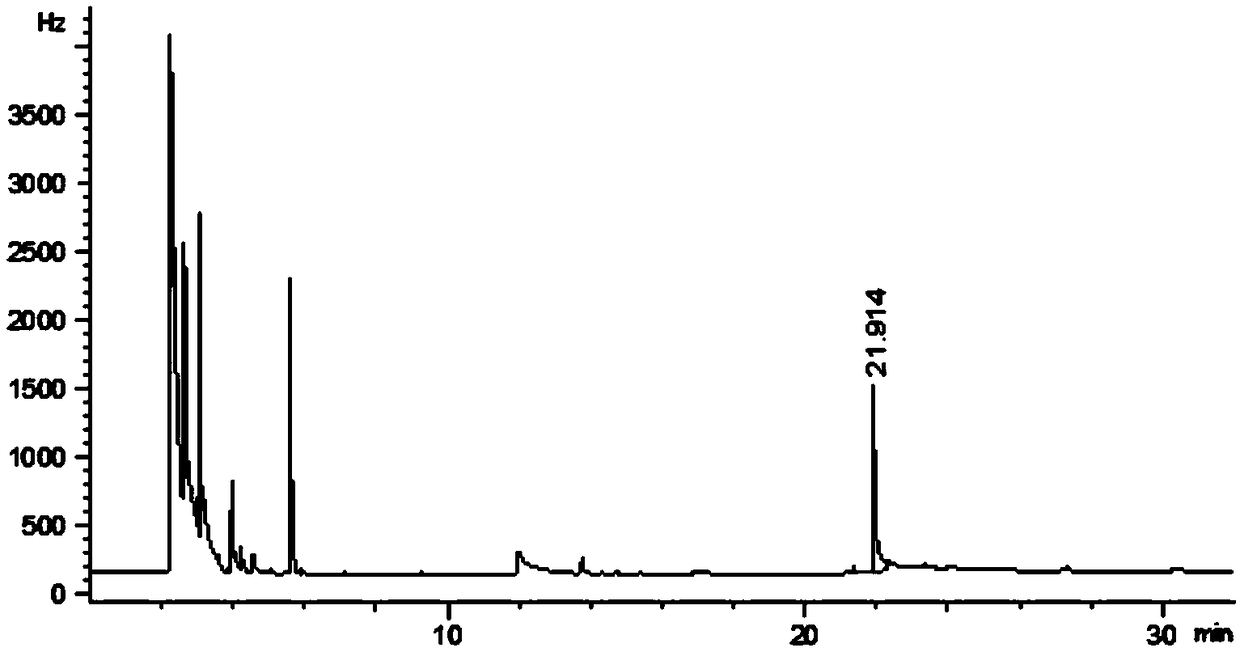

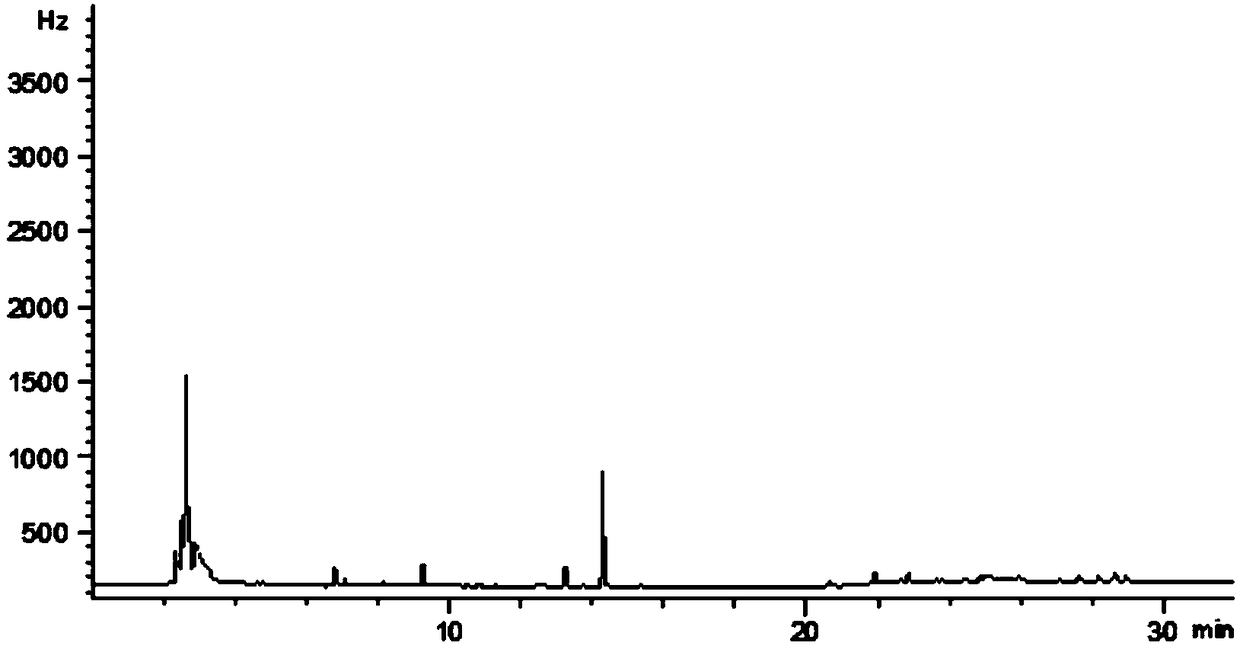

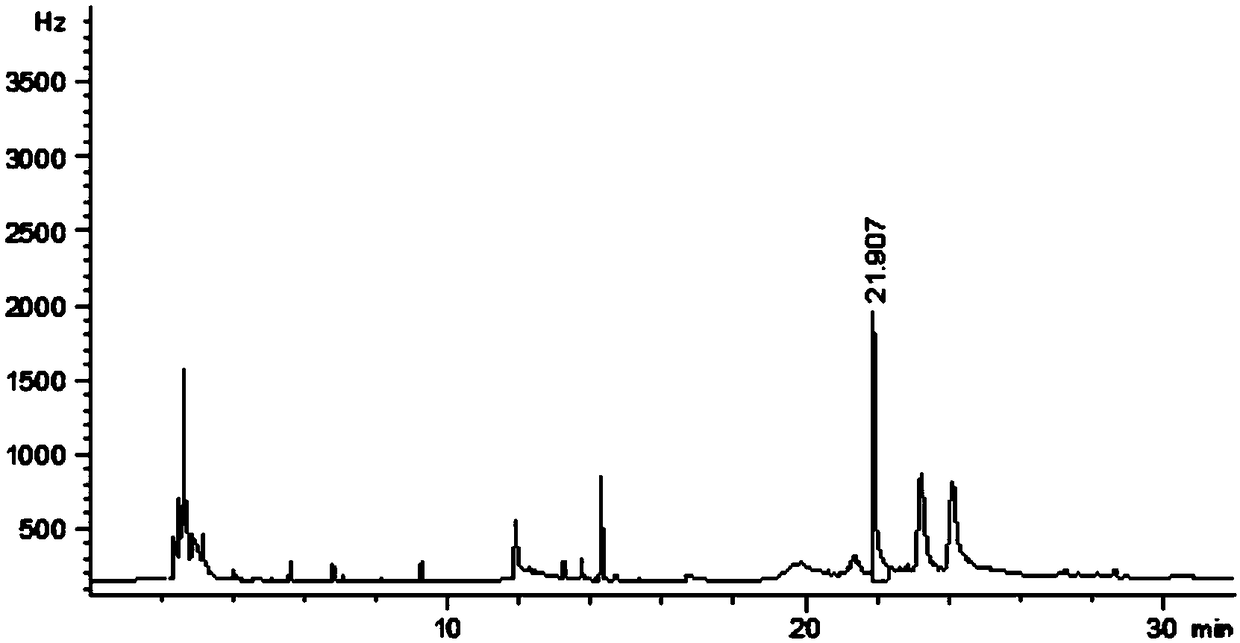

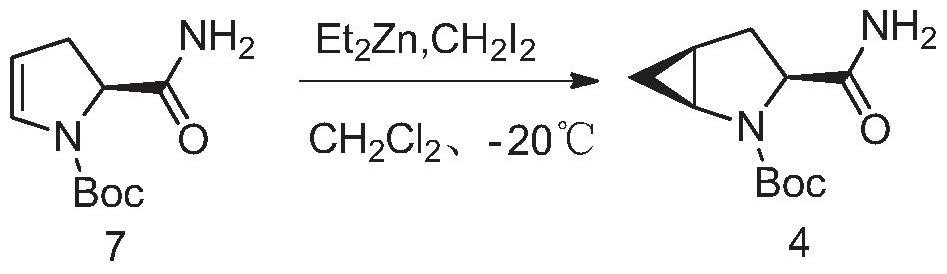

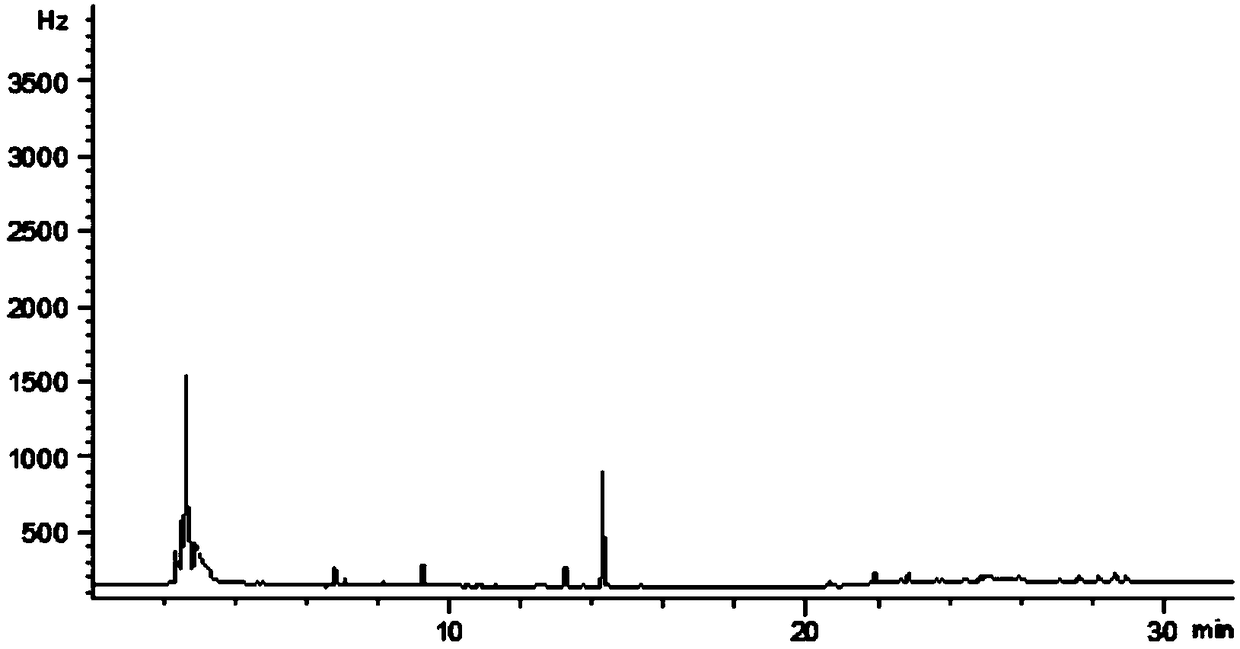

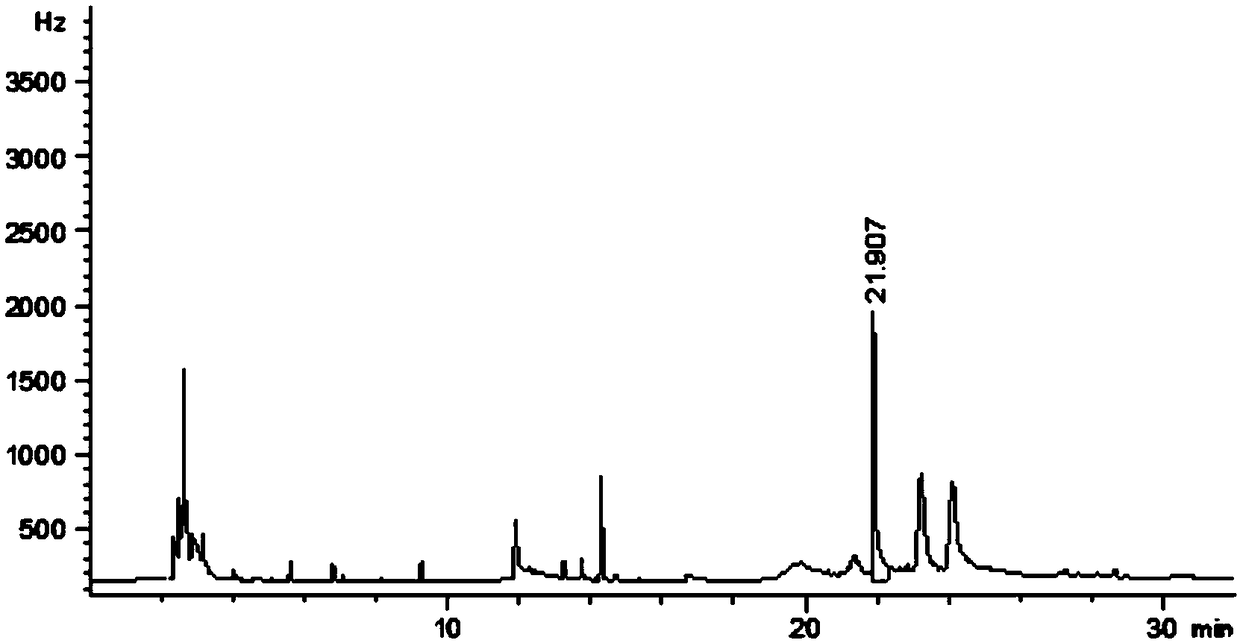

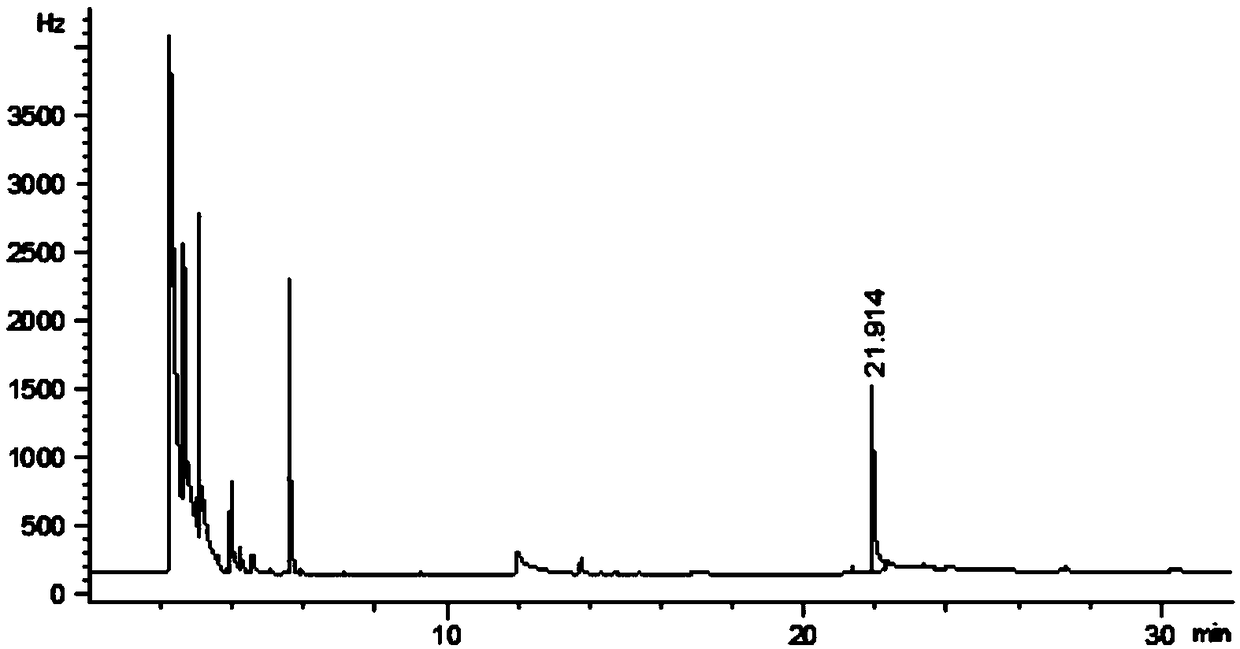

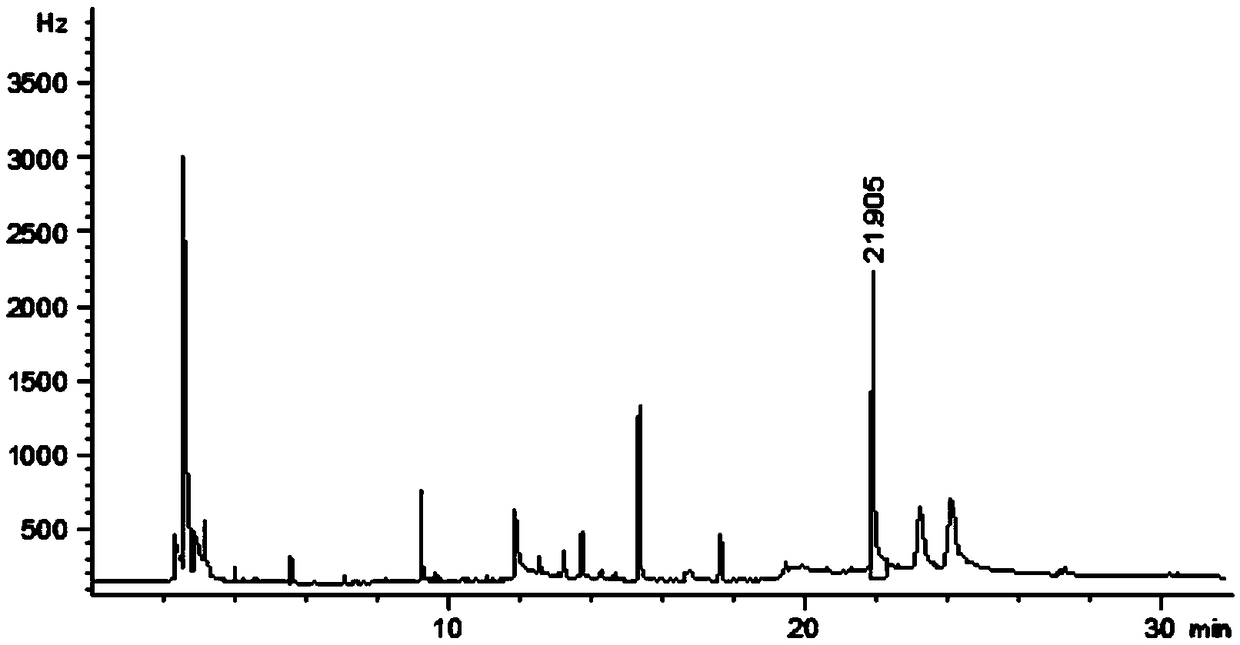

Quantitative detection method for residual quantity of chlorantraniliprole in soil

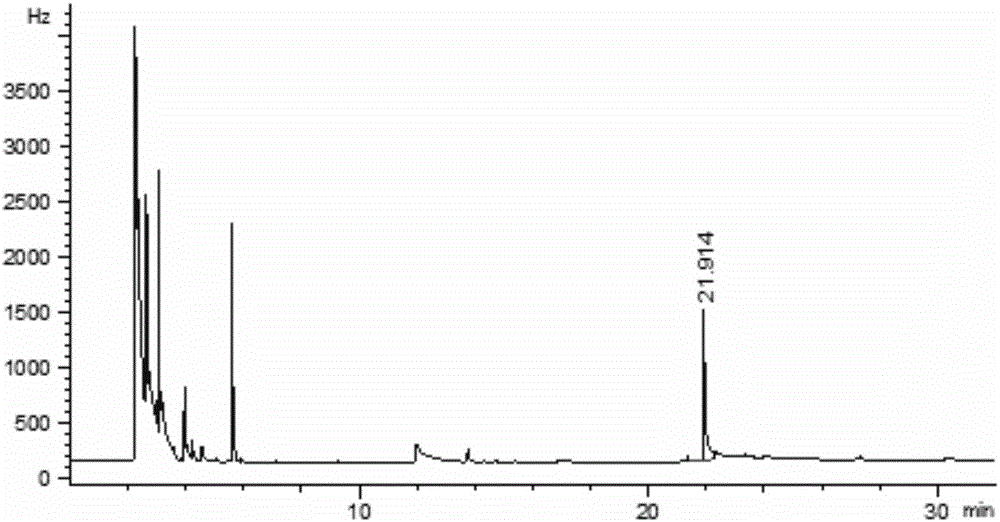

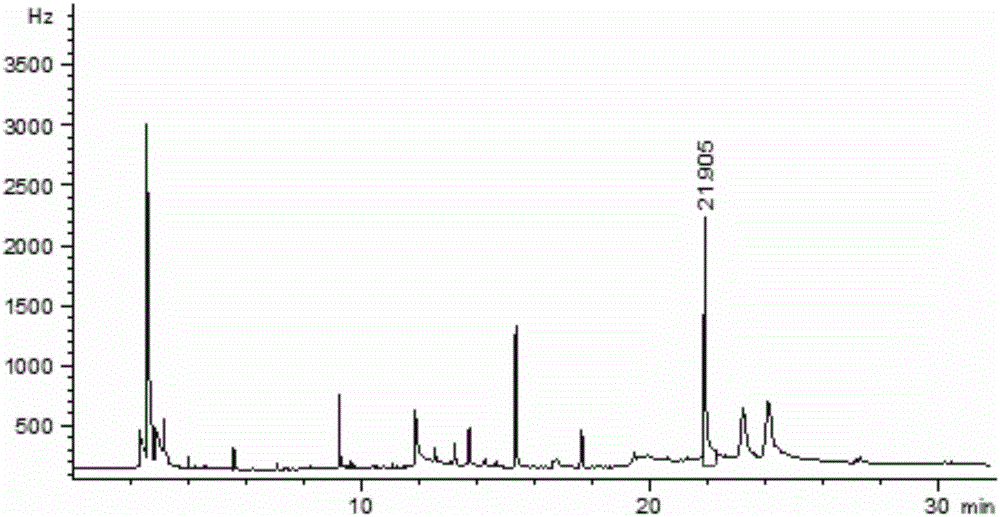

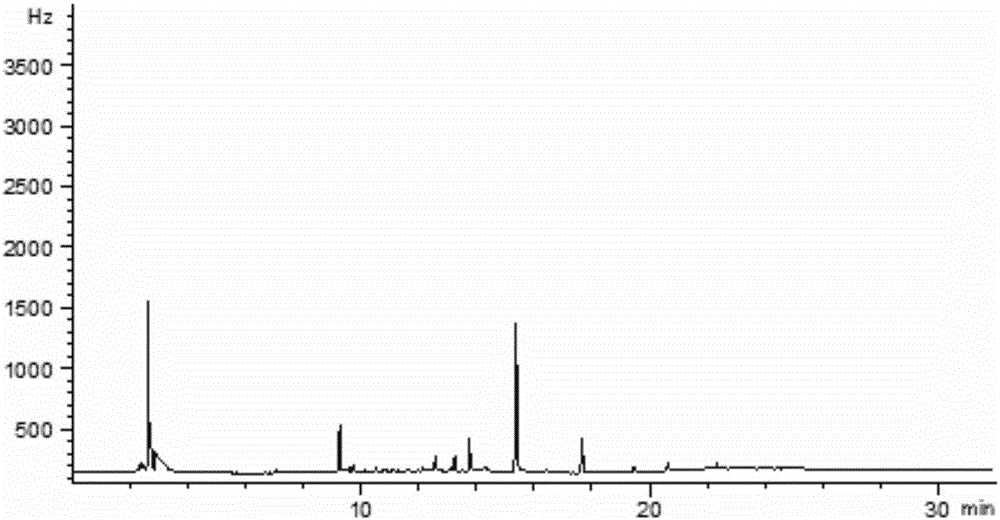

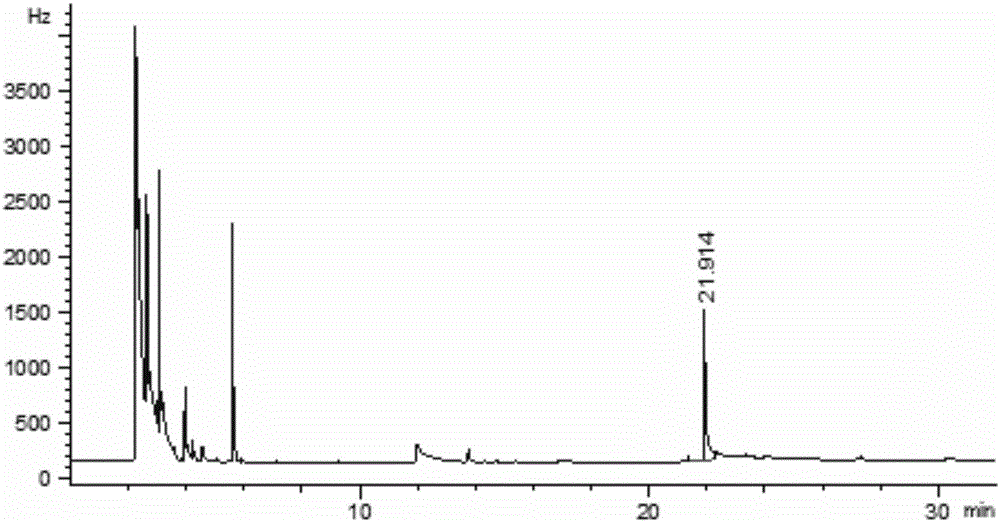

The invention provides a quantitative detection method for the residual quantity of chlorantraniliprole in the soil. The method is characterized in that the ultrasonic extraction of residual chlorantraniliprole in the soil is conducted in an acetonitrile solvent, and then impurities are removed by adopting a proper amount of MWCNTS and PSA adsorbent. An obtained supernate is subjected to nitrogen-blowing, concentrating and drying, and then the volume is metered by adopting an acetone and n-hexane mixed solvent, wherein the volume ratio of acetone to n-hexane in the mixed solvent is 1:1. After that, the obtained mixture is subjected to programmed warming and separating by adopting a HP-5 chromatographic column, and the ECD determination is conducted by an electronic capture detector. Finally, the residual quantity of chlorantraniliprole is quantitatively detected based on the matrix external standard method. Experiments prove that, the above method is simple, rapid and accurate in operation, easy to popularize and master, and low in cost. Therefore, the method provides a rapid and reliable method for the residual quantity measurement of chlorantraniliprole in the soil, and the requirements of the batch sample analysis on quality and progress can be met.

Owner:SUZHOU ACADEMY OF AGRI SCI

Quantitative determination method for general chlorantraniliprole residual quantity

InactiveCN106526009ALow commercial priceReduce usageComponent separationElectron capture detectorQuantitative determination

The invention relates to a quantitative determination method for general chlorantraniliprole residual quantity. The method is characterized in that residual chlorantraniliprole in a test sample is subjected to ultrasonic extraction by an acetonitrile solvent, a proper amount of MWCNTS and PSA adsorbents are used for removing impurity, a supernatant is subject to nitrogen blowing and concentrating until nearly dry; volume metering is carried out by using an acetone-hexane mixed solvent with volume ratio of 1:1, a HP-5 chromatographic column program is used for heating and separating, electron capture detector ECD detection is carried out, and a matrix external standard method is used for quantification. Through test, the method has the advantages of simple, fast and accurate operation, easy popularization and grasping, low cost, is the rapid and reliable method for detecting the residual chlorantraniliprole in different samples, and can satisfy the quality and progress requirement by analysis of large-batch samples.

Owner:连云港市农村能源环境保护办公室 +1

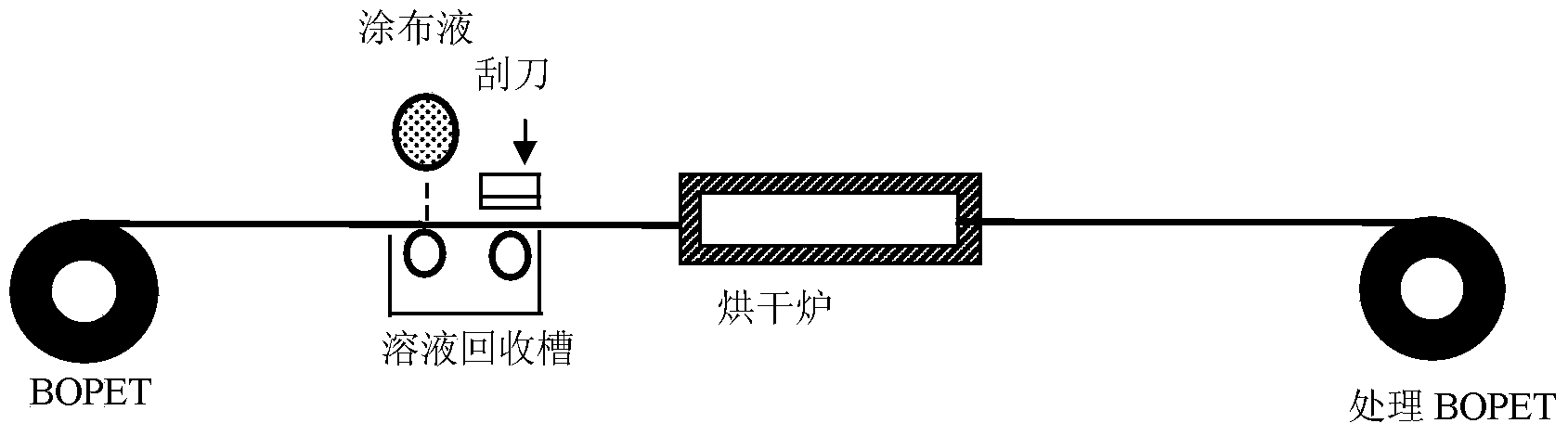

Preparation method for anti-ultraviolet heatproof BOPET film

ActiveCN103522560AImprove insulation performanceGood heat insulationFlat articlesPolymer scienceHeat resistance

A preparation method for an anti-ultraviolet heatproof BOPET film relates to a preparation method for a BOPET film, and mainly aims at solving the problems that conventional BOPET films are bad in anti-ultraviolet performance and heatproofness. The preparation method comprises: 1, preparing a sericite solution; 2, preparing a titanium dioxide / sericite solution which is a coating liquid; and 3, immersing BOPET films in the coating liquid for coating by employing a doctor-blade method, drying and rolling. According to the preparation method for the anti-ultraviolet heatproof BOPET film, the employed raw materials are conventional reagents in the field, and have low commercial price; and compared with untreated BOPET films, the prepared anti-ultraviolet heatproof BOPET film is improved in softening point temperature by 20% and obviously reinforced in UV absorption characteristic peak of the film surface after treated by placing in a UV ageing oven under the conditions of 100 DEG for 1 h. The preparation method is simple in technology, does not pollute environment, and is applicable to industrialized production.

Owner:HARBIN INST OF TECH

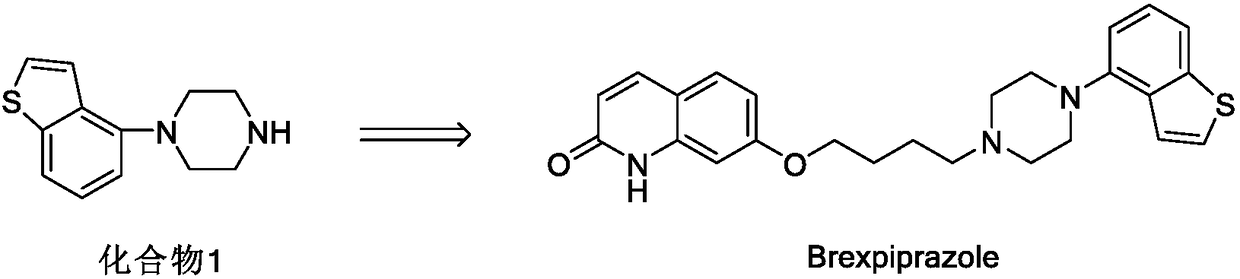

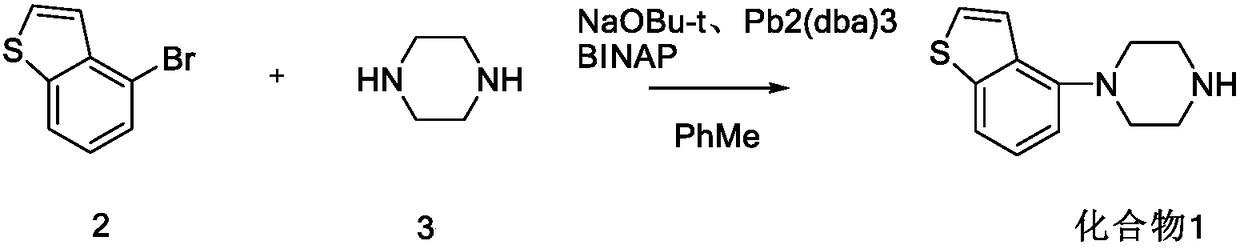

Preparation method of benzothiophene compound intermediate

InactiveCN109422722AHigh cost of industrializationImprove conversion rateOrganic chemistryState of artBenzothiophene

The invention provides a preparation method of a novel brexpiprazole intermediate. The method is as below: in the presence of a cuprous catalyst and a ligand, carrying out a coupling reaction on witha compound 4-halobenzo[b]thiophene and N-protecting piperazine through alkali. Compared with the prior art, the method replaces precious metal palladium with cheap copper iodide under the suitable ligand, and obtains the brexpiprazole intermediate compound with high conversion rate; and the method has the advantages of safer and more convenient reaction, low cost, less environmental pollution andeasy operation, and can be applied to industrialized production.

Owner:SHANGHAI SHYNDEC PHARMA CO LTD

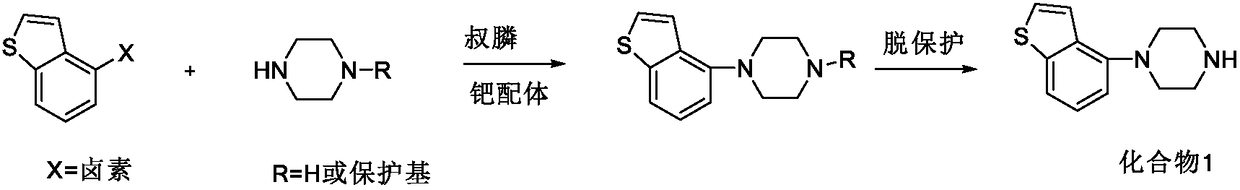

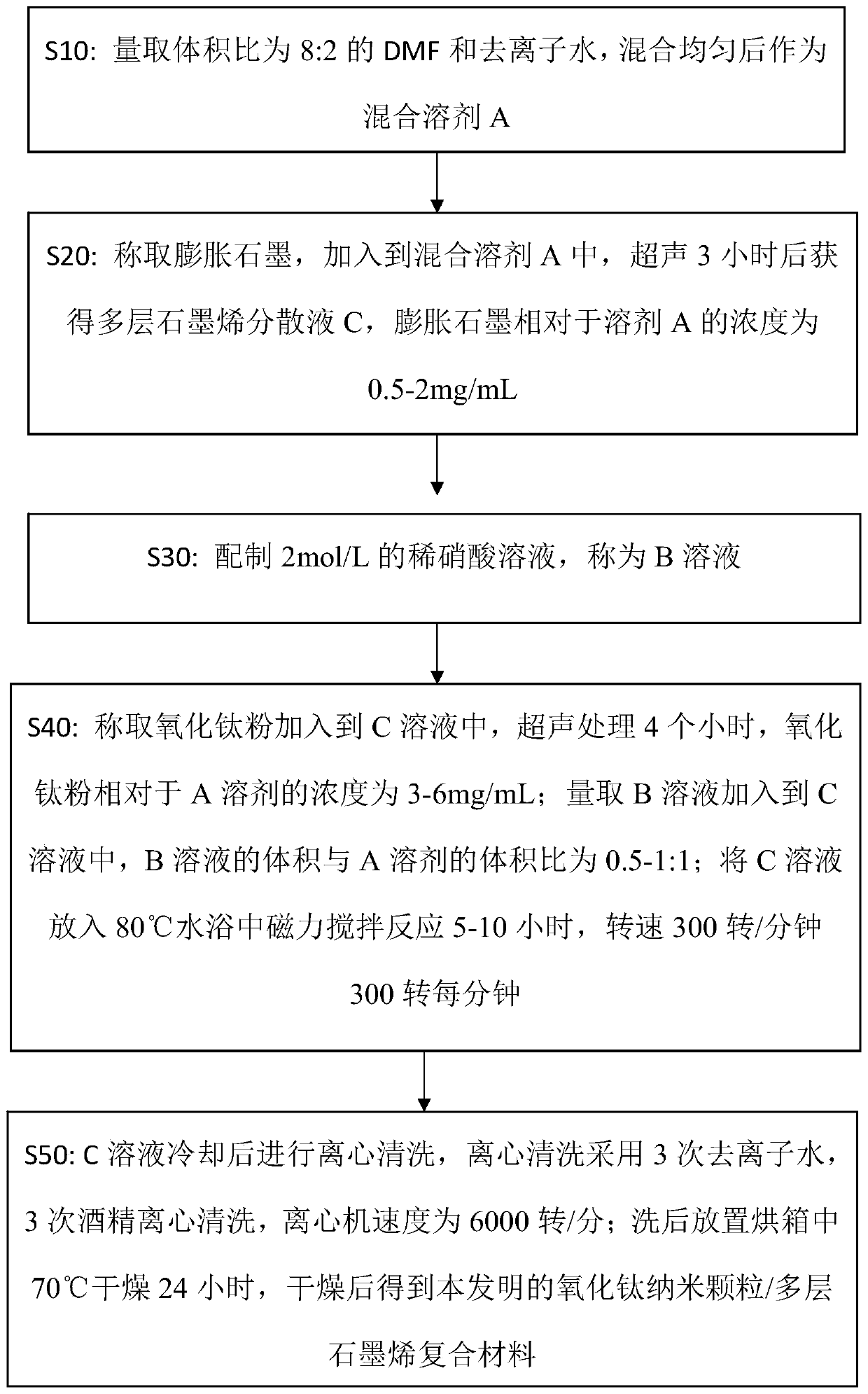

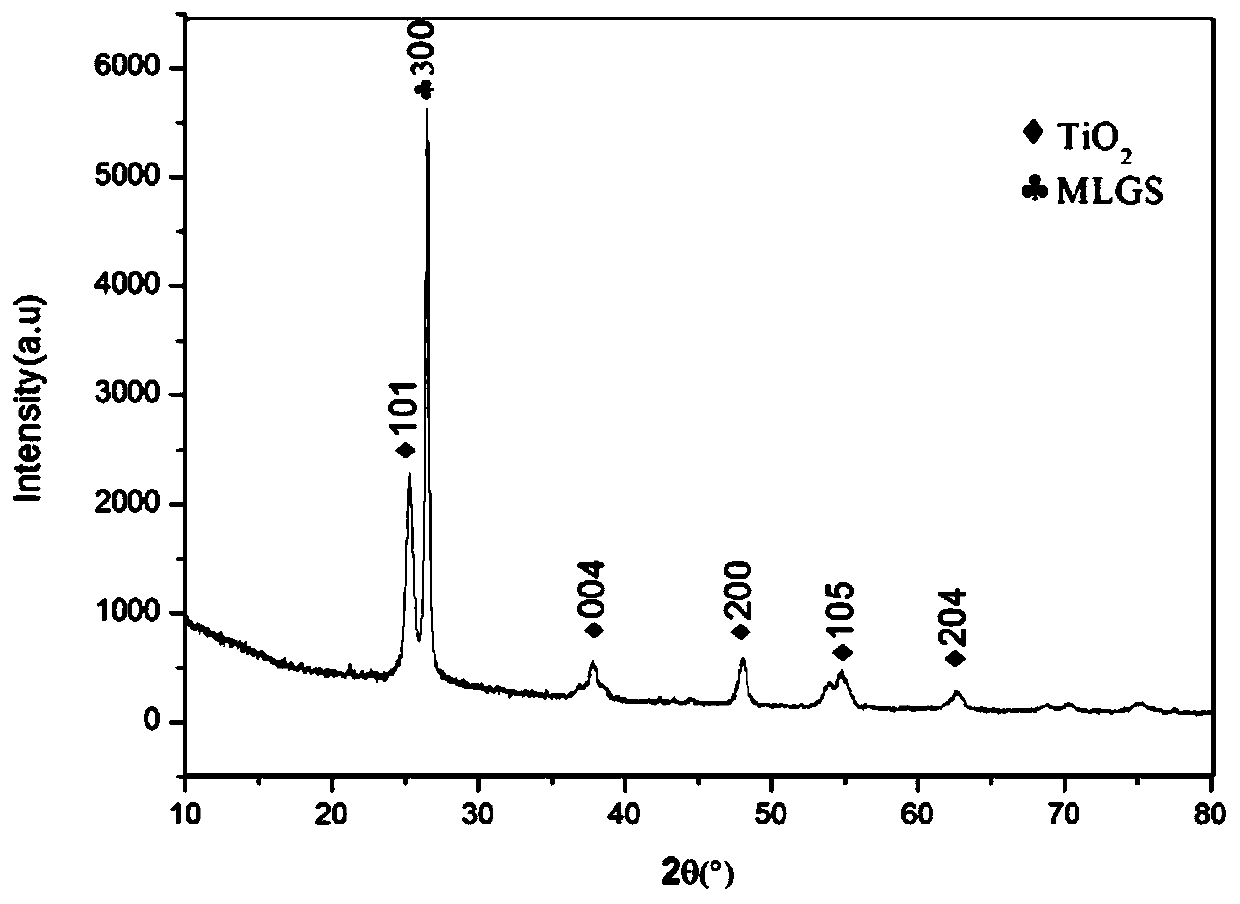

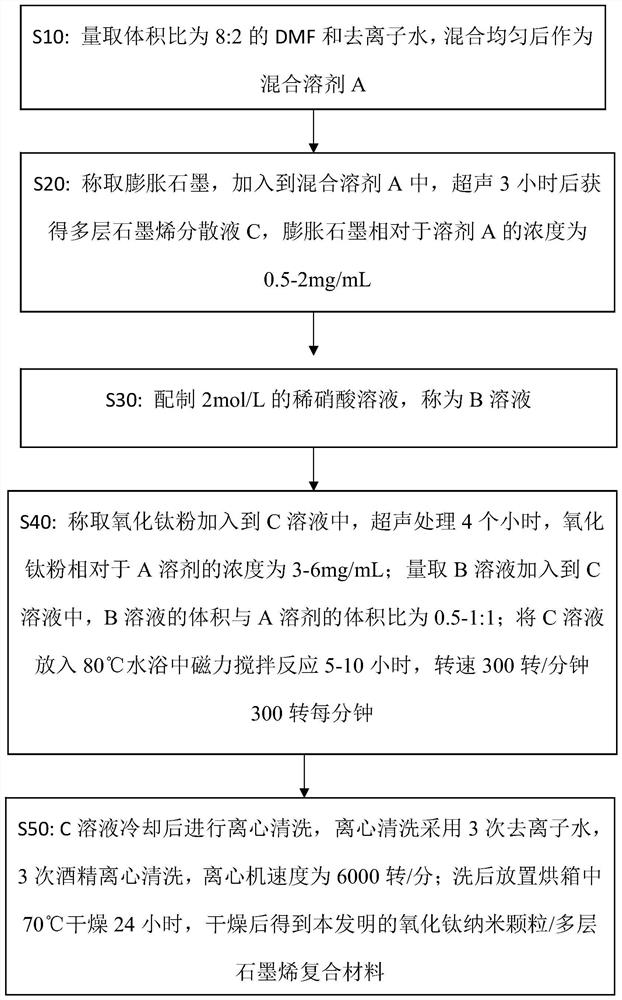

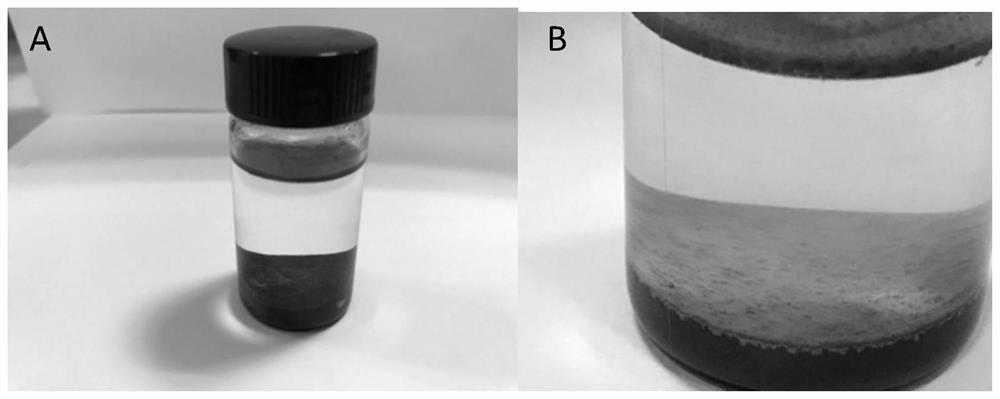

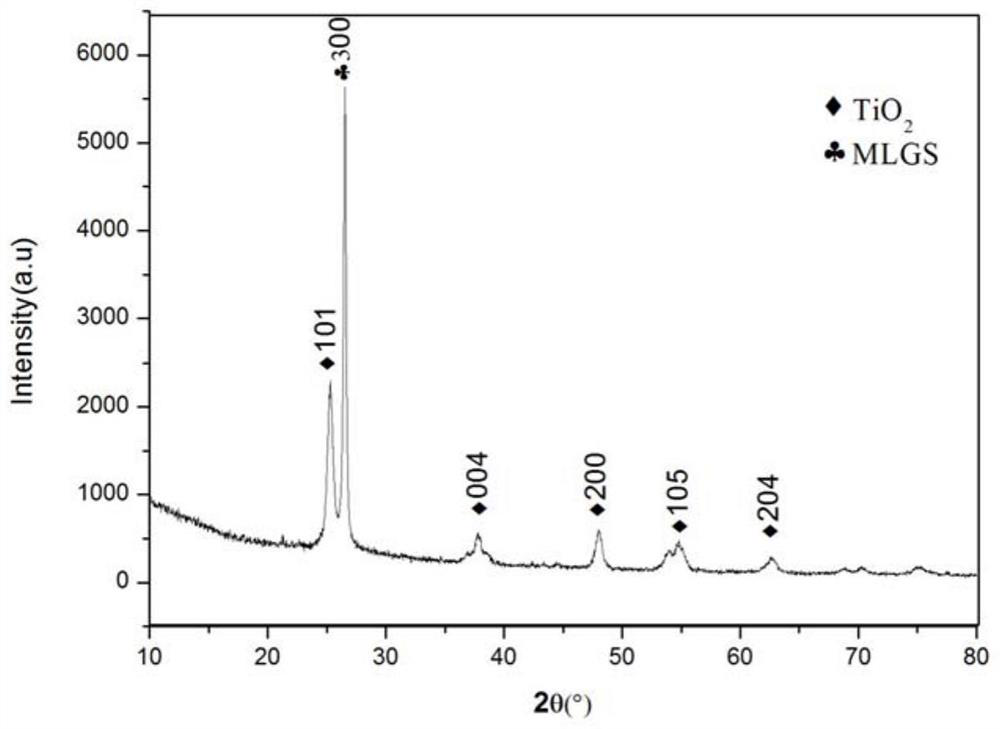

Preparation method of titanium oxide nanoparticle/multilayer graphene composite material

ActiveCN110201658AEasy to makeLow costPhysical/chemical process catalystsGrapheneCvd grapheneNanometre

The invention discloses a preparation method of a titanium oxide nanoparticle / multilayer graphene composite material. The preparation method adopting nanometer titanium oxide particles as a raw material comprises the following steps: adds nanometer titanium oxide to a DMF and water mixed solution, adding a dilute nitric acid solution, generating organic functional groups on the surface of the nanometer titanium oxide under a 80 DEG C water bath condition, and uniformly depositing the nanometer titanium oxide on the surface of multilayer graphene under the action of the molecular force of the surface of the multilayer graphene to finally obtain the uniformly-compounded titanium oxide nanoparticle / multilayer graphene composite material. The preparation method of the invention is simple, andis suitable for industrial production.

Owner:HANGZHOU DIANZI UNIV

Quantitative detection method for chlorantraniliprole residue in tea leaf

ActiveCN106546675ALarge specific surface areaLarge adsorption capacityComponent separationElectron capture detectorNitrogen

The invention relates to a quantitative detection method for chlorantraniliprole residue in tea leaf. The quantitative detection method is characterized in that the residual chlorantraniliprole in tea leaf is subjected to ultrasonic extraction with an acetonitrile solvent, impurities are removed with a proper amount of MWCNTS and a PSA adsorbent, the supernatant is subjected to nitrogen blowing and concentration to achieve a close drying state, volume metering is performed with an acetone-n-hexane mixed solvent having a volume ration of 1:1, programmed heating separation is performed with a HP-5 chromatographic column, ECD determination is performed with an electron capture detector, and quantitation is performed through a matrix external standard method. According to the present invention, the test results confirm that the method has characteristics of simple, rapid and accurate operation, easy popularizing and grasping and low cost, provides the rapid and reliable method for the determination of the chlorantraniliprole residue in the tea leaf, and can meet the requirements of the large-batch sample analysis on the quality and the progress.

Owner:SUZHOU ACADEMY OF AGRI SCI

Preparation method of 2, 3, 3, 3-tetrafluoropropene

The invention provides a preparation method of 2, 3, 3, 3-tetrafluoropropene, which comprises the following steps: taking monochlorodifluoromethane (R22) and methane chloride (methyl chloride) as raw materials and carrying out thermal cracking reaction at a high temperature of 600-1000 DEG C under the condition that N2 exits to prepare the 2, 3, 3, 3-tetrafluoropropene, wherein the volume ratio of the monochlorodifluoromethane to the methane chloride is 1-3:1, and the retention time of a reactant is 0.01-0.2 seconds. The reaction raw material used in the preparation method is easy to obtain, the defect of high cost of the used raw material in the prior art is overcome, the production cost is greatly reduced, and the reaction process is simple. The prepared 2, 3, 3, 3-tetrafluoropropene has the advantages of zero ODP and low GWP and can be used as a substitute of an automotive air-conditioning refrigerant.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Method for preparing biodegradable anion-exchange membrane

InactiveCN108187499ASolve environmental problemsWide variety of sourcesSemi-permeable membranesDispersed particle separationElectricityIon-exchange membranes

The invention belongs to the technical field of membrane separation and in particular relates to a method for preparing a biodegradable anion-exchange membrane. The method comprises the following steps: by taking microcrystalline cellulose as a base material, performing acidification hydrolysis and amination with hydrochloric acid, and performing cross-linking, thereby obtaining the anion-exchangemembrane which has the characteristics of being high in mechanical strength, good in acid-alkali resistance, good in hydrophilcity, biodegradability, and the like. The membrane is applicable to acid-alkali enriched environments of electroosmosis application environments and can be naturally degraded in the environments after the service life, and the problem that the environment can be damaged byconventional discarded ion exchange membranes can be solved.

Owner:KUNMING UNIV OF SCI & TECH

Environment-friendly powdery urea-formaldehyde resin adhesive

InactiveCN107858121AEasy to buyLow commercial priceNon-macromolecular adhesive additivesStarch derivtive adhesivesSal ammoniacChemistry

An environmentally friendly powdery urea-formaldehyde resin adhesive, comprising the following components in parts by weight: 120-140 parts of starch, 23-33 parts of formaldehyde, 20-24 parts of urea, 3-5 parts of hydrogen peroxide, and sodium hydroxide 3-5 parts, 0.8-1 part of formic acid, 0.6-1 part of ammonia water, 30-40 parts of UF resin, 18-24 parts of nano-copper oxide, 5-10 parts of dispersion liquid; also discloses an environmentally friendly powdery urea-formaldehyde resin The preparation method of the adhesive: adding nano-copper oxide into the nano-copper oxide dispersion liquid to uniformly disperse it, mixing it with oxidized starch and UF resin glue, putting it into the reaction kettle for heating and reacting to obtain a colloidal mixture A, and finally Put it in for spray drying and centrifugation to obtain powdery urea-formaldehyde resin adhesive. To sum up, the present invention has the characteristics of high bonding strength, water resistance, and long storage period. Starch is used as the main raw material, which effectively reduces environmental hazards, reduces production costs, and improves the production benefits of enterprises.

Owner:李琛璞

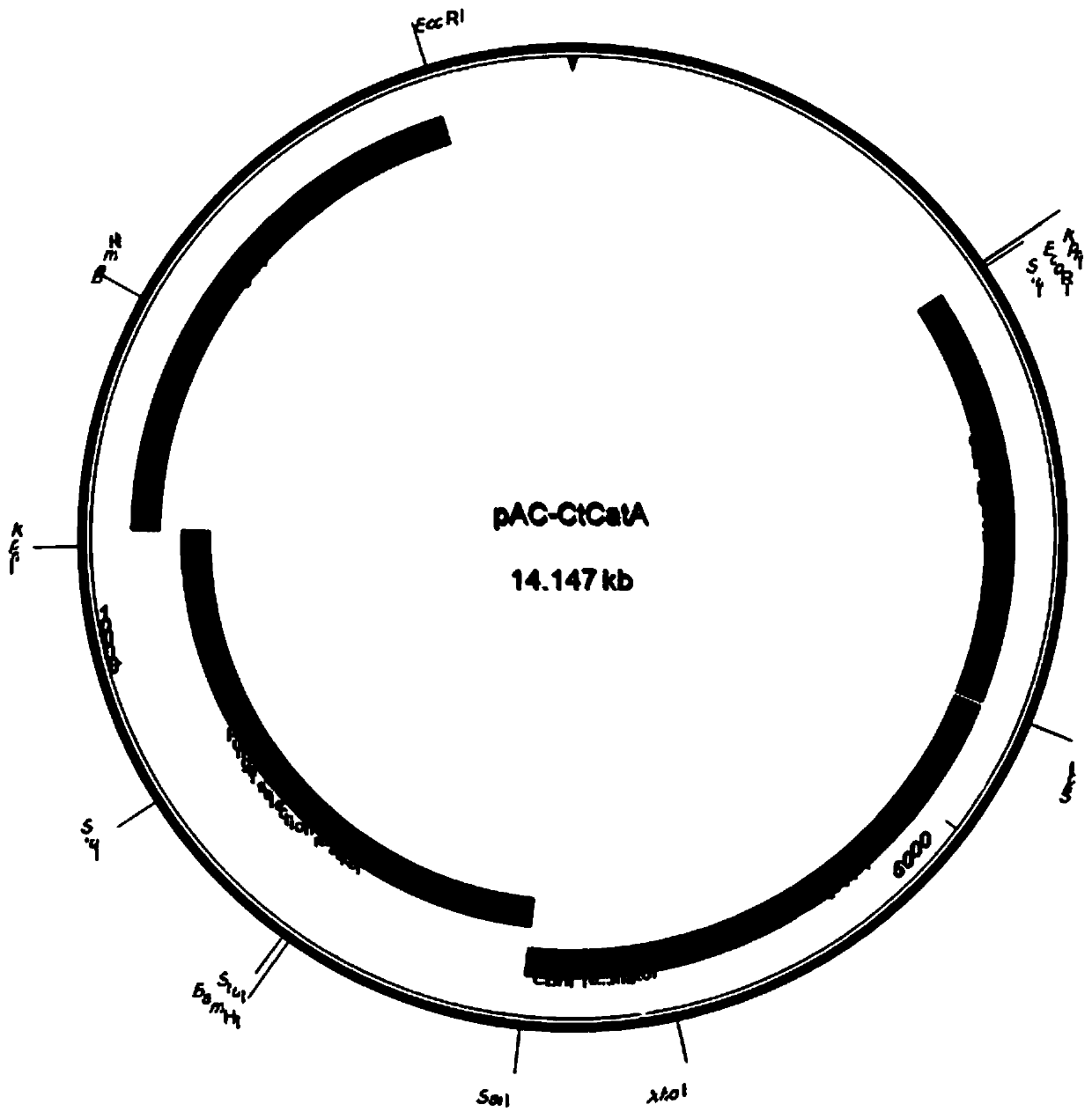

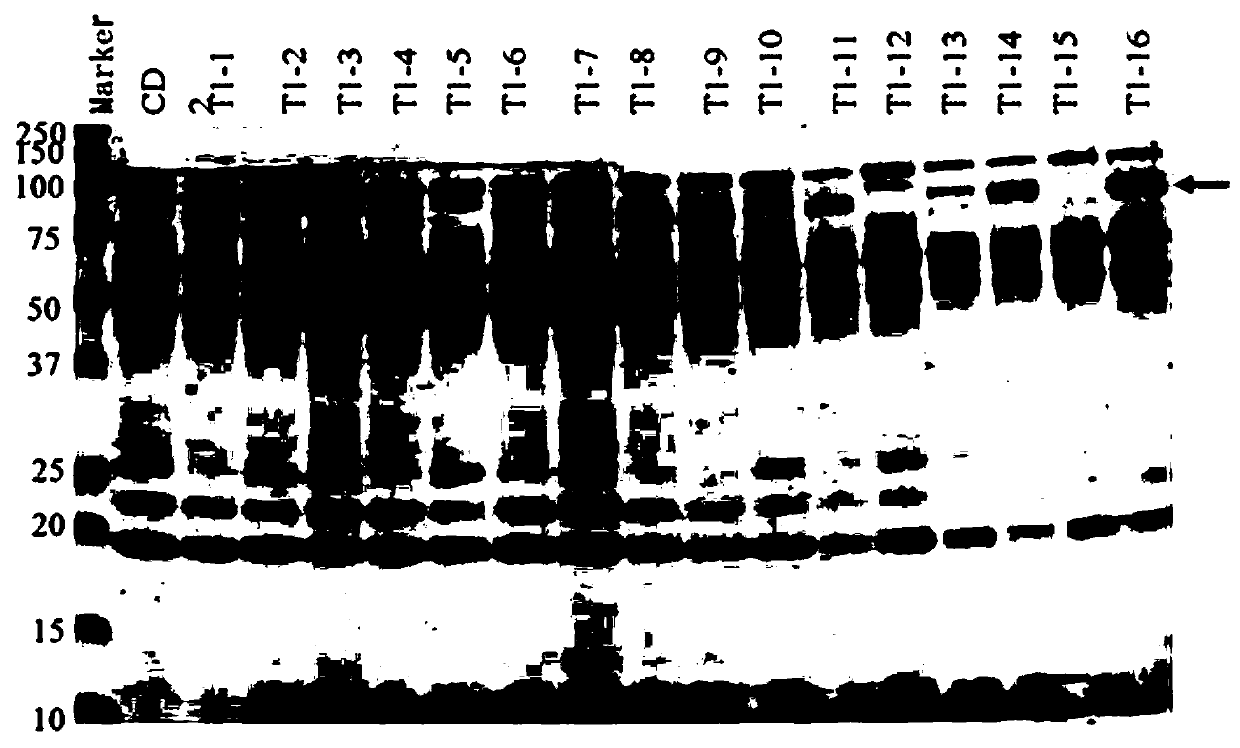

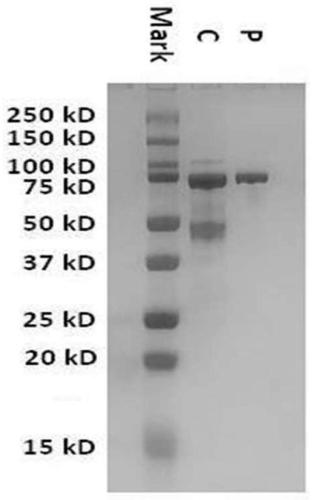

Chaetomium thermophilum temperature-resistant catalase and application

InactiveCN110373396ALow commercial priceLow costFungiMicroorganism based processesHigh humidityAntibiotic Y

The invention discloses chaetomium thermophilum temperature-resistant catalase and application. An amino acid sequence of chaetomium thermophilum temperature-resistant catalase is shown as SEQ ID No.1. Chaetomium thermophilum temperature-resistant catalase is obtained through heterogeneous expression and fermenting production of chaetomium thermophilum temperature-resistant catalase CatA gene, hashigh resistance to high temperature and high humidity and can be used for replacing antibiotics in livestock-poultry breeding.

Owner:SHANGHAI YOUTELL BIOCHEM +1

Preparation method of 2, 3, 3, 3-tetrafloropropylene

ActiveCN103833511AReduce the probability of side effectsAvoid the production of highly toxic substance perfluoroisobutyleneHalogenated hydrocarbon preparationChemistryPyrolysis

The invention provides a preparation method of 2, 3, 3, 3-tetrafloropropylene. The method comprises the following steps: with monochlorodifluoromethane and monochloro methane which are in a molar ratio of (0.5-4):1 as reaction raw materials, preheating the reaction raw materials, then mixing with superheated steam, wherein the volume ratio of the superheated steam to the reaction raw materials is (1-20):1, the temperature of the superheated steam is 900-1100 DEG C, the temperature in the reaction section is 600-1100 DEG C, and the stay time of reactants in the reaction section is 0.01-1s; and quenching, deacidifying, drying and rectifying and separating the product mixed flow to obtain 2, 3, 3, 3-tetrafloropropylene. The method provided by the invention overcomes the deficiency that a hollow tube is prone to carbonization in pyrolysis and side reactions are complex, the equipment maintenance rate is reduced, and meanwhile, the reaction period is prolonged, and the utilization ratio of the device is improved. The method provided by the invention has the characteristics of use of easily available raw materials, simple reaction process and the like. The obtained 2, 3, 3, 3-tetrafloropropylene has the advantages of zero ODP (Ozone Depletion Potential) and low GWP (Global Warming Potential), and is used as a substituent of automotive air conditionor refrigerant.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

Antibacterial low-toxicity modified pueraria starch powdery adhesive

InactiveCN107916079AEasy to buyLow commercial priceNon-macromolecular adhesive additivesProtein adhesivesSodium acetateAdhesive

An antibacterial and low-toxic modified pueraria starch powdery adhesive, comprising the following components in parts by weight: 120-140 parts of pueraria starch, 6-10 parts of montmorillonite, 20-30 parts of casein, 22 parts of sodium acetate ‑24 parts, 3‑5 parts of hydrochloric acid, 7‑9 parts of crosslinking agent, 1‑3 parts of coupling agent, 7‑9 parts of defoaming agent, 25‑35 parts of composite preservative, 13‑17 parts of antibacterial agent, urea 18-22 parts, 17-25 parts of cetyltrimethylammonium bromide, 4-6 parts of potassium permanganate; the present invention also discloses an antibacterial and low-toxic modified Pueraria starch powder adhesive Preparation method: first mix the oxidized kudzu starch, compound preservative and organically modified montmorillonite, then add urea and casein for heating reaction to obtain mixture B, then add dispersant, coupling agent and defoamer to obtain glue The solid C is finally spray-dried and centrifuged to obtain a powdery kudzu root starch adhesive. The invention has the characteristics of high bonding strength, water resistance, antibacterial, long environmental protection storage period, etc., effectively reduces the harm to the environment, reduces the production cost, and improves the production benefit of the enterprise.

Owner:李琛璞

Water-soluble florfenicol effervescent agent and preparation method thereof

InactiveCN109419781ADisintegrates quicklyStrong disintegrationAntibacterial agentsOrganic active ingredientsInorganic saltsOrganic acid

The invention relates to the field of veterinary antibiotics, and discloses a water-soluble florfenicol effervescent agent and a preparation method thereof. The florfenicol effervescent agent includes, by weight, 1-20 parts of ultrafine florfenicol powder, 0.2-5 parts of a cosolvent, 3-5 parts of an organic acid (an acid agent), and 1-11 parts of inorganic salt (an alkaline agent), with the balance being a filler and the total being 100 parts. Raw and auxiliary ingredients are safe, easily available and cheap, the process is simple, and the method has advantages of strong operability, low production cost, short preparation time and low production energy consumption, and is suitable for large-scale production and promotion.

Owner:王小桥

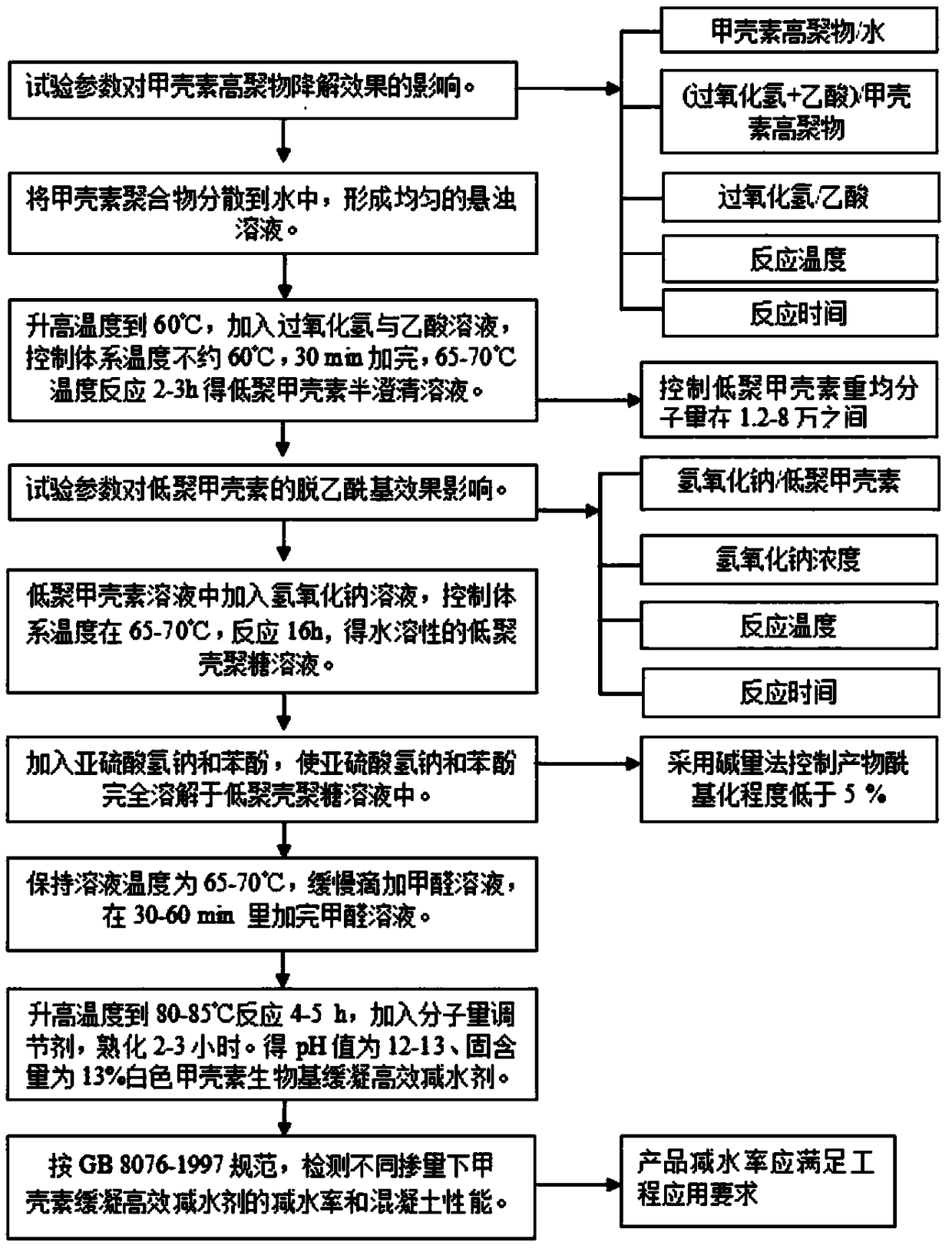

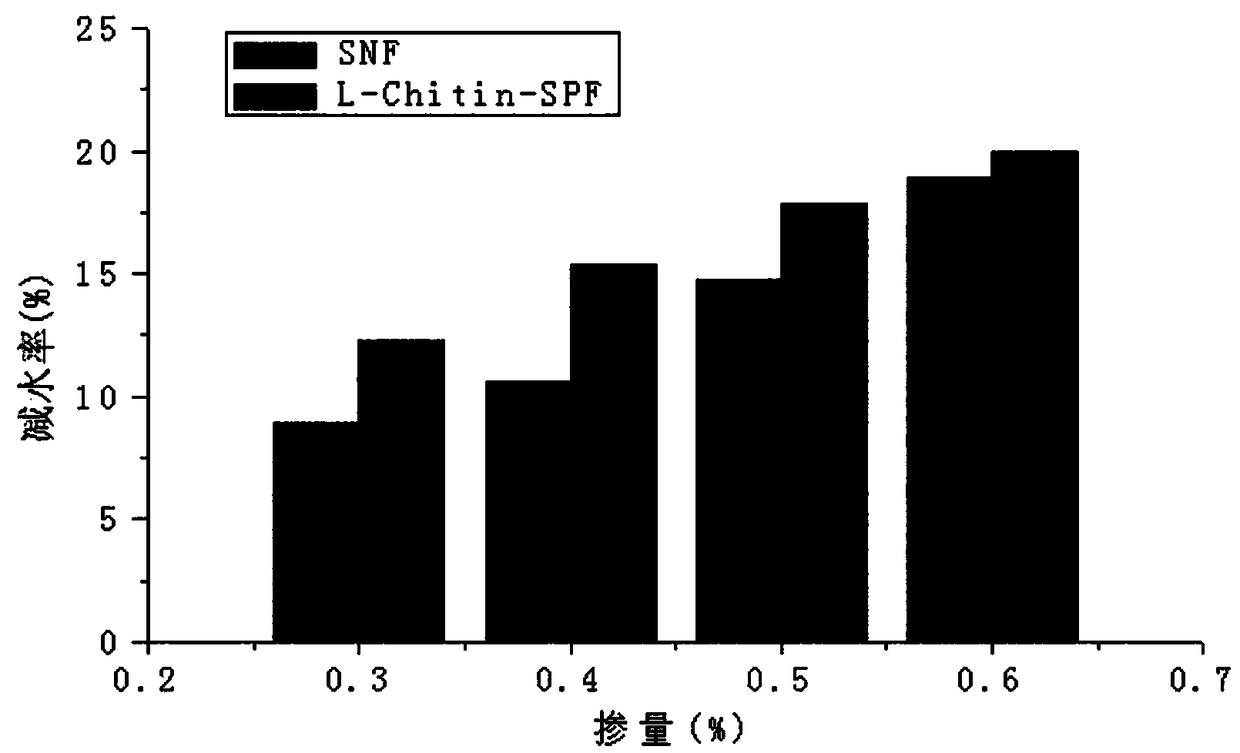

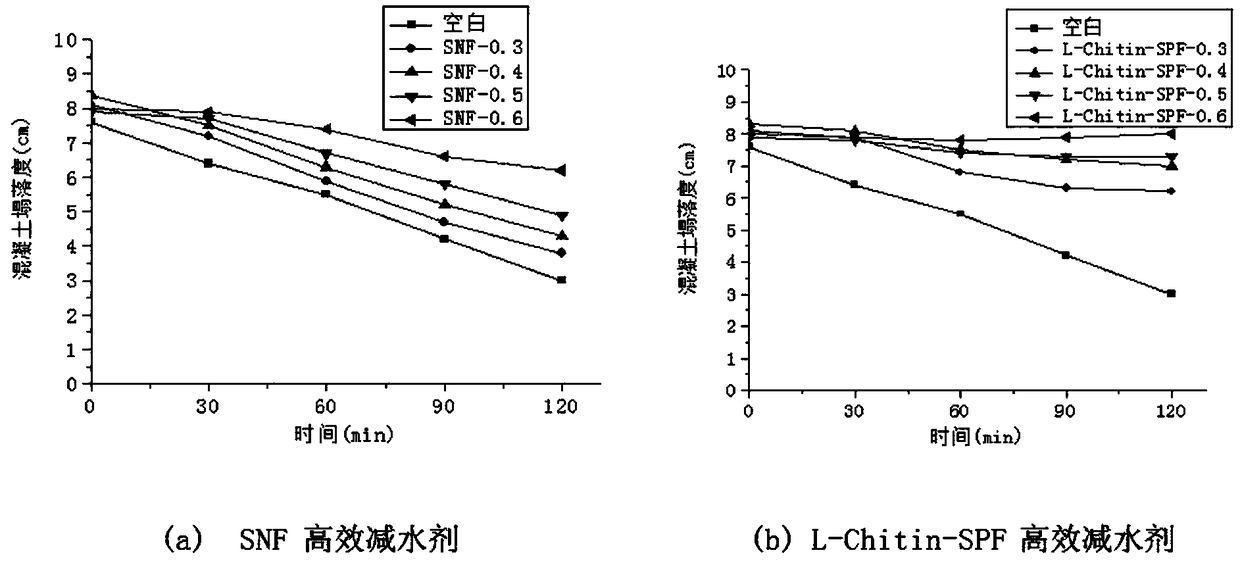

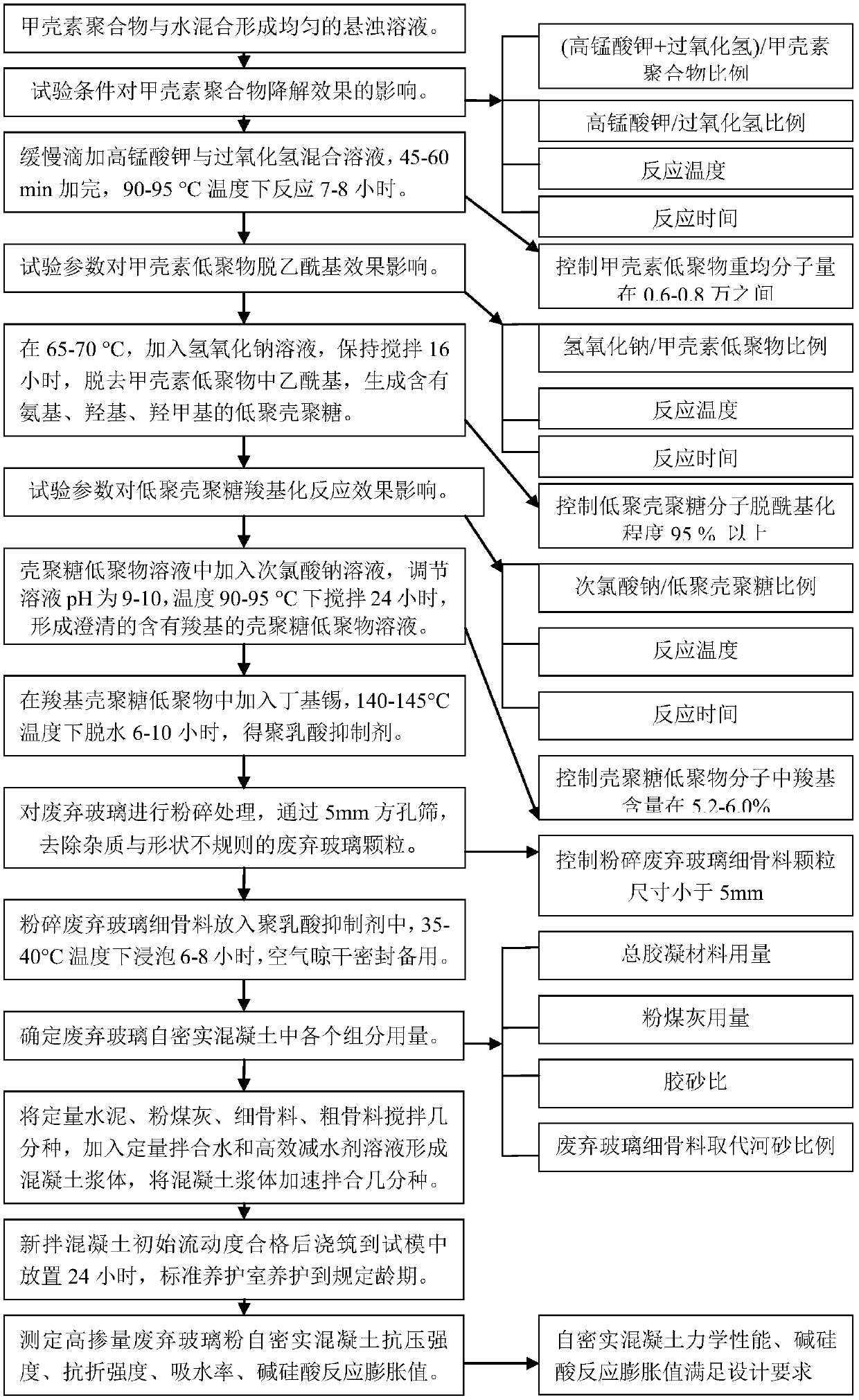

A method of using natural chitin to prepare bio-based retarding high-efficiency water reducer

The invention relates to a method for preparing a bio-base high-efficiency delayed-coagulation water-reducing agent from natural chitin. The method comprises the following steps: degrading a natural high polymer, and carrying out functional group remolding, so as to obtain a chitosan oligosaccharide intermediate containing functional groups such as amino and hydroxymethyl; carrying out condensation reaction by virtue of phenol and formaldehyde under alkaline conditions so as to generate a phenolic aldehyde intermediate, and carrying out addition reaction by virtue of sodium hydrogen sulfite and formaldehyde so as to introduce hydrophilic sulfonic acid groups to the phenolic aldehyde intermediate; and linking the chitosan oligosaccharide intermediate with the sulfonated phenolic aldehyde intermediate by virtue of hydroxymethyl polycondensation, so as to obtain the bio-base high-efficiency delayed-coagulation water-reducing agent with good water-reducing and delayed-coagulation effects. The chitin bio-base high-efficiency delayed-coagulation water-reducing agent has the characteristics of low raw material cost, environment-friendly protection process and the like and further has relatively good water-reducing and delayed-coagulation effects. The chitin bio-base high-efficiency delayed-coagulation water-reducing agent has economic and environmental protection benefits and is a novel high-efficiency water-reducing agent with great promise.

Owner:JINLING INST OF TECH

Antibacterial and low-toxin modified corn starch powdery adhesive

InactiveCN107815271AEasy to buyLow commercial priceNon-macromolecular adhesive additivesStarch adhesivesSodium acetateAdhesive

An antibacterial and low-toxic modified corn starch powdery adhesive, comprising the following components in parts by weight: 120-140 parts of corn starch, 6-10 parts of montmorillonite, 20-30 parts of casein, 22 parts of sodium acetate ‑24 parts, 3‑5 parts of hydrochloric acid, 7‑9 parts of crosslinking agent, 1‑3 parts of coupling agent, 7‑9 parts of defoaming agent, 25‑35 parts of composite preservative, 13‑17 parts of antibacterial agent, urea 18-22 parts, 17-25 parts of cetyltrimethylammonium bromide; the present invention also discloses a preparation method of an antibacterial and low-toxic modified corn starch powdery adhesive: first corn starch, compound Preservatives and organically modified montmorillonite are mixed evenly, then urea and casein are added for heating reaction to obtain mixture B, then dispersant, coupling agent and defoamer are added to obtain jelly C, and finally spray drying and centrifugation are carried out. Obtain powdery kudzu root starch adhesive. The invention has the characteristics of high bonding strength, water resistance, antibacterial, long environmental protection storage period, etc., effectively reduces the harm to the environment, reduces the production cost, and improves the production benefit of the enterprise.

Owner:李琛璞

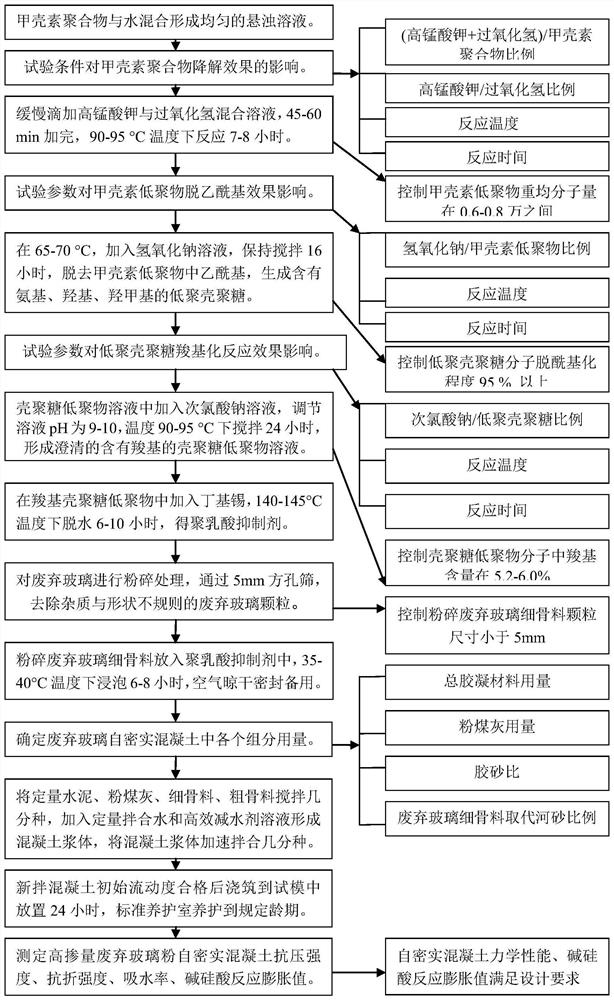

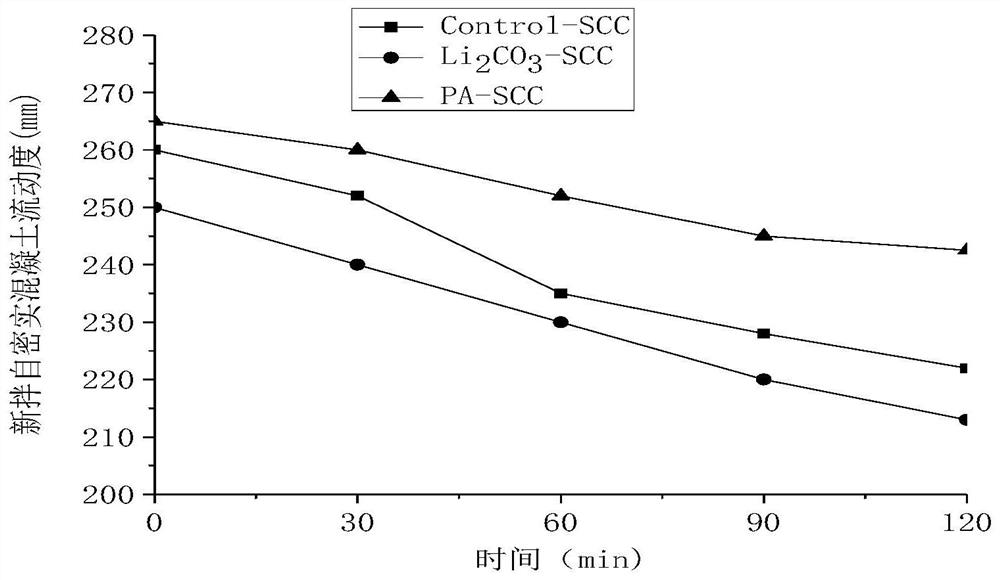

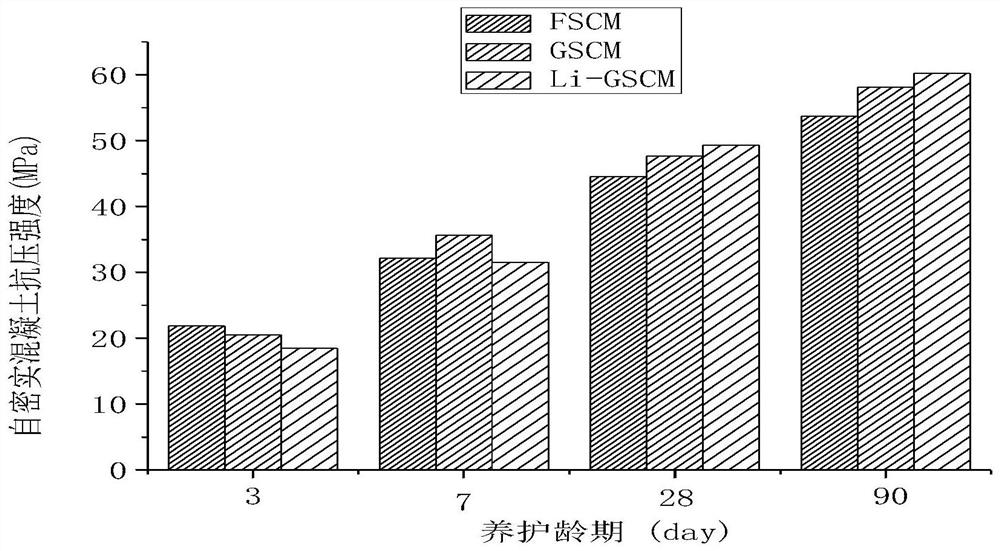

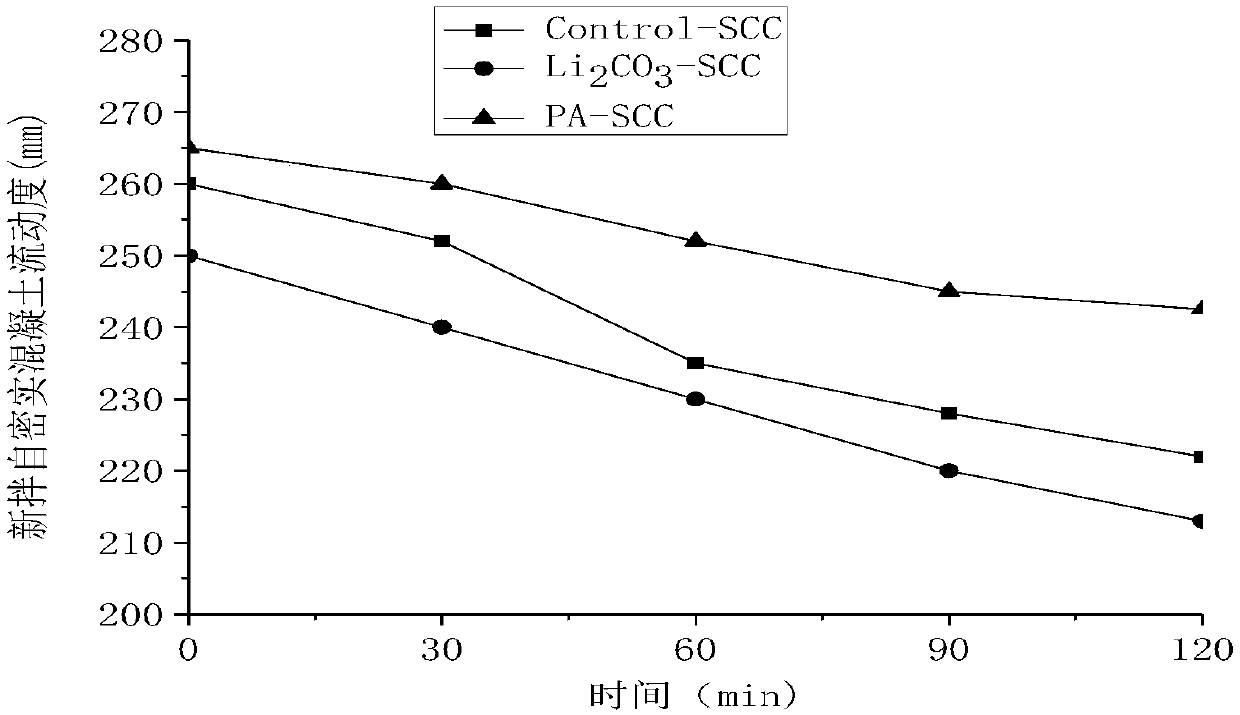

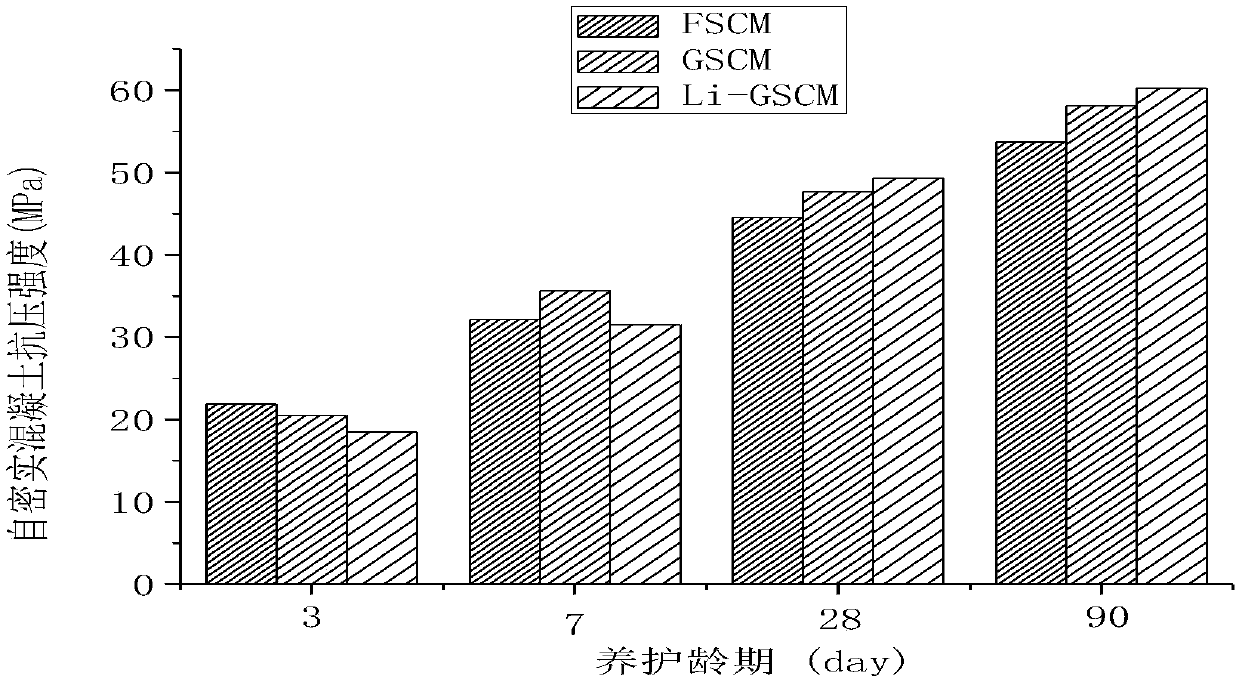

A preparation method of low-alkali silicic acid reaction expansion high-volume waste crushed glass self-compacting concrete

ActiveCN109534745BAlkali silicic acid reaction inhibitionWide variety of sourcesSilicic acidPolylactic acid

The invention relates to a low-alkali silicic acid reaction expanded high-doping amount waste pulverized glass self-compacting concrete preparation method. According to the invention, a natural chitinhigh polymer is subjected to degradation, deacylation, carboxylation, and intramolecular dehydration, and is modified to a low molecular weight polylactic acid base silicic acid reaction inhibitor; awaste pulverized glass fine aggregate covered by the polylactic acid base silicic acid reaction inhibitor is used to replace s river sand fine aggregate into the self-compacting concrete, and the low-alkali silicic acid reaction expanded high-doping amount waste pulverized glass self-compacting concrete is prepared. the addition of polylactic acid effectively inhibits the alkali silicic acid reaction in the high-doping amount waste pulverized glass self-compacting concrete. The high-doping amount waste pulverized glass self-compacting concrete has better working performance and durability performance and good volume stability than that of the traditional self-compacting concrete, which expands the application range of waste glass and can produce good technical, economic, social and environmental benefits.

Owner:JINLING INST OF TECH

A general-purpose quantitative detection method for chlorantraniliprole residues

Owner:连云港市农村能源环境保护办公室 +1

The preparation method of 2,3,3,3-tetrafluoropropene

The invention provides a preparation method of 2, 3, 3, 3-tetrafloropropylene. The method comprises the following steps: with monochlorodifluoromethane and monochloro methane which are in a molar ratio of (0.5-4):1 as reaction raw materials, preheating the reaction raw materials, then mixing with superheated steam, wherein the volume ratio of the superheated steam to the reaction raw materials is (1-20):1, the temperature of the superheated steam is 900-1100 DEG C, the temperature in the reaction section is 600-1100 DEG C, and the stay time of reactants in the reaction section is 0.01-1s; and quenching, deacidifying, drying and rectifying and separating the product mixed flow to obtain 2, 3, 3, 3-tetrafloropropylene. The method provided by the invention overcomes the deficiency that a hollow tube is prone to carbonization in pyrolysis and side reactions are complex, the equipment maintenance rate is reduced, and meanwhile, the reaction period is prolonged, and the utilization ratio of the device is improved. The method provided by the invention has the characteristics of use of easily available raw materials, simple reaction process and the like. The obtained 2, 3, 3, 3-tetrafloropropylene has the advantages of zero ODP (Ozone Depletion Potential) and low GWP (Global Warming Potential), and is used as a substituent of automotive air conditionor refrigerant.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

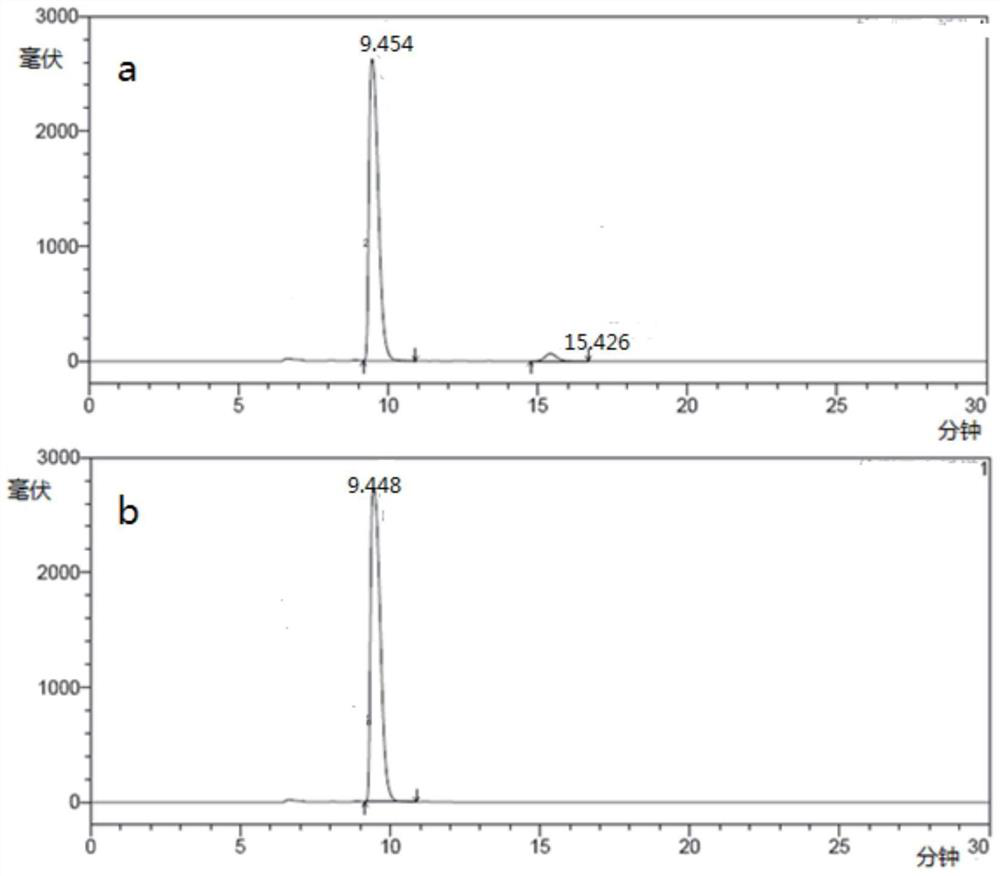

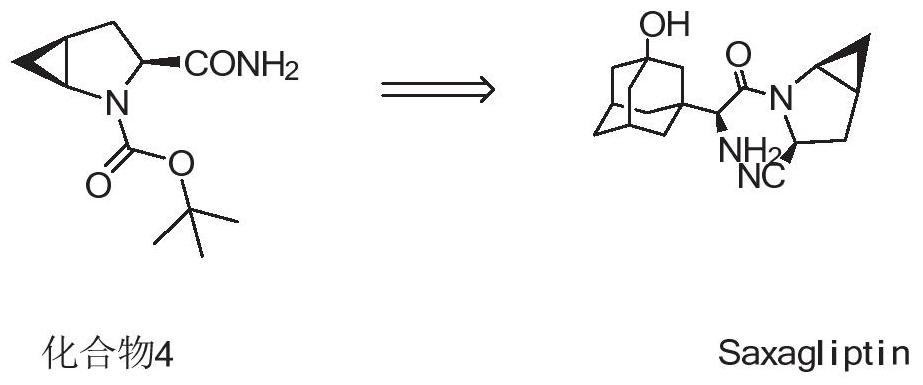

Preparation method of saxagliptin intermediate

The invention discloses a preparation method of a saxagliptin intermediate compound. The method comprises the following steps: in an ether organic solvent, in the presence of an acid, under the catalysis of cuprous catalyst and zinc powder, react compound I with dibromomethane. The preparation method has low cost, less environmental pollution and simple operation, and can be applied to industrialized industries.

Owner:SHANGHAI SHYNDEC PHARMA CO LTD

Black gingko nut health food and making method thereof

The invention relates to black gingko nut health food and a making method thereof. The health food is made by enabling pure gingko nut to self-ferment under the condition that the temperature is 60 to 65 DEG C and the humidity is 85 to 100% for 8 to 10 days and then taking out the gingko nut to be placed at a cool and ventilated place for 1 to 2 days. The black gingko nut self-ferments, has a simple process, is easy for batch production, saves the production cost, and can effectively reduce market sale price, so as to benefit the customers. The making method of the black gingko nut health food is carried out by self-fermenting under the condition of constant temperature, the fermentation accelerates the nutriment conversion of the gingko nut, the total amino acid and the total sugar are increased, and health food tastes sweet, is light in flavor, is antioxidant and strengthens the immunity.

Owner:徐州绿之野生物食品有限公司

A quantitative detection method for chlorantraniliprole residues in tea

ActiveCN106546675BLarge specific surface areaLarge adsorption capacityComponent separationElectron capture detectorNitrogen

The invention relates to a quantitative detection method for chlorantraniliprole residue in tea leaf. The quantitative detection method is characterized in that the residual chlorantraniliprole in tea leaf is subjected to ultrasonic extraction with an acetonitrile solvent, impurities are removed with a proper amount of MWCNTS and a PSA adsorbent, the supernatant is subjected to nitrogen blowing and concentration to achieve a close drying state, volume metering is performed with an acetone-n-hexane mixed solvent having a volume ration of 1:1, programmed heating separation is performed with a HP-5 chromatographic column, ECD determination is performed with an electron capture detector, and quantitation is performed through a matrix external standard method. According to the present invention, the test results confirm that the method has characteristics of simple, rapid and accurate operation, easy popularizing and grasping and low cost, provides the rapid and reliable method for the determination of the chlorantraniliprole residue in the tea leaf, and can meet the requirements of the large-batch sample analysis on the quality and the progress.

Owner:SUZHOU ACADEMY OF AGRI SCI

A quantitative detection method for chlorantraniliprole residues in soil

The invention provides a quantitative detection method for the residual quantity of chlorantraniliprole in the soil. The method is characterized in that the ultrasonic extraction of residual chlorantraniliprole in the soil is conducted in an acetonitrile solvent, and then impurities are removed by adopting a proper amount of MWCNTS and PSA adsorbent. An obtained supernate is subjected to nitrogen-blowing, concentrating and drying, and then the volume is metered by adopting an acetone and n-hexane mixed solvent, wherein the volume ratio of acetone to n-hexane in the mixed solvent is 1:1. After that, the obtained mixture is subjected to programmed warming and separating by adopting a HP-5 chromatographic column, and the ECD determination is conducted by an electronic capture detector. Finally, the residual quantity of chlorantraniliprole is quantitatively detected based on the matrix external standard method. Experiments prove that, the above method is simple, rapid and accurate in operation, easy to popularize and master, and low in cost. Therefore, the method provides a rapid and reliable method for the residual quantity measurement of chlorantraniliprole in the soil, and the requirements of the batch sample analysis on quality and progress can be met.

Owner:SUZHOU ACADEMY OF AGRI SCI

Preparation method of ultraviolet-resistant and high-temperature-resistant methyl silicone resin

The invention relates to a preparation method of ultraviolet-resistant and high-temperature-resistant methyl silicone resin, relates to the preparation method of modified methyl silicone resin, and is used for solving the problems that the existing methyl silicone resin is poor in high temperature and ultraviolet resistance, complicated in preparation method and high in cost. The preparation method comprises the following steps of:1, dispersing ethyl orthosilicate in anhydrous ethanol and then adding a mixing solution of deionized water, the anhydrous ethanol and ammonia, thereby obtaining a silica ethanol solution; 2, dispersing tetrabutyl titanate in the anhydrous ethanol and then adding the mixing solution of the deionized water, the anhydrous ethanol and hydrochloric acid, thereby obtaining a titania ethanol solution; 3, dispersing methyl triethoxysilane and diethoxydimethylsilane in the anhydrous ethanol, thereby preparing a methyl silicone resin prepolymer; and 4, regulating the pH values of the solutions obtained in the steps 1 and 2 to be 7 and performing a refluxing operation after adding the prepolymer, thereby obtaining the methyl silicone resin. The method is conventional in raw material preparation as well as simple and easy to implement. The thermal weight loss rate of the modified methyl silicone resin at the temperature of 300 DEG C is 0.6, so that the modified methyl silicone resin is good in ultraviolet resistance.

Owner:HARBIN INST OF TECH

Low-alkali silicic acid reaction expanded high-doping amount waste pulverized glass self-compacting concrete preparation method

ActiveCN109534745AAlkali silicic acid reaction inhibitionWide variety of sourcesSilicic acidAcyl group

The invention relates to a low-alkali silicic acid reaction expanded high-doping amount waste pulverized glass self-compacting concrete preparation method. According to the invention, a natural chitinhigh polymer is subjected to degradation, deacylation, carboxylation, and intramolecular dehydration, and is modified to a low molecular weight polylactic acid base silicic acid reaction inhibitor; awaste pulverized glass fine aggregate covered by the polylactic acid base silicic acid reaction inhibitor is used to replace s river sand fine aggregate into the self-compacting concrete, and the low-alkali silicic acid reaction expanded high-doping amount waste pulverized glass self-compacting concrete is prepared. the addition of polylactic acid effectively inhibits the alkali silicic acid reaction in the high-doping amount waste pulverized glass self-compacting concrete. The high-doping amount waste pulverized glass self-compacting concrete has better working performance and durability performance and good volume stability than that of the traditional self-compacting concrete, which expands the application range of waste glass and can produce good technical, economic, social and environmental benefits.

Owner:JINLING INST OF TECH

A kind of preparation method of titanium oxide nanoparticle/multilayer graphene composite material

ActiveCN110201658BLow commercial priceEasy to makePhysical/chemical process catalystsGrapheneTitanium surfaceNanoparticle

The invention discloses a method for preparing a titanium oxide nanoparticle / multilayer graphene composite material. Nano-titanium oxide particles are used as raw materials, and nano-titanium oxide is added to a mixed solution of DMF and water, and dilute nitric acid solution is added. Under the condition of water bath at ℃, organic functional groups are generated on the surface of nano-titanium oxide, and nano-titanium oxide is uniformly deposited on the surface of multi-layer graphene through the molecular force on the surface of multi-layer graphene, and finally uniform composite titanium oxide nanoparticles / multi-layer graphene are obtained composite material. The preparation process of the invention is simple and suitable for industrialized production.

Owner:HANGZHOU DIANZI UNIV

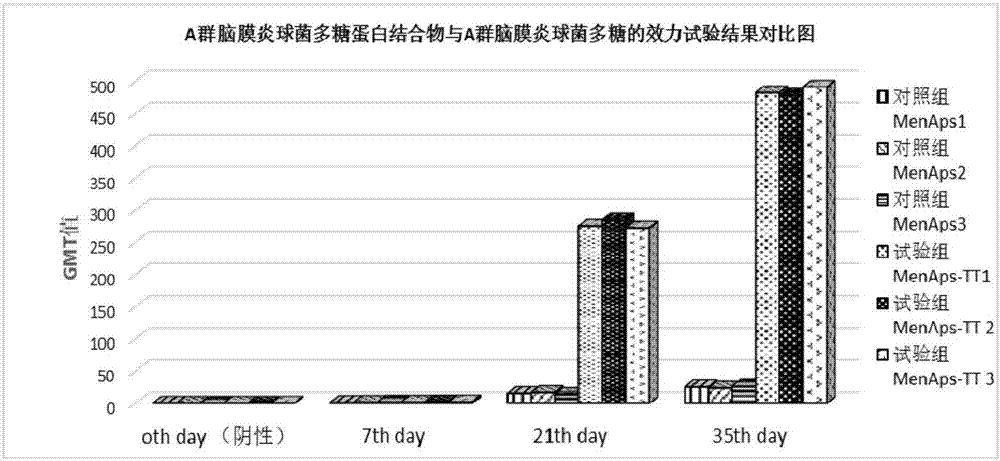

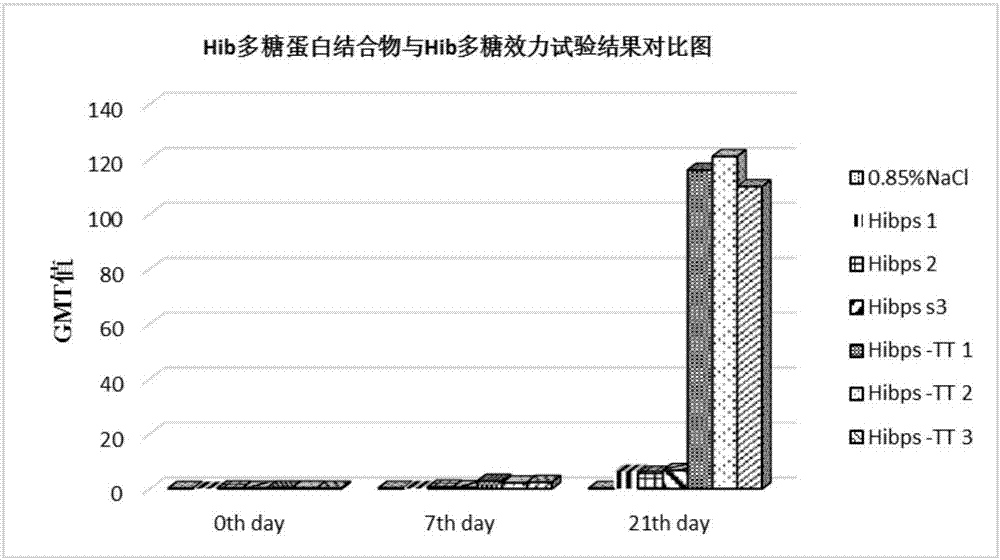

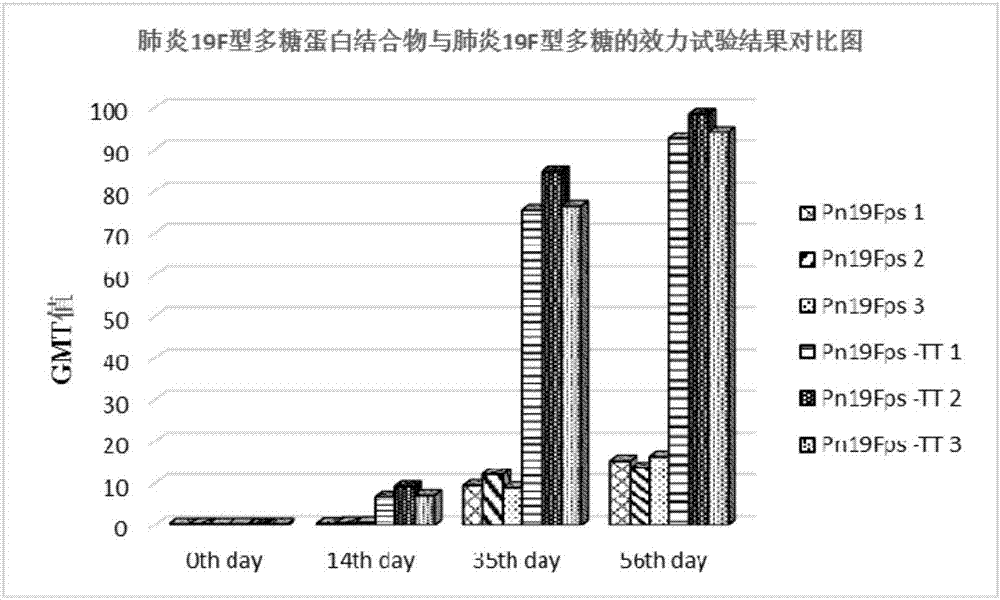

Preparation method of bacterial polysaccharide and protein conjugate vaccine by using DSC as activating agent

InactiveCN107261130ATo achieve the effect of polysaccharideLow toxicityAntibacterial agentsBacterial antigen ingredientsConjugate vaccineSuccinimidyl carbonate

The invention discloses a preparation method of a bacterial polysaccharide and protein conjugate vaccine. The preparation method comprises the following step that before covalent binding of bacterial polysaccharide and protein, enabling bacterial polysaccharide and N,N'-disuccinimidyl carbonate (DSC) to generate activating reaction in an alkaline water solution with pH (potential of hydrogen) value of 8.0 to 9.5, so as to form the succinimidyl carbonate of the bacterial polysaccharide. The preparation method has the advantages that by using the N,N'-disuccinimidyl carbonate (DCS) as a bacterial polysaccharide activating agent, the toxicity is lower, the environment-friendly effect is realized, the cost is low, and the preparation cost of the vaccine is reduced; the activating time of polysaccharide is short, the number of steps is fewer, the whole binding cycle from polysaccharide activating to polysaccharide and protein binding is 4 to 5 days, the content of free polysaccharids is lower, and the animal immunogenicity is better.

Owner:云南沃森生物技术股份有限公司

A 3D printing material based on modified chitosan

ActiveCN107880325BHigh biodegradation rateGood flexibilityAdditive manufacturing apparatusPolymer scienceSodium phosphates

The invention relates to a 3D printing material based on modified chitosan. The printing material is prepared from raw materials in parts by weight as follows: 80-100 parts of modified chitosan, 20-40parts of butadiene styrene rubber, 20-35 parts of kaolin, 10-15 parts of an organosilicon coupling agent, 10-15 parts of hydroxy propyl methyl cellulose, 1-4 parts of polycaprolactone, 1-4 parts of liquid paraffin, 1-5 parts of polyethylene glycol, 2-5 parts of nano porous activated carbon, 2-6 parts of sodium polyphosphate, 3-9 parts of nano silicon dioxide, 3-9 parts of talc powder, 2-6 parts of zeolite powder, 1-4 parts of a surfactant and 3-5 parts of an antioxidant. Through addition of the modified chitosan, the biodegradation rate of the material, the flexibility of the material and theintegration property with rubber and other organic high polymer material components are increased, and the 3D printing material has the advantages of high impact toughness resistance and high stretching strength under the synergistic action of the raw materials through compounding, is easy to form and adopts a simple forming process.

Owner:范一鸣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com