Method for simultaneously producing electronic-grade dichIorosilane, electronic-grade trichlorosilane and electronic-grade silicon tetrachloride

A technology of dichlorodihydrosilicon and trichlorosilane, applied in chemical instruments and methods, silicon compounds, halide silicon compounds, etc., can solve the problems of unstable impurity control, high raw material requirements, and extremely high requirements, and achieve specific heat capacity. Large, good effect, less impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0037] In the description of the present invention, the material referred to by DCS is dichlorodihydrosilane, the material referred to by TCS is trichlorosilane, the material referred to by STC is silicon tetrachloride, and E- represents electronic grade. The reactor is the disproportionation reactor.

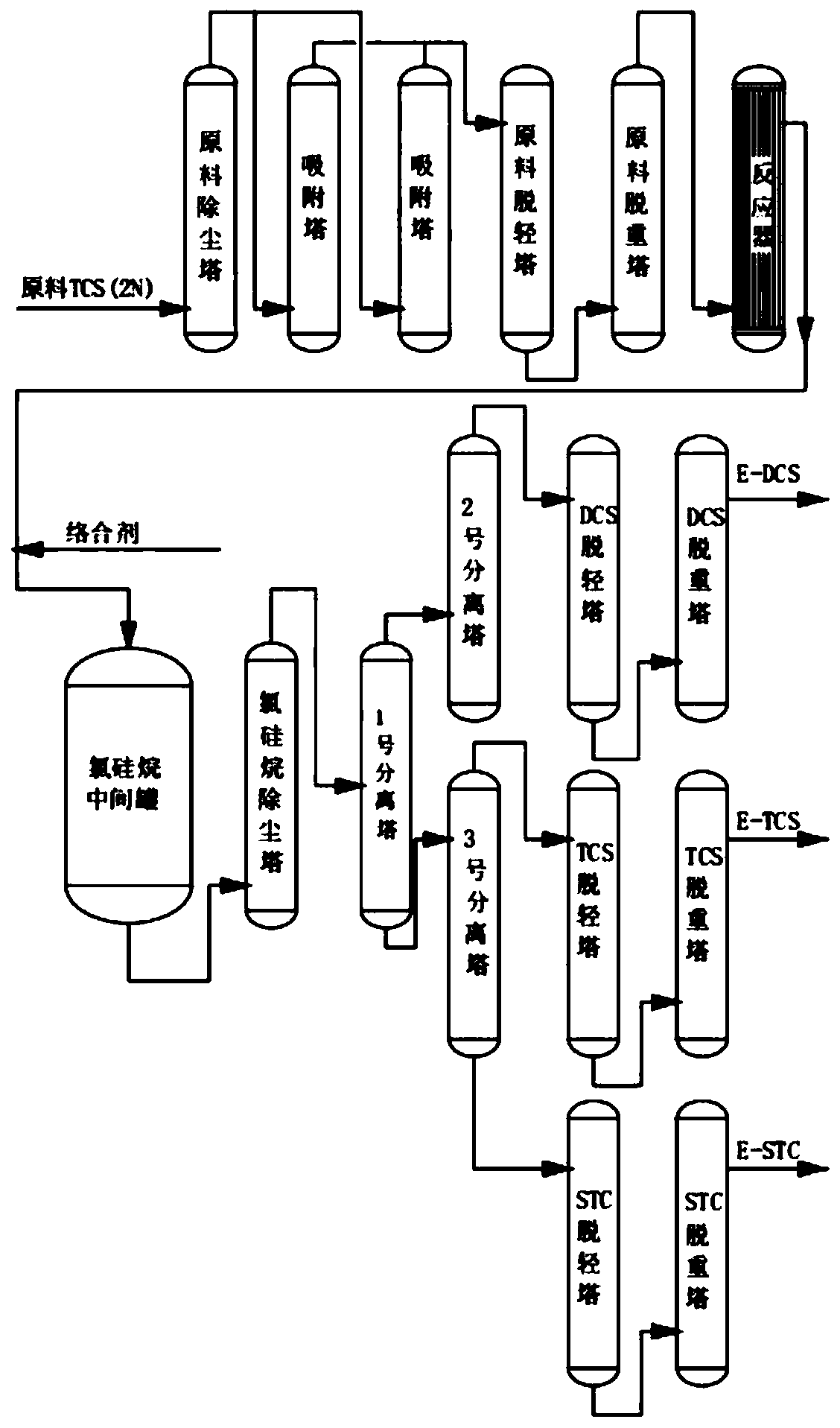

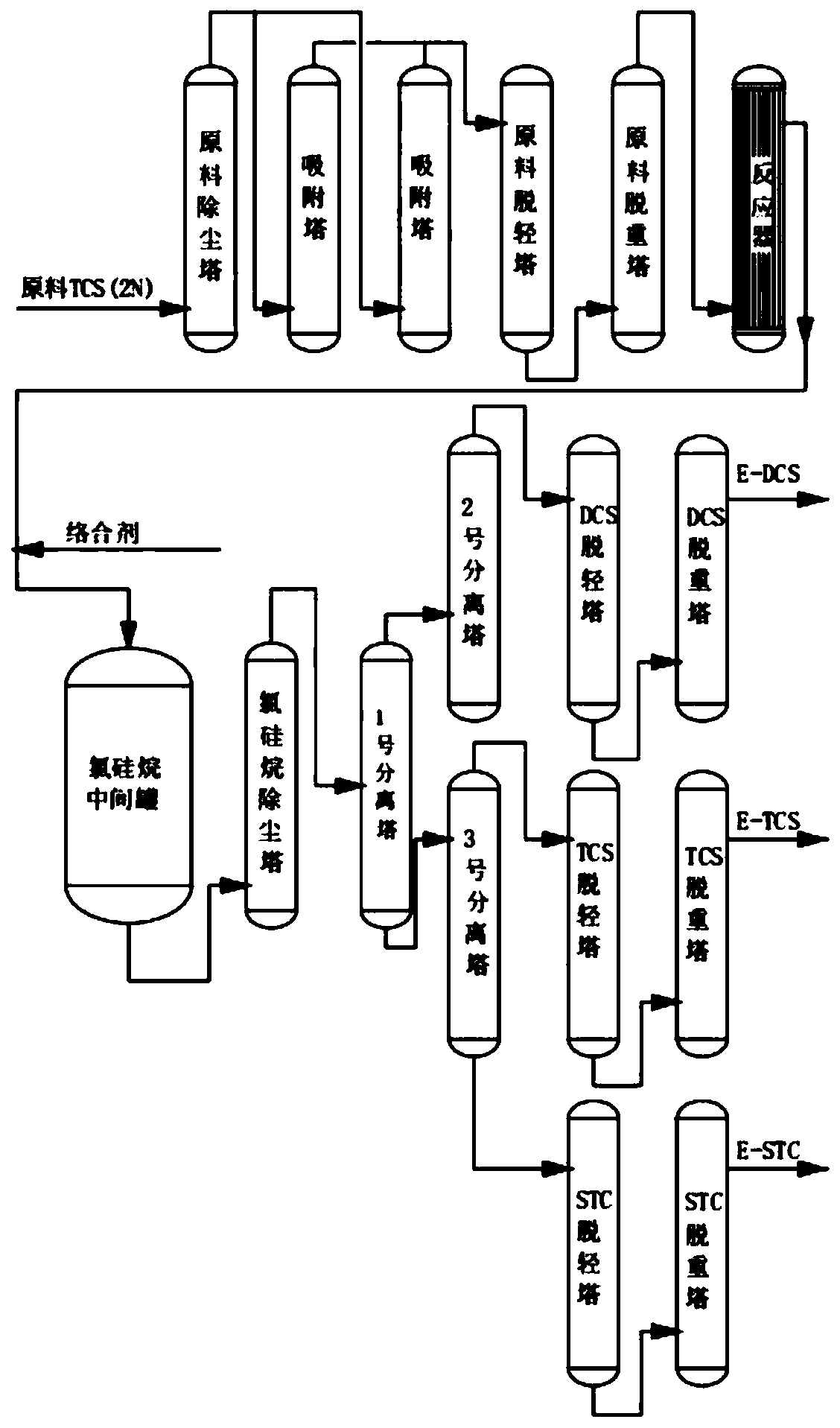

[0038] like figure 1 As shown, the present invention relates to a method for utilizing trichlorosilane to simultaneously produce electronic grade dichlorodihydrogen silicon, electronic grade trichlorosilane and electronic grade silicon tetrachloride, comprising the following steps:

[0039] S1, using crude trichlorosilane (purity 2N) as raw material, perform a dedusting treatment in the raw material dedusting tower; the tower pressure is 0.2-0.4MPa, the tower t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com