Correction fluid preparation method

A technology of correction fluid and emulsion, applied in the direction of coating, etc., can solve the problems of slow drying rate and weak paper bonding strength, and achieve the effects of increasing interaction force, improving stability, and increasing bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

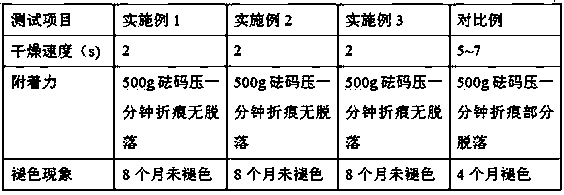

Examples

preparation example Construction

[0024] A preparation method of a correction fluid, the preparation method comprising the steps of:

[0025] (1) In parts by weight, take 70~80 parts of distilled water, 30~40 parts of styrene, 10~15 parts of butyl acrylate, 7~8 parts of methyl methacrylate, 3~4 parts of acrylic acid, 3~4 Parts of polyvinyl alcohol solution, 1~2 parts of sodium dodecyl sulfonate, 1~2 parts of octylphenol polyoxyethylene ether, 0.8~1 part of initiator, 0.06~0.08 parts of sodium bicarbonate, styrene, acrylic acid Mix butyl ester, methyl methacrylate, and acrylic acid evenly, add sodium dodecyl sulfonate, octylphenol polyoxyethylene ether, sodium bicarbonate, polyvinyl alcohol solution, and distilled water, and pre-emulsify at 280~300r / min 25~30min, heat up to 70~75℃, add initiator, keep warm for 55~60min, cool to room temperature, get emulsion, set aside;

[0026] (2) In parts by weight, take 10~15 parts of acetone, 3~4 parts of isopropanol, 3~4 parts of nano-zinc oxide, 0.1~0.2 parts of titanat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com