A kind of preparation method of titanium oxide nanoparticle/multilayer graphene composite material

A technology of multi-layer graphene and nano-particles, applied in the field of materials, can solve the problems of low dispersion between nano-TiO2 particles and graphene, high cost of graphene oxide preparation, and low preparation efficiency, so as to facilitate industrial production and low cost , The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better illustrate the process and solutions of the present invention, the following inventions will be further described in conjunction with the accompanying drawings and embodiments. The specific embodiments described here are only used to explain the present invention, not to limit the present invention.

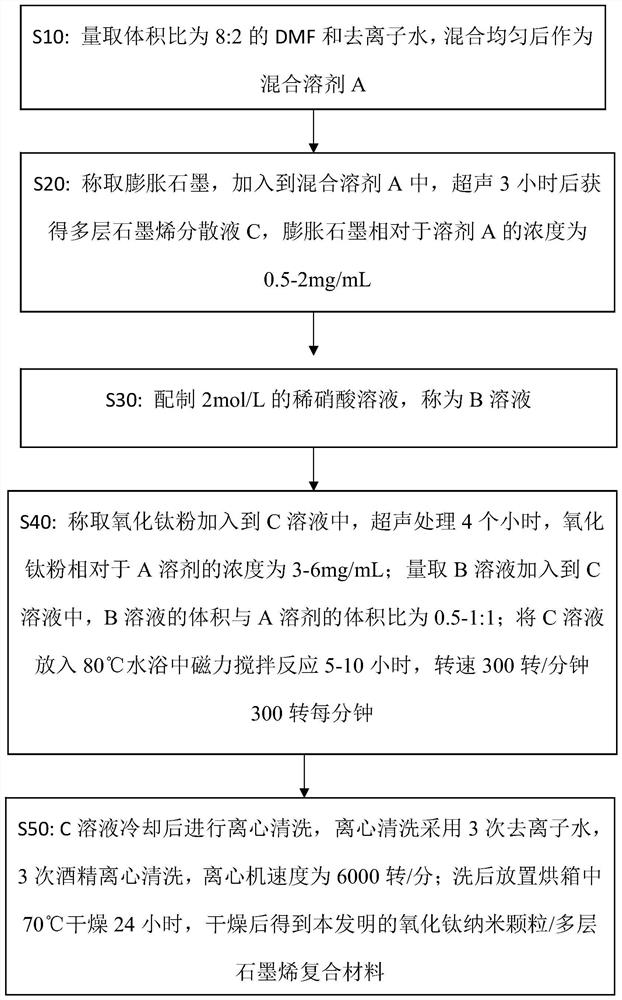

[0027] In order to solve the technical problems existing in the prior art, see figure 1 , shows that the present invention proposes a kind of nano-TiO 2 A flow chart of the preparation method steps of particles evenly distributed on the multilayer graphene, comprising the following steps:

[0028] S10, measure DMF and deionized water with a volume ratio of 8:2, and mix them uniformly as mixed solvent A.

[0029] S20, weigh the expanded graphite, add it to the mixed solvent A, and obtain the multilayer graphene dispersion C after ultrasonication for 3 hours, the concentration of the expanded graphite relative to the solvent A is 0.5-2 mg / mL.

[0030] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com