A crane tube pipe connection structure that is easy to disassemble

A technology for connecting structures and pipes, applied in the direction of pipes/pipe joints/fittings, flange connections, passing components, etc., which can solve the problems of easy damage and instability of joints, easy deviation of sealing rings, inconvenient disassembly and cleaning of pipes, etc. To achieve the effect of ensuring the sealing effect and the stability of the rubber ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

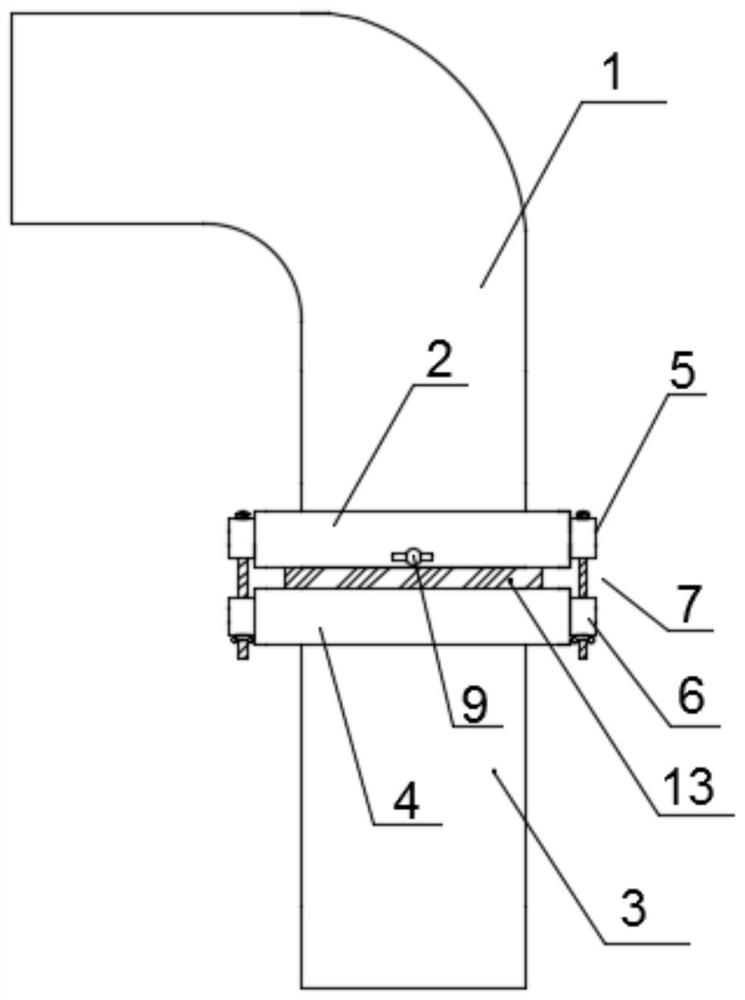

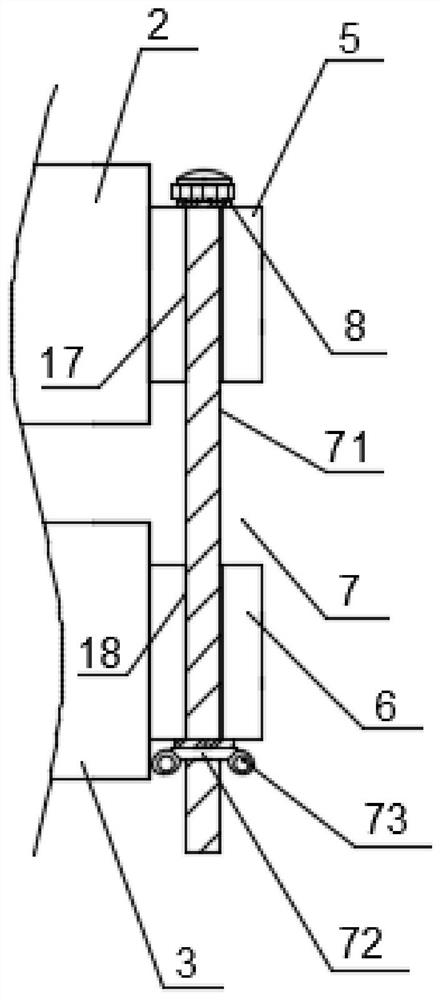

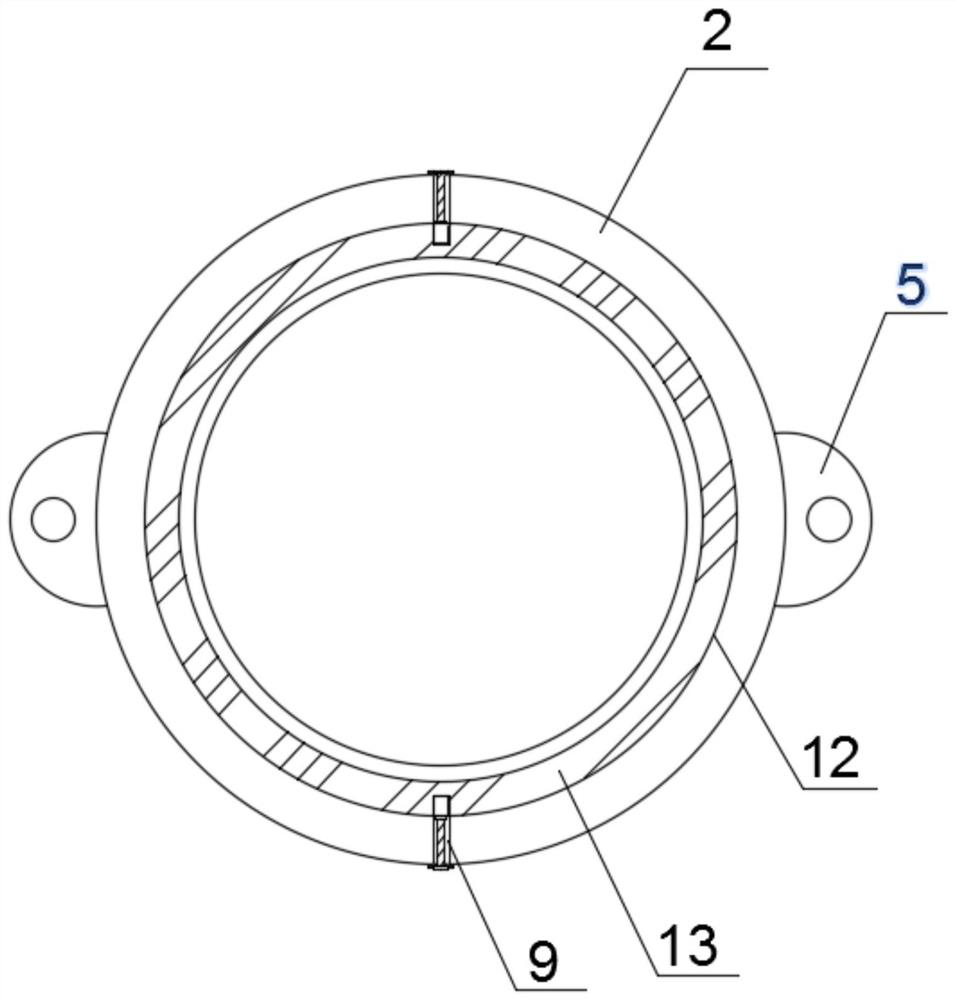

[0027] Such as Figure 1-6 As shown, this specific embodiment adopts the following technical solutions: a crane pipe pipe connection structure that is easy to disassemble, including an elbow 1, one end of the elbow 1 is welded with a first connecting flange 2, and the lower end of the elbow 1 is connected with a The vertical pipe 3 is welded with a second connecting flange 4 at one end of the vertical pipe 3 opposite to the curved pipe 1, the first side block 5 is fixedly connected to both sides of the first connecting flange 2, and the two sides of the second connecting flange 4 are fixed The second side block 6 is connected, and the limit mechanism 7 is connected between the first side block 5 and the second side block 6 facing each other. The limit mechanism 7 includes a bolt 71, and the bolt 71 is twisted into the first side block 5 and the second side block 6, the first side block 5 and the second side block 6 can be fixed by bolts 71, and the two ends of the bolts 71 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com