Preparation method for anti-ultraviolet heatproof BOPET film

An anti-ultraviolet and film technology, applied in the direction of flat products, other household appliances, household appliances, etc., can solve the problems of anti-ultraviolet activity and poor heat resistance, achieve good anti-ultraviolet and heat insulation performance, low commercial price, ultraviolet The effect of absorption characteristic peak enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

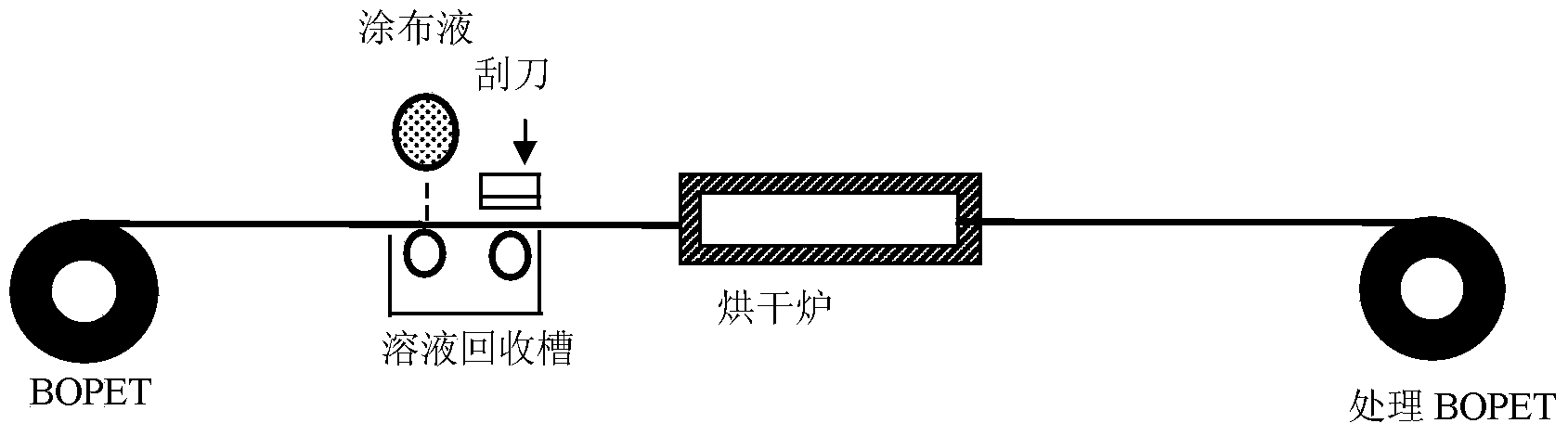

Image

Examples

specific Embodiment approach 1

[0013] Specific embodiment one: the preparation method of the anti-ultraviolet, heat-resistant BOPET film of the present embodiment is specifically carried out according to the following steps:

[0014] 1. Take 0.2g of silane coupling agent and disperse it in 100-150g of deionized water, adjust the pH value to 3-4 with nitric acid, then add 10g of sericite, and stir magnetically for 20-30min to obtain a sericite solution;

[0015] 2. Take 10-15g of tetrabutyl titanate and disperse it in 90-100g of absolute ethanol, and stir it magnetically for 30-40min to obtain the ethanol dispersion of tetrabutyl titanate, then add 10-15g of deionized water, 50-60g of absolute ethanol and 10-12g of nitric acid solution, magnetically stirred for 30 minutes to obtain a mixed solution, and then added the mixed solution dropwise to the sericite solution, at 50-60°C, 500-800r / min with magnetic force Stir for 5-6 hours to obtain a titanium dioxide / sericite solution, which is the coating solution; ...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment is different from Embodiment 1 in that the model of the silane coupling agent in step 1 is KH-550. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0019] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the particle size of sericite in step 1 is 100-500 nm. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com