A kind of transparent water-based waterproof paint for building and preparation method thereof

A waterproof coating and technology for construction, applied in the field of construction waterproof coating and its preparation, transparent water-based waterproof coating for construction and its preparation, can solve the problems of poor transparency, limited penetration depth, poor water resistance, etc., and achieve excellent acid and alkali resistance , Improving the impermeability pressure and good stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of transparent water-based waterproof coating for buildings, in terms of mass, comprising the following components and a preparation method: 269.8kg of water, 700kg of water-soluble polyurethane, 8kg of propylene glycol, 8kg of triethanolamine, silicon nanomaterials (nano-dioxide with a mass content of 0.45%) Silicon oxide solution) 5kg, perfluorooctane ammonium sulfonate 0.2kg, ultraviolet absorber (UV-284) 3kg were added to the stirring tank, stirred at 400r / min for 30min, then added associative polyurethane thickener (Guangzhou Guanzhi Chemical OS-6040) 5kg, SPA202 defoamer 1kg, continue to stir for 1 hour, mix evenly to get the finished product.

[0037] The clarity of the finished paints described above was tested. attached figure 1 The transparency comparison chart before and after coating the above waterproof coating on glass shows that the coating film has good transparency, does not cover the bottom, and has a high degree of self-cleaning.

Embodiment 2

[0039] A kind of transparent water-based waterproof coating for buildings, in terms of mass, comprising the following components and a preparation method: 170kg of water, 780kg of water-soluble polyurethane, 14kg of propylene glycol, 12kg of triethanolamine, silicon nanomaterials (nano dioxide with a mass content of 0.30%) Silicon solution) 9kg, potassium perfluorooctane sulfonate 0.5kg, UV-284 ultraviolet absorber 7kg into the stirring tank, stirring at 300r / min stirring speed for 40min, then adding alkali swelling acrylate thickener (Guangzhou Guanzhi Chemical industry HASE-60) 6kg, SN345 defoamer 1.5kg, continue to stir for 30min, mix evenly to get the finished product.

Embodiment 3

[0041] A kind of transparent water-based waterproof paint for building, in terms of mass, comprising the following components and a preparation method: 134.4kg of water, 800kg of water-soluble polyurethane, 16kg of propylene glycol, 16kg of triethanolamine, silicon nanomaterials (nano-dioxide with a mass content of 0.15%) Silica solution) 10kg, potassium perfluorooctane sulfonate 0.6kg, UV-284 ultraviolet absorber 8kg were added to the stirring tank, stirred at a stirring speed of 300r / min for 1h, and then added alkali-swellable acrylate thickener (Shanghai Paul Lijia Chemical Co., Ltd. BLJ-80) 12kg, SN345 defoamer 3kg, continue to stir for 45min, mix evenly to get the finished product.

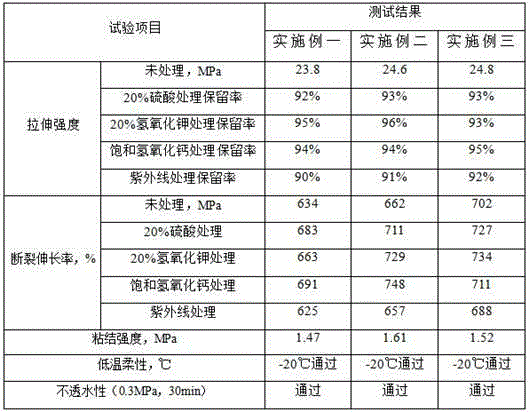

[0042] Test above-mentioned finished product according to GB / T16777-2008 " building waterproof coating test method " standard, the result is as table 1, it can be seen that the tensile strength>20MPa, elongation at break>600% of the building transparent water-based waterproof coating developed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com