Low-alkali silicic acid reaction expanded high-doping amount waste pulverized glass self-compacting concrete preparation method

A self-compacting concrete and alkali silicic acid reaction technology, applied in the field of new building materials, can solve the problems of increasing the production cost of waste crushed glass self-compacting concrete, low consumption of waste crushed glass, large alkali silicic acid reaction expansion, etc. Low price, cost saving, low water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

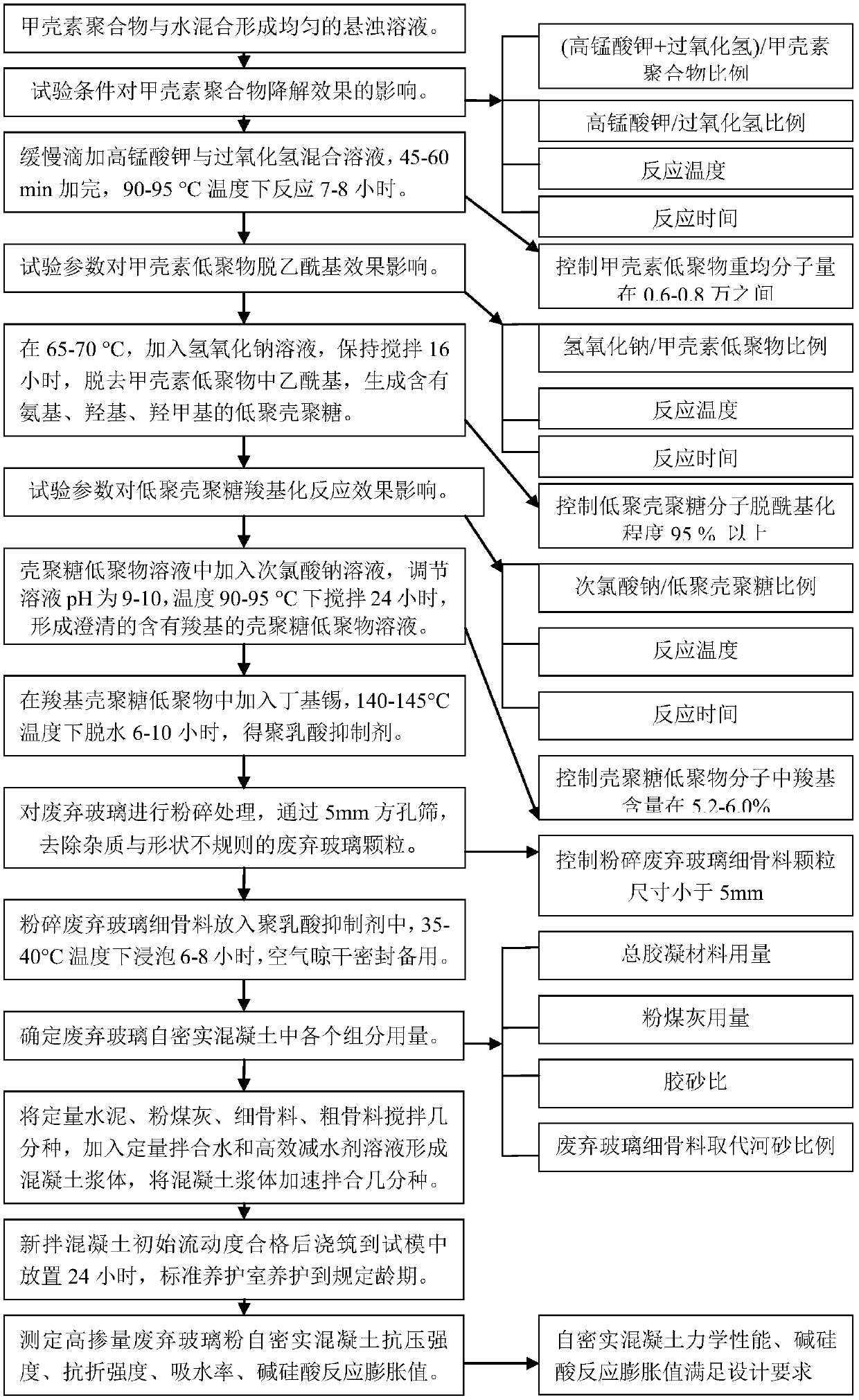

Method used

Image

Examples

Embodiment Construction

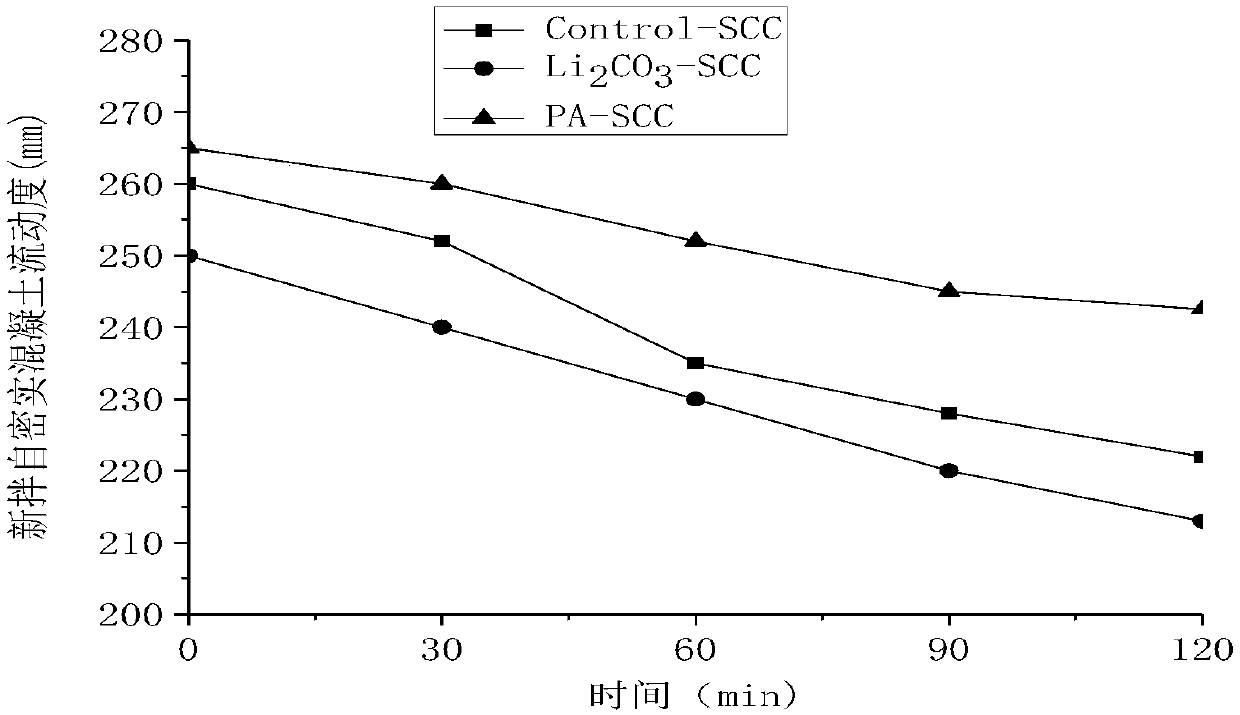

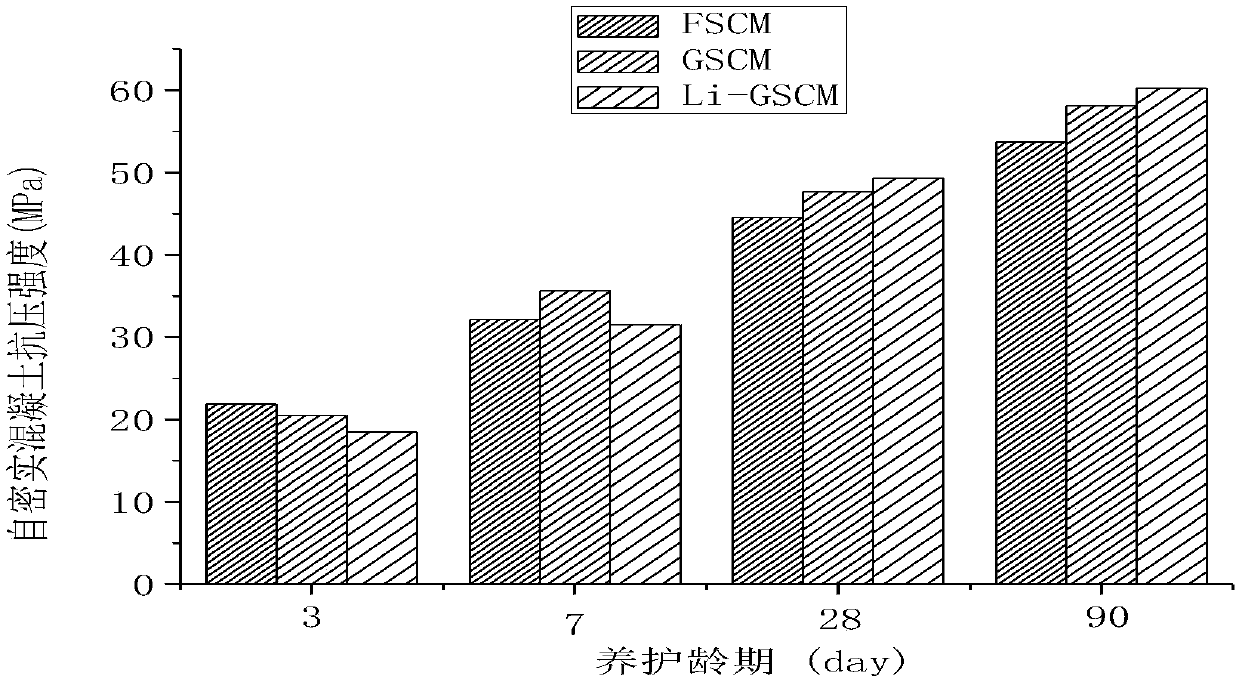

[0045] The present invention will be further described below in conjunction with specific examples. In the embodiment of the present invention, the technical scheme of the present invention is used to prepare one cubic meter of low-alkali silicic acid reaction expansion high-volume waste crushed glass self-compacting concrete, and under the same mix ratio, the high-volume waste crushed glass without lithium salt The properties of self-compacting concrete and self-compacting concrete samples with high content of waste crushed glass added with lithium salt were compared.

[0046] 1. Preparation of polylactic acid alkali silicic acid reaction inhibitor using chitin polymer

[0047] 1.1. Degradation of chitin polymer

[0048] Weigh 245-250kg of chitin polymer (weight average molecular weight is 411,900) and 750-755kg of water into a reaction vessel equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser. Raise the temperature to 85-90°C and accelerate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com