Connecting line processing method and connecting line

A processing method and technology for connecting wires, applied in the direction of connection insulation, assembly/disassembly of contacts, conductors, etc., can solve the problems of increased molding, reduced processing efficiency, increased production costs, etc., to reduce the loss of raw materials and improve connection stability performance and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are listed below, and detailed descriptions are as follows in conjunction with the accompanying drawings.

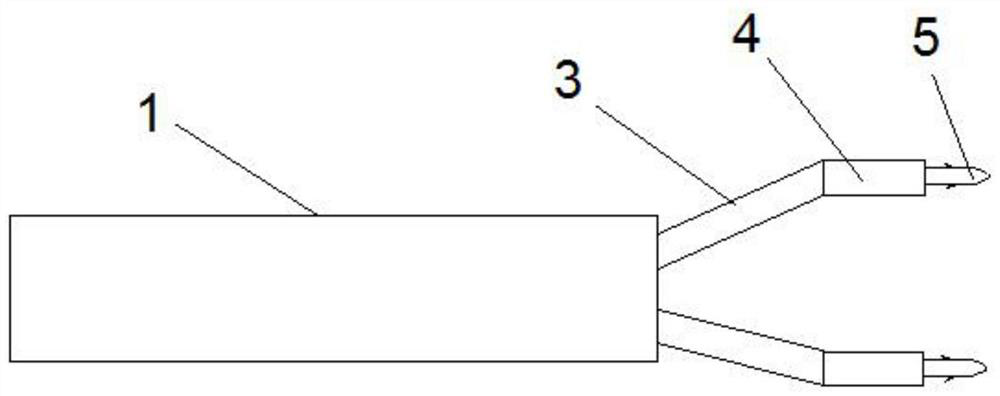

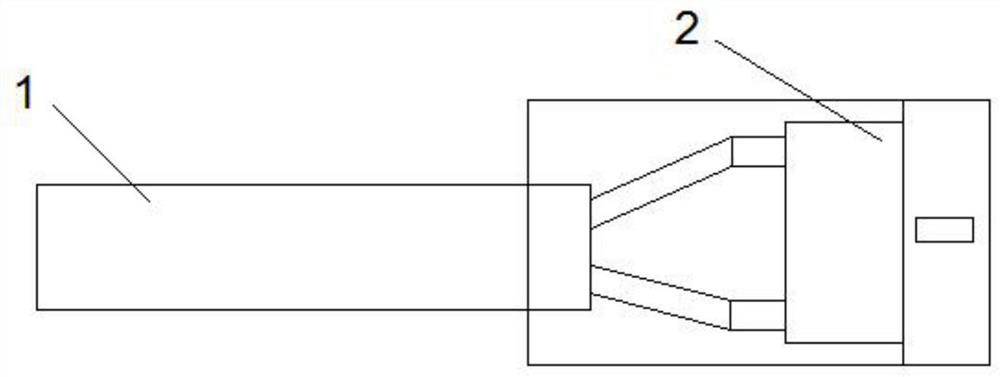

[0025] Combine below Figure 1-3 Description of the invention:

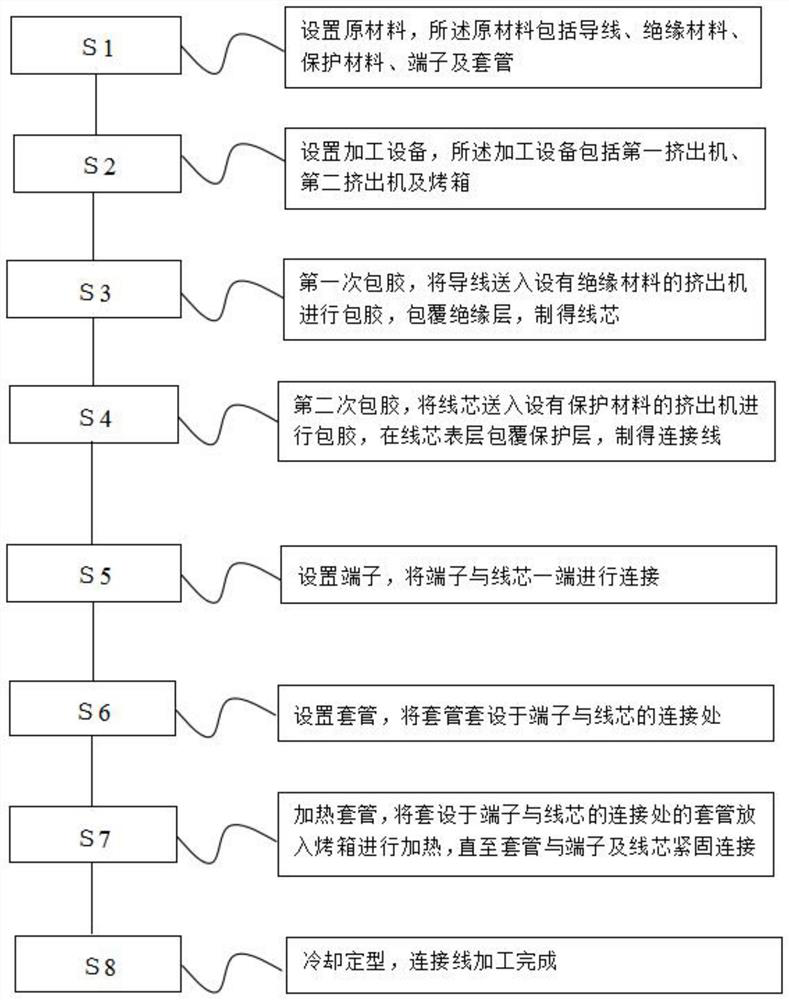

[0026] This embodiment discloses a connection wire processing method and connection wire, including the following steps: step S1, setting raw materials, the raw materials including wires, insulating materials, protective materials, terminals and sleeves; step S2, setting processing equipment, the The processing equipment includes a first extruder, a second extruder, and an oven; step S3, the first time of encapsulation, sending the wire into an extruder equipped with an insulating material for encapsulation, covering the insulating layer, and obtaining a wire Core; step S4, the second encapsulation, the wire core is sent to an extruder equipped with protective materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com