Flange isolation pad used for prefabricating box girder and construction method of flange isolation pad

A construction method and isolation pad technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as easy demolition, concrete loss, and difficult installation, so as to improve product quality and production efficiency, avoid loss, and have good toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

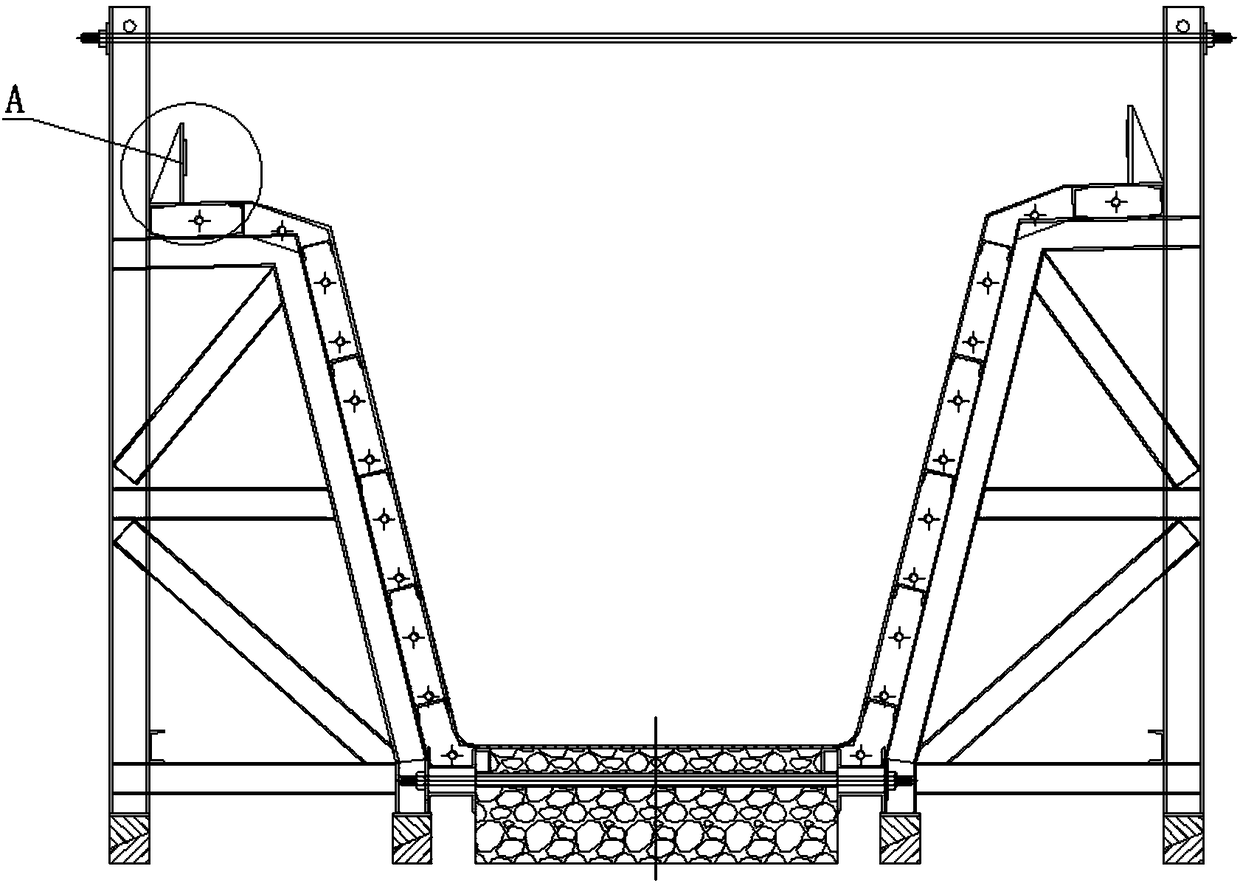

[0037] The specific embodiments and working principles of the present invention will be described in further detail below with reference to the accompanying drawings.

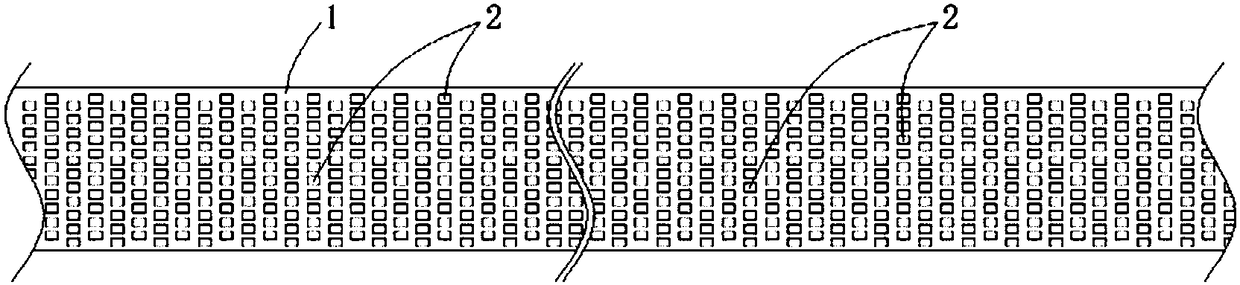

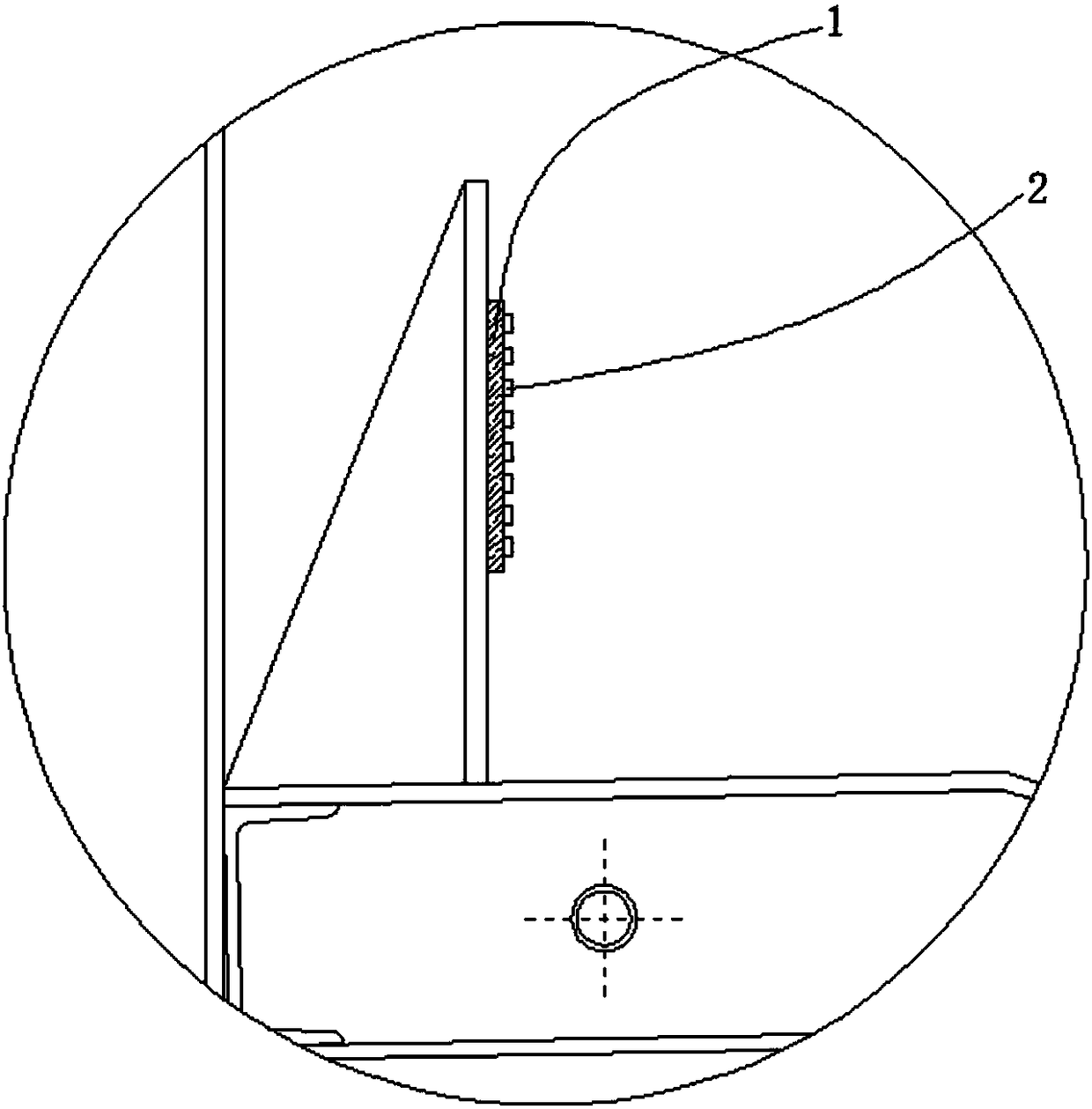

[0038] Such as figure 1 As shown, a flange isolation pad for prefabricated box girder includes an isolation pad body 1 made of wear-resistant soft material. One side of the isolation pad body 1 is a smooth surface and the other side is a rough surface. There are protrusions 2 distributed on the rough surface, and the protrusions 2 are uniformly distributed on the isolation pad body 1 in a staggered manner. When the box girder is prefabricated, the smooth surface is in contact with the comb plate through binding. The protrusion 2 faces inward.

[0039] In this example, the protrusion 2 adopts a prismatic solid structure, and correspondingly, the cross section of the protrusion 2 is square. In this way, the contact surface between the protrusion and the concrete structure is enlarged, and the concrete surface after p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com