Preparation method of polystyrene foam microsphere

A technology of polystyrene and foam microspheres, which is applied in the field of polymer processing and molding, can solve the problems of cumbersome operation, complicated preparation process, and difficult process control, and achieve the effect of simple process, controllable particle size, and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

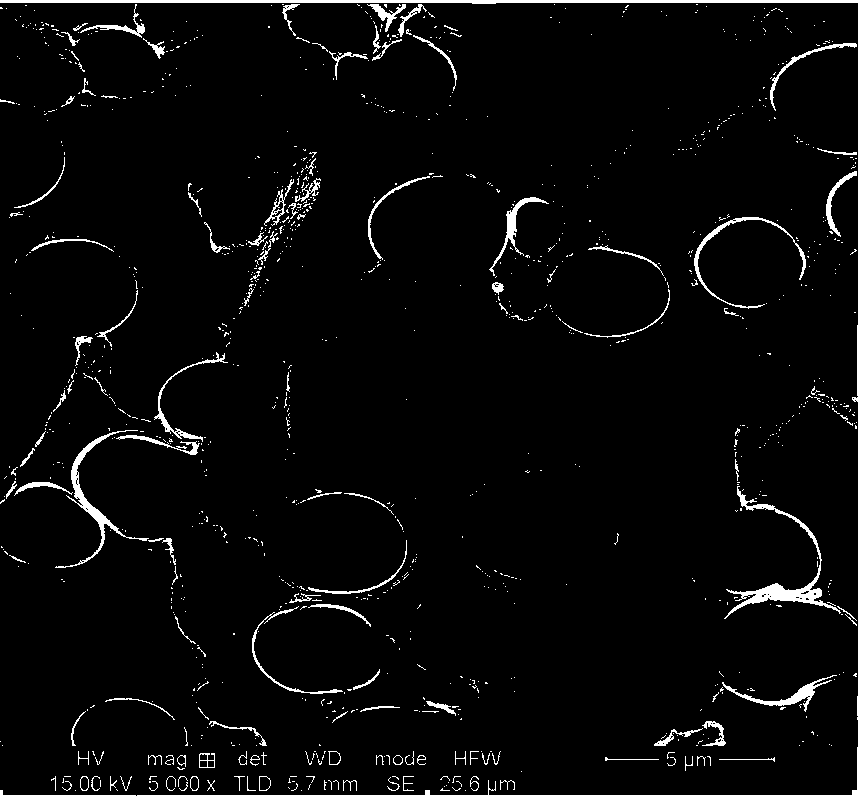

Image

Examples

Embodiment 1

[0025] Prepare polystyrene, hexane and benzene at a mass fraction of 4.0: 1.0: 96.0 to prepare an oil phase solution; polyethylene oxide and water to prepare an aqueous solution at a mass fraction of 0.01: 99.9, filter the aqueous solution, and use the filtrate as the external water phase; prepare the prepared oil Ultrasonic the phase solution for 1 min before the preparation of the emulsion, draw 3 ml of distilled water, 3 ml of the oil phase solution and 50 ml of the outer water phase solution with a syringe respectively, and connect the syringe with the inner water phase, oil phase and outer water phase of the emulsion generator respectively. The pipes are connected and fixed on the corresponding micro-injection pumps; respectively adjust the flow rates of the inner water phase, oil phase and outer water corresponding to the micro-injection pumps to 1.5ml / h, 3.0 ml / h and 200.0 ml / h, respectively Distilled water, oil phase and external water phase are injected into the intern...

Embodiment 2

[0027] Polystyrene, dodecane and fluorobenzene are prepared as an oil phase solution at a mass fraction of 15.0: 5.0: 90.0; polyacrylic acid and water are prepared as an aqueous solution at a mass fraction of 1.0: 99.0, and the aqueous solution is filtered, and the filtrate is used as an external aqueous phase; the prepared The oil phase solution was ultrasonicated for 5 min before emulsion preparation, and 3 ml of distilled water, 3 ml of oil phase solution, and 50 ml of external water phase solution were sucked up with a syringe, and the syringe was connected to the internal water phase, oil phase, and external water phase of the emulsion generator, respectively. connected with the corresponding pipeline, and installed and fixed on the corresponding micro-injection pump; respectively adjust the flow rate of the inner water phase, oil phase and outer water corresponding to the micro-injection pump to 1.0 ml / h, 4.0 ml / h and 400.0 ml / h, respectively Inject distilled water, oil p...

Embodiment 3

[0029] Polystyrene, hexadecane, and 1,2-dichloroethane were prepared as an oil phase solution at a mass fraction of 25.0: 10.0: 65.0; polyvinyl alcohol and water were prepared as an aqueous solution at a mass fraction of 4.0: 96.0, and the aqueous solution was filtered, and the filtrate was used as an external Water phase: Sonicate the prepared oil phase solution for 10 min before emulsion preparation, draw 3 ml of distilled water, 3 ml of oil phase solution and 50 ml of external water phase solution with a syringe respectively, and connect the syringe with the inner water of the emulsion generator Phase, oil phase and external water phase are connected by pipes, and installed and fixed on the corresponding micro-injection pump; respectively adjust the flow rate of the micro-injection pump corresponding to the internal water phase, oil phase and external water to 2.0 ml / h, 6.0 ml / h and 800.0 ml / h, respectively inject distilled water, oil phase and external water phase into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com