Soaking extraction processing equipment and soaking extraction processing method

A technology of processing equipment and processing methods, applied in separation methods, chemical instruments and methods, tobacco, etc., can solve the problems of poor control of the clearance between the screw and the shell, difficult manufacturing, and differences in material soaking and extraction time and extraction rate. , to achieve the effect of improving the level of homogenization soaking and extraction of tobacco materials, improving soaking efficiency and effect, and simplifying the sewage treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

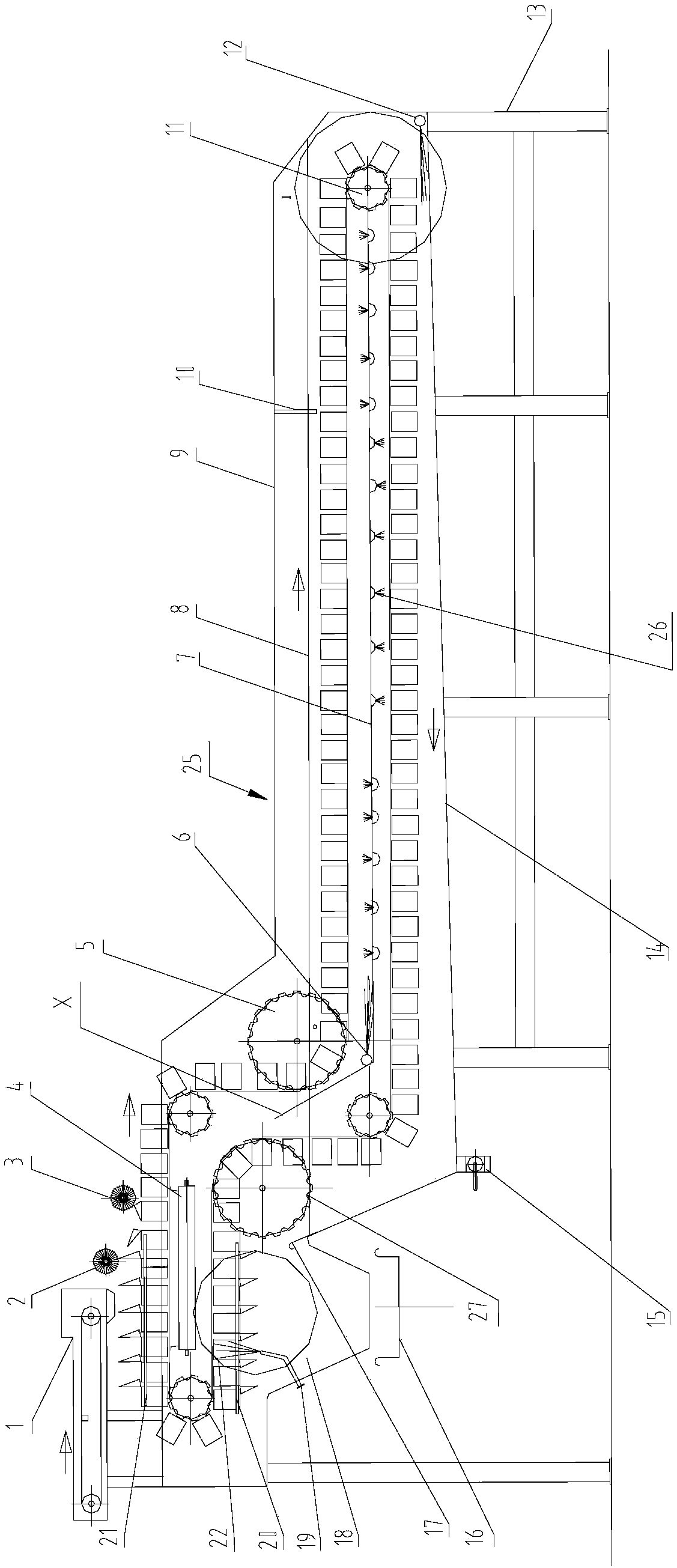

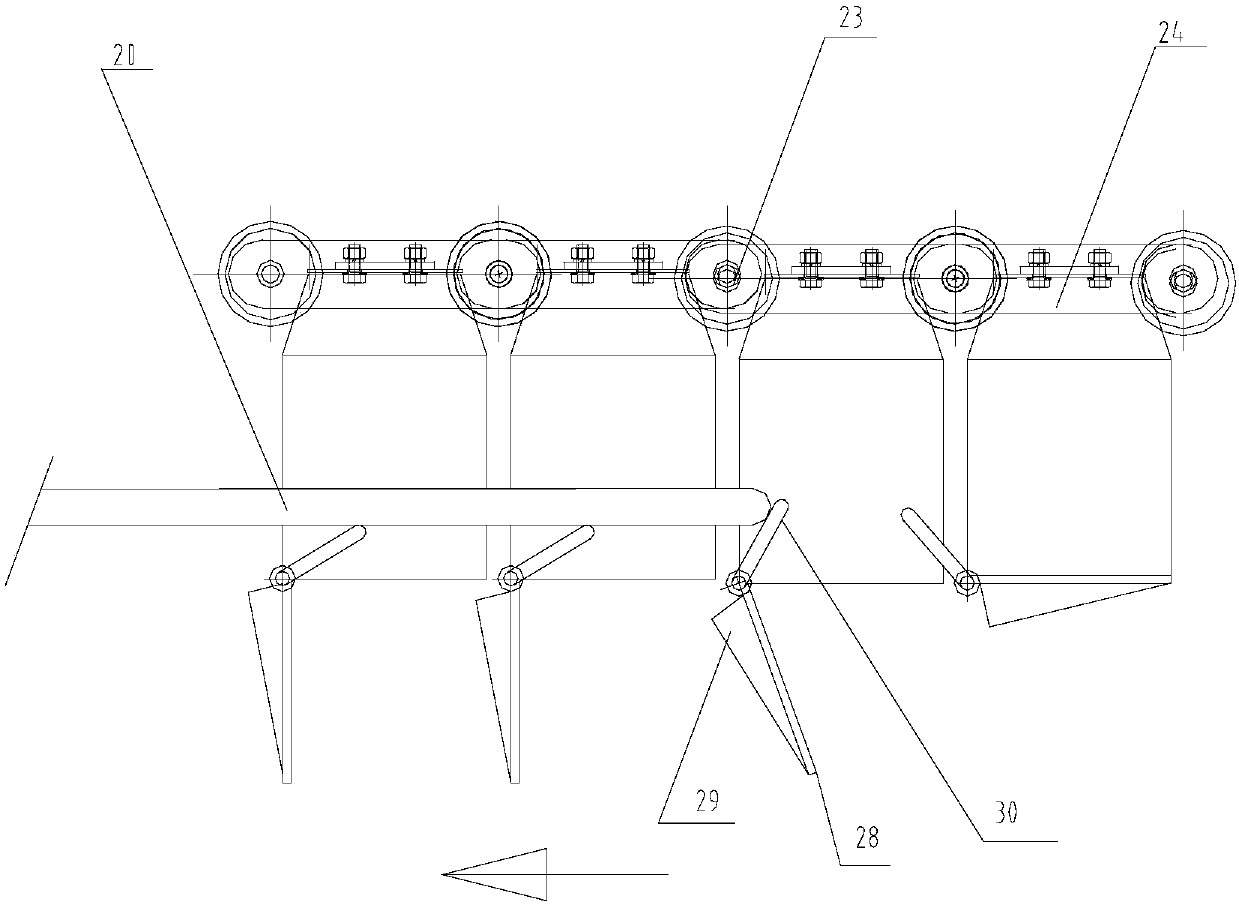

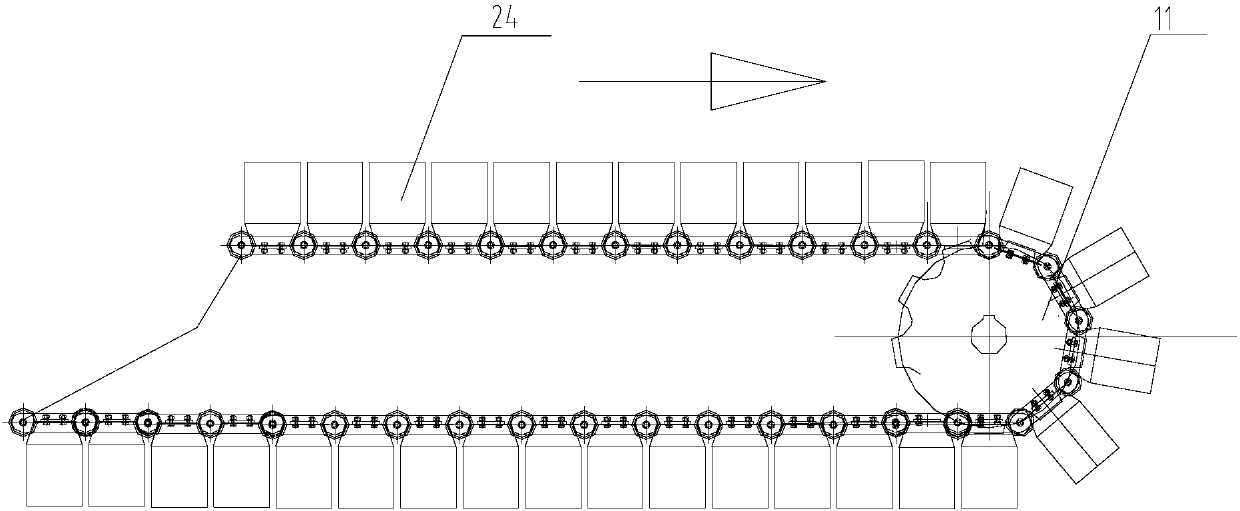

[0037] Such as figure 1 , 2 , shown in 3, the present invention comprises frame 13, casing 25, feeding device 1, discharge hopper 18, and casing 25 is installed on the frame 13, and frame 13 supports casing bottom plate 14, and casing 25 preferably adopts inclined The form of installation, such as figure 1 As shown, it is inclined to the drain valve 15 direction, which is convenient for cleaning the casing, and the casing is a similar rectangular water container welded by stainless steel plates. Along the casing length direction, side chain conveyor 23 is installed in the casing 25, and some soaking boxes 24 are installed on the wing plate between the adjacent side chains of side chain conveyor 23. The side chain conveyor 23 can also be replaced by other conveying devices. The selection of other conveying devices needs to consider two factors, one is to facilitate the installation of the soaking box 24, and the other is that the conveying device can operate in liquid. The s...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that: this embodiment is not provided with a partition 7, and the water adding device 26 is directly installed on the box body.

[0047] Compared with Embodiment 1, the present embodiment is slightly worse in soaking extraction effect. During the soaking extraction process, the concentration of the soaking water is distributed irregularly in the tank. Taking the separator in Example 1 as a boundary, in the absence of a separator, there is convection in the upper and lower parts of the water, which makes the concentration distribution of the water disordered and affects the effect of soaking and extraction.

Embodiment 3

[0049] The difference between this embodiment and the first embodiment is that: the water adding device 26 is arranged at the left end of the partition, and is located below the transition wheel 5 . This embodiment also adopts the downstream extraction process. During the soaking extraction process, the water adding device 26 supplies water to the direction of the driving wheel 11, and the direction of water flow is the same as that of the driving wheel 11. figure 1 The directions of the arrows in are in the same direction. When extracting downstream, the concentration below the partition is high, and the concentration above the partition is small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com