Loading arm pipeline connecting structure convenient to disassemble and assemble

A technology for connecting structures and pipes, applied in the direction of pipes/pipe joints/fittings, flange connections, passing components, etc., which can solve the problems of easily damaged and unstable connections, easy displacement of sealing rings, inconvenient maintenance, etc. Sealing effect, rubber ring stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

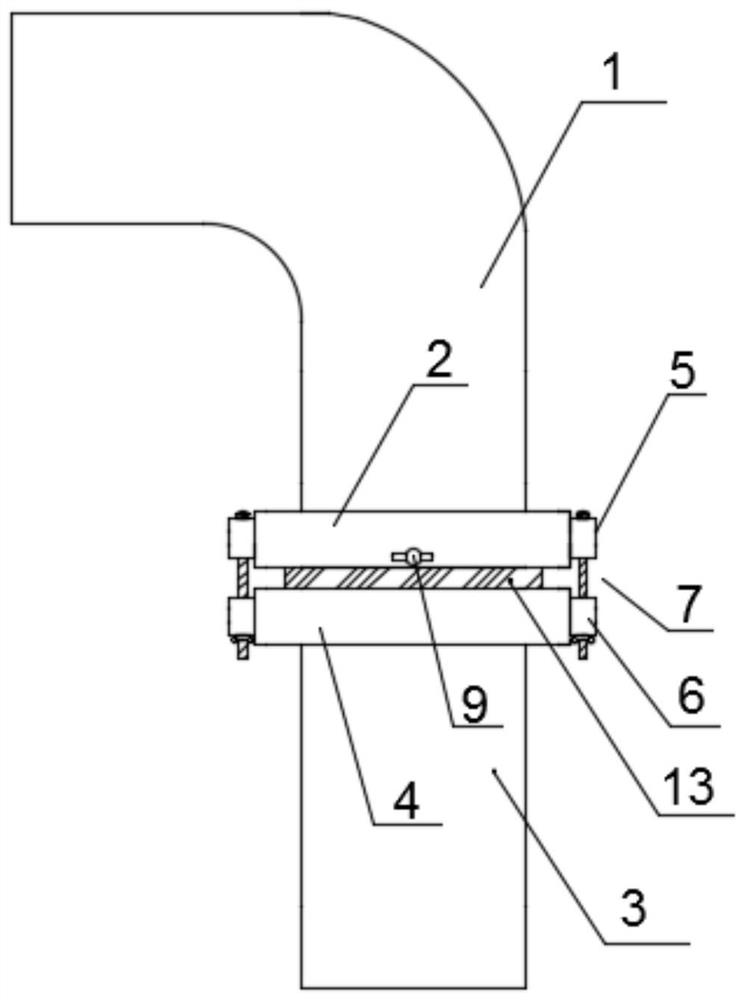

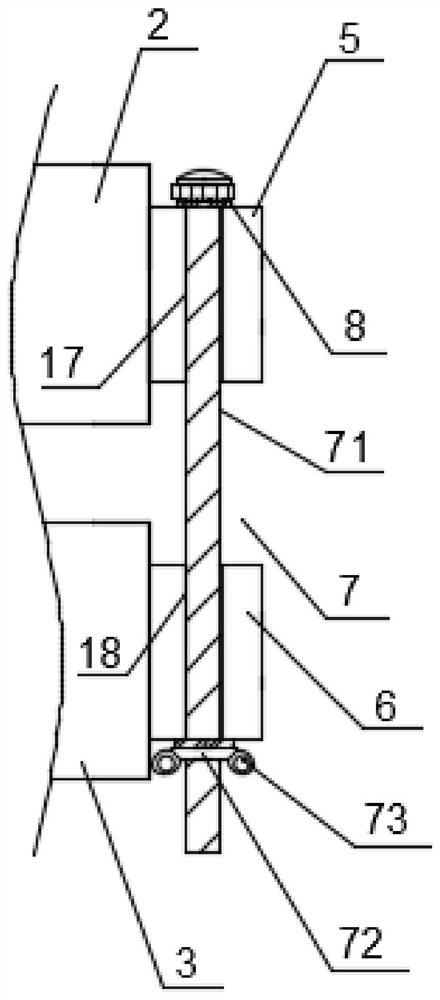

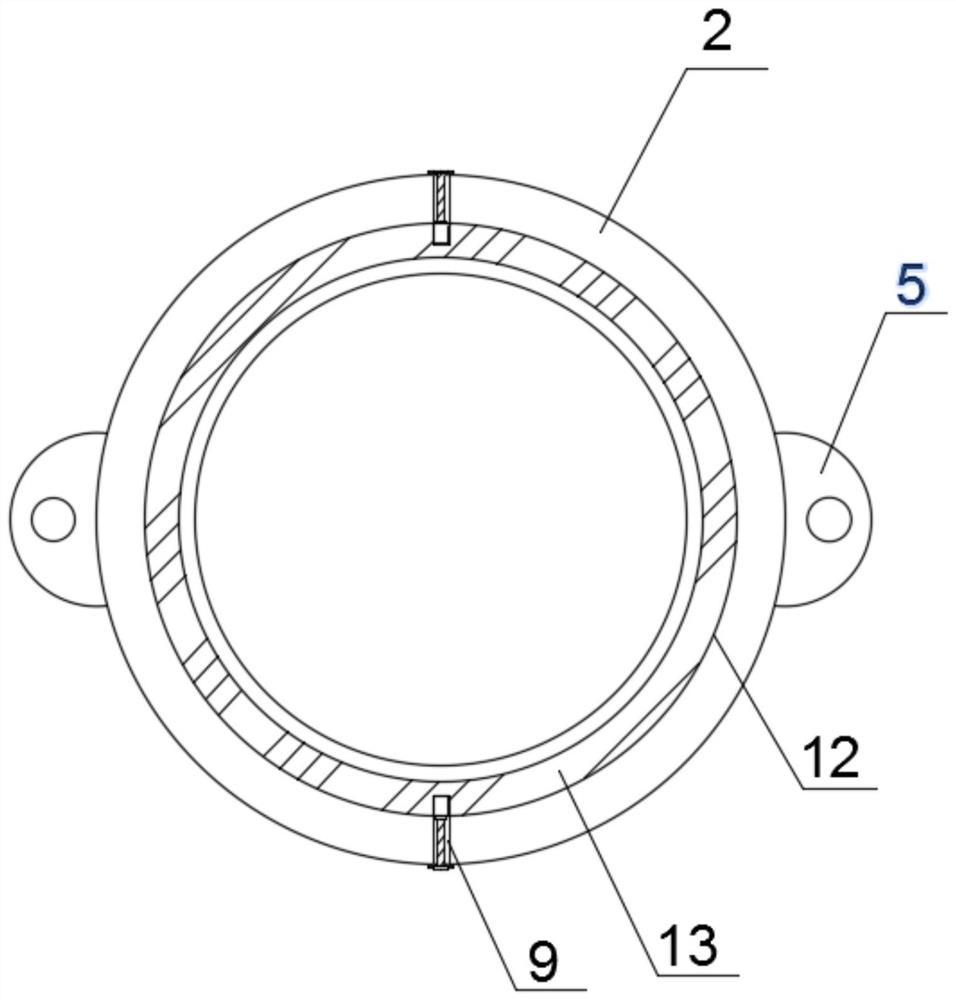

[0027] like Figure 1-6 As shown, this specific embodiment adopts the following technical solutions: a crane pipe pipe connection structure that is easy to disassemble, which is characterized in that it includes an elbow 1, one end of the elbow 1 is welded with a first connecting flange 2, and the elbow 1 The lower end of the vertical pipe 3 is connected with a vertical pipe 3, and one end of the vertical pipe 3 opposite to the elbow 1 is welded with a second connecting flange 4, and both sides of the first connecting flange 2 are fixedly connected with a first side block 5, and the second connecting flange 4 The two sides of the two sides are fixedly connected with the second side block 6, and the limit mechanism 7 is connected between the first side block 5 and the second side block 6 facing each other. The limit mechanism 7 includes a bolt 71, and the bolt 71 is twisted into the second side block. Between the side block 5 and the second side block 6, the first side block 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com