Method for treating high-concentration difficulty-degradable alkaline waste liquid by using iron carbon activated persulfate

A technology for activating persulfate and persulfate, applied in the field of organic pollutants, can solve the problems of persistent, efficient and rapid removal of unfavorable COD, short service life of catalysts, and high processing costs, and achieves the benefits of efficient processing and saving acid addition. The effect of neutralizing and good degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

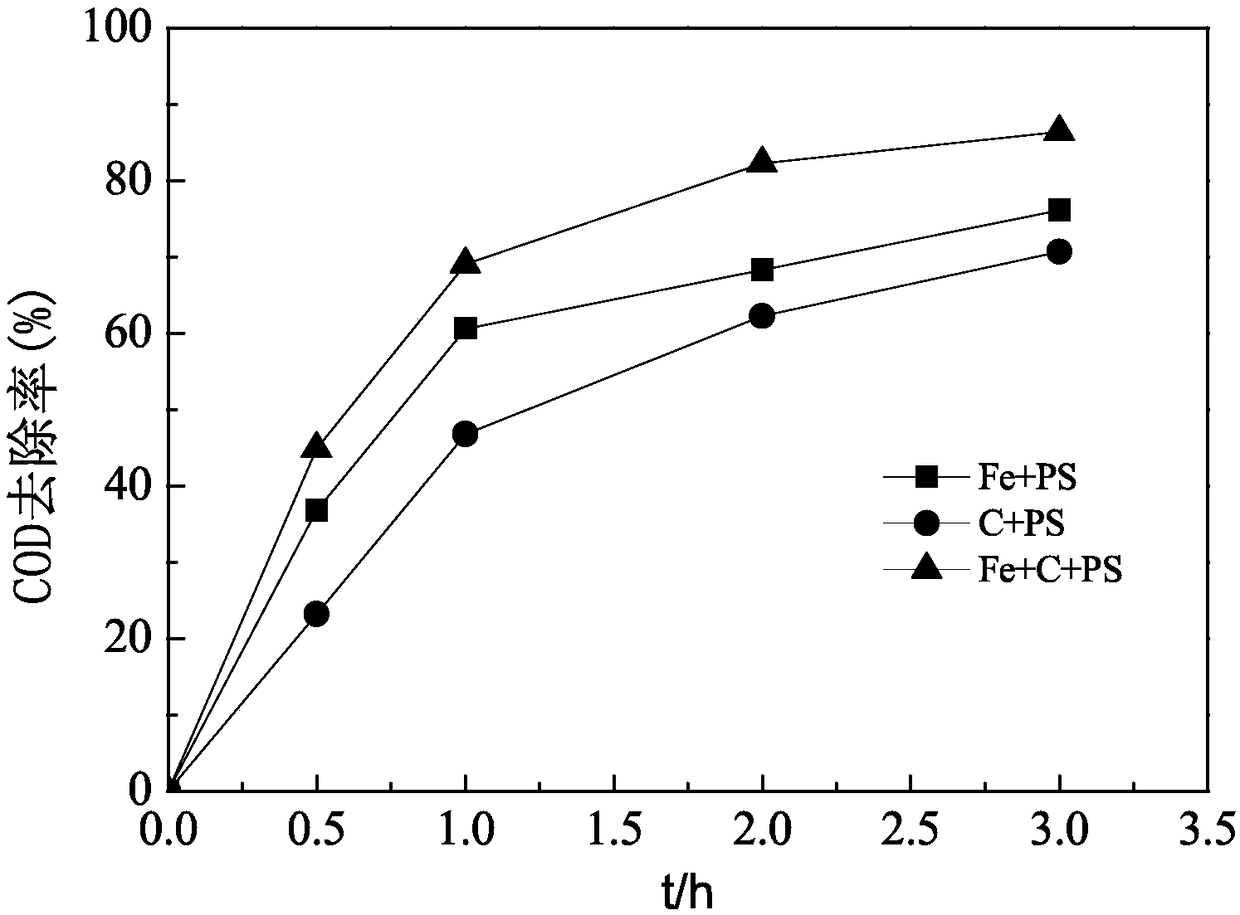

[0033] Take solid sodium persulfate (2.2g) and add it to 100ml of high-concentration organic industrial wastewater with pH = 10.5, add ① 0.47g of micron zero-valent iron (that is, micron-level zero-valent iron), ② 0.12g of C powder, and ③ micron zero-valent iron Valence iron 0.47g and C powder 0.12g. Put it in a water bath shaker and shake it at 200 r / min at room temperature for 3 hours to complete the removal of COD in high-concentration organic industrial wastewater by using persulfate solution. like figure 1 Shown: In the case of only adding C powder, the degradation rate of COD in wastewater within 3 hours is 76.2%; in the case of only adding micron zero-valent iron powder, the degradation rate of COD in wastewater is close to 70.7% in 3 hours %; when C powder and micron zero-valent iron are added, the degradation rate of COD in wastewater exceeds 86.4% within 3 hours, which well illustrates that activated carbon powder and zero-valent iron can play a significant role in ...

Embodiment 2

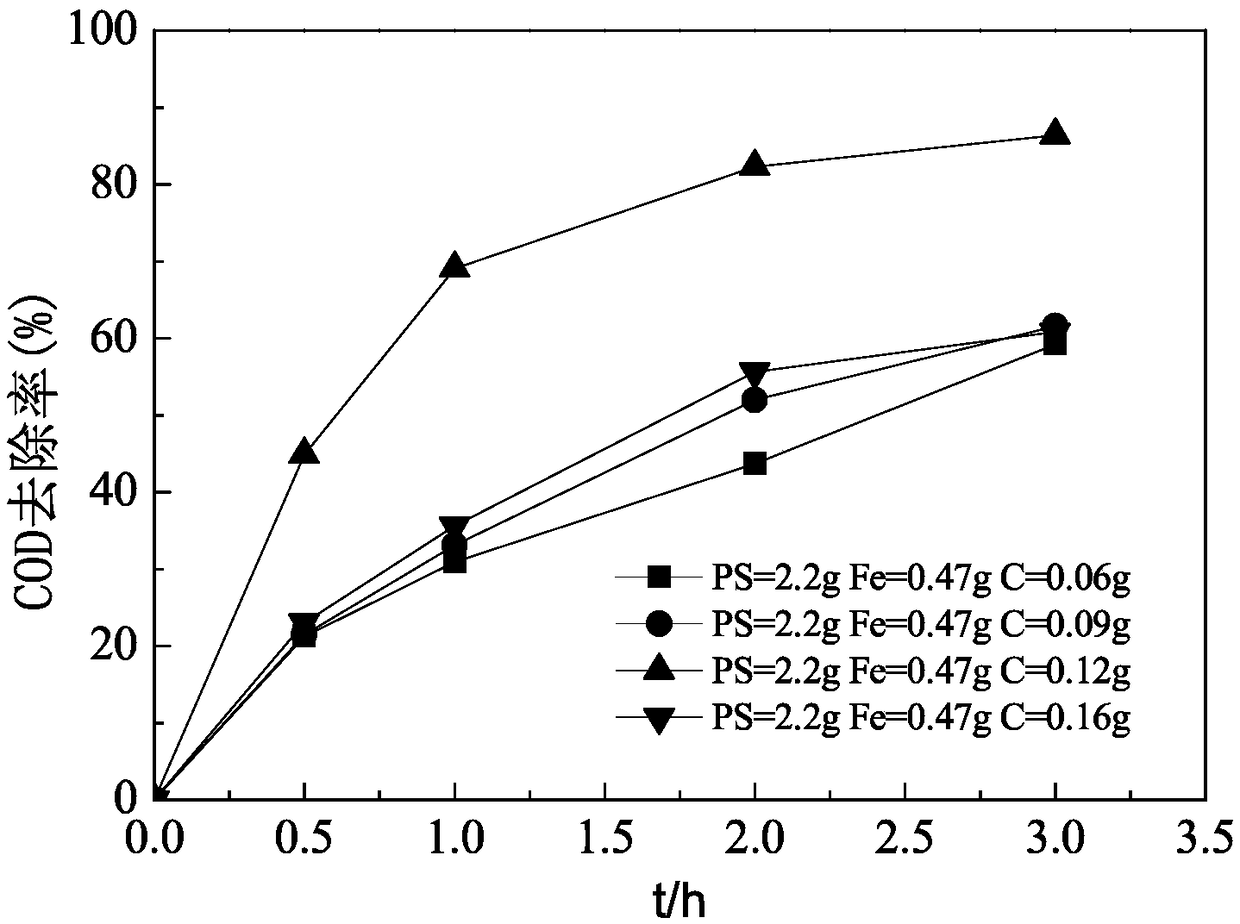

[0035] Add 2.2g of sodium persulfate, 0.47g of micron zero-valent iron, and 0.06g, 0.09g, 0.12g and 0.16g of C powder into 100ml of high-concentration organic industrial wastewater with pH=10.5, and place them in a water bath shaker. 200r / min room temperature shaking reaction for 3h, that is to complete the removal of COD by using persulfate solution and micron zero-valent iron with different specific gravity and activated carbon powder. Such as figure 2 As shown, the removal rates of COD in this example reached 59.25%, 61.6%, 86.4%, and 60.8%, respectively, indicating that the effect is the best when the ratio of zero-valent iron to activated carbon is about 4:1.

Embodiment 3

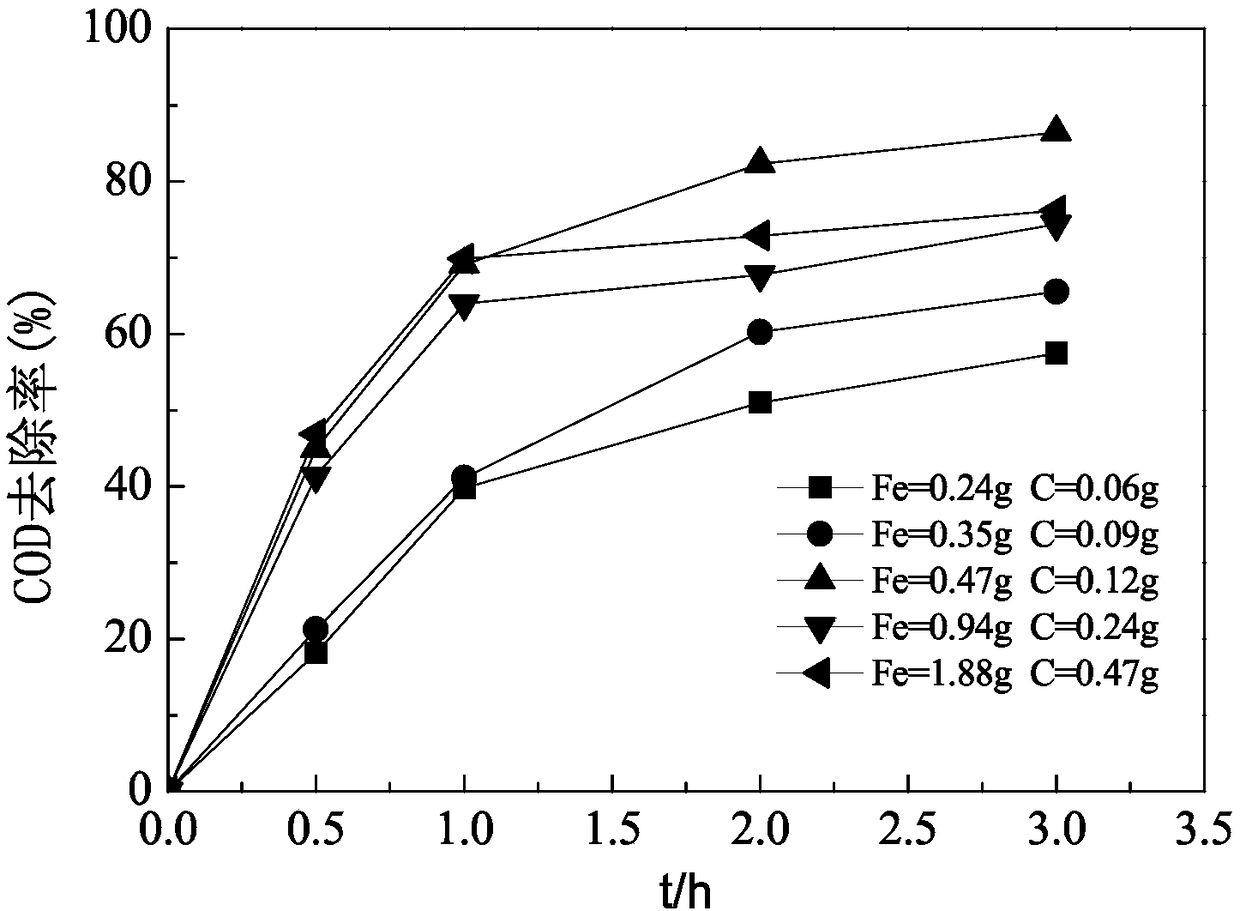

[0037] Take 2.2g sodium persulfate, take 0.24g micron zero-valent iron and 0.06g carbon powder, 0.35g micron zero-valent iron and 0.09g carbon powder, 0.47g micron zero-valent iron and 0.12g carbon powder, 0.94g micron zero-valent iron and 0.24g of carbon powder, 1.88g of micron zero-valent iron and 0.47g of carbon powder were added to 100ml of high-concentration organic industrial wastewater with a pH of 10.5, placed in a water-bath oscillator and shaken for 3 hours at room temperature at 200r / min. That is, the removal of COD by using persulfate solution and different micron zero-valent iron and carbon powder dosage under the same iron-to-carbon ratio is completed. Such as image 3 As shown, the removal rate of COD in this example reaches 57.5%, 65.5%, 86.4%, 74.4%, 76.2%, respectively, indicating that the optimal dosage of zero-valent iron and carbon powder is 4.7g / L and 1.2g / L respectively. L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com