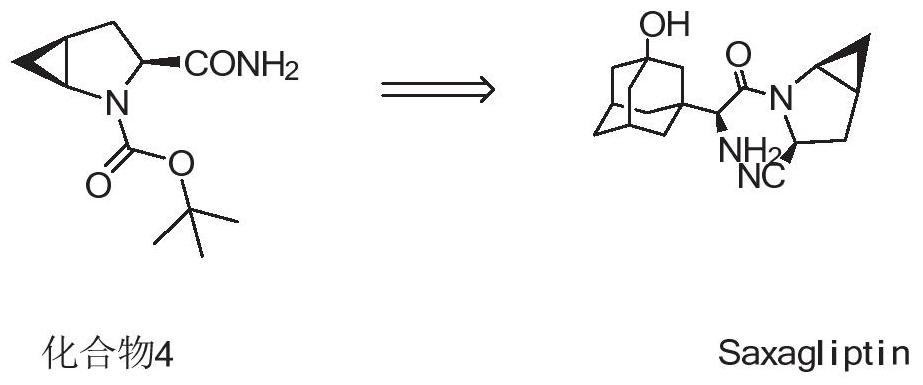

Preparation method of saxagliptin intermediate

An intermediate and volume technology, applied in organic chemistry and other directions, can solve the problems of high industrialization cost, harsh reaction conditions, expensive process raw materials, etc., and achieve the effects of low cost, simple operation and less environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

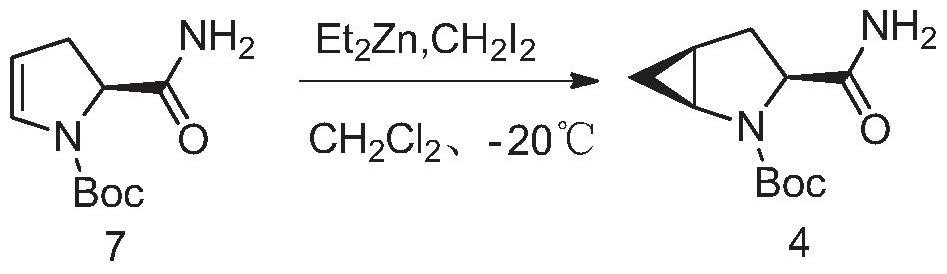

Method used

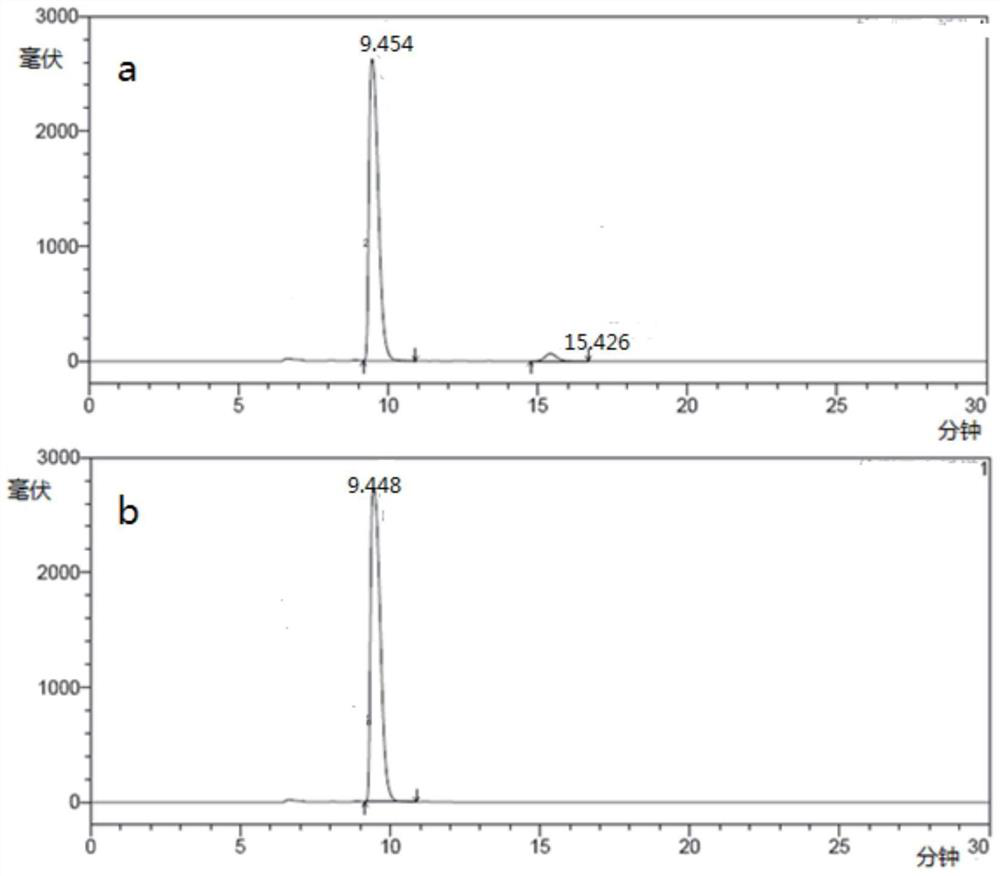

Image

Examples

Embodiment 1

[0045]

[0046] Add 20g of compound 5 (N-boc-4,5-dehydroproline ethyl ester), 20g of zinc powder, 11.2g of CuBr, 400ml of tetrahydrofuran into a 500mL three-necked flask, stir at 25°C, and 2 Protection, adding CH dropwise 2 Br 2 135g, heat up to 40°C, slowly add trifluoroacetic acid (2ml) dropwise, the color of the reaction solution changes from gray-green to purple-black, the reaction is triggered, the temperature rises from 40°C to 47°C, and reacts at 40°C-50°C for 18 hours, The raw materials were basically reacted completely, concentrated under reduced pressure, added 1L ethyl acetate, 400ml water, 100ml saturated aqueous sodium bicarbonate solution, stirred, filtered with suction, separated phases, concentrated the ethyl acetate phase, and used n-heptane / ethyl acetate=30: 1 was passed through the column to obtain 7 g of compound 6 (yield 32.5%). 1 H-NMR (CDCl 3 , 400MHz): 4.5-4.6(m, 1H), 4.16-4.20(m, 2H), 3.47-3.51(m, 1H), 2.50-2.56(m, 1H), 2.20-2.36(m, 1H), 1.55 -1...

Embodiment 2

[0049] Add 4g of compound 5 (N-boc-4,5-dehydroproline ethyl ester), 4g of zinc powder, 2.2g of CuBr, 80ml of tetrahydrofuran into a 100mL three-necked flask, stir at 0°C, and 2 Protection, adding CH dropwise 2 Br 2 27g, slowly add trifluoroacetic acid (2ml) dropwise, react at 0°C for 72h, concentrate under reduced pressure, add 200ml ethyl acetate, 80ml water, 20ml saturated aqueous sodium bicarbonate solution, stir, filter with suction, separate phases, concentrate ethyl acetate The phase was passed through the column with n-heptane / ethyl acetate=30:1 to obtain 0.6 g of compound 6 (yield 14.4%).

Embodiment 3

[0051] Add 4g of compound 5 (N-boc-4,5-dehydroproline ethyl ester), 4g of zinc powder, 2.2g of CuBr, 80ml of tetrahydrofuran into a 100mL three-necked flask, and stir at 66°C under N 2 Protection, adding CH dropwise 2 Br 2 27g, slowly add trifluoroacetic acid (2ml) dropwise, react at 66°C for 3h, concentrate under reduced pressure, add 200ml ethyl acetate, 80ml water, 20ml saturated aqueous sodium bicarbonate solution, stir, suction filter, separate phases, concentrate ethyl acetate Phase was passed through the column with n-heptane / ethyl acetate=30:1 to obtain 0.3 g of compound 6 (yield 7.08%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com