A method of using natural chitin to prepare bio-based retarding high-efficiency water reducer

A high-efficiency water-reducing agent and chitin technology, which is applied in the field of using natural chitin to prepare a bio-based retarding high-efficiency water-reducing agent, can solve the problems of limited use, easy bleeding of concrete, physical health damage, etc., and can save material costs. Expenses, low commercial prices, and the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] According to the method described in this patent technology, a batch (1 ton) of natural chitin bio-based retarding superplasticizer is produced for concrete application research.

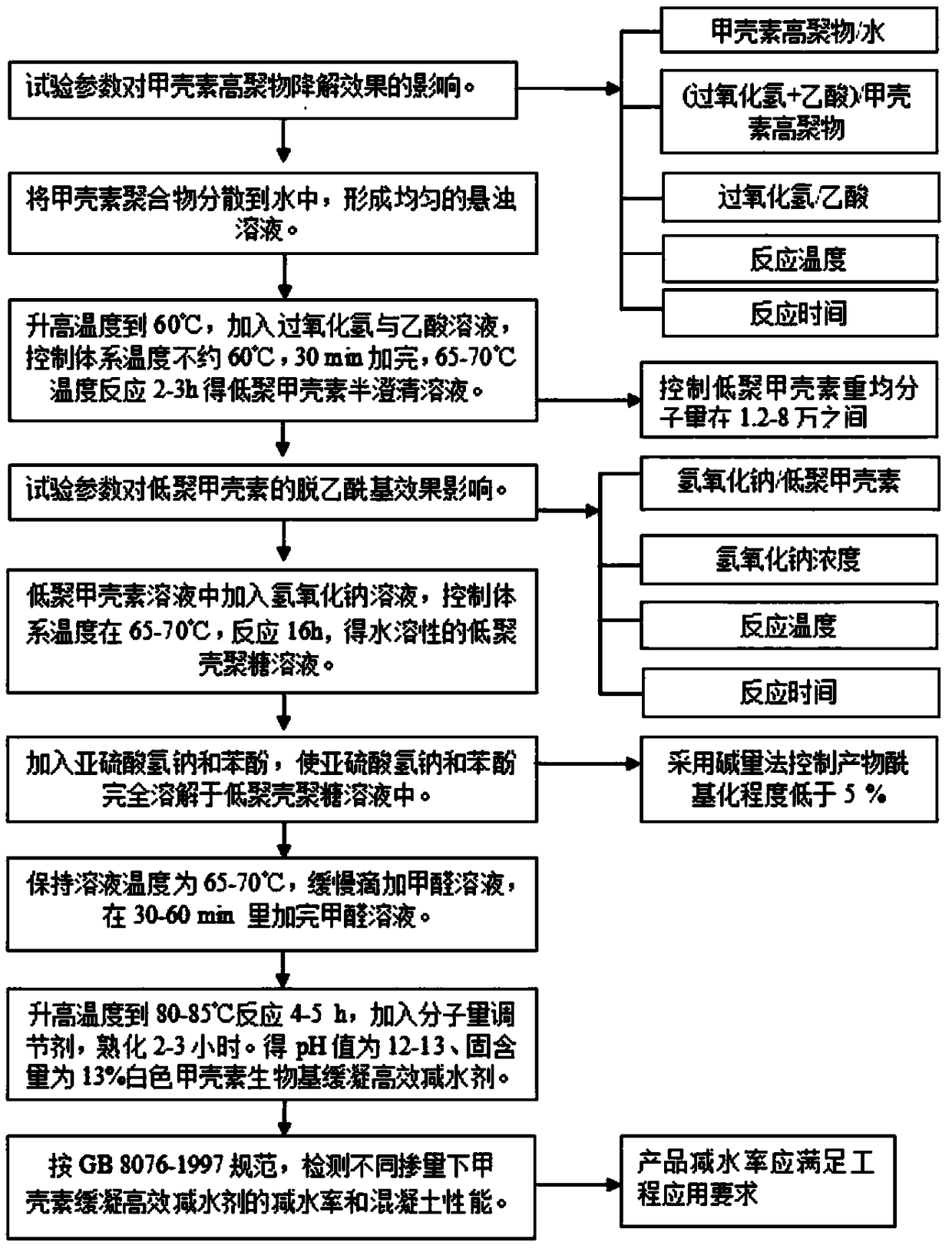

[0041] Preparation of natural chitin bio-based retarding superplasticizer

[0042] 1. Preparation of oligomeric chitin

[0043] Weigh 160-170kg of natural chitin polymer (the weight average molecular weight is 411,900) and 830-840kg of water into a reaction vessel equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser, and proceed at a certain speed. After stirring, the chitin polymer is dispersed into the water to form a uniform suspension solution. Raise the temperature to 60°C, add dropwise a mixed solution of 15-17kg hydrogen peroxide (50% concentration) and 5-7kg acetic acid (99.8% concentration) under stirring, control the temperature not to exceed 60°C, and complete the addition within 30 minutes , React at a temperature of 65-70°C for 3 hours to obtain a s...

Embodiment 2

[0049] According to the method described in this patent technology, a batch (1.5 tons) of natural chitin bio-based retarding superplasticizer was produced for concrete application research.

[0050] Preparation of natural chitin bio-based retarding superplasticizer

[0051] 1. Preparation of oligomeric chitin

[0052] Weigh 240-255kg of natural chitin polymer (weight-average molecular weight: 411,900) and 1200-1300kg of water into a reaction vessel equipped with a stirrer, thermometer, dropping funnel, and reflux condenser, and stir at a certain speed , chitin polymer dispersed in water to form a uniform suspension solution. Raise the temperature to 60°C, add dropwise a mixed solution of 22-25.5kg hydrogen peroxide (50% concentration) and 7.5-10.5kg acetic acid (99.8% concentration) while stirring, control the temperature not to exceed 60°C, and add in 30 minutes Complete reaction at 65-70°C for 3.5 hours to obtain a semi-clear solution of oligomeric chitin. The molecular w...

Embodiment 3

[0058] According to the method described in this patent technology, a batch (2 tons) of natural chitin bio-based retarding superplasticizer was produced for concrete application research.

[0059] Preparation of natural chitin bio-based retarding superplasticizer

[0060] 1. Preparation of oligomeric chitin

[0061] Weigh 320-340kg of natural chitin polymer (the weight average molecular weight is 411,900) and 1660-1680kg of water into a reaction vessel equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser, and proceed at a certain speed. After stirring, the chitin polymer is dispersed into the water to form a uniform suspension solution. Raise the temperature to 60°C, add dropwise a mixed solution of 30-34kg hydrogen peroxide (50% concentration) and 10-14kg acetic acid (99.8% concentration) under stirring, control the temperature not to exceed 60°C, and complete the addition within 30 minutes , React at a temperature of 65-70°C for 3 hours to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com